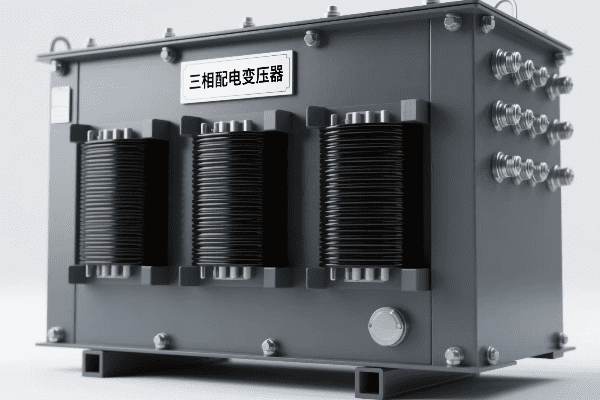

3-Phase Distribution Transformer: Powering Industrial Growth and Commercial Expansion?

Industries and businesses are growing fast. They need more power. But can our current power systems keep up?

3-phase distribution transformers are key to powering industrial growth and commercial expansion. These transformers can handle high power demands, offer better efficiency, and support the complex needs of modern industries and businesses.

I’ve worked with power systems for many years. I’ve seen how important 3-phase transformers are for industry and commerce. Let’s look at how these transformers are changing the game.

Meeting Growing Demands: Scaling 3-Phase Distribution Transformers for Industrial Expansion?

Industries are getting bigger and using more power. How can we make sure they have the electricity they need?

Scaling 3-phase distribution transformers is crucial for meeting the growing power demands of expanding industries. These transformers can be designed to handle increasing loads, allowing for seamless industrial growth without major infrastructure overhauls.

In my work, I’ve seen many industries struggle with power supply as they grow. Let’s dive into how we’re scaling up transformers to meet these challenges:

Modular Design: Building Blocks of Power

One of the best ways to scale up power is through modular transformer designs. Here’s why this approach works so well:

- Easy Expansion: We can add more modules as power needs grow.

- Flexible Installation: Modules can fit in tight spaces or be spread out.

- Faster Upgrades: We can add new modules without long downtimes.

I once worked on a project where we used modular transformers for a growing factory. We started with two modules and added three more over five years. The factory never had to stop production for major electrical upgrades.

Higher Capacity Cores

We’re also making transformer cores that can handle more power:

| Core Type | Power Handling | Size Increase |

|---|---|---|

| Traditional | Base level | Base size |

| High-capacity | 2x-3x more | 20-30% larger |

| Ultra-high | 4x-5x more | 40-50% larger |

These new cores let us pack more power into a smaller space. This is great for industries that are growing but don’t have much room for bigger transformers.

Advanced Cooling Systems

As transformers handle more power, they generate more heat. We’re using new cooling methods to solve this:

- Oil-to-Air Cooling: Uses special oils and large radiators.

- Forced-Air Cooling: Fans blow air over the transformer to cool it.

- Water Cooling: For the biggest transformers, we use water cooling systems.

In a recent project, we installed a water-cooled transformer in a steel mill. It could handle 50% more power than the old transformer, but it fit in the same space.

Smart Load Management

We’re not just making transformers bigger. We’re making them smarter too:

- Real-time Monitoring: Keeps track of power use and adjusts as needed.

- Predictive Load Balancing: Uses AI to predict power needs and balance loads.

- Automatic Tap Changing: Adjusts voltage levels to match changing demands.

These smart features help transformers handle varying loads more efficiently. This is especially useful for industries with fluctuating power needs.

Optimizing Efficiency and Reliability: 3-Phase Transformers in High-Demand Industrial Settings?

Industries need a lot of power. But they also need that power to be reliable and efficient. How do 3-phase transformers meet these needs?

3-phase transformers in high-demand industrial settings are optimized for both efficiency and reliability. They use advanced materials and designs to minimize losses, and incorporate features that ensure consistent power supply even under challenging conditions.

I’ve worked on many industrial power projects. I know how crucial efficiency and reliability are. Let’s look at how we’re improving these aspects:

Core Materials: The Heart of Efficiency

The core of a transformer is where efficiency starts. We’re using new materials to make cores better:

- Amorphous Metal: This reduces energy loss by up to 70% compared to old materials.

- Grain-Oriented Electrical Steel: This material aligns with the magnetic field, reducing losses.

- Nano-crystalline Alloys: These are still new, but they promise even lower losses.

I recently replaced an old transformer with one using an amorphous metal core. The factory saw their electricity bill drop by 15% right away.

Winding Techniques: Precision Matters

How we wind the coils in a transformer affects its efficiency and reliability:

| Winding Type | Efficiency | Reliability |

|---|---|---|

| Layer Winding | Good | Very Good |

| Disc Winding | Very Good | Excellent |

| Helical Winding | Excellent | Good |

We choose the winding type based on the specific needs of each industrial setting. For a chemical plant with corrosive environments, we used disc winding for its excellent reliability.

Insulation Systems: Keeping Cool Under Pressure

Good insulation is key for reliability. We’re using new materials and methods:

- Nomex Paper: This can withstand very high temperatures.

- Ester Fluids: These are safer and more environmentally friendly than old transformer oils.

- Hybrid Insulation: We combine different materials for the best performance.

In a steel mill project, we used ester fluid insulation. It improved fire safety and let the transformer handle higher loads safely.

Monitoring and Diagnostics: Catching Problems Early

We’re adding smart systems to transformers to keep them running smoothly:

- Dissolved Gas Analysis: This checks the transformer oil for signs of problems.

- Partial Discharge Monitoring: This catches insulation issues before they become serious.

- Temperature Monitoring: This keeps track of hot spots that could cause failures.

These systems help us fix small issues before they become big problems. In one factory, our monitoring system caught a developing fault that could have caused a major outage if left unchecked.

Versatility in Power Distribution: Adapting 3-Phase Transformers to Diverse Commercial Loads?

Different businesses need different kinds of power. How can one type of transformer meet all these needs?

3-phase transformers are highly adaptable to diverse commercial loads. They can be configured to handle various voltage levels, load patterns, and power quality requirements, making them suitable for a wide range of commercial applications.

In my career, I’ve worked with many types of businesses. Each has unique power needs. Let’s explore how 3-phase transformers adapt to these diverse demands:

Voltage Flexibility: Meeting Various Needs

Commercial settings often need different voltages. 3-phase transformers can handle this:

- Multiple Taps: These let us adjust the output voltage easily.

- Wide Range Transformers: These can handle big voltage changes without losing efficiency.

- Auto-transformers: These are great for small voltage adjustments.

I once set up a transformer for a shopping mall. It could supply different voltages for stores, restaurants, and a cinema, all from one unit.

Load Profile Management

Different businesses use power differently throughout the day. We design transformers to handle these varying loads:

| Load Type | Characteristic | Transformer Feature |

|---|---|---|

| Steady | Constant power use | High base efficiency |

| Peaky | Big power spikes | Good overload capacity |

| Cyclical | Regular high/low patterns | Smart load management |

For a data center with cyclical loads, we used a transformer with smart load management. It adjusted its operation to match the data center’s daily patterns, improving efficiency.

Power Quality Solutions

Some businesses need very clean power. 3-phase transformers can help with this:

- Harmonic Mitigation: Special designs reduce harmonic distortion.

- Voltage Regulation: Keeps voltage steady even when loads change.

- Surge Protection: Guards against power spikes that can damage equipment.

I installed a transformer with harmonic mitigation for a printing company. It solved their problem with equipment malfunctions caused by poor power quality.

Specialized Configurations

We can set up 3-phase transformers in special ways for unique needs:

- Delta-Wye Configuration: Good for mixed loads of power and lighting.

- Zig-Zag Winding: Helps balance uneven loads and reduces harmonics.

- Scott-T Connection: Converts 3-phase power to 2-phase for old equipment.

In an old factory modernization project, we used a Scott-T transformer. It let them keep some old 2-phase equipment while upgrading the rest of the system to 3-phase.

Future-Ready Infrastructure: Flexible 3-Phase Transformer Solutions for Rapidly Evolving Industrial Zones?

Industrial areas are changing fast. How can we make sure our power systems keep up?

Flexible 3-phase transformer solutions are key to creating future-ready infrastructure in rapidly evolving industrial zones. These transformers are designed to adapt to changing power needs, integrate with smart grid technologies, and support sustainable energy initiatives.

I’ve seen industrial zones change a lot over the years. Power needs change too. Let’s look at how we’re making transformers ready for the future:

Scalable Power Solutions

Future-ready transformers need to grow with industrial zones:

- Modular Systems: We can add or remove capacity as needed.

- Upgradable Components: Key parts can be replaced with newer technology.

- Flexible Installations: Transformers that can be easily moved or reconfigured.

I worked on an industrial park project where we used modular transformers. As new businesses moved in, we could quickly add power capacity without major construction.

Smart Grid Integration

Modern industrial zones need smart power systems:

| Feature | Benefit |

|---|---|

| Real-time Monitoring | Quick response to changes |

| Two-way Communication | Better grid management |

| Automated Controls | Efficient power distribution |

In a recent smart city project, our transformers could communicate with the grid. This helped balance power use across the whole industrial zone.

Renewable Energy Support

Many industries are moving to renewable energy. Transformers need to support this:

- Bi-directional Power Flow: Handles power from solar panels or wind turbines.

- Energy Storage Integration: Works with battery systems for consistent power.

- Microgrid Compatibility: Supports local power generation and distribution.

I helped set up a transformer system for a green industrial park. It could handle power from roof-top solar panels and send excess energy back to the grid.

Advanced Materials and Designs

We’re using new technologies to make transformers better:

- High-temperature Superconductors: These could revolutionize transformer efficiency.

- Nanotechnology in Insulation: Improves cooling and extends transformer life.

- 3D Printed Components: Allows for complex designs and quick replacements.

These technologies are still new, but they’re already showing promise. In a pilot project, we used a transformer with nanotech-enhanced insulation. It ran cooler and more efficiently than traditional models.

Enabling Smart Industries: The Role of 3-Phase Distribution Transformers in Technological Advancement?

Industries are getting smarter. They use more tech. How do transformers help with this?

3-phase distribution transformers play a crucial role in enabling smart industries. They provide the reliable, high-quality power needed for advanced technologies, and integrate with smart systems to support data-driven industrial processes.

I’ve worked on many projects to make industries smarter. Transformers are a big part of this. Let’s explore how they’re helping advance technology in industry:

Power Quality for Sensitive Equipment

Smart industries use a lot of sensitive equipment. This equipment needs clean, stable power:

- Voltage Regulation: Keeps voltage steady for precise operations.

- Harmonic Filtering: Removes ‘noise’ from the power supply.

- Transient Suppression: Protects against sudden power spikes.

I once set up a transformer system for a semiconductor factory. The clean power it provided was crucial for their high-precision manufacturing processes.

Data Center Support

Data centers are the backbone of smart industries. They need special power solutions:

| Requirement | Transformer Feature |

|---|---|

| High Reliability | Redundant systems |

| Efficiency | Low-loss designs |

| Scalability | Modular configurations |

For a large data center project, we used a system of parallel transformers. This allowed for maintenance without shutting down and easy expansion as the data center grew.

Integration with Industrial IoT

The Internet of Things (IoT) is changing industries. Transformers are part of this change:

- Sensor Networks: Transformers with built-in sensors provide real-time data.

- Predictive Maintenance: AI uses this data to predict when maintenance is needed.

- Energy Use Optimization: Smart transformers help balance loads across a factory.

In a smart factory project, our transformer system was connected to the factory’s IoT network. It helped optimize energy use based on production schedules.

Supporting Automation and Robotics

Modern factories use a lot of automation and robotics. These systems need reliable power:

- Fast Response to Load Changes: Robots can start and stop quickly, changing power needs.

- Precision Power Delivery: Automated systems need exact power levels.

- Fault Tolerance: Production can’t stop because of small power issues.

I worked on upgrading the power system for an automated car factory. The transformers we installed could handle the rapid load changes from robotic welding and assembly lines.

Enabling Edge Computing

Many smart industries are moving to edge computing. This needs power in new places:

- Distributed Power Systems: Small, efficient transformers near computing nodes.

- Cooling Integration: Transformers designed to work with edge computing cooling systems.

- Redundancy: Multiple small transformers instead of one big one for better reliability.

In a recent project, we set up a network of small transformers throughout a smart warehouse. This supported their distributed computing system for inventory management and automated picking.

Conclusion

3-phase distribution transformers are vital for industrial and commercial growth. They offer scalability, efficiency, versatility, future-readiness, and support for smart technologies. These transformers are key to powering the industries of today and tomorrow.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group