Step-Up or Step-Down: Which Transformer Do You Need?

Are you confused about choosing the right transformer for your project? You’re not alone. Many engineers struggle with this decision, but it’s crucial for efficient power distribution.

Step-up and step-down transformers are essential components in electrical systems. They manipulate voltage levels for various applications. Step-up transformers increase voltage for long-distance transmission, while step-down transformers reduce voltage for local distribution and consumer use.

In my 20 years as an electrical engineer, I’ve seen countless projects succeed or fail based on transformer selection. This guide will walk you through the key differences, applications, and considerations for both types. Whether you’re a seasoned professional or a curious beginner, you’ll gain valuable insights to make informed decisions in your electrical projects.

What’s the Difference: Step-Up vs. Step-Down Transformers?

Have you ever wondered why we need different types of transformers? The answer lies in the diverse voltage requirements across our electrical grid.

Step-up transformers increase voltage while decreasing current. Step-down transformers do the opposite. The key difference is in their winding ratios. Step-up transformers have more secondary windings, while step-down transformers have more primary windings.

Let’s dive deeper into the world of transformers. I remember my first project involving a large power distribution system. I was amazed at how these seemingly simple devices could manipulate electricity so effectively.

Basic Principles

Both step-up and step-down transformers work on the same fundamental principle: electromagnetic induction. Here’s a quick breakdown:

- Primary Coil: Connected to the input power source.

- Secondary Coil: Delivers the output power.

- Iron Core: Enhances the magnetic field between coils.

The key difference lies in the number of windings in each coil.

Mathematical Relationships

Understanding the math behind transformers is crucial. Here are the basic formulas:

- Voltage Ratio: Vp / Vs = Np / Ns

- Current Ratio: Ip / Is = Ns / Np

- Power Equality: Vp Ip = Vs Is (ignoring losses)

Where:

- Vp = Primary Voltage

- Vs = Secondary Voltage

- Np = Number of Primary Windings

- Ns = Number of Secondary Windings

- Ip = Primary Current

- Is = Secondary Current

Comparison Table

| Aspect | Step-Up Transformer | Step-Down Transformer |

|---|---|---|

| Winding Ratio | Ns > Np | Np > Ns |

| Voltage | Vs > Vp | Vs < Vp |

| Current | Is < Ip | Is > Ip |

| Primary Use | Increase voltage for transmission | Decrease voltage for distribution |

Understanding these differences is crucial for selecting the right transformer for your project. In my early career, I once mistakenly specified a step-down transformer for a long-distance transmission project. The resulting voltage drop was a costly lesson I’ll never forget.

Where Are They Used: Applications of Step-Up and Step-Down Transformers?

Are you wondering where you might encounter these transformers in real life? The answer is everywhere! From power plants to your smartphone charger, transformers are ubiquitous in our electrified world.

Step-up transformers are crucial in power generation and long-distance transmission. Step-down transformers are essential for local power distribution and consumer electronics. Understanding their applications helps in appreciating their role in our daily lives.

Let’s explore the diverse applications of these transformers. I’ve worked on projects ranging from massive power plants to tiny electronic devices, and transformers play a crucial role in all of them.

Step-Up Transformer Applications

-

Power Generation Plants

- Increase voltage from generators (typically 11kV-25kV) to transmission levels (100kV-800kV).

- Enable efficient long-distance power transmission.

-

Renewable Energy Systems

- Solar farms and wind turbines use step-up transformers to match grid voltage.

- I once worked on a wind farm project where step-up transformers were crucial for integrating the variable output into the grid.

-

Industrial Equipment

- Some high-power industrial processes require voltages higher than standard supply.

- Examples include electric arc furnaces and some types of welding equipment.

Step-Down Transformer Applications

-

Electrical Substations

- Reduce high transmission voltages to distribution levels (typically 11kV-33kV).

- Further step-down transformers reduce voltage to residential levels (120V/240V).

-

Consumer Electronics

- Chargers for laptops, phones, and other devices use small step-down transformers.

- These transformers are often integrated into the charging brick.

-

Industrial Machinery

- Many industrial machines operate at lower voltages than the main supply.

- Step-down transformers provide the appropriate voltage levels for various equipment.

Application Comparison Table

| Application | Step-Up Transformer | Step-Down Transformer |

|---|---|---|

| Power Grid | Power plants to transmission lines | Substations to local distribution |

| Renewable Energy | Solar/wind farms to grid | Not typically used |

| Consumer Electronics | Rarely used | Common in chargers and adapters |

| Industrial | Specific high-voltage processes | General machinery and equipment |

Understanding these applications is crucial for electrical system design. I once consulted on a factory automation project where proper transformer selection was key to ensuring compatible voltage levels across various machines and control systems.

How to Choose: Selecting the Right Transformer for Your Project?

Are you feeling overwhelmed by the technical specifications when selecting a transformer? Don’t worry, you’re not alone. Choosing the right transformer can make or break your electrical project.

Selecting the right transformer involves considering voltage requirements, power capacity, efficiency, and environmental factors. It’s crucial to match the transformer’s specifications with your project’s needs for optimal performance and safety.

Let me guide you through the selection process. Over the years, I’ve developed a systematic approach to choosing transformers that has saved my clients time, money, and headaches.

Key Factors to Consider

-

Voltage Requirements

- Input Voltage: What’s the available supply voltage?

- Output Voltage: What voltage do your loads require?

- Voltage Regulation: How stable does the output voltage need to be?

-

Power Capacity

- Total Load: Calculate the total power requirement of all connected devices.

- Future Expansion: Always factor in some extra capacity for future needs.

-

Efficiency

- Core Losses: Consider using low-loss materials like amorphous cores for high-efficiency needs.

- Copper Losses: Larger conductors reduce losses but increase cost and size.

-

Environmental Factors

- Temperature: Will the transformer operate in extreme temperatures?

- Humidity: Is moisture protection necessary?

- Altitude: High-altitude applications may require special considerations.

-

Physical Constraints

- Size and Weight: Especially important for mobile or space-constrained applications.

- Mounting Options: Consider whether you need a pole-mounted, pad-mounted, or indoor transformer.

Selection Process

-

Determine Voltage Transformation Needs

- If output voltage > input voltage: Choose a step-up transformer

- If output voltage < input voltage: Choose a step-down transformer

-

Calculate Required Power Capacity

- Sum up the power requirements of all loads

- Add 20-30% for future expansion and safety margin

-

Consider Efficiency Requirements

- High-efficiency transformers cost more upfront but save on operating costs

- Calculate the total cost of ownership (TCO) over the expected lifespan

-

Evaluate Environmental Factors

- Choose appropriate insulation and cooling methods based on the operating environment

-

Check Physical Constraints

- Ensure the chosen transformer fits within the available space

- Consider transportation and installation requirements

Transformer Selection Checklist

| Factor | Considerations | Example |

|---|---|---|

| Voltage Ratio | Input vs. Output Voltage | 480V to 120V (Step-Down) |

| Power Capacity | Total Load + Future Expansion | 100kVA + 20% = 120kVA |

| Efficiency | Core and Copper Losses | 98% efficiency at rated load |

| Environment | Temperature, Humidity, Altitude | Indoor, 0-40°C, sea level |

| Physical | Size, Weight, Mounting | 1m x 1m x 1.5m, 500kg, Pad-mounted |

I once worked on a project where the client insisted on a lower-capacity transformer to save costs. Six months later, they had to replace it due to increased power demands. Always plan for future growth!

Remember, selecting the right transformer is not just about meeting current needs but also about anticipating future requirements. A well-chosen transformer will provide reliable service for decades, making it a crucial investment in any electrical system.

Conclusion

Choosing between step-up and step-down transformers depends on your specific voltage and power requirements. Consider factors like efficiency, environmental conditions, and future expansion needs. Proper selection ensures optimal performance, safety, and longevity in your electrical systems.

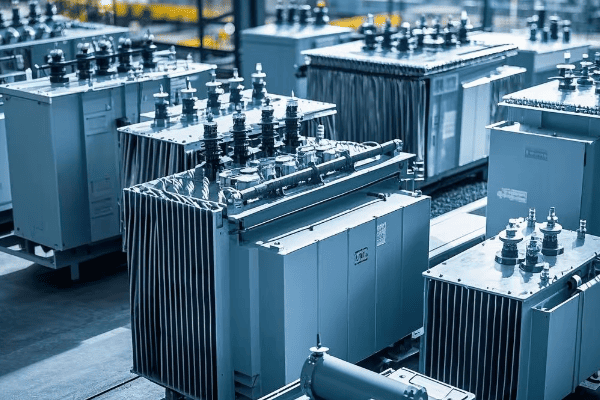

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group