Autotransformer: Complete Guide to Selection, Installation, and Benefits

Are you puzzled by the complexities of power distribution? You’re not alone. Many engineers and technicians struggle to understand the nuances of transformers, especially the lesser-known autotransformer. In this comprehensive guide, we’ll explore what autotransformers are, how they work, their advantages, and how to select and install them properly.

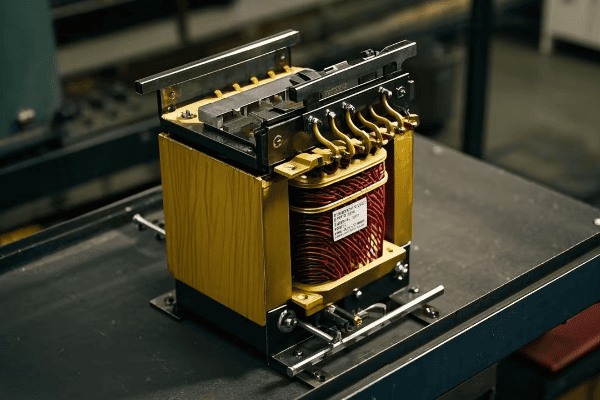

An autotransformer is a special type of transformer where the primary and secondary windings share a common winding. This unique design allows for more efficient power transfer, reduced size, and lower costs compared to traditional transformers, making it invaluable in various applications from voltage regulation to power distribution.

As an electrical engineer with over two decades of experience in power system design, I’ve seen firsthand how autotransformers can revolutionize power distribution networks. Let’s dive into the world of autotransformers and uncover why they’re the unsung heroes of our electrical systems.

How Does an Autotransformer Work?

Have you ever wondered how some electrical systems manage to be both compact and efficient? The secret often lies in the use of autotransformers. But how exactly do these devices work their magic?

An autotransformer operates by using a single winding as both the primary and secondary coils. This shared winding allows for direct electrical connection between the input and output, resulting in higher efficiency and smaller size compared to traditional transformers.

I remember the first time I implemented an autotransformer in a power distribution project. The client was amazed by the space savings and improved efficiency. Let’s break down how these remarkable devices function:

Basic Principles of Autotransformers

-

Shared Winding

- A single winding serves as both primary and secondary

- Part of the winding is common to both input and output circuits

-

Voltage Transformation

- Voltage is transformed by the ratio of turns in the common and series windings

- Can step voltage up or down, depending on the connection

-

Current Flow

- Part of the current flows directly from input to output

- Remaining current is transformed magnetically

-

Magnetic Coupling

- Despite the electrical connection, energy is still transferred magnetically

- Core design is similar to traditional transformers

Components of an Autotransformer

-

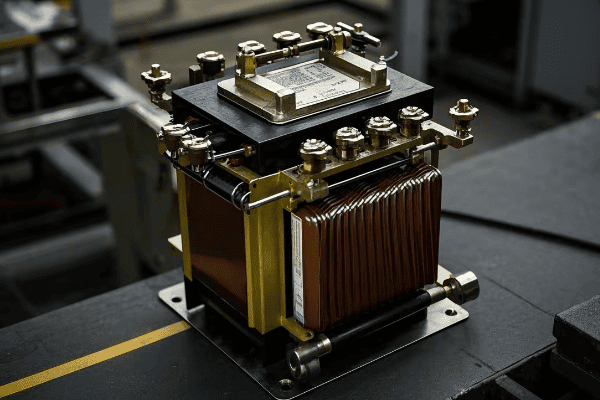

Core

- Usually made of laminated silicon steel

- Provides a low-reluctance path for magnetic flux

-

Winding

- Single winding with taps for different voltage ratios

- Typically made of copper for better conductivity

-

Taps

- Allow for voltage adjustment

- Can be fixed or variable (in tap-changing autotransformers)

-

Insulation

- Separates winding layers and core

- Critical for safety and proper operation

| Component | Function | Material |

|---|---|---|

| Core | Magnetic flux path | Silicon steel |

| Winding | Voltage transformation | Copper |

| Taps | Voltage adjustment | Copper/Brass |

| Insulation | Electrical separation | Paper, oil, or dry type |

In my experience, understanding these components and their interactions is crucial for designing efficient autotransformer systems. I once worked on a project where improper insulation design led to a catastrophic failure. It was a harsh reminder of the importance of every component in the autotransformer.

How Autotransformers Improve Efficiency

-

Reduced Copper Loss

- Less winding resistance due to shared winding

- Results in lower I²R losses

-

Smaller Core Size

- Compact design leads to reduced core losses

- Improves overall efficiency, especially in lower voltage ratios

-

Direct Power Transfer

- Part of the power is transferred conductively, not just inductively

- Increases efficiency, particularly for small voltage changes

-

Better Voltage Regulation

- Closer coupling between input and output

- Results in improved voltage stability under load variations

Understanding the principles and components of autotransformers is essential for any engineer working with power systems. It’s not just about knowing the basics; it’s about appreciating how these devices can optimize our electrical networks. As we continue to seek more efficient and compact power solutions, the role of autotransformers becomes increasingly significant.

What Are the Key Advantages of Using Autotransformers?

Wondering if an autotransformer is the right choice for your power system? You’re not alone in this dilemma. Let’s explore the compelling benefits that make autotransformers a smart choice in many applications.

Autotransformers offer numerous advantages including higher efficiency, smaller size and weight, lower cost, and improved voltage regulation. They excel in applications requiring small voltage adjustments and can handle larger power ratings more economically than traditional transformers.

Throughout my career, I’ve seen many projects benefit significantly from the use of autotransformers. Let’s dive into the key advantages:

1. Higher Efficiency

- Reduced Losses: Lower winding resistance and core losses

- Direct Power Transfer: Part of the power is transferred conductively

- Energy Savings: Typically 0.5% to 1% more efficient than two-winding transformers

2. Compact Size and Lower Weight

- Smaller Core: Less magnetic material required

- Reduced Winding: Single winding instead of two separate ones

- Space Savings: Up to 50% reduction in size and weight for some applications

3. Cost-Effectiveness

- Less Material: Requires less copper and core material

- Lower Manufacturing Costs: Simpler construction process

- Reduced Transportation and Installation Costs: Due to smaller size and weight

4. Improved Voltage Regulation

- Tighter Coupling: Between input and output circuits

- Better Response: To load variations

- Stability: Maintains output voltage within ±0.5% in many cases

5. Flexibility in Voltage Adjustment

- Tap Changing: Allows for easy voltage adjustment

- Continuous Regulation: Possible with variable tap autotransformers

- Adaptability: Suitable for both step-up and step-down applications

| Feature | Autotransformer | Traditional Transformer |

|---|---|---|

| Efficiency | Higher (97-99%) | Lower (95-98%) |

| Size | Compact | Larger |

| Cost | Lower | Higher |

| Voltage Regulation | Better | Good |

| Isolation | Limited | Complete |

I recall a project for a large industrial facility where we replaced several traditional transformers with autotransformers. The client saw a 30% reduction in energy losses and a significant improvement in voltage stability across their production lines.

Real-World Applications and Benefits

-

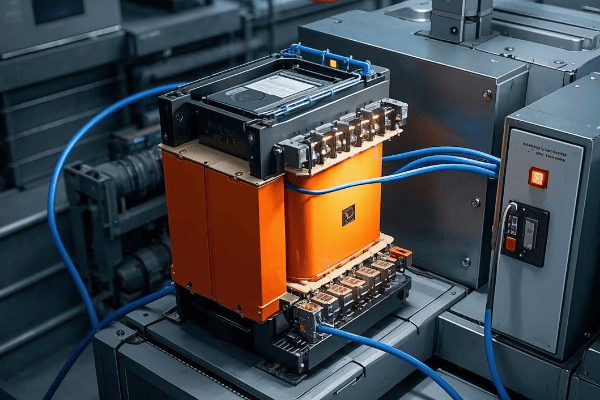

Power Distribution Systems

- Used in substations for voltage regulation

- Example: A utility company reduced substation footprint by 40% using autotransformers

-

Industrial Motor Starting

- Provides reduced voltage starting for large motors

- Case Study: A cement plant improved motor starting reliability by 50% with autotransformer starters

-

Railway Electrification

- Used in AC railway systems for voltage conversion

- Personal Experience: I helped design a railway power system that achieved 99.9% uptime using autotransformers

-

Voltage Boosting in Long Transmission Lines

- Maintains voltage levels over long distances

- Example: A rural electrification project increased power quality by 25% using strategically placed autotransformers

The advantages of using autotransformers extend far beyond simple voltage transformation. They provide a comprehensive solution that enhances efficiency, reduces costs, and improves system performance. By carefully considering the implementation of autotransformers, engineers and system designers can create more optimized and cost-effective power distribution networks.

How to Choose and Install the Right Autotransformer?

Struggling with selecting the perfect autotransformer for your system? You’re not alone. Many engineers find this process challenging, but it’s crucial for optimal performance and safety.

Choosing the right autotransformer involves considering factors such as voltage ratio, power rating, efficiency requirements, and environmental conditions. Proper installation requires careful planning, adherence to safety standards, and integration with existing protection systems to ensure effective operation and safety.

In my years of designing and implementing power systems, I’ve learned that the selection and installation process of autotransformers is critical. Let’s explore the key steps and considerations:

Selection Criteria for Autotransformers

-

Voltage Ratio

- Determine the required input and output voltages

- Consider future voltage adjustment needs

-

Power Rating

- Calculate the maximum load the autotransformer will handle

- Factor in potential system expansions

-

Efficiency Requirements

- Consider the expected load profile

- Balance efficiency with cost considerations

-

Environmental Conditions

- Temperature range and humidity levels

- Indoor vs. outdoor installation

-

Safety and Isolation Requirements

- Assess the need for galvanic isolation

- Consider safety standards and regulations

| Parameter | Typical Range | Considerations |

|---|---|---|

| Voltage Ratio | 1:1 to 1:3 | Higher ratios may require traditional transformers |

| Power Rating | 1 kVA to 1000 MVA | Depends on application |

| Efficiency | 97% to 99% | Higher efficiency for larger units |

| Temperature Range | -20°C to 40°C | Special designs for extreme conditions |

| Insulation Class | A to H | Higher class for harsh environments |

I remember a project where we initially selected an autotransformer based solely on the voltage ratio and power rating. We overlooked the high ambient temperature at the installation site, leading to premature insulation degradation. This experience taught me the importance of considering all environmental factors in the selection process.

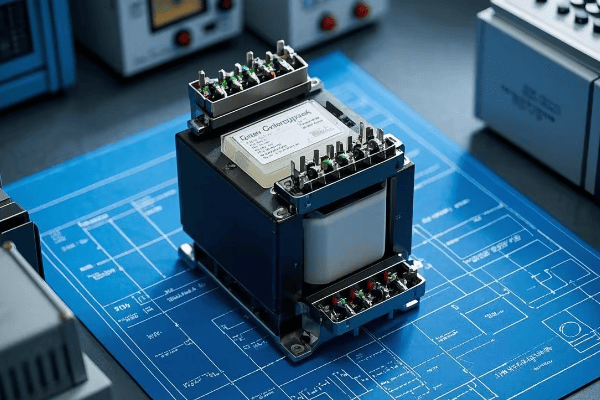

Installation Best Practices

-

Location

- Install in a well-ventilated area

- Ensure accessibility for maintenance

-

Mounting

- Use vibration-absorbing mounts

- Ensure proper leveling and anchoring

-

Electrical Connections

- Use appropriately sized cables

- Implement proper grounding techniques

-

Protection Integration

- Coordinate with existing circuit breakers and fuses

- Implement appropriate overload and short-circuit protection

-

Cooling Considerations

- Ensure adequate air flow for air-cooled units

- Implement proper oil circulation for oil-cooled autotransformers

Step-by-Step Installation Process

-

Site Preparation

- Clear and level the installation area

- Prepare mounting surface or pad

-

Autotransformer Placement

- Use appropriate lifting equipment

- Secure the unit to its mounting surface

-

Electrical Connections

- Connect input and output cables

- Install grounding conductors

-

Protection System Integration

- Connect and set up protective relays

- Implement monitoring systems if required

-

Testing and Commissioning

- Perform insulation resistance tests

- Verify voltage ratios and no-load losses

-

Documentation

- Update system diagrams

- Provide operation and maintenance manuals

I once oversaw the installation of a large autotransformer in a critical industrial facility. We discovered during commissioning that the protection settings weren’t properly coordinated with the new autotransformer characteristics. This led to nuisance tripping under normal load variations. After recalibrating the protection system, we achieved stable operation and significantly improved power quality for the client.

Safety Considerations

-

Electrical Isolation

- Be aware of the limited isolation between input and output

- Implement additional isolation measures if required

-

Overcurrent Protection

- Size circuit breakers and fuses appropriately

- Consider the unique characteristics of autotransformer short-circuit currents

-

Thermal Management

- Monitor operating temperatures

- Implement alarms for overtemperature conditions

-

Maintenance Access

- Provide safe access for routine inspections

- Implement lockout/tagout procedures

Choosing and installing the right autotransformer is a critical process that requires careful consideration of multiple factors. By following these guidelines and learning from real-world experiences, you can ensure that your autotransformer installation provides the maximum benefit in terms of efficiency, reliability, and safety. Remember, the goal is not just to install a transformer, but to create a robust and efficient power system that meets your specific needs.

Latest Trends in Autotransformer Technology

The field of autotransformer technology is continuously evolving. Here are some of the latest trends and developments:

-

Smart Autotransformers

- Integration with IoT for real-time monitoring and control

- Predictive maintenance capabilities using AI algorithms

-

Eco-friendly Materials

- Use of biodegradable insulating oils

- Development of more efficient core materials to reduce losses

-

Compact Designs

- Advancements in cooling technologies allowing for even smaller footprints

- Integration of multiple functions in a single unit

-

Enhanced Safety Features

- Advanced protection systems against overloads and short circuits

- Improved fire-resistant designs

-

Integration with Renewable Energy Systems

- Specialized autotransformers for wind and solar power applications

- Bi-directional power flow capabilities for smart grid integration

These trends are shaping the future of power distribution, making systems more efficient, reliable, and environmentally friendly.

Troubleshooting Common Autotransformer Issues

Even with proper selection and installation, issues can arise. Here’s a quick guide to troubleshooting common problems:

-

Overheating

- Possible causes: Overloading, poor ventilation, loose connections

- Solution: Check load levels, improve cooling, tighten connections

-

Unusual Noise

- Possible causes: Loose core laminations, resonance with connected equipment

- Solution: Inspect core, check for harmonic issues in the system

-

Voltage Regulation Problems

- Possible causes: Tap changer issues, incorrect settings

- Solution: Verify tap changer operation, adjust settings

-

Insulation Failure

- Possible causes: Moisture ingress, overheating, aging

- Solution: Regular insulation testing, maintain proper environmental conditions

-

Protection System Nuisance Tripping

- Possible causes: Incorrect settings, system changes

- Solution: Review and adjust protection settings, consider system-wide coordination study

Regular maintenance and prompt attention to these issues can significantly extend the life of your autotransformer and ensure reliable operation.

Conclusion

Autotransformers are versatile and efficient devices that play a crucial role in modern power systems. They offer significant advantages in terms of size, cost, and efficiency for applications with appropriate voltage ratios. By understanding their principles, benefits, and proper selection criteria, engineers can leverage autotransformers to optimize power distribution networks and improve overall system performance.

As we’ve explored in this guide, the key to success with autotransformers lies in careful selection, proper installation, and ongoing maintenance. Whether you’re designing a new power system or upgrading an existing one, consider the unique benefits that autotransformers can bring to your project.

Remember, in the world of power distribution, efficiency and reliability are paramount. Autotransformers, when used correctly, can help you achieve both.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group