Top 10 Applications of Power Transformers in Modern Industry?

Have you ever wondered how electricity powers our modern world? From bustling cities to remote industrial sites, power transformers play a crucial role in making it all possible.

Power transformers are essential in modern industry for converting voltage levels and enabling efficient power transmission and distribution. They are used in electricity generation, heavy manufacturing, renewable energy systems, transportation, urban development, mining, data centers, healthcare, petrochemicals, and aerospace industries.

As an electrical engineer with years of experience in the power industry, I’ve seen firsthand how vital these devices are across various sectors. Let’s explore the top 10 applications of power transformers that are shaping our modern industrial landscape.

Powering the Grid: Power Transformers in Electricity Generation and Distribution Networks?

Ever wondered how electricity from a power plant reaches your home? Power transformers are the unsung heroes making this journey possible.

Power transformers are crucial in electricity generation and distribution networks. They step up voltage for efficient long-distance transmission and step it down for local distribution, ensuring power reaches consumers safely and efficiently across vast distances.

Let’s dive deeper into how power transformers keep our lights on:

Generation: Stepping Up for the Journey

At power plants, transformers play a vital role:

-

Generator Step-Up Transformers:

- Increase voltage from generators (typically 15-25kV) to transmission levels (230kV-765kV).

- Enable efficient long-distance power transmission.

-

Auxiliary Transformers:

- Power plant’s own equipment and systems.

- Ensure continuous operation of critical plant functions.

Transmission: The High-Voltage Highway

Transformers are crucial in the transmission network:

-

Substation Transformers:

- Further step up voltage for ultra-long distance transmission.

- Interconnect different parts of the grid at transmission substations.

-

Phase-Shifting Transformers:

- Control power flow between different parts of the grid.

- Enhance grid stability and efficiency.

Distribution: Bringing Power to the People

As electricity nears its destination, transformers step in again:

-

Primary Distribution Transformers:

- Step down voltage from transmission to distribution levels (typically to 4-34.5kV).

- Feed power to local distribution networks.

-

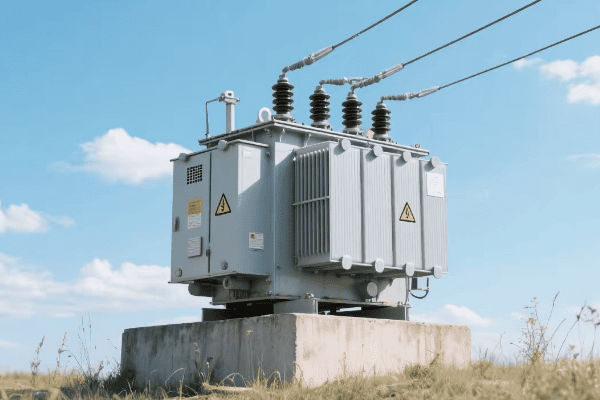

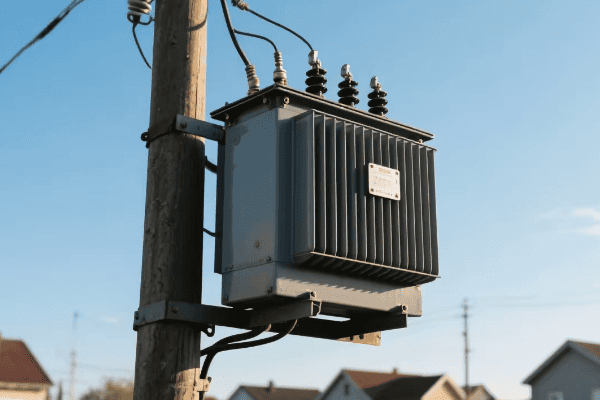

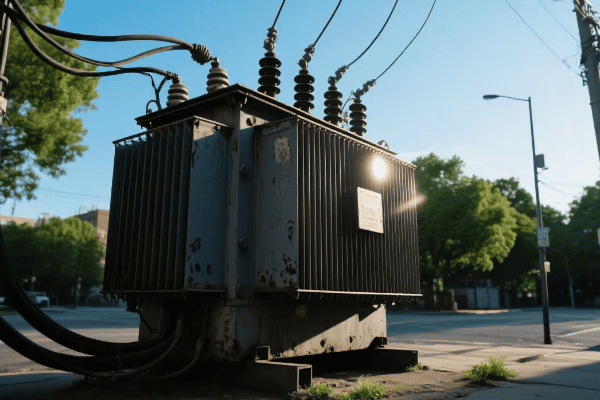

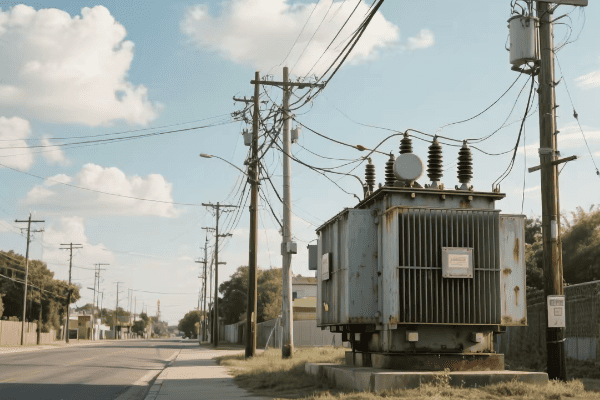

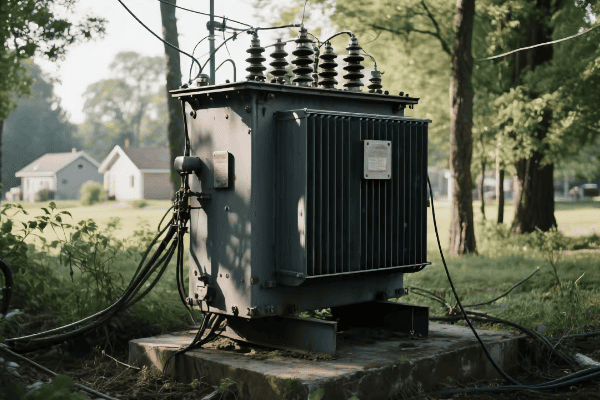

Secondary Distribution Transformers:

- Further reduce voltage to levels suitable for end-users (120V/240V for homes, 480V for businesses).

- Often seen as pole-mounted or pad-mounted units in neighborhoods.

Here’s a comparison of transformer types in the power grid:

| Transformer Type | Typical Voltage Range | Power Capacity | Key Features |

|---|---|---|---|

| Generator Step-Up | 15-25kV to 230-765kV | 100-1500 MVA | High impedance, surge protection |

| Transmission | 230kV to 765kV | 100-1000 MVA | Extra high voltage insulation |

| Substation | 765kV to 69kV | 10-300 MVA | On-load tap changers |

| Distribution | 69kV to 120/240V | 5-50 MVA | Overload capacity, compact design |

I remember working on a project to upgrade a major substation. We were replacing an aging 500MVA transformer with a new, more efficient model. The logistics of moving these massive units were incredible – the new transformer weighed over 400 tons! But what really struck me was the immediate impact on grid stability once it was online. The new transformer’s advanced features, like real-time monitoring and dynamic voltage regulation, significantly reduced power fluctuations in the region.

Power transformers in the electricity grid are more than just voltage converters. They’re the backbone of our entire power distribution system. As our energy needs grow and change, these transformers are evolving to meet new challenges:

Smart Grid Integration

Modern grid transformers are becoming smarter:

-

Digital Monitoring:

- Real-time data on load, temperature, and oil condition.

- Enables predictive maintenance and rapid response to potential issues.

-

Dynamic Voltage Regulation:

- Automatic adjustment to changing grid conditions.

- Improves power quality and grid stability.

Efficiency and Sustainability

Transformer design is focusing on energy efficiency:

-

Low-Loss Core Materials:

- Use of amorphous metals and advanced silicon steels.

- Significantly reduce energy losses in the transformer.

-

Green Insulation:

- Bio-based oils replacing mineral oils.

- Improve environmental sustainability and reduce fire risk.

As we move towards a more decentralized, renewable-based energy system, power transformers will play an even more critical role. They’ll need to handle bidirectional power flows, integrate with smart grid technologies, and support the increasing variability of renewable energy sources. The future of our power grid depends on these often-overlooked devices, silently working to keep our world powered.

Industrial Giants: Power Transformers in Heavy Manufacturing and Process Industries?

Have you ever wondered how massive steel mills or chemical plants get the enormous amount of power they need? The answer lies in specialized power transformers designed for heavy industry.

Power transformers are essential in heavy manufacturing and process industries for providing the large amounts of power needed for industrial processes. They handle high voltages and currents, ensure reliable power supply for critical operations, and often include special features for harsh industrial environments.

Let’s explore how power transformers keep our industrial giants running:

Powering Heavy Machinery

In manufacturing, transformers supply power to various equipment:

-

Arc Furnace Transformers:

- Provide high current at low voltage for steel melting.

- Handle extreme load fluctuations.

-

Rolling Mill Transformers:

- Power large motors in steel and aluminum production.

- Designed for high overload capacity.

Process Industry Applications

Transformers play a crucial role in continuous process industries:

-

Rectifier Transformers:

- Convert AC to DC for electrolysis processes in chemical and metal industries.

- Handle high harmonic content.

-

Variable Frequency Drive (VFD) Transformers:

- Power speed control systems for pumps and compressors.

- Designed to handle non-linear loads.

Here’s a comparison of transformer types in heavy industry:

| Transformer Type | Typical Power Range | Special Features | Common Applications |

|---|---|---|---|

| Arc Furnace | 50-150 MVA | High short-circuit strength | Steel manufacturing |

| Rolling Mill | 10-50 MVA | High overload capacity | Metal processing |

| Rectifier | 20-100 MVA | Harmonic mitigation | Aluminum smelting, chlorine production |

| VFD | 5-30 MVA | K-factor rated | Oil & gas, mining |

I once worked on a project to upgrade the power system for a large aluminum smelter. We installed a new 80MVA rectifier transformer to power the electrolysis cells. The challenges were immense – the transformer had to handle enormous currents and deal with the harsh, corrosive environment of the smelter. But the results were impressive. The new transformer improved energy efficiency by 3%, which might not sound like much, but in an industry where energy costs are a major factor, it translated to millions in savings annually.

Power transformers in heavy industry are more than just large versions of standard transformers. They’re highly specialized units designed to meet the unique demands of industrial processes:

Rugged Design for Harsh Environments

Industrial transformers must withstand tough conditions:

-

Enhanced Cooling Systems:

- Forced oil and forced air cooling for high-temperature environments.

- Some use water-cooled designs for extreme heat.

-

Robust Mechanical Design:

- Reinforced tank and core to withstand vibrations and shocks.

- Special coatings for corrosion resistance in chemical plants.

Load Management and Power Quality

Industrial processes often have unique power requirements:

-

Load Tap Changers:

- Allow voltage adjustment under load.

- Critical for processes that require precise voltage control.

-

Harmonic Mitigation:

- Special designs to handle non-linear loads common in industrial drives.

- Use of phase-shifting techniques to cancel out harmonics.

As industry 4.0 and smart manufacturing continue to evolve, power transformers in these settings are adapting to new challenges. They’re becoming more intelligent, with advanced monitoring systems that integrate with plant-wide control networks. Some are even incorporating solid-state components for more precise power control.

The future of industrial power transformers will likely see even more integration with digital systems, enabling real-time optimization of power usage across entire plants. We might see transformers that can dynamically adjust their characteristics based on changing process needs, or units that can seamlessly switch between different power sources, including renewables.

In the world of heavy industry, where reliability and efficiency are paramount, power transformers will continue to play a critical role. They’re the unsung heroes that keep our industrial giants running, enabling the production of the materials and goods that form the backbone of our modern world.

Green Energy Integration: Power Transformers in Renewable Energy Systems?

Ever wondered how the energy from a wind farm or solar array makes it to your home? Power transformers are the key link in making renewable energy grid-compatible and widely available.

Power transformers are crucial in renewable energy systems for converting and integrating variable power output from sources like wind and solar into the grid. They handle voltage step-up for transmission, manage power quality issues, and enable bidirectional power flow in smart grid applications.

Let’s explore how power transformers are powering the green energy revolution:

Solar Power Integration

Transformers play multiple roles in solar energy systems:

-

Inverter Transformers:

- Convert DC output from solar panels to AC for grid use.

- Step up voltage from inverter levels to distribution or transmission voltages.

-

Collection Substation Transformers:

- Aggregate power from multiple solar arrays.

- Step up voltage for long-distance transmission from large solar farms.

Wind Farm Applications

In wind energy, transformers are essential at various stages:

-

Turbine Transformers:

- Step up voltage from individual wind turbines (typically 690V) to collection system voltage (33kV-66kV).

- Often located in the base or nacelle of the wind turbine.

-

Substation Transformers:

- Further step up voltage from collection system to transmission levels.

- Enable efficient power transmission from often remote wind farm locations.

Here’s a comparison of transformer applications in different renewable energy settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Solar Inverter | 1-5 MVA | 600-1500V DC | 33kV AC | Harmonic mitigation |

| Solar Farm Substation | 50-500 MVA | 33kV | 230kV+ | Tap changers for voltage control |

| Wind Turbine | 2-10 MVA | 690V | 33-66kV | Compact design for nacelle mounting |

| Wind Farm Substation | 100-500 MVA | 33-66kV | 230kV+ | Reactive power compensation |

I remember working on a project to connect a large offshore wind farm to the grid. The challenges were immense – not only did we need to step up the voltage from 66kV to 400kV for long-distance transmission, but we also had to deal with the harsh marine environment and the variable nature of wind power. We ended up using a combination of onshore and offshore transformers with advanced monitoring and control systems. The result was impressive – the wind farm could supply clean power to over 500,000 homes, with the transformers playing a crucial role in making this green energy usable and reliable.

Power transformers in renewable energy systems are more than just voltage converters. They’re key components in making green energy practical and grid-compatible. As renewable energy continues to grow, these transformers are evolving to meet new challenges:

Smart Grid Integration

Modern renewable energy transformers are becoming smarter:

-

Bidirectional Power Flow:

- Handle power flowing both to and from the grid.

- Essential for smart grid applications and energy storage integration.

-

Real-Time Monitoring:

- Advanced sensors and communication systems for grid operators.

- Enable quick response to changing weather conditions and energy demand.

Power Quality Management

Renewable sources present unique power quality challenges:

-

Harmonic Mitigation:

- Special designs to handle harmonics from inverters.

- Ensure clean power delivery to the grid.

-

Voltage Regulation:

- On-load tap changers for dynamic voltage control.

- Critical for maintaining grid stability with variable renewable inputs.

As we push towards a greener future, with ambitious renewable energy targets, the role of power transformers in this sector will only grow in importance. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities or advanced power electronics for more precise control.

The future might bring transformers that can actively balance and optimize power flow between various renewable sources, conventional generation, and energy storage systems. They could become key nodes in a highly dynamic, AI-managed smart grid, helping to maximize the use of renewable energy while maintaining grid stability.

In the world of renewable energy, where variability and grid integration are key challenges, power transformers will continue to be critical components. They’re not just enabling our transition to cleaner energy sources; they’re actively shaping how we harness and use the power of nature to build a more sustainable future.

Electrifying Transportation: Power Transformers in Railway and Electric Vehicle Infrastructure?

Ever wondered how electric trains run so smoothly or how fast-charging stations for electric vehicles work? The answer lies in specialized power transformers designed for modern transportation needs.

Power transformers are essential in railway systems and electric vehicle (EV) infrastructure. They provide the necessary power for electric trains, subway systems, and high-capacity EV charging stations. These transformers handle high power demands, ensure safety, and support the growing electrification of transportation.

Let’s explore how power transformers are revolutionizing our transportation systems:

Railway Electrification

Transformers play a crucial role in powering electric railways:

-

Traction Substations:

- Convert high voltage from the grid to levels suitable for trains (typically 25kV AC or 3kV DC).

- Spaced along the railway to provide continuous power.

-

Trackside Transformers:

- Step down voltage for signaling and auxiliary systems.

- Ensure reliable power for critical safety and communication equipment.

Electric Vehicle Charging Infrastructure

In the rapidly growing EV sector, transformers are key:

-

Fast Charging Stations:

- Step down medium voltage to levels suitable for DC fast chargers.

- Handle high power demands for rapid charging of multiple vehicles.

-

Grid Integration:

- Manage the impact of large-scale EV charging on the local grid.

- Some include energy storage systems for load balancing.

Here’s a comparison of transformer applications in transportation electrification:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Railway Traction | 5-60 MVA | 110kV+ | 25kV AC or 3kV DC | Phase conversion, harmonics management |

| Subway System | 1-5 MVA | 33kV | 750V DC | Compact design for underground installation |

| EV Fast Charging | 0.5-5 MVA | 33kV | 400V AC | Rapid load changes, smart grid integration |

| EV Charging Hub | 5-20 MVA | 110kV | 33kV/400V | Load balancing, energy storage integration |

I once worked on a project to upgrade the power system for a major city’s subway network. We were replacing old rectifier transformers with new, more efficient models that included advanced harmonic mitigation. The challenges were significant – we had to work in confined underground spaces and ensure zero disruption to the subway service. But the results were impressive. The new transformers not only improved energy efficiency by 20% but also reduced heat generation, which was crucial in the confined subway environment. It was fascinating to see how these transformers, hidden away in substations, played such a crucial role in keeping millions of commuters moving every day.

Power transformers in transportation electrification are more than just power conversion devices. They’re enablers of sustainable mobility. As we move towards more electrified transportation systems, these transformers are evolving to meet new challenges:

Smart Power Management

Modern transportation transformers are becoming more intelligent:

-

Real-Time Load Management:

- Adaptive systems that can handle rapi1. Real-Time Load Management:

- Adaptive systems that can handle rapid load changes in EV charging.

- Integrate with smart grid systems for demand response capabilities.

-

Predictive Maintenance:

- Advanced monitoring systems to predict and prevent failures.

- Crucial for maintaining reliable public transportation and EV charging networks.

Energy Efficiency and Sustainability

Transformer design is focusing on minimizing losses:

-

High-Efficiency Cores:

- Use of advanced materials like amorphous metals to reduce core losses.

- Particularly important in applications with continuous power flow, like railways.

-

Eco-Friendly Cooling:

- Development of biodegradable cooling fluids.

- Some designs use air or synthetic esters instead of traditional mineral oil.

As we push towards more sustainable transportation, the role of power transformers in this sector will only grow. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities or advanced power electronics for more precise control of power flow.

The future might bring transformers that can dynamically adjust to the changing needs of EV charging patterns or railway power demands. We might see units that can seamlessly switch between different power sources, including renewables, to optimize energy use and reduce carbon footprint.

In the world of electrified transportation, where reliability and efficiency are paramount, power transformers will continue to play a critical role. They’re not just enabling the shift away from fossil fuels in transportation; they’re actively shaping how we move people and goods in a cleaner, more sustainable future.

Urban Development: Power Transformers in Smart Cities and Commercial Complexes?

Ever wondered how modern skyscrapers stay powered or how smart cities manage their complex energy needs? Power transformers are the unsung heroes behind the scenes, making our urban environments function smoothly.

Power transformers are crucial in smart cities and commercial complexes for efficient power distribution, integration of renewable energy sources, and support of smart grid technologies. They enable energy management in large buildings, power urban infrastructure, and facilitate the implementation of smart city initiatives.

Let’s explore how power transformers are shaping our urban landscapes:

High-Rise Power Distribution

In towering skyscrapers, transformers play a vital role:

-

Step-Down Transformers:

- Reduce incoming high voltage to levels usable within the building.

- Often located in basement levels or dedicated electrical rooms.

-

Floor-Level Transformers:

- Further step down voltage for different building zones.

- Enable efficient power distribution in tall structures.

Smart Grid Integration

In modern urban developments, transformers enable smart energy management:

-

Bidirectional Power Flow:

- Allow integration of rooftop solar and other distributed energy resources.

- Enable buildings to both consume and produce energy.

-

Smart Metering:

- Support advanced metering infrastructure for real-time energy monitoring.

- Facilitate demand response programs and dynamic pricing.

Here’s a comparison of transformer applications in urban settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| High-Rise Main | 2-10 MVA | 33kV | 11kV | Compact dry-type design |

| Floor Distribution | 500kVA – 2MVA | 11kV | 400V | Low noise, fire-resistant |

| Smart Grid Node | 1-5 MVA | 33kV | 11kV/400V | Communication interfaces, real-time monitoring |

| Urban Substation | 20-100 MVA | 110kV | 33kV/11kV | Underground installation, low noise |

I once worked on a project to upgrade the power system for a new "smart" office complex. We implemented a network of intelligent transformers that not only provided power but also collected real-time data on energy usage. The system could automatically adjust power distribution based on demand, integrate rooftop solar panels, and even communicate with the city’s smart grid for demand response events. It was fascinating to see how these transformers became the nervous system of the building’s energy management, enabling a level of efficiency and flexibility that was previously impossible.

Power transformers in urban environments are evolving beyond their traditional role. They’re becoming key components in the complex energy ecosystems of smart cities:

Energy Efficiency and Sustainability

Urban transformers are at the forefront of energy conservation:

-

Ultra-Low Loss Designs:

- Use of advanced core materials and winding techniques to minimize energy waste.

- Critical in dense urban environments where every bit of efficiency counts.

-

Green Cooling Solutions:

- Development of biodegradable insulating fluids.

- Some designs use natural esters, reducing environmental impact and fire risk.

Smart Monitoring and Control

Modern urban transformers are becoming more intelligent:

-

IoT Integration:

- Equipped with sensors and communication modules for real-time monitoring.

- Enable predictive maintenance and rapid response to potential issues.

-

Load Balancing:

- Dynamic adjustment of power distribution based on real-time demand.

- Crucial for managing the complex and changing energy needs of urban environments.

As our cities become smarter and more energy-conscious, the role of power transformers will continue to evolve. We might see transformers that can actively participate in energy markets, automatically adjusting their operation to optimize cost and efficiency based on real-time pricing and demand.

The future could bring transformers with integrated energy storage capabilities, helping to smooth out the variability of renewable energy sources and provide backup power during outages. We might even see transformers that can learn and adapt to the unique energy patterns of their urban environment, continuously optimizing their performance.

In the landscape of smart cities and modern commercial complexes, power transformers are more than just electrical devices. They’re becoming intelligent nodes in a vast, interconnected energy network, helping to create more sustainable, efficient, and resilient urban environments. As we continue to reimagine our cities for the future, these often-overlooked devices will play a crucial role in powering our urban evolution.

Mining and Minerals: Power Transformers in Resource Extraction Operations?

Have you ever considered the massive amount of power required to run a modern mine? From crushing ore to powering enormous excavators, power transformers play a critical role in keeping the mining industry operational.

Power transformers are essential in mining and mineral extraction for providing reliable, high-capacity power to heavy machinery and processing equipment. They handle the harsh conditions of mining environments, support 24/7 operations, and often include special features for remote locations and extreme climates.

Let’s dig into how power transformers keep our resource extraction operations running:

Powering Heavy Machinery

In open-pit and underground mines, transformers supply power to various equipment:

-

Excavator and Dragline Transformers:

- Provide high power for massive earth-moving equipment.

- Often mobile or semi-mobile to follow mining operations.

-

Conveyor System Transformers:

- Power long conveyor belts for ore transportation.

- Distributed along the conveyor route for efficient power delivery.

Mineral Processing Plants

Transformers play a crucial role in ore processing facilities:

-

Crusher and Mill Transformers:

- Supply power to energy-intensive crushing and grinding equipment.

- Handle high starting currents and variable loads.

-

Electrolysis Transformers:

- Provide DC power for electrowinning processes in metal refineries.

- Designed for high current, low voltage output.

Here’s a comparison of transformer applications in mining operations:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Dragline | 5-15 MVA | 33kV | 6.6kV | Mobile design, shock resistant |

| Conveyor System | 1-5 MVA | 33kV | 690V | Distributed along route, dust-proof |

| Ore Crusher | 2-10 MVA | 33kV | 11kV | High overload capacity |

| Electrowinning | 10-50 MVA | 110kV | 600V DC | Rectifier integrated, high current |

I once worked on a project to upgrade the power system for a large copper mine in a remote desert location. We were replacing aging transformers with new, more efficient models designed specifically for the harsh, dusty environment. The challenges were immense – not only did we have to design for extreme heat and dust, but we also had to ensure 24/7 reliability in a location where any downtime could cost millions. We implemented a system of ruggedized transformers with advanced cooling and filtering systems. The result was impressive – energy efficiency improved by 15%, and unplanned downtime due to electrical issues dropped to near zero. It was a powerful reminder of how critical these often-overlooked devices are in keeping our resource extraction industries running.

Power transformers in mining and mineral extraction are more than just scaled-up versions of standard units. They’re highly specialized devices designed to meet the unique demands of these challenging environments:

Rugged Design for Extreme Conditions

Mining transformers must withstand tough conditions:

-

Enhanced Cooling Systems:

- Forced oil and forced air cooling for high-temperature environments.

- Some use water-cooled designs for underground applications.

-

Dust and Moisture Protection:

- Sealed designs to prevent ingress of dust and moisture.

- Special coatings for corrosion resistance in chemically harsh environments.

Mobility and Flexibility

Many mining operations require power equipment that can move with the extraction process:

-

Mobile Substations:

- Transformers mounted on skids or trailers for easy relocation.

- Enable power supply to follow the mining face in open-pit operations.

-

Modular Designs:

- Allow for easy transportation to remote locations.

- Facilitate quick setup and commissioning in new mining areas.

As the mining industry continues to evolve, with a focus on automation and sustainability, power transformers in this sector are adapting to new challenges. We’re seeing the integration of smart monitoring systems that can predict maintenance needs and optimize performance in real-time. Some transformers are being designed to work seamlessly with renewable energy sources, helping mines reduce their carbon footprint.

The future of mining transformers might include units with integrated energy storage, allowing for better management of peak loads and integration of intermittent renewable power. We could see transformers that can automatically adjust their characteristics based on the specific needs of different mining processes, or units that can operate efficiently at ultra-high altitudes for mountain-top mining operations.

In the world of mining and mineral extraction, where reliability and efficiency can make or break operations, power transformers will continue to play a critical role. They’re the unsung heroes that keep our mines productive, enabling the extraction of the raw materials that fuel our modern world, all while adapting to the industry’s evolving needs for sustainability and efficiency.

Data Center Dynamics: Power Transformers in IT and Cloud Computing Facilities?

Ever wondered how massive data centers, the backbone of our digital world, stay powered 24/7? The answer lies in sophisticated power transformer systems designed specifically for these critical IT facilities.

Power transformers are crucial in data centers and cloud computing facilities for providing reliable, high-quality power to servers, cooling systems, and network equipment. They ensure uninterrupted operation, manage high-density power needs, and support redundancy systems critical for maintaining data integrity and service availability.

Let’s explore how power transformers keep our digital world running:

Main Facility Power

In large data centers, transformers play a vital role in power distribution:

-

Utility Interface Transformers:

- Step down incoming high voltage to medium voltage for facility distribution.

- Often include features for power quality management.

-

UPS Input/Output Transformers:

- Interface between the utility power and Uninterruptible Power Supply (UPS) systems.

- Provide isolation and voltage matching for UPS equipment.

Server Room Power Distribution

Within the data center, specialized transformers support IT equipment:

-

PDU Transformers:

- Power Distribution Unit transformers step down voltage for server racks.

- Provide clean, stable power to sensitive IT equipment.

-

Isolation Transformers:

- Reduce electrical noise and provide galvanic isolation.

- Critical for maintaining data integrity in sensitive computing environments.

Here’s a comparison of transformer applications in data center settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Main Facility | 10-50 MVA | 110kV | 11kV/400V | Redundant design, on-load tap changers |

| UPS System | 1-5 MVA | 11kV | 400V | K-rated for harmonic loads |

| PDU | 50-500 kVA | 400V | 208V | Low impedance, multiple outputs |

| Isolation | 10-100 kVA | 400V | 400V | High isolation, low noise |

I once worked on a project to upgrade the power system for a major cloud computing provider’s data center. The challenge was immense – we needed to increase power capacity and efficiency without any downtime in a facility that was already running 24/7. We implemented a new transformer system with N+1 redundancy, advanced monitoring, and the ability to seamlessly switch between multiple power sources. The most interesting part was the integration of smart PDU transformers that could dynamically allocate power based on real-time server demands. The result was a 20% increase in power capacity, a 15% improvement in energy efficiency, and most importantly, zero unplanned downtime during and after the upgrade.

Power transformers in data centers are more than just voltage converters. They’re critical components in ensuring the reliability and efficiency of our digital infrastructure:

Efficiency and Heat Management

In data centers, every bit of efficiency counts:

-

High-Efficiency Designs:

- Use of low-loss materials to minimize heat generation.

- Critical in environments where cooling is a major operational cost.

-

Advanced Cooling Systems:

- Integration with facility cooling systems for optimal heat management.

- Some use biodegradable fluids for better heat dissipation and environmental safety.

Reliability and Redundancy

For data centers, downtime is not an option:

-

N+1 or 2N Redundancy:

- Multiple transformer systems to ensure continuous operation even during maintenance or failures.

- Automatic switchover capabilities for seamless power transition.

-

Continuous Monitoring:

- Real-time monitoring of load, temperature, and key performance indicators.

- Integration with data center infrastructure management (DCIM) systems for proactive maintenance.

As data centers continue to grow in size and importance, the role of power transformers in these facilities will only become more critical. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities or advanced power electronics for more precise control of power quality.

The future might bring transformers that can dynamically adjust their characteristics based on changing IT loads, or units that can seamlessly integrate with renewable energy sources to support green data center initiatives. We might see transformers with AI-driven predictive maintenance capabilities, ensuring even higher levels of reliability.

In the world of data centers and cloud computing, where every millisecond of uptime is crucial, power transformers will continue to be the unsung heroes. They’re not just enabling our digital lives; they’re actively shaping the future of how we store, process, and access the vast amounts of data that drive our modern world.

Healthcare Heroes: Power Transformers in Hospitals and Medical Research Centers?

Have you ever considered what keeps life-saving medical equipment running without interruption? Behind the scenes, specialized power transformers play a crucial role in ensuring reliable power for healthcare facilities.

Power transformers are essential in hospitals and medical research centers for providing clean, stable, and uninterrupted power to critical medical equipment. They support life-support systems, imaging devices, and sensitive research instruments, often with redundant systems to ensure continuous operation even during power outages.

Let’s explore how power transformers keep our healthcare facilities operational:

Critical Care Power Systems

In hospital settings, transformers ensure reliable power for life-saving equipment:

-

Emergency Power Transformers:

- Interface between backup generators and critical hospital systems.

- Ensure rapid, seamless transition during power outages.

-

Isolation Transformers:

- Provide clean, noise-free power to sensitive medical equipment.

- Critical for accurate diagnostics and patient safety.

Medical Imaging Equipment

Transformers play a vital role in powering advanced imaging technologies:

-

MRI System Transformers:

- Supply stable power for superconducting magnets and cooling systems.

- Often include specialized shielding to prevent interference.

-

CT and X-ray Transformers:

- Provide high-voltage power for X-ray tube operation.

- Handle the pulsed loads typical of imaging equipment.

Here’s a comparison of transformer applications in healthcare settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Emergency Power | 500kVA – 2MVA | 11kV | 400V | Fast switching, redundant design |

| Isolation | 10-100kVA | 400V | 400V | Ultra-low noise, high isolation |

| MRI System | 50-200kVA | 400V | Multiple outputs | EMI shielding, precise regulation |

| CT Scanner | 100-300kVA | 400V | High voltage DC | Pulsed load handling |

I once worked on a project to upgrade the power system for a major teaching hospital. The challenge was to implement a new transformer system that could handle the increasing power demands of modern medical equipment while ensuring absolutely no interruption to critical care services. We designed a redundant system with multiple isolation transformers and advanced power quality management. The most interesting part was integrating these with the hospital’s emergency power system to ensure seamless transition during outages. The result was impressive – power quality improved significantly, reducing equipment malfunctions, and the hospital was able to install new, advanced imaging systems without concerns about power capacity or stability.

Power transformers in healthcare facilities are more than just voltage converters. They’re critical components in ensuring the reliability and safety of medical services:

Power Quality and Patient Safety

In medical environments, clean power is crucial:

-

Harmonic Mitigation:

- Advanced designs to handle harmonics generated by medical equipment.

- Ensure clean power delivery to sensitive diagnostic tools.

-

Leakage Current Control:

- Specialized designs to minimize leakage currents.

- Critical for patient safety, especially in operating rooms and ICUs.

Reliability and Redundancy

For healthcare, power failure is not an option:

-

N+1 Redundancy:

- Multiple transformer systems to ensure continuous operation even during maintenance.

- Automatic transfer switches for seamless power transition.

-

Continuous Monitoring:

- Real-time monitoring of load, temperature, and power quality.

- Integration with building management systems for proactive maintenance.

As medical technology continues to advance, with more sophisticated and power-hungry equipment, the role of power transformers in healthcare facilities will only grow in importance. We’re likely to see even more specialized designs, perhaps with integrated energy storage capabilities for critical equipment or advanced power conditioning features for ultra-sensitive diagnostic tools.

The future might bring transformers with AI-driven predictive maintenance capabilities, ensuring even higher levels of reliability for life-critical systems. We might see units that can dynamically adjust their output based on the specific needs of different medical procedures, or transformers that can seamlessly integrate with renewable energy sources to support green hospital initiatives.

In the world of healthcare, where every second can make a difference between life and death, power transformers will continue to be the unsung heroes. They’re not just enabling the operation of life-saving equipment; they’re actively contributing to the advancement of medical care by providing the stable, clean power that modern medicine relies on.

Petrochemical Powerhouses: Power Transformers in Oil and Gas Refineries?

Ever wondered how massive oil refineries and gas processing plants manage their enormous power needs? The answer lies in specialized power transformers designed to handle the unique challenges of the petrochemical industry.

Power transformers are crucial in oil and gas refineries for powering large-scale processing equipment, pumps, and control systems. They handle high power demands, operate in hazardous environments, and often include special features for explosion protection and corrosion resistance.

Let’s explore how power transformers keep our petrochemical industries running:

Process Power Supply

In refineries, transformers power various stages of oil and gas processing:

-

Distillation Column Transformers:

- Supply power to heating elements and pumps in distillation towers.

- Handle high temperatures and corrosive environments.

-

Compressor and Pump Transformers:

- Power large motors for fluid movement and gas compression.

- Often include variable frequency drive (VFD) compatibility.

Control and Safety Systems

Transformers play a crucial role in maintaining safe operations:

-

Instrumentation Transformers:

- Provide clean, stable power for control systems and sensors.

- Often include high levels of electrical noise suppression.

-

Emergency Shutdown Transformers:

- Ensure power to critical safety systems during emergencies.

- Designed for high reliability and rapid response.

Here’s a comparison of transformer applications in petrochemical settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| Process Power | 5-50 MVA | 110kV | 11kV/6.6kV | Explosion-proof, corrosion-resistant |

| Compressor Drive | 10-100 MVA | 110kV | 11kV | VFD compatible, high starting current |

| Instrumentation | 100-500 kVA | 11kV | 400V/230V | High isolation, EMI shielding |

| Emergency Systems | 1-5 MVA | 11kV | 400V | Rapid response, redundant design |

I once worked on a project to upgrade the power system for a major oil refinery. The challenges were immense – we needed to design transformers that could withstand corrosive atmospheres, extreme temperatures, and potential explosive environments. We implemented a system of specially designed transformers with advanced cooling systems, explosion-proof enclosures, and corrosion-resistant materials. The most interesting aspect was integrating these with the refinery’s advanced process control systems to enable real-time power management. The result was a 25% increase in energy efficiency and a significant improvement in process reliability.

Power transformers in petrochemical applications are highly specialized units designed to meet the unique demands of this industry:

Hazardous Environment Protection

Refineries present unique safety challenges:

-

Explosion-Proof Design:

- Specially designed enclosures to prevent ignition of surrounding gases.

- Pressure relief systems to manage internal faults safely.

-

Chemical Resistance:

- Use of special materials and coatings to resist corrosive atmospheres.

- Sealed designs to prevent ingress of harmful gases and liquids.

Efficiency and Reliability

In 24/7 operations, performance is critical:

-

Advanced Cooling Systems:

- Use of forced oil and forced air cooling for high-temperature environments.

- Some designs incorporate water cooling for extreme heat conditions.

-

Online Monitoring:

- Real-time monitoring of key parameters like temperature, gas content, and load.

- Integration with plant-wide control systems for predictive maintenance.

As the petrochemical industry evolves, with a growing focus on efficiency and environmental sustainability, power transformers in this sector are adapting to new challenges. We’re seeing the integration of smart monitoring systems that can predict maintenance needs and optimize performance in real-time. Some transformers are being designed to work more efficiently with variable speed drives, supporting energy-saving initiatives in refineries.

The future of petrochemical transformers might include units with even more advanced materials for corrosion resistance and heat management. We could see transformers with integrated energy recovery systems, capturing waste heat for use in other refinery processes. There might also be developments in modular, plug-and-play transformer systems that can be quickly deployed or reconfigured as refinery needs change.

In the world of oil and gas processing, where reliability and safety are paramount, power transformers will continue to play a critical role. They’re not just enabling the production of the fuels and chemicals that drive our economy; they’re actively contributing to making these processes safer, more efficient, and more environmentally friendly.

Aerospace and Defense: Power Transformers in High-Tech Manufacturing and Testing Facilities?

Have you ever considered the precision power needs behind manufacturing a jet engine or testing advanced defense systems? Specialized power transformers play a crucial role in these high-tech aerospace and defense facilities.

Power transformers are essential in aerospace and defense manufacturing for providing clean, stable power to precision machinery, testing equipment, and sensitive electronics. They support high-power applications, ensure power quality for accurate measurements, and often include features for electromagnetic compatibility in sensitive environments.

Let’s explore how power transformers support the cutting edge of aerospace and defense technology:

Precision Manufacturing Power

In aerospace manufacturing, transformers power various high-precision processes:

-

CNC Machine Transformers:

- Supply stable power to computer-controlled manufacturing equipment.

- Often include power conditioning to ensure accuracy in machining.

-

Additive Manufacturing Transformers:

- Power 3D printing and laser sintering equipment for aerospace components.

- Handle the unique load profiles of additive manufacturing processes.

Testing and Simulation Facilities

Transformers play a crucial role in powering advanced testing equipment:

-

Wind Tunnel Transformers:

- Supply high power for large fan motors in aerodynamic testing facilities.

- Handle variable loads and provide precise speed control.

-

Radar System Test Transformers:

- Provide clean power for sensitive radar testing equipment.

- Include advanced EMI shielding to prevent interference with tests.

Here’s a comparison of transformer applications in aerospace and defense settings:

| Application | Typical Power Range | Input Voltage | Output Voltage | Special Features |

|---|---|---|---|---|

| CNC Machining | 500kVA – 2MVA | 11kV | 400V | Precision voltage regulation |

| Additive Manufacturing | 100-500kVA | 400V | Multiple outputs | Load profile management |

| Wind Tunnel | 5-20 MVA | 33kV | 11kV | Variable frequency output |

| Radar Testing | 1-5 MVA | 11kV | 400V | Ultra-low EMI, high isolation |

I once worked on a project to design the power system for a new aerospace engine testing facility. The challenges were unique – we needed to provide extremely stable and clean power for sensitive measurement equipment while also supplying massive amounts of power for engine test runs. We implemented a sophisticated transformer system with advanced harmonic mitigation, precise voltage regulation, and the ability to handle rapid load changes. The most fascinating aspect was integrating these transformers with a real-time power quality monitoring system that could detect and correct power anomalies faster than the blink of an eye. The result was a testing facility capable of running the most demanding tests on next-generation aircraft engines with unprecedented accuracy and reliability.

Power transformers in aerospace and defense applications are highly specialized units designed to meet the exacting standards of these industries:

Electromagnetic Compatibility

In sensitive testing environments, managing electromagnetic interference is crucial:

-

Advanced Shielding:

- Use of sophisticated shielding techniques to prevent EMI/RFI emissions.

- Critical for maintaining the integrity of sensitive electronic tests.

-

Low Partial Discharge:

- Designs that minimize partial discharge to reduce interference with sensitive equipment.

- Essential for high-altitude aerospace applications.

Precision and Reliability

In high-stakes aerospace and defense applications, performance is critical:

-

Ultra-Precise Voltage Regulation:

- Use of advanced voltage regulation techniques to maintain extremely stable output.

- Critical for powering precision manufacturing and testing equipment.

-

Ruggedized Design:

- Built to withstand vibration, shock, and extreme environmental conditions.

- Necessary for reliability in demanding aerospace and defense applications.

As aerospace and defense technologies continue to advance, with increasing use of advanced materials, AI-driven systems, and hypersonic technologies, the demands on power systems will grow even more complex. We’re likely to see transformers with even more advanced EMI suppression capabilities, perhaps using new materials or active cancellation techniques.

The future might bring transformers with integrated power quality analysis systems, capable of not just supplying power but also providing real-time feedback on power usage and quality to optimize testing and manufacturing processes. We could see the development of ultra-lightweight, high-efficiency transformers for use in aircraft and spacecraft, pushing the boundaries of what’s possible in mobile power systems.

In the world of aerospace and defense, where precision and reliability can mean the difference between success and failure, power transformers will continue to play a critical behind-the-scenes role. They’re not just enabling the production and testing of advanced technologies; they’re actively contributing to pushing the boundaries of what’s possible in flight, space exploration, and national defense.

Conclusion

Power transformers are crucial across diverse industries, from powering cities to enabling cutting-edge aerospace technologies. Their ability to efficiently convert voltage levels and provide reliable power makes them indispensable in our modern, technology-driven world.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group