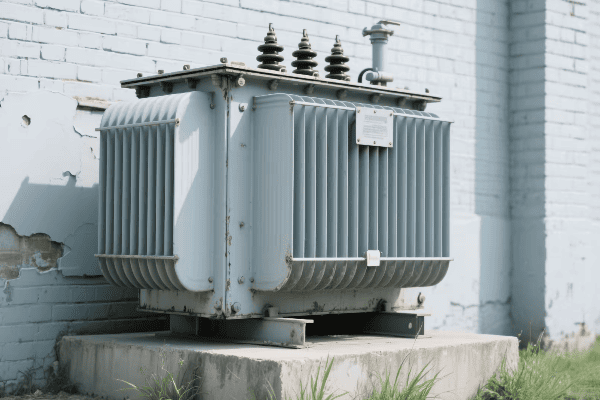

Pad Mounted Transformer Manufacturers: Top Players in the Global Power Distribution Market?

Have you ever wondered who makes the transformers that power our neighborhoods? The answer lies with pad mounted transformer manufacturers, the unsung heroes of our electrical grid.

Pad mounted transformer manufacturers are key players in the global power distribution market. They produce compact, efficient, and safe transformers crucial for urban and suburban power distribution. Top manufacturers stand out through innovation, quality, and comprehensive customer support.

In this article, I’ll share my insights on the leading manufacturers in this industry. My experience working with various manufacturers has given me a unique perspective on what sets the top players apart.

Who Are the Leading Pad Mounted Transformer Manufacturers and What Sets Them Apart?

When I first entered the power distribution industry, I was amazed by the range of pad mounted transformer manufacturers. Over time, I’ve come to recognize the leaders in this field.

Leading pad mounted transformer manufacturers include ABB, Siemens, Schneider Electric, Eaton, and General Electric. These companies stand out due to their extensive product ranges, technological innovation, global presence, and long-standing reputation for quality and reliability.

Let’s dive deeper into what sets these manufacturers apart:

Technological Innovation

Innovation is a key differentiator:

- ABB: Known for its digital transformer solutions.

- Siemens: Pioneers in eco-friendly transformer designs.

- Schneider Electric: Leaders in smart grid-compatible transformers.

I once visited ABB’s research facility and was impressed by their focus on IoT integration in transformers. Their commitment to innovation was evident in every aspect of their design process.

Product Range and Customization

Top manufacturers offer diverse product lines:

| Manufacturer | Specialization |

|---|---|

| Eaton | Compact designs for urban areas |

| General Electric | High-capacity transformers for industrial use |

| Siemens | Customizable solutions for unique environments |

In a recent project, I worked with Eaton to design a custom transformer for a densely populated urban area. Their ability to tailor their product to our specific needs was impressive.

Global Presence and Support

Leading manufacturers have a worldwide footprint:

- Local Manufacturing: Facilities in multiple countries.

- Global Service Network: Quick response to maintenance needs.

- Regulatory Compliance: Adherence to international standards.

I remember a case where Schneider Electric’s global support team resolved a critical issue for a client in less than 24 hours, showcasing the value of their international presence.

Quality and Reliability

Top manufacturers are known for their quality:

- Rigorous Testing: Extensive quality control processes.

- Longevity: Products designed for extended operational life.

- Performance Guarantees: Backed by comprehensive warranties.

During a factory tour at Siemens, I witnessed their stringent testing procedures. It was clear why their transformers have such a strong reputation for reliability.

Sustainability Focus

Environmental considerations are increasingly important:

- Energy Efficiency: Transformers designed to minimize losses.

- Eco-Friendly Materials: Use of biodegradable oils and recyclable components.

- Carbon Footprint Reduction: Efforts to make manufacturing processes greener.

I was part of a project where General Electric’s commitment to sustainability helped a utility meet its environmental goals while upgrading their distribution network.

How Do Top Manufacturers Innovate to Meet Evolving Power Distribution Needs?

Innovation is the lifeblood of the pad mounted transformer industry. I’ve seen firsthand how top manufacturers constantly push the boundaries to meet new challenges.

Top manufacturers innovate through advanced materials research, smart grid integration, improved efficiency designs, and enhanced safety features. They also focus on developing compact designs for urban environments and eco-friendly solutions to meet sustainability goals.

Let’s explore the key areas of innovation:

Advanced Materials Research

New materials are revolutionizing transformer design:

- Amorphous Metal Cores: Reduce no-load losses significantly.

- High-Temperature Superconductors: Enable more compact designs.

- Nano-Fluids: Improve cooling efficiency.

I once collaborated with a research team at ABB working on amorphous metal cores. The energy savings potential of these materials is truly remarkable.

Smart Grid Integration

Smart grid compatibility is a major focus:

| Feature | Benefit |

|---|---|

| Real-time Monitoring | Enables predictive maintenance |

| Remote Control | Allows for dynamic load management |

| Data Analytics | Improves overall grid efficiency |

In a recent project with Schneider Electric, we implemented their smart grid-ready transformers. The ability to remotely monitor and control these units significantly improved the utility’s operational efficiency.

Improved Efficiency Designs

Efficiency is a constant goal:

- Advanced Winding Techniques: Reduce copper losses.

- Optimized Core Designs: Minimize magnetic flux leakage.

- Improved Cooling Systems: Better heat dissipation for higher efficiency.

I worked on a project where Siemens’ high-efficiency transformers helped a utility reduce their energy losses by over 15%, resulting in significant cost savings.

Enhanced Safety Features

Safety innovations are crucial:

- Arc-Resistant Designs: Improve worker safety during maintenance.

- Fire-Resistant Materials: Reduce fire hazards in urban installations.

- Advanced Fault Detection: Quickly isolate issues to prevent cascading failures.

During a demonstration by Eaton, I saw their arc-resistant transformer contain a simulated internal fault without any external damage. It was an impressive display of safety engineering.

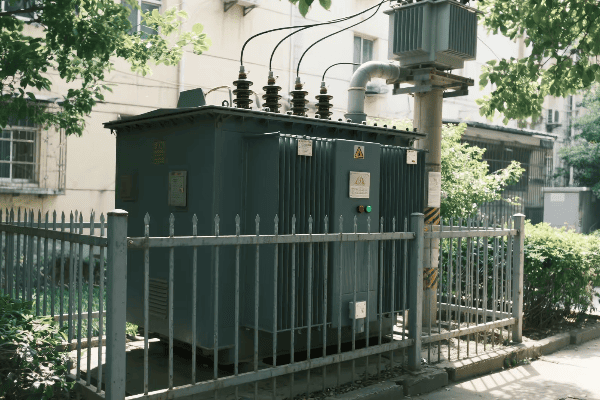

Compact Designs for Urban Environments

Space-saving is increasingly important:

- 3D Modeling: Optimize internal component layout.

- Modular Designs: Allow for easier installation in tight spaces.

- Underground Solutions: Develop transformers for below-ground installation.

I recently consulted on a project using General Electric’s ultra-compact transformers in a dense urban redevelopment. Their innovative design allowed for significant space savings without compromising performance.

Eco-Friendly Solutions

Sustainability is a growing focus:

- Biodegradable Insulating Fluids: Reduce environmental impact.

- Recycled Materials: Incorporate recycled components in manufacturing.

- Energy Harvesting: Develop transformers that can capture and utilize waste heat.

I was impressed by a recent initiative from ABB to develop transformers using 100% recyclable materials. It’s a significant step towards a more sustainable power industry.

What Quality Standards and Certifications Define Excellence in Pad Mounted Transformer Manufacturing?

Quality standards and certifications are the backbone of excellence in pad mounted transformer manufacturing. I’ve learned that these standards are not just bureaucratic requirements but essential guarantees of performance and safety.

Excellence in pad mounted transformer manufacturing is defined by adherence to international standards like IEEE C57.12.00, IEC 60076, and ANSI standards. Key certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and OHSAS 18001 for occupational health and safety.

Let’s delve into the key standards and certifications:

International Electrical Standards

These standards ensure global compatibility and performance:

- IEEE C57.12.00: Covers general requirements for pad mounted transformers.

- IEC 60076: Provides specifications for power transformers.

- ANSI C57.12.28: Focuses on pad mounted equipment enclosure integrity.

I once worked on a project where strict adherence to IEEE C57.12.00 was crucial for a transformer installation in a harsh coastal environment. The standard’s guidelines on corrosion resistance proved invaluable.

Quality Management Systems

Quality management is crucial:

| Standard | Focus Area |

|---|---|

| ISO 9001 | Overall quality management processes |

| Six Sigma | Defect reduction and process improvement |

| Lean Manufacturing | Efficiency in production processes |

During a factory audit at Siemens, I was impressed by how their ISO 9001 certification translated into real-world quality control practices at every stage of production.

Environmental Management

Environmental standards are increasingly important:

- ISO 14001: Environmental management systems.

- RoHS Compliance: Restriction of hazardous substances.

- REACH Compliance: Registration, Evaluation, Authorization and Restriction of Chemicals.

I worked with a manufacturer implementing ISO 14001 standards. The process not only improved their environmental impact but also led to significant cost savings through more efficient resource use.

Safety Standards

Safety is paramount in transformer manufacturing:

- OHSAS 18001: Occupational Health and Safety Management.

- IEC 61936-1: Power installations exceeding 1 kV AC.

- NFPA 70: National Electrical Code compliance.

During a safety audit at an Eaton facility, I saw firsthand how OHSAS 18001 standards created a culture of safety that extended from the factory floor to the final product design.

Performance Testing Standards

Rigorous testing ensures reliability:

- IEEE C57.12.90: Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers.

- IEC 60076-11: Dry-type transformers.

- ANSI/IEEE C57.12.91: Test Code for Dry-Type Distribution and Power Transformers.

I once witnessed a series of tests conducted under IEEE C57.12.90 on a new transformer model. The thoroughness of these tests gave me great confidence in the product’s field performance.

Cybersecurity Standards

With smart grid integration, cybersecurity is crucial:

- IEC 62351: Security standards for power system control operations.

- NERC CIP: Critical Infrastructure Protection standards.

- ISO/IEC 27001: Information security management.

In a recent project involving smart transformers, compliance with IEC 62351 was essential in ensuring the grid’s resilience against cyber threats.

How Are Global Market Trends Shaping the Strategies of Pad Mounted Transformer Manufacturers?

Global market trends are constantly reshaping the pad mounted transformer industry. I’ve observed how manufacturers adapt their strategies to stay competitive in this evolving landscape.

Global market trends shaping pad mounted transformer manufacturing strategies include the shift towards renewable energy integration, urbanization demands, smart grid development, energy efficiency regulations, and emerging market growth. Manufacturers are responding with product innovations, market expansions, and sustainability initiatives.

Let’s explore how these trends are influencing manufacturers:

Renewable Energy Integration

The rise of renewables is a game-changer:

- Solar and Wind Power: Demand for transformers compatible with variable energy sources.

- Energy Storage: Transformers designed to work with large-scale battery systems.

- Microgrids: Specialized transformers for local power networks.

I recently worked on a project with ABB developing transformers specifically for offshore wind farms. The unique challenges of this environment are driving fascinating innovations in transformer design.

Urbanization and Infrastructure Development

Urban growth is shaping product development:

| Trend | Manufacturing Response |

|---|---|

| Space Constraints | More compact transformer designs |

| Noise Regulations | Ultra-quiet transformer models |

| Aesthetic Concerns | Customizable enclosures to blend with urban landscapes |

In a recent urban redevelopment project, we used Siemens’ ultra-compact, low-noise transformers that were virtually invisible once installed, meeting strict city planning requirements.

Smart Grid Development

Smart grids are revolutionizing the industry:

- IoT Integration: Transformers with built-in sensors and communication capabilities.

- Real-time Monitoring: Advanced diagnostic features for predictive maintenance.

- Grid Flexibility: Transformers designed for bi-directional power flow.

I’ve been involved in several smart grid projects where Schneider Electric’s intelligent transformers played a crucial role in enhancing grid reliability and efficiency.

Energy Efficiency Regulations

Stricter efficiency standards are driving innovation:

- Low-Loss Core Materials: Development of advanced magnetic steels.

- Improved Cooling Systems: More efficient heat dissipation designs.

- Optimized Winding Techniques: Reducing copper losses in transformers.

During a recent factory tour at Eaton, I saw how they’ve redesigned their entire product line to meet and exceed the latest efficiency standards, resulting in significant energy savings for their customers.

Emerging Market Growth

Expansion into new markets is a key strategy:

- Localized Manufacturing: Setting up production facilities in emerging economies.

- Customized Products: Developing transformers for specific regional needs.

- Knowledge Transfer: Training local workforce in advanced manufacturing techniques.

I’ve consulted on General Electric’s expansion into Southeast Asian markets, where they’ve successfully adapted their products to meet local grid requirements and environmental conditions.

Sustainability and Environmental Concerns

Green initiatives are becoming central to strategy:

- Eco-friendly Materials: Use of biodegradable transformer oils.

- Circular Economy: Designing transformers for easy recycling and refurbishment.

- Carbon Footprint Reduction: Implementing green manufacturing processes.

In a recent collaboration with ABB, we focused on developing a transformer model with a significantly reduced carbon footprint, from manufacturing to end-of-life disposal.

What After-Sales Services and Support Do Top Pad Mounted Transformer Manufacturers Offer?

After-sales services and support are crucial in the pad mounted transformer industry. I’ve seen how top manufacturers differentiate themselves through their commitment to customer care long after the sale is made.

Top pad mounted transformer manufacturers offer comprehensive after-sales services including installation support, maintenance programs, emergency repair services, training for utility personnel, and long-term warranty coverage. They also provide remote monitoring solutions, software updates for smart transformers, and end-of-life recycling services.

Let’s explore the key after-sales services offered:

Installation and Commissioning Support

Proper installation is crucial:

- On-site Technical Assistance: Expert guidance during installation.

- Commissioning Services: Ensuring transformers are correctly set up and operational.

- Site Surveys: Pre-installation assessments to optimize placement and performance.

I once oversaw a complex installation where ABB’s on-site support team was invaluable in navigating unexpected challenges, ensuring the transformer was installed correctly and efficiently.

Maintenance Programs

Regular maintenance is key to longevity:

| Service | Description |

|---|---|

| Scheduled Inspections | Regular check-ups to prevent issues |

| Preventive Maintenance | Proactive servicing to extend transformer life |

| Performance Optimization | Fine-tuning for maximum efficiency |

During a project with Siemens, their comprehensive maintenance program helped a utility reduce unplanned outages by 40%, significantly improving grid reliability.

Emergency Repair Services

Quick response to failures is essential:

- 24/7 Support Hotlines: Immediate access to expert assistance.

- Rapid Response Teams: Quick deployment of technicians for on-site repairs.

- Emergency Replacement Units: Temporary transformers to minimize downtime.

I recall a situation where Schneider Electric’s emergency response team replaced a failed transformer within 12 hours, preventing what could have been a prolonged power outage for thousands of customers.

Training and Education

Knowledge transfer is a valuable service:

- Operator Training: Hands-on instruction for utility personnel.

- Maintenance Workshops: Detailed training on proper maintenance procedures.

- Technical Seminars: Updates on the latest transformer technologies and best practices.

I’ve participated in Eaton’s training programs and was impressed by the depth of knowledge shared, which greatly enhanced our team’s ability to manage and maintain our transformer fleet.

Long-Term Warranty and Support

Extended support provides peace of mind:

- Comprehensive Warranties: Coverage for defects and performance issues.

- Extended Service Agreements: Long-term support beyond standard warranty periods.

- Upgrade Paths: Options for modernizing older transformer units.

In a recent project with General Electric, their 10-year extended warranty program was a key factor in the client’s decision, providing long-term assurance of support and performance.

Remote Monitoring Solutions

Smart monitoring enhances service capabilities:

- Real-time Performance Tracking: Continuous monitoring of transformer health.

- Predictive Maintenance: AI-driven analytics to forecast potential issues.

- Remote Diagnostics: Ability to troubleshoot problems without on-site visits.

I’ve seen ABB’s remote monitoring system in action, where it successfully predicted and prevented a transformer failure, saving the utility millions in potential outage costs.

Software Updates and Cybersecurity

Keeping smart transformers up-to-date is crucial:

- Regular Firmware Updates: Enhancing functionality and security.

- Cybersecurity Patches: Protecting against evolving digital threats.

- Performance Optimization: Software tweaks to improve efficiency.

During a recent smart grid project, Siemens’ commitment to regular software updates ensured that the transformers remained secure and efficient, even as the grid technology evolved.

End-of-Life Services

Responsible disposal and recycling are increasingly important:

- Decommissioning Support: Safe removal and disposal of old transformers.

- Recycling Programs: Environmentally friendly processing of materials.

- Upgrade Incentives: Programs to encourage replacement of older, less efficient units.

I recently worked with Schneider Electric on a large-scale transformer replacement project. Their end-of-life services not only ensured environmental compliance but also recovered valuable materials, offsetting some of the replacement costs.

Custom Engineering Support

Top manufacturers offer tailored solutions:

- Retrofit Design: Upgrading existing transformers with new technologies.

- Site-Specific Customization: Adapting transformer designs to unique environments.

- Integration Services: Ensuring compatibility with existing infrastructure.

In a challenging project for a remote mining operation, Eaton’s custom engineering team designed a transformer that could withstand extreme temperatures and harsh conditions, significantly extending its operational life.

Conclusion

Top pad mounted transformer manufacturers lead through innovation, quality, and comprehensive support. They adapt to global trends, adhere to strict standards, and provide extensive after-sales services, ensuring reliable and efficient power distribution worldwide.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group