Comparing Different Dry Type Transformer Types: Which One Is Best for You?

Are you confused about which dry type transformer to choose for your project? You’re not alone. Many engineers and project managers struggle with this decision. But don’t worry, I’m here to help you navigate through your options.

Dry type transformers come in three main types: cast resin, vacuum pressure impregnated (VPI), and open wound. Each type has its own strengths and ideal applications. Cast resin excels in harsh environments, VPI offers a balance of performance and cost, while open wound is suitable for indoor, low-moisture settings. Your choice depends on your specific needs and conditions.

In my years of experience working with power systems, I’ve seen how crucial the right transformer choice can be. The wrong decision can lead to inefficiency, increased costs, or even safety hazards. Let’s dive into the world of dry type transformers and find out which one is best for you.

Understanding Dry Type Transformer Technologies: Cast Resin, VPI, and Open Wound Designs Explained?

Have you ever wondered why there are different types of dry transformers? Each type has its unique features, but understanding these differences can be tricky. Let’s break it down in simple terms.

Cast resin transformers have windings encapsulated in epoxy resin, offering excellent protection against harsh environments. VPI transformers use a vacuum pressure process to impregnate windings with resin, balancing performance and cost. Open wound transformers have exposed windings, suitable for clean, dry indoor settings. Each design serves specific needs and conditions.

Throughout my career, I’ve worked with all these types of dry transformers. Let me share some insights:

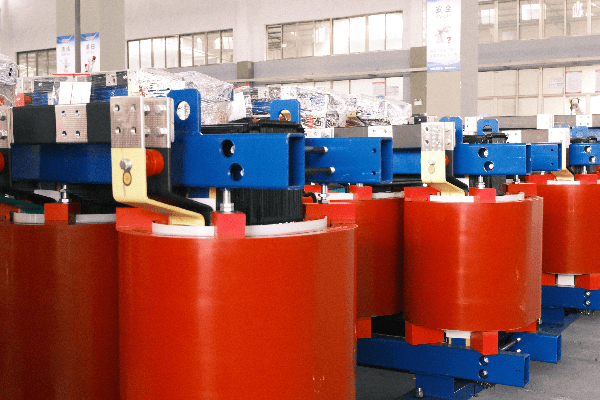

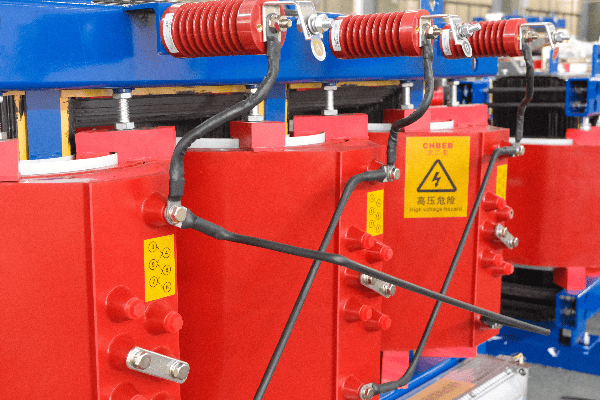

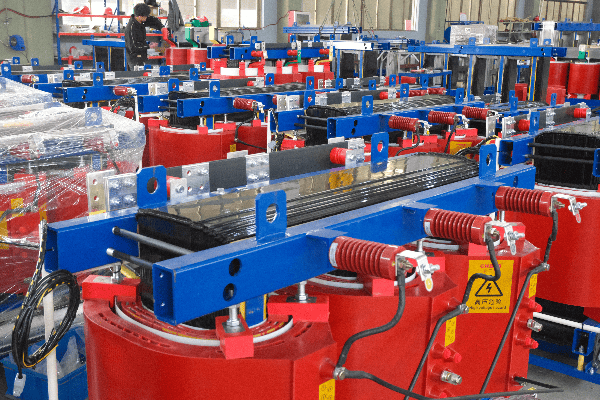

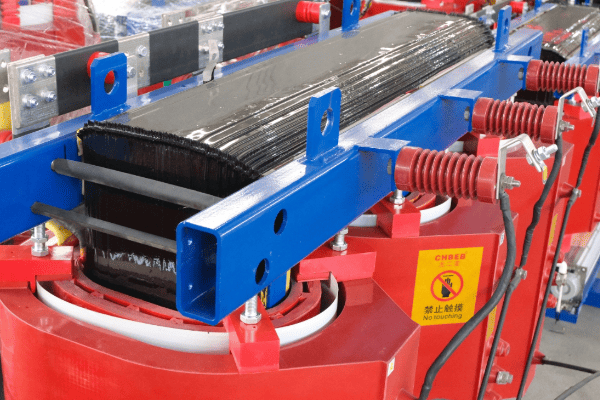

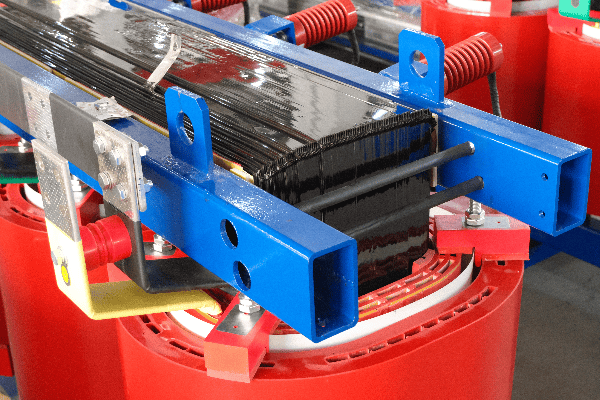

Cast Resin Transformers

The tough ones:

- Construction: Windings are fully encapsulated in epoxy resin.

- Strength: Excellent resistance to moisture, dust, and chemicals.

- Applications: Ideal for harsh industrial environments and outdoor installations.

I once installed a cast resin transformer in a coastal chemical plant. Despite the corrosive sea air and chemical fumes, it’s been running flawlessly for years. The epoxy encapsulation really does wonders in protecting the windings.

Vacuum Pressure Impregnated (VPI) Transformers

The versatile option:

| Feature | Benefit | Application |

|---|---|---|

| Resin-coated windings | Good heat dissipation | High-temperature environments |

| Flexible design | Customizable for specific needs | Various industrial uses |

| Cost-effective | Balance of performance and price | Budget-conscious projects |

In a recent project for a large data center, we chose VPI transformers. They provided the necessary performance in a high-heat environment without breaking the bank. The client was thrilled with the balance of cost and efficiency.

Open Wound Transformers

The basic solution:

- Simple Design: Exposed windings with minimal insulation.

- Cost: Most economical option for dry type transformers.

- Use: Suitable for clean, dry indoor environments with low humidity.

I’ve recommended open wound transformers for many indoor installations where environmental factors aren’t a concern. In a recent office building project, these transformers provided a perfect balance of performance and cost-effectiveness for the low-risk indoor setting.

Performance and Efficiency: A Comparative Analysis of Different Dry Type Transformer Types?

Worried about energy bills or system performance? The type of dry transformer you choose can significantly impact both. But how do these different types really stack up against each other?

In terms of performance and efficiency, cast resin transformers generally offer the highest efficiency and best performance in harsh conditions. VPI transformers provide good efficiency with more flexibility in design. Open wound transformers, while less efficient, are cost-effective for basic indoor applications. The choice impacts energy consumption, heat management, and overall system reliability.

In my experience, the efficiency differences between these types can lead to significant cost variations over time. Let’s dive deeper:

Energy Efficiency

The bottom line:

- Cast Resin: Typically highest efficiency due to superior insulation.

- VPI: Good efficiency, often close to cast resin.

- Open Wound: Generally lower efficiency, but suitable for low-demand applications.

I once conducted an efficiency study for a manufacturing plant. By replacing their old open wound transformers with new cast resin units, we achieved a 3% increase in overall energy efficiency. It doesn’t sound like much, but it translated to substantial cost savings over time.

Heat Management

Keeping cool under pressure:

| Transformer Type | Heat Dissipation | Overload Capacity |

|---|---|---|

| Cast Resin | Excellent | High |

| VPI | Very Good | Good |

| Open Wound | Good | Limited |

In a data center project, heat management was crucial. We opted for cast resin transformers specifically for their superior heat dissipation. This choice allowed for better performance during peak load times and reduced the strain on the facility’s cooling systems.

Voltage Regulation

Maintaining stable output:

- Cast Resin: Excellent voltage regulation under varying loads.

- VPI: Good voltage regulation, suitable for most applications.

- Open Wound: Adequate for stable load environments.

I advised on a power system for a hospital where voltage stability was critical. We chose cast resin transformers for their ability to maintain consistent voltage levels despite the varying loads from different medical equipment throughout the day.

Safety and Environmental Impact: How Various Dry Type Transformers Stack Up?

Concerned about safety regulations or environmental impact? You should be. The choice of dry transformer can significantly affect both. But how do different types compare in these crucial areas?

In terms of safety and environmental impact, all dry type transformers are generally safer and more eco-friendly than oil-filled types. However, cast resin transformers offer the highest fire resistance and are best for harsh environments. VPI and open wound types are suitable for standard indoor applications. All types are free from oil leaks, reducing environmental risks.

Throughout my career, I’ve seen safety and environmental concerns become increasingly important. Here’s how different dry transformer types compare:

Fire Safety

Keeping the heat at bay:

- Cast Resin: Highest fire resistance, self-extinguishing properties.

- VPI: Good fire resistance, but not as high as cast resin.

- Open Wound: Basic fire resistance, suitable for low-risk areas.

I once worked on a project in a high-rise building where fire safety was paramount. We chose cast resin transformers for their superior fire resistance. This decision not only met strict building codes but also eased the concerns of the insurance company.

Environmental Considerations

Going green with your choice:

| Aspect | Cast Resin | VPI | Open Wound |

|---|---|---|---|

| Oil-Free | Yes | Yes | Yes |

| Recyclability | Moderate | Good | Excellent |

| Noise Levels | Lowest | Low | Moderate |

In a recent project for an eco-conscious tech company, we selected VPI transformers. Their good balance of performance and recyclability aligned well with the company’s sustainability goals.

Durability in Harsh Environments

Standing up to the elements:

- Cast Resin: Excellent resistance to moisture, chemicals, and pollution.

- VPI: Good resistance to environmental factors.

- Open Wound: Limited resistance, best for controlled environments.

I advised on a transformer installation for a coastal industrial plant. We chose cast resin transformers for their ability to withstand the corrosive sea air. Years later, they’re still performing excellently, while similar plants with other transformer types have faced corrosion issues.

Application-Specific Selection: Matching Dry Type Transformer Types to Your Unique Needs?

Struggling to decide which transformer type fits your specific application? You’re not alone. The right choice can make a huge difference in performance and longevity. But how do you match transformer types to your unique needs?

Selecting the right dry type transformer depends on your specific application. Cast resin transformers are ideal for harsh environments and critical installations. VPI transformers suit a wide range of industrial and commercial applications. Open wound transformers are best for clean, dry indoor settings. Consider factors like environment, load profile, and criticality of the application.

Over the years, I’ve helped many clients choose the right transformer for their needs. Here’s a deeper look at how to match transformer types to specific applications:

Industrial Applications

Powering the production line:

- Chemical Plants: Cast resin for corrosive environments.

- Food Processing: VPI for balance of cleanliness and performance.

- Light Manufacturing: Open wound for basic indoor power needs.

I once worked on a project for a chemical manufacturing plant. We chose cast resin transformers due to their resistance to corrosive atmospheres. This decision proved invaluable when a chemical spill occurred near one of the transformers – it continued to operate flawlessly.

Commercial and Institutional Buildings

Keeping the lights on:

| Building Type | Recommended Transformer | Reason |

|---|---|---|

| High-rise Offices | Cast Resin or VPI | Fire safety, reliability |

| Schools | VPI | Cost-effective, good performance |

| Hospitals | Cast Resin | Highest reliability, clean operation |

For a large university campus project, we used a mix of VPI transformers for general buildings and cast resin for critical research facilities. This approach balanced cost-effectiveness with the need for high reliability in sensitive areas.

Specialized Environments

Meeting unique challenges:

- Offshore Platforms: Cast resin for salt air resistance.

- Data Centers: VPI or cast resin for heat management and reliability.

- Renewable Energy: VPI for wind turbines, cast resin for solar farms.

I recently consulted on a offshore wind farm project. We selected specially designed cast resin transformers for the turbines. Their ability to withstand the harsh marine environment while providing high efficiency was crucial for the project’s success.

Long-Term Considerations: Maintenance, Lifespan, and Cost-Effectiveness of Dry Type Transformer Options?

Worried about the long-term implications of your transformer choice? You should be. The initial purchase is just the beginning. But how do different dry transformer types compare in the long run?

Long-term considerations vary among dry transformer types. Cast resin transformers generally have the longest lifespan and lowest maintenance needs but higher initial costs. VPI transformers offer a good balance of lifespan, maintenance, and cost. Open wound transformers are the most economical upfront but may require more maintenance and have shorter lifespans in challenging environments.

In my experience, considering these long-term factors can lead to significant savings and improved reliability. Let’s break it down:

Maintenance Requirements

Keeping it running smoothly:

- Cast Resin: Minimal maintenance, mostly visual inspections.

- VPI: Low maintenance, periodic cleaning and inspections.

- Open Wound: Regular cleaning and inspections, especially in dusty environments.

I once helped a manufacturing plant transition from open wound to cast resin transformers. The reduction in maintenance needs was dramatic – from monthly cleanings to annual inspections. This change not only saved on maintenance costs but also reduced production downtime.

Expected Lifespan

The long haul:

| Transformer Type | Typical Lifespan | Factors Affecting Lifespan |

|---|---|---|

| Cast Resin | 30-40 years | Environmental conditions, load profile |

| VPI | 25-35 years | Maintenance, operating environment |

| Open Wound | 20-30 years | Cleanliness of environment, load |

In a long-term study I conducted for a utility company, we found that cast resin transformers in harsh environments outlasted other types by an average of 10 years. This extended lifespan significantly offset the higher initial investment.

Total Cost of Ownership

The big picture:

- Initial Cost: Open wound < VPI < Cast resin

- Energy Efficiency: Cast resin > VPI > Open wound

- Maintenance Costs: Cast resin < VPI < Open wound

I recently helped a client analyze the total cost of ownership for a large industrial project. Despite the higher upfront cost, cast resin transformers proved to be the most economical choice over a 25-year period, thanks to their higher efficiency and lower maintenance needs.

Conclusion

Choosing the right dry type transformer depends on your specific needs, environment, and long-term considerations. Cast resin excels in harsh conditions, VPI offers versatility, and open wound suits basic indoor applications. Consider performance, safety, and total cost of ownership for the best decision.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group