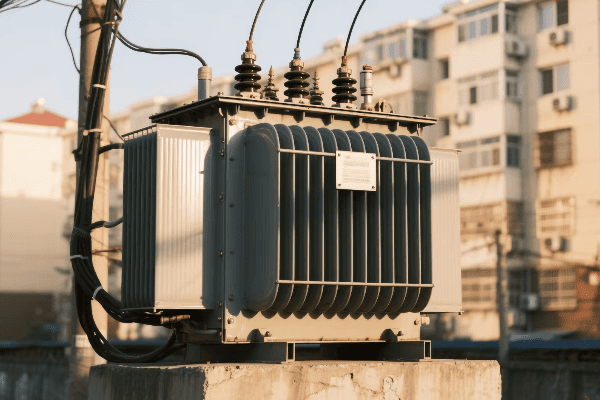

Choosing the Right Power Transformer: Essential Factors to Consider?

Are you struggling to select the perfect power transformer for your project? You’re not alone. Many engineers and project managers find this decision daunting. But don’t worry, I’m here to guide you through the process.

Choosing the right power transformer involves considering several key factors: technical specifications, application-specific requirements, efficiency metrics, safety standards, environmental impact, and total cost of ownership. By carefully evaluating these aspects, you can select a transformer that not only meets your current needs but also provides long-term value and reliability.

In my years of experience working with power systems, I’ve seen how crucial this decision can be. The right transformer can make your project a success, while the wrong choice can lead to inefficiencies, increased costs, and even safety hazards. Let’s dive into the essential factors you need to consider when choosing a power transformer.

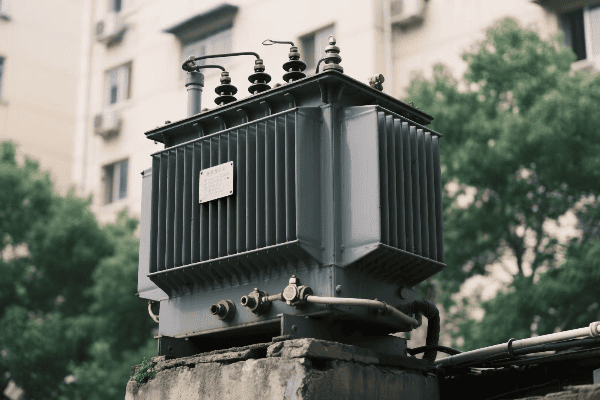

Technical Specifications: Key Parameters to Evaluate When Selecting a Power Transformer?

Have you ever felt overwhelmed by the technical jargon in transformer datasheets? You’re not alone. But understanding these specifications is crucial for making the right choice. So, what are the key parameters you should focus on?

Key technical parameters for power transformer selection include power rating (kVA or MVA), voltage ratio, impedance, efficiency, temperature rise, and insulation class. These specifications determine the transformer’s capacity, performance, and suitability for your specific application. Evaluating these parameters ensures you choose a transformer that meets your power needs and operational requirements.

Throughout my career, I’ve helped many clients navigate these technical specifications. Let’s break down the most important ones:

Power Rating and Voltage Ratio

The basics you can’t ignore:

- Power Rating: Measured in kVA or MVA, it determines the transformer’s capacity.

- Voltage Ratio: Primary to secondary voltage, crucial for your system compatibility.

- Current Rating: Derived from power and voltage, important for circuit protection.

I once worked on a project where the client initially underestimated their power needs. We had to replace a newly installed transformer within a year due to rapid business growth. Now, I always advise clients to consider future expansion in their initial selection.

Impedance and Efficiency

The performance indicators:

| Parameter | Importance | Typical Range |

|---|---|---|

| Impedance | Affects short-circuit current and voltage regulation | 4-8% for distribution transformers |

| Efficiency | Determines energy losses and operating costs | >98% for modern designs |

| No-load Loss | Constant loss, important for lightly loaded transformers | Varies by design and rating |

In a recent industrial project, we chose a transformer with slightly higher impedance. This decision helped limit fault currents in the facility’s electrical system, enhancing overall safety and reducing the required ratings of downstream circuit breakers.

Temperature Rise and Insulation Class

Keeping it cool and safe:

- Temperature Rise: Indicates how much the transformer heats up under load.

- Insulation Class: Determines the maximum operating temperature.

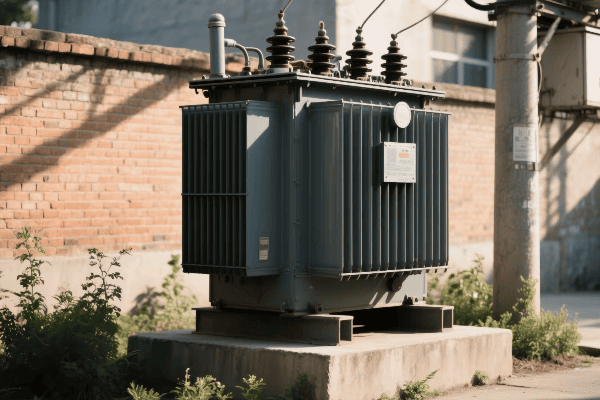

- Cooling Method: Oil-immersed or dry-type, each with its own advantages.

I once consulted on a project in a hot, humid climate. We opted for a transformer with a higher insulation class and more efficient cooling system. This choice ensured reliable operation even during the hottest months, preventing costly downtime.

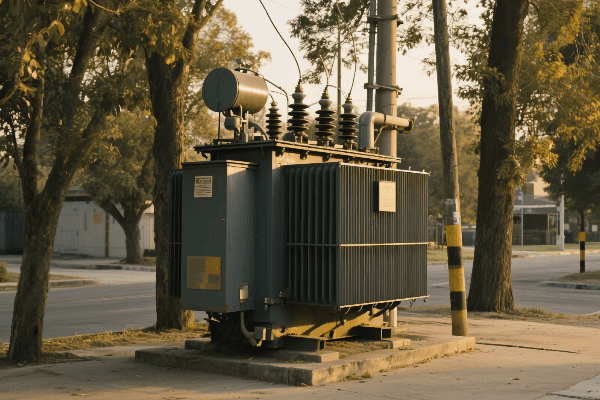

Application-Specific Considerations: Matching Transformer Characteristics to Usage Requirements?

Ever bought a tool that seemed perfect on paper but didn’t quite fit your needs in practice? The same can happen with transformers if you don’t consider your specific application. So, how do you ensure the transformer you choose is right for your unique situation?

Application-specific considerations for transformer selection include environmental conditions, load profile, harmonic content, duty cycle, and special requirements like overload capacity or noise levels. Matching these characteristics to your usage requirements ensures optimal performance, reliability, and longevity of the transformer in its intended application.

In my experience, understanding the application is just as important as knowing the technical specs. Let’s explore some key considerations:

Environmental Factors

Adapting to the surroundings:

- Indoor vs. Outdoor Installation: Affects enclosure type and protection rating.

- Ambient Temperature: Influences cooling system design and capacity.

- Altitude: Can affect insulation requirements and cooling efficiency.

I once worked on a project for a mining operation in a high-altitude, dusty environment. We had to specify a transformer with enhanced cooling and special air filters to ensure reliable operation in those harsh conditions.

Load Profile and Duty Cycle

Understanding the demand:

| Factor | Consideration | Impact on Selection |

|---|---|---|

| Load Profile | Constant vs. Variable Load | Affects size and efficiency requirements |

| Peak Demand | Maximum expected load | Determines transformer capacity |

| Duty Cycle | Continuous or Intermittent | Influences temperature rise and cooling needs |

In a recent data center project, we analyzed the expected load profile carefully. This led us to choose a transformer with good efficiency at partial loads, as the data center’s power demand fluctuated throughout the day.

Special Requirements

Meeting unique needs:

- Harmonic Mitigation: K-factor rated transformers for non-linear loads.

- Noise Levels: Low-noise designs for residential or office settings.

- Overload Capacity: Important for applications with frequent short-term overloads.

I helped design a power system for a hospital where both low noise and high reliability were crucial. We selected a dry-type transformer with enhanced overload capacity and special low-noise design, ensuring quiet operation and the ability to handle critical medical equipment loads.

Efficiency and Performance Metrics: Assessing the Long-Term Value of Power Transformers?

Are you focused solely on the upfront cost of a transformer? If so, you might be missing out on significant long-term savings. But how do you evaluate a transformer’s efficiency and performance to ensure you’re making a smart investment?

Assessing transformer efficiency and performance involves examining metrics like load and no-load losses, efficiency at various load levels, voltage regulation, and temperature rise. These factors directly impact energy costs, operational reliability, and transformer lifespan. Evaluating these metrics helps in selecting a transformer that offers the best long-term value and performance.

Throughout my career, I’ve seen how focusing on efficiency can lead to substantial savings. Let’s dive into the key metrics:

Load and No-Load Losses

The hidden energy drains:

- No-Load Losses: Constant losses, regardless of load.

- Load Losses: Vary with the square of the load current.

- Total Losses: Sum of no-load and load losses at rated conditions.

I once helped a manufacturing plant upgrade their transformers. By choosing units with lower losses, we reduced their energy costs by 15% annually. The initial investment was higher, but the payback period was less than three years.

Efficiency at Various Load Levels

Performance across the spectrum:

| Load Level | Importance | Typical Efficiency |

|---|---|---|

| 25% Load | Common in many applications | 97-98% |

| 50% Load | Often the sweet spot for efficiency | 98-99% |

| 100% Load | Maximum capacity, but not always most efficient | 98-99% |

In a recent project for a shopping mall, we selected transformers optimized for efficiency at 50% load. This choice matched their typical usage pattern and resulted in lower operating costs compared to standard models.

Voltage Regulation and Stability

Keeping the power steady:

- Voltage Regulation: Measure of voltage drop from no-load to full-load.

- Tap Changers: Allow for voltage adjustment to maintain stable output.

- Dynamic Response: Important for applications with fluctuating loads.

I advised on a power system for a large data center where voltage stability was crucial. We implemented transformers with on-load tap changers, ensuring consistent voltage levels despite varying server loads throughout the day.

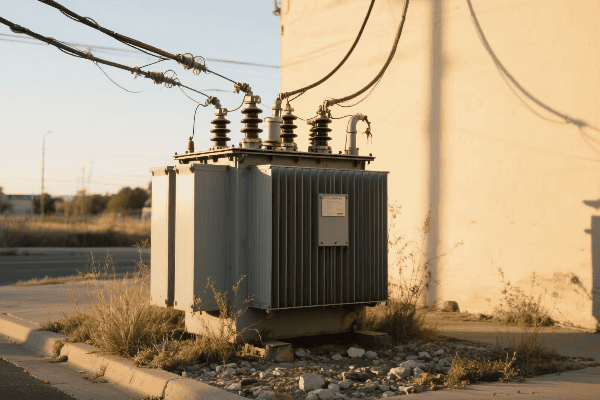

Safety and Environmental Factors: Ensuring Compliance and Sustainability in Transformer Selection?

Worried about safety regulations or environmental impact? You should be. Choosing a transformer isn’t just about power; it’s about protecting people and the planet. But how do you navigate the maze of safety standards and environmental considerations?

Selecting a power transformer with safety and environmental factors in mind involves considering fire resistance, noise levels, oil containment (for oil-filled types), and energy efficiency standards. It also includes evaluating the use of eco-friendly materials and the transformer’s overall environmental impact. Compliance with relevant safety standards and environmental regulations is crucial.

In my years of experience, I’ve seen safety and environmental concerns become increasingly important. Here’s what you need to focus on:

Safety Standards and Compliance

Protecting people and property:

- Fire Safety: Especially important for indoor installations.

- Electrical Safety: Compliance with IEC, IEEE, or regional standards.

- Seismic Requirements: Critical in earthquake-prone areas.

I once worked on a project in a high-rise building where fire safety was paramount. We chose dry-type transformers with the highest fire resistance rating, which not only met building codes but also eased the concerns of the insurance company.

Environmental Considerations

Going green with your choice:

| Factor | Consideration | Impact |

|---|---|---|

| Energy Efficiency | Meets or exceeds standards like NEMA TP-1 | Reduces carbon footprint |

| Oil vs. Dry Type | Environmental risk in case of leaks | Affects installation location |

| Noise Levels | Important in urban or sensitive areas | Impacts surrounding environment |

In a recent project for an eco-conscious tech company, we selected ultra-efficient, low-noise transformers. This choice not only reduced their energy consumption but also helped them achieve LEED certification for their new office building.

Sustainable Materials and Practices

Thinking beyond operation:

- Recyclable Materials: Considering end-of-life disposal.

- Biodegradable Fluids: Alternative to mineral oil in some applications.

- Manufacturing Process: Evaluating the supplier’s environmental practices.

I advised a utility company on their transformer procurement policy. We included criteria for evaluating manufacturers’ sustainability practices, leading to partnerships with suppliers who used recycled materials and energy-efficient production methods.

Total Cost of Ownership: Balancing Initial Investment with Operational Expenses and Future Scalability?

Are you tempted to go for the cheapest transformer option? Think twice. The initial price tag doesn’t tell the whole story. But how do you calculate the true cost of a transformer over its lifetime?

Total Cost of Ownership (TCO) for a power transformer includes the initial purchase price, installation costs, energy losses over its lifespan, maintenance expenses, and potential replacement costs. It also considers future scalability and adaptability to changing needs. Evaluating TCO helps in making a cost-effective decision that balances upfront costs with long-term operational expenses.

Throughout my career, I’ve helped many clients understand and optimize their transformer TCO. Let’s break down the key components:

Initial Costs vs. Operational Expenses

The visible and hidden costs:

- Purchase Price: The upfront cost of the transformer.

- Installation Costs: Including transportation, site preparation, and commissioning.

- Energy Losses: A major component of long-term costs.

I once helped a client compare two transformer options. The more expensive unit had lower losses. Our TCO analysis showed that despite a 20% higher initial cost, it would save them money within five years due to reduced energy losses.

Maintenance and Reliability

Keeping it running smoothly:

| Aspect | Consideration | Impact on TCO |

|---|---|---|

| Maintenance Requirements | Frequency and complexity of maintenance | Affects ongoing costs |

| Expected Lifespan | Longevity of the transformer | Influences replacement timeline |

| Reliability | Probability of failures or outages | Can lead to costly downtime |

In a manufacturing plant project, we opted for a slightly more expensive transformer with advanced monitoring features. This choice reduced maintenance needs and prevented several potential failures, saving the client from costly production interruptions.

Future Scalability and Adaptability

Planning for tomorrow:

- Load Growth: Considering future expansion needs.

- Technology Changes: Adaptability to smart grid technologies.

- Regulatory Changes: Anticipating future efficiency standards.

I advised a growing tech startup on their power infrastructure. We chose a modular transformer system that allowed for easy capacity increases. This foresight saved them significant costs and disruption when they expanded their operations just two years later.

Conclusion

Choosing the right power transformer requires careful consideration of technical specs, application needs, efficiency, safety, environmental factors, and total cost of ownership. Balancing these factors ensures optimal performance, reliability, and long-term value for your specific requirements.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group