Choosing the Right Oil Immersed Transformer: Key Factors to Consider?

Are you puzzled about which oil immersed transformer to choose? You’re not alone. Many people find this decision overwhelming. But don’t worry, I’m here to guide you through the process.

Choosing the right oil immersed transformer involves considering several key factors. These include power capacity, voltage ratings, cooling efficiency, environmental impact, and longevity. The ideal transformer should meet your specific power needs while being efficient, environmentally friendly, and durable.

As someone who has worked with oil immersed transformers for years, I’ve seen how crucial this choice can be. The right transformer can save you money and headaches in the long run. Let’s dive into the key factors you need to consider when choosing your oil immersed transformer.

Transformer Spa Day: Why Do Some Transformers Love to Bathe in Oil?

Have you ever wondered why some transformers are always taking an oil bath? It’s not because they’re high-maintenance divas. There’s a good reason for their oil obsession.

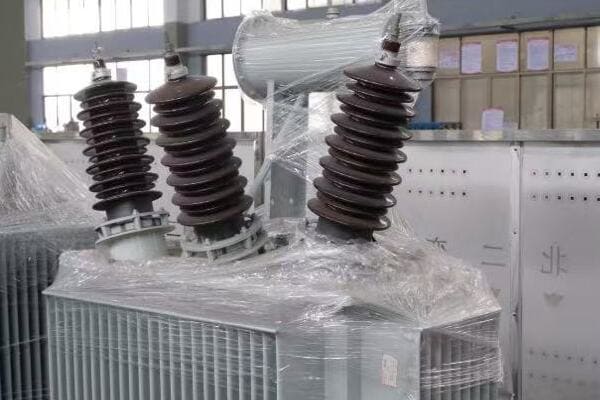

Oil immersed transformers use oil for insulation and cooling. The oil helps dissipate heat, prevents arcing between components, and extends the transformer’s lifespan. This oil bath allows these transformers to handle higher voltages and larger loads more efficiently than their dry-type counterparts.

I remember the first time I saw the inside of an oil immersed transformer. It was like peeking into a high-tech aquarium. Let’s explore why these transformers love their oil so much.

The Magic of Transformer Oil

Transformer oil isn’t just any oil. It’s a special blend with unique properties:

- High Dielectric Strength: This means it’s great at insulating against electrical current.

- Excellent Heat Transfer: It helps move heat away from the transformer’s core and windings.

- Chemical Stability: It doesn’t break down easily under high temperatures and electrical stress.

Benefits of the Oil Bath

The oil in these transformers serves several crucial functions:

- Cooling: As the transformer heats up, the oil circulates, carrying heat away from vital components.

- Insulation: The oil prevents electrical arcing between parts at different voltages.

- Protection: It shields the internal components from moisture and oxygen, which can cause degradation.

Here’s a quick comparison of oil immersed vs. dry-type transformers:

| Feature | Oil Immersed | Dry-Type |

|---|---|---|

| Cooling Efficiency | High | Lower |

| Suitable for High Voltages | Yes | Limited |

| Size for Same Capacity | Smaller | Larger |

| Maintenance | Regular oil checks needed | Less maintenance |

| Indoor/Outdoor Use | Both (with proper housing) | Primarily indoor |

Types of Transformer Oils

Not all transformer oils are created equal:

- Mineral Oil: The most common type, derived from petroleum.

- Silicone Oil: Better fire resistance, but more expensive.

- Vegetable-based Oil: Biodegradable and environmentally friendly.

I once worked on a project where we switched from mineral oil to vegetable-based oil in a transformer near a sensitive ecological area. The improved environmental profile gave everyone peace of mind.

Maintenance of Oil Immersed Transformers

While oil immersed transformers have many benefits, they do require some special care:

- Regular Oil Testing: Checking for moisture, acidity, and dissolved gases.

- Oil Filtering: Removing contaminants to maintain oil quality.

- Oil Replacement: Sometimes necessary after many years of service.

Safety Considerations

Oil immersed transformers come with some unique safety considerations:

- Fire Risk: While rare, oil fires can be intense. Modern transformers use less flammable oils.

- Environmental Concerns: Proper containment is necessary to prevent oil leaks.

- Disposal: Used transformer oil must be disposed of properly.

I once dealt with a transformer oil leak at a substation. The cleanup was extensive, but it taught us valuable lessons about proper containment and maintenance.

Oil immersed transformers might seem like they’re just taking a perpetual bath, but that oil is working hard. It’s keeping the transformer cool, insulated, and protected. When choosing an oil immersed transformer, consider the type of oil, maintenance requirements, and safety factors. With proper care, these oil-loving transformers can provide reliable service for decades.

Size Matters: Finding the Goldilocks Zone for Your Oil-Loving Transformer?

Have you ever tried to squeeze into clothes that are too small? Or felt lost in an oversized jacket? Choosing the right size transformer is a bit like that. Too small, and it’ll be overworked and inefficient. Too big, and you’re wasting money and space.

Choosing the right size oil immersed transformer involves matching the kVA rating to your power needs. You need to consider current load requirements, potential future growth, peak demand, and efficiency at different load levels. The ideal size ensures optimal performance and cost-effectiveness.

I once helped a small factory that was constantly tripping their undersized transformer. After upgrading to the right size, their operations ran smoothly, and their energy bills even went down. Let’s dive into how you can find the perfect fit for your power needs.

Understanding Transformer Ratings

Transformer size is typically expressed in kVA (kilovolt-amperes). Here’s what you need to know:

- kVA vs. kW: kVA is apparent power, while kW is real power. For most applications, you can assume they’re roughly equal.

- Common Sizes: Oil immersed transformers can range from small 5 kVA units to massive 100,000 kVA behemoths.

- Voltage Ratings: Each transformer has primary and secondary voltage ratings. Make sure these match your needs.

Calculating Your Power Requirements

To find the right size, you need to know your power needs:

- List All Loads: Write down all equipment that will be powered.

- Find Wattage: Note the power consumption of each device.

- Calculate Total: Add up all the wattages.

- Consider Power Factor: Divide by your system’s power factor (typically 0.8 to 0.9).

- Add Safety Margin: Add 15-20% for future growth and peak demands.

Here’s a simple example:

| Equipment | Wattage |

|---|---|

| Machine 1 | 5000W |

| Machine 2 | 7500W |

| Lighting | 2000W |

| HVAC | 10000W |

| Total | 24500W |

Assuming a power factor of 0.85 and adding a 20% margin:

(24500 / 0.85) * 1.2 ≈ 34,600 VA or 35 kVA

Factors to Consider

Choosing the right size isn’t just about current needs:

- Future Expansion: Plan for potential growth.

- Peak Demand: Account for times when all equipment might be running simultaneously.

- Duty Cycle: Consider if loads are continuous or intermittent.

- Efficiency: Transformers are most efficient when loaded to 50-70% of their capacity.

I once worked with a tech startup that was rapidly expanding. We chose a transformer with extra capacity, which saved them from having to upgrade again just a year later.

The Dangers of Incorrect Sizing

Choosing the wrong size transformer can lead to problems:

- Undersized: Can lead to overheating, reduced lifespan, and frequent outages.

- Oversized: Results in higher initial costs, lower efficiency, and wasted space.

Sizing Guidelines

Here’s a general guide to help you choose:

| Load (kVA) | Recommended Transformer Size (kVA) |

|---|---|

| 0-25 | 25 |

| 25-50 | 50 |

| 50-100 | 100 |

| 100-167 | 167 |

| 167-250 | 250 |

Remember, it’s usually better to go slightly larger than your calculated need to allow for future growth and peak demands.

When to Seek Professional Help

While these guidelines can help, some situations call for professional assistance:

- Complex Loads: If you have a mix of motors, electronics, and other diverse loads.

- Critical Applications: Where power interruption could be dangerous or costly.

- Large Systems: For loads above 1000 kVA, it’s best to consult an expert.

I once helped a hospital choose transformers for their new wing. The mix of sensitive medical equipment and critical power needs required careful calculation and selection.

Choosing the right size oil immersed transformer is crucial for efficient and reliable power. It’s not just about meeting your current needs, but also planning for the future. By considering all factors and using these guidelines, you can ensure you find the Goldilocks zone for your transformer – not too big, not too small, but just right.

Keeping It Cool: How Oil Helps Your Transformer Beat the Heat?

Have you ever wondered why transformers don’t melt down under the immense heat they generate? The secret lies in their cooling system, and for oil immersed transformers, that cooling superhero is the oil itself.

Oil in transformers serves as an excellent cooling medium. It circulates through the transformer, absorbing heat from the core and windings, and then releases it through radiators. This efficient cooling system allows oil immersed transformers to handle higher loads and maintain better efficiency than their air-cooled counterparts.

I once witnessed a transformer overheat due to a cooling system failure. The repair was costly and time-consuming. Let’s dive into how oil keeps your transformer cool and why it’s so important.

The Heat Challenge in Transformers

Transformers generate heat due to two main factors:

- Core Losses: Heat generated in the iron core due to changing magnetic fields.

- Copper Losses: Heat produced in the windings due to electrical resistance.

Without proper cooling, this heat can:

- Degrade insulation

- Reduce efficiency

- Shorten the transformer’s lifespan

- In extreme cases, cause catastrophic failure

How Oil Beats the Heat

Oil is an excellent cooling medium for several reasons:

- High Specific Heat Capacity: It can absorb a lot of heat without a significant temperature rise.

- Good Thermal Conductivity: It efficiently transfers heat from hot spots to cooler areas.

- Natural Circulation: As oil heats, it rises, creating a natural circulation that aids cooling.

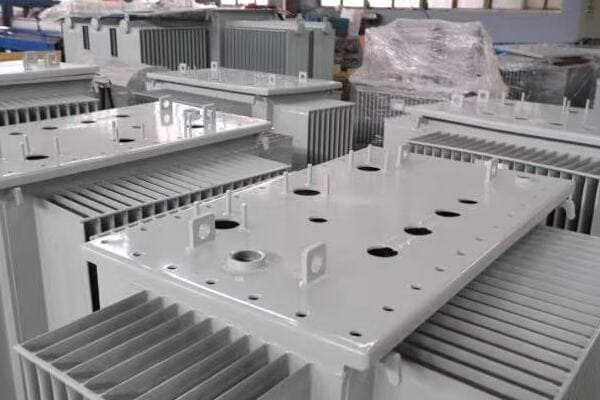

Types of Oil Cooling Systems

There are several types of oil cooling systems, each suited for different transformer sizes and applications:

-

ONAN (Oil Natural Air Natural):

- Oil circulates naturally

- Cooling fins or radiators dissipate heat to the air

- Suitable for smaller transformers

-

ONAF (Oil Natural Air Forced):

- Similar to ONAN, but with added fans to boost air cooling

- Used for medium-sized transformers

-

OFAF (Oil Forced Air Forced):

- Oil is pumped through the system

- Fans force air over the radiators

- Used for larger transformers

-

ODAF (Oil Directed Air Forced):

- Oil is directed to flow through specific hot spots

- Fans force air over the radiators

- Used for very large or heavily loaded transformers

Here’s a comparison of these cooling methods:

| Cooling Method | Oil Circulation | Air Cooling | Typical Use |

|---|---|---|---|

| ONAN | Natural | Natural | Small transformers |

| ONAF | Natural | Forced | Medium transformers |

| OFAF | Forced | Forced | Large transformers |

| ODAF | Forced & Directed | Forced | Very large transformers |

I once worked on upgrading a transformer from ONAN to ONAF cooling. The addition of fans significantly increased its load capacity, saving the client from having to replace the entire transformer.

Monitoring and Maintaining Cooling Efficiency

To ensure your transformer stays cool:

- Temperature Monitoring: Regular checks of oil and winding temperatures.

- Oil Quality Tests: Checking for contaminants that could reduce cooling efficiency.

- Radiator Maintenance: Ensuring radiators are clean and unobstructed.

- Fan Maintenance: For ONAF, OFAF, and ODAF systems, regular fan checks are crucial.

Innovations in Transformer Cooling

The world of transformer cooling is constantly evolving:

- Vegetable-based Oils: Better heat absorption and environmental friendliness.

- Nanofluid-enhanced Oils: Improved thermal conductivity.

- Smart Cooling Systems: Adjusting cooling based on real-time load and temperature data.

I recently worked with a utility company testing nanofluid-enhanced transformer oil. The improved cooling efficiency was impressive, allowing for higher load capacity without upgrading the transformer size.

The Impact of Proper Cooling

Effective cooling doesn’t just prevent overheating. It also:

- Improves efficiency

- Extends transformer lifespan

- Allows for higher load capacity

- Reduces maintenance needs and downtime

Keeping your transformer cool is crucial for its performance and longevity. The oil in oil immersed transformers isn’t just there for insulation – it’s a hardworking cooling hero. By understanding and maintaining your transformer’s cooling system, you can ensure it runs efficiently and reliably for years to come. Remember, a cool transformer is a happy transformer!

Green and Clean: Choosing an Oil Transformer That Mother Nature Would Approve?

Are you concerned about the environmental impact of your power equipment? You’re not alone. With growing awareness of environmental issues, choosing an eco-friendly oil transformer has become more important than ever.

Environmentally friendly oil transformers use biodegradable oils, have better energy efficiency, and are designed for easier recycling at end-of-life. They reduce the risk of soil and water contamination, have a lower carbon footprint, and often comply with stricter environmental regulations.

I once helped a company switch to eco-friendly transformers. Not only did it improve their environmental profile, but it also led to energy savings and positive PR. Let’s explore how you can choose an oil transformer that Mother Nature would approve.

The Environmental Challenges of Traditional Oil Transformers

Traditional oil transformers pose several environmental risks:

- Oil Spills: Can contaminate soil and water

- Non-biodegradable Oils: Persist in the environment if leaked

- Energy Inefficiency: Higher losses mean more power generation and higher emissions

- End-of-life Disposal: Can be challenging due to hazardous materials

Eco-Friendly Alternatives

Modern, environmentally friendly transformers address these issues:

-

Biodegradable Oils:

- Vegetable-based oils

- Synthetic esters

-

High-Efficiency Designs:

- Amorphous metal cores

- Better winding designs

-

Recyclable Materials:

- Use of materials that are easier to recycle at end-of-life

-

Compact Designs:

- Reduce material use and transportation emissions

Here’s a comparison of traditional and eco-friendly transformers:

| Feature | Traditional Transformer | Eco-Friendly Transformer |

|---|---|---|

| Oil Type | Mineral Oil | Vegetable Oil or Synthetic Ester |

| Biodegradability | Low | High |

| Fire Safety | Lower Flash Point | Higher Flash Point |

| Efficiency | Standard | High Efficiency |

| Lifespan | Standard | Often Longer |

| Recyclability | Challenging | Easier |

Benefits of Eco-Friendly Transformers

Choosing a green transformer offers several advantages:

- Reduced Environmental Risk: Biodegradable oils minimize the impact of potential leaks.

- Improved Safety: Many eco-friendly oils have higher flash points, reducing fire risk.

- Energy Savings: Higher efficiency means lower operating costs and reduced carbon footprint.

- Regulatory Compliance: Often meet stricter environmental regulations.

- Positive Corporate Image: Demonstrates commitment to sustainability.

I once worked with a utility company that switched to vegetable oil transformers in an environmentally sensitive area. The move not only protected the local ecosystem but also improved relations with the community.

Key Factors in Choosing an Eco-Friendly Transformer

When selecting an environmentally friendly transformer, consider:

- Oil Type: Look for biodegradable options like vegetable oils or synthetic esters.

2.2. Efficiency Ratings: Choose transformers with high-efficiency ratings to reduce energy losses. - Material Composition: Opt for designs that use recyclable materials.

- Size and Weight: Compact designs often mean less material use and easier transportation.

- Lifespan: Longer-lasting transformers reduce the need for replacements and associated waste.

- Manufacturer’s Environmental Commitment: Look for companies with strong environmental policies.

Innovations in Eco-Friendly Transformer Technology

The field of green transformer technology is constantly evolving:

- Nanotechnology: Enhancing oil properties for better performance and longevity.

- Smart Monitoring: Allowing for optimal operation and early problem detection.

- Hybrid Insulation Systems: Combining eco-friendly liquids with solid insulation for better performance.

- Carbon-Neutral Manufacturing: Some companies are moving towards carbon-neutral production processes.

I recently visited a transformer manufacturing plant that had implemented carbon-neutral processes. It was inspiring to see how they had reimagined their entire production line with sustainability in mind.

Overcoming Challenges in Adopting Green Transformers

While eco-friendly transformers offer many benefits, there are challenges to consider:

- Higher Initial Costs: Green technologies often come with a higher price tag.

- Performance in Extreme Conditions: Some bio-based oils may have limitations in very cold climates.

- Retrofitting Existing Systems: Switching to eco-friendly oils in existing transformers can be complex.

To address these challenges:

- Consider the long-term savings from improved efficiency and longer lifespan.

- Work with manufacturers to find solutions suitable for your specific environmental conditions.

- Plan a phased approach to upgrading your transformer fleet.

The Future of Green Transformer Technology

As we look to the future, we can expect:

- Improved Bio-based Oils: Better performance across a wider range of conditions.

- Advanced Recycling Techniques: Making end-of-life disposal even more eco-friendly.

- Integration with Renewable Energy: Transformers specifically designed for wind and solar farms.

- Zero-Waste Manufacturing: Pushing towards completely sustainable production processes.

Choosing an environmentally friendly oil transformer is not just good for the planet; it’s often good for your bottom line too. With improved efficiency, longer lifespans, and better safety profiles, these green transformers are paving the way for a more sustainable energy future. As you consider your next transformer purchase, remember that the most powerful choice might just be the one that Mother Nature would approve.

Transformer Life Coach: Picking a Long-Lasting Oil Companion for Your Power Needs?

Have you ever had a appliance break down just after the warranty expired? Frustrating, isn’t it? When it comes to transformers, longevity is key. After all, these aren’t just any appliances – they’re the lifeblood of your power system.

Choosing a long-lasting oil transformer involves considering factors like build quality, materials used, cooling efficiency, and maintenance requirements. A durable transformer should have high-quality insulation, efficient cooling systems, robust mechanical design, and be able to withstand electrical and environmental stresses over time.

I once worked with a company that had to replace their transformer every 10 years. After switching to a more durable model, they haven’t had to replace it in over 20 years. Let’s explore how you can choose a transformer that will be your reliable power companion for decades to come.

Key Factors in Transformer Longevity

Several factors contribute to a transformer’s lifespan:

- Insulation Quality: The insulation system is often the limiting factor in a transformer’s life.

- Cooling Efficiency: Better cooling means less stress on components.

- Load Management: How well the transformer handles varying loads.

- Environmental Protection: Resistance to moisture, contaminants, and temperature extremes.

- Mechanical Strength: Ability to withstand physical stresses, including short-circuit forces.

Insulation Systems: The Heart of Longevity

The insulation system is crucial for transformer life:

- Oil Quality: High-grade insulating oil resists breakdown over time.

- Solid Insulation: Usually cellulose-based, it needs to resist degradation.

- Sealed Systems: Prevent moisture and oxygen ingress, which can degrade insulation.

Here’s a comparison of insulation life expectancies:

| Insulation System | Expected Lifespan |

|---|---|

| Standard Mineral Oil | 30-40 years |

| High-Grade Mineral Oil | 40-50 years |

| Synthetic Ester | 50-60 years |

| Natural Ester (Vegetable Oil) | 50-60 years |

I once worked on upgrading a transformer’s insulation system from standard mineral oil to a high-grade synthetic ester. The improved insulation properties significantly extended the transformer’s expected lifespan.

Cooling Systems: Keeping Your Transformer Young

Efficient cooling is key to longevity:

- ONAN (Oil Natural Air Natural): Simple and reliable, but limited cooling capacity.

- ONAF (Oil Natural Air Forced): Added fans improve cooling efficiency.

- OFAF (Oil Forced Air Forced): Pumps and fans provide even better cooling.

- ODAF (Oil Directed Air Forced): Most efficient, directs oil flow to hotspots.

The right cooling system can significantly extend a transformer’s life by reducing thermal stress on insulation and other components.

Load Management and Monitoring

How a transformer is used affects its lifespan:

- Load Cycling: Frequent large load changes can stress the transformer.

- Overloading: Even short periods of overload can degrade insulation.

- Smart Monitoring: Modern systems can optimize loading and predict maintenance needs.

I helped implement a smart monitoring system for a utility company. It allowed them to better manage transformer loads, extending the life of their entire transformer fleet.

Environmental Protection

Protecting against environmental factors is crucial:

- Sealed Tank Design: Prevents moisture ingress.

- Corrosion-Resistant Materials: Especially important in coastal or industrial areas.

- Temperature Extremes: Design should account for your local climate.

Mechanical Strength

A transformer needs to withstand various mechanical stresses:

- Short-Circuit Forces: Can cause winding deformation.

- Transportation Stresses: Especially important for large transformers.

- Seismic Activity: In earthquake-prone areas, special designs may be needed.

Maintenance: The Key to Longevity

Even the best-designed transformer needs proper care:

- Regular Oil Testing: Checks for contaminants and degradation.

- Dissolved Gas Analysis: Can detect developing faults early.

- Periodic Inspections: Check for physical issues like leaks or loose connections.

- Proactive Repairs: Addressing small issues before they become big problems.

I once worked with a client who implemented a rigorous maintenance program. Their transformers consistently outlasted industry averages, saving them significant replacement costs.

The Cost-Benefit Analysis of Longevity

While long-lasting transformers often have higher upfront costs, they can be more economical in the long run:

- Reduced Replacement Frequency: Fewer disruptions and lower long-term capital costs.

- Lower Maintenance Costs: High-quality transformers often require less frequent maintenance.

- Improved Reliability: Fewer unexpected failures mean less downtime and associated costs.

Choosing a long-lasting oil transformer is an investment in your power system’s future. By considering factors like insulation quality, cooling efficiency, load management, and environmental protection, you can select a transformer that will be a reliable companion for decades. Remember, in the world of transformers, longevity isn’t just about age – it’s about consistent, reliable performance year after year.

Conclusion

Choosing the right oil immersed transformer involves balancing factors like cooling efficiency, environmental impact, and longevity. By considering these key aspects, you can select a transformer that not only meets your power needs but also offers long-term reliability, efficiency, and environmental responsibility.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group