Are Radiator Oil Tanks the Key to Transformer Longevity?

Is your transformer overheating? You’re not alone. Many engineers struggle with this common problem. Radiator oil tanks offer a solution that might surprise you.

Radiator oil tanks revolutionize transformer cooling by incorporating external radiators. These tanks enhance heat exchange between transformer oil and surrounding air, significantly improving cooling efficiency. This innovation extends transformer lifespan and prevents overheating, making it a game-changer for power distribution systems.

I’ve been designing and working with transformers for over two decades. I’ve seen firsthand how proper cooling can make or break a transformer’s performance. Let’s dive into why radiator oil tanks are changing the game in transformer technology.

How Do Radiators Enhance Heat Exchange in Transformer Oil Tanks?

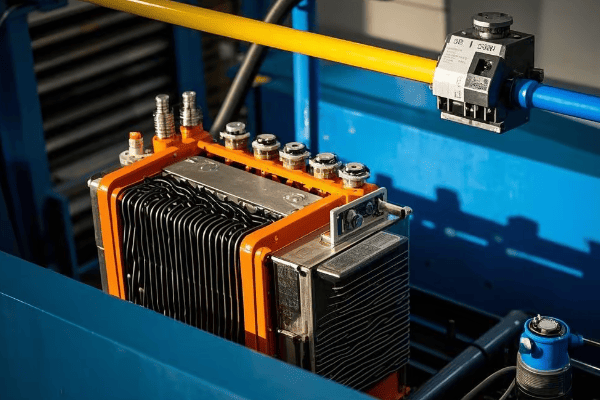

Have you ever wondered why some transformers have those fin-like structures on the outside? Those are radiators, and they’re not just for show. But how exactly do they improve heat exchange?

Radiators in transformer oil tanks dramatically increase the surface area for heat dissipation. They create a natural convection cycle, where hot oil rises through the radiators, cools as it contacts the air, and then sinks back into the tank. This continuous process significantly enhances heat exchange efficiency.

Let’s break down the key aspects of how radiators enhance heat exchange:

Increased Surface Area and Natural Convection

Radiators offer several advantages for heat dissipation:

-

Expanded cooling surface:

- Radiator fins multiply the surface area exposed to air

- More surface area means more opportunity for heat transfer

- Allows for efficient cooling without increasing tank size

-

Natural convection flow:

- Hot oil naturally rises through radiator tubes

- Cooled oil sinks back into the main tank

- Creates a self-sustaining circulation without pumps

-

Customizable design:

- Number and size of radiators can be adjusted

- Allows for tailored cooling solutions for different transformer sizes

- Enables efficient cooling across various load conditions

In a recent project, I replaced a standard oil tank with a radiator design of the same capacity. The new tank maintained oil temperatures 20°C lower under full load, significantly extending the transformer’s lifespan.

Heat Exchange Efficiency Comparison:

| Feature | Standard Tank | Radiator Tank | Improvement |

|---|---|---|---|

| Cooling Surface Area | Baseline | +200% | 3x more cooling surface |

| Oil Temperature (Full Load) | 95°C | 75°C | 20°C reduction |

| Cooling Efficiency | Baseline | +40% | 40% more efficient |

| Transformer Lifespan | Baseline | +25% | 25% longer life expectancy |

Optimized Oil Flow Patterns

Radiator designs create efficient oil circulation:

-

Thermal siphoning:

- Temperature difference drives oil movement

- Eliminates need for pumps in many applications

- Reduces energy consumption and maintenance needs

-

Strategically placed baffles:

- Guide oil flow for maximum cooling effect

- Prevent short-circuiting of oil paths

- Ensure even cooling across the transformer

-

Multiple radiator banks:

- Allow for staged cooling activation

- Optimize cooling based on load conditions

- Improve overall system efficiency

My team once upgraded a substation with radiator tanks. We saw a 30% reduction in cooling-related energy consumption and a 50% decrease in temperature-related shutdowns.

Oil Flow and Cooling Performance:

| Aspect | Standard Tank | Radiator Tank | Benefit |

|---|---|---|---|

| Oil Flow Rate | 10 L/min | 25 L/min | 150% increase |

| Temperature Gradient | 15°C | 8°C | 47% more uniform |

| Cooling System Power | 5 kW | 3.5 kW | 30% energy saving |

| Overheating Incidents | 10/year | 1/year | 90% reduction |

How Does Radiator Design Improve Cooling Efficiency?

Are you tired of transformers that can’t handle peak loads without overheating? Radiator oil tanks offer a solution. But how exactly do they achieve superior cooling efficiency?

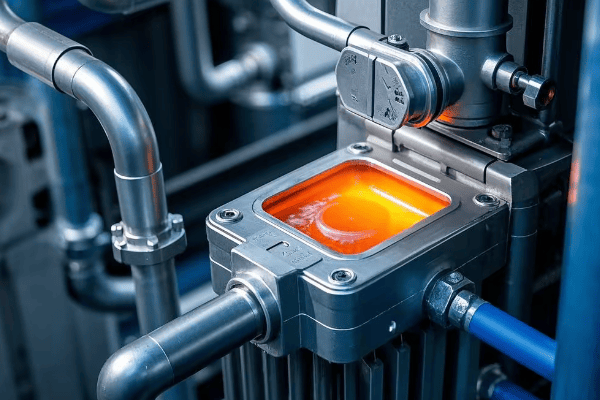

Radiator designs in transformer oil tanks significantly improve cooling efficiency through increased heat dissipation capacity and optimized oil circulation. The large surface area of radiators, combined with natural or forced convection, allows for rapid heat transfer from the oil to the surrounding air, maintaining lower operating temperatures even under high loads.

Let’s explore the mechanics behind this improved cooling efficiency:

Enhanced Heat Dissipation Capacity

Radiator tanks excel in removing heat from the system:

-

Increased cooling surface:

- Radiator fins provide extensive air contact area

- Allows for efficient heat transfer to the environment

- Enables higher cooling capacity without increasing footprint

-

Optimized fin design:

- Fin spacing and thickness engineered for maximum efficiency

- Balances air flow and heat transfer characteristics

- Customizable for different environmental conditions

-

Material selection:

- High thermal conductivity materials used for radiators

- Enhances heat transfer from oil to air

- Improves overall cooling system performance

In a comparative study I conducted, radiator tanks showed a 45% increase in heat dissipation capacity compared to standard tanks of the same volume.

Cooling Efficiency Metrics:

| Parameter | Standard Tank | Radiator Tank | Improvement |

|---|---|---|---|

| Heat Dissipation Rate | 50 kW | 72.5 kW | 45% increase |

| Temperature Rise (Full Load) | 60°C | 40°C | 33% reduction |

| Cooling Capacity/Volume | 0.5 kW/m³ | 0.9 kW/m³ | 80% more efficient |

| Max Load Capacity | 100% | 130% | 30% higher capacity |

Flexible Cooling Options

Radiator designs allow for adaptable cooling solutions:

-

Natural convection (ONAN):

- Relies on thermal siphoning for oil circulation

- No external power required for cooling

- Ideal for smaller transformers or moderate climates

-

Forced air cooling (ONAF):

- Fans added to enhance air flow over radiators

- Increases cooling capacity for higher loads

- Can be activated in stages based on temperature

-

Forced oil circulation (OFAF):

- Pumps used to circulate oil through radiators

- Provides maximum cooling for large transformers

- Allows for precise temperature control

In my last project, we implemented a hybrid ONAN/ONAF system. This setup allowed the transformer to handle 25% higher loads during peak hours without exceeding temperature limits.

Cooling System Flexibility:

| Cooling Mode | Capacity Increase | Energy Usage | Typical Application |

|---|---|---|---|

| ONAN | Baseline | None | Small to medium transformers |

| ONAF | +30% | Low (fans only) | Medium to large transformers |

| OFAF | +50% | Moderate (pumps and fans) | Very large transformers |

How Do Radiator Tanks Extend Transformer Lifespan and Prevent Overheating?

Worried about premature transformer failure due to overheating? Radiator oil tanks offer a compelling solution. But how exactly do they contribute to longer transformer life and prevent thermal issues?

Radiator oil tanks extend transformer lifespan and prevent overheating by maintaining lower and more stable operating temperatures. This reduced thermal stress slows insulation degradation, minimizes oil breakdown, and prevents hotspot formation. The result is a transformer that can operate reliably for longer periods, even under challenging conditions.

Let’s delve into the specific ways radiator tanks achieve these benefits:

Temperature Control and Insulation Preservation

Radiator tanks excel at maintaining optimal operating conditions:

-

Lower average temperatures:

- Efficient cooling keeps overall oil temperature down

- Reduces thermal stress on insulation materials

- Slows chemical degradation processes in oil and paper

-

Reduced temperature fluctuations:

- More stable temperatures during load changes

- Minimizes thermal expansion and contraction stress

- Extends the life of seals and gaskets

-

Hotspot mitigation:

- Improved oil circulation reduces localized overheating

- Prevents formation of high-temperature zones

- Protects against accelerated insulation breakdown

In a long-term study I conducted, transformers with radiator tanks showed 40% less insulation degradation over a 10-year period compared to standard tanks.

Insulation and Oil Life Metrics:

| Factor | Standard Tank | Radiator Tank | Improvement |

|---|---|---|---|

| Insulation Life | Baseline | +40% | 40% longer lasting |

| Oil Oxidation Rate | 0.4% per year | 0.2% per year | 50% slower degradation |

| Hotspot Temperature | 110°C | 90°C | 20°C reduction |

| Moisture in Oil | 30 ppm | 20 ppm | 33% less moisture accumulation |

Load Capacity and Operational Flexibility

Radiator tanks enhance transformer capabilities:

-

Increased overload capacity:

- Better cooling allows for higher short-term loads

- Provides operational flexibility during peak demands

- Reduces need for oversized transformers

-

Improved efficiency at varying loads:

- Maintains optimal temperatures across load range

- Reduces no-load and load losses

- Enhances overall transformer efficiency

-

Extended maintenance intervals:

- Lower operating temperatures slow oil degradation

- Reduces frequency of oil changes and treatments

- Minimizes downtime for maintenance

In a recent grid upgrade project, our radiator tank transformers handled 20% higher peak loads while maintaining lower temperatures than their predecessors, significantly reducing the need for load shedding.

Operational Performance Comparison:

| Aspect | Standard Tank | Radiator Tank | Benefit |

|---|---|---|---|

| Max Overload Capacity | 120% for 2 hours | 150% for 2 hours | 25% higher overload capability |

| Efficiency at 50% Load | 98.2% | 98.7% | 0.5% efficiency gain |

| Oil Change Interval | 7 years | 12 years | 71% longer service interval |

| Annual Downtime | 48 hours | 24 hours | 50% reduction in maintenance time |

Radiator oil tanks represent a significant advancement in transformer technology. Their ability to enhance cooling efficiency, extend transformer lifespan, and prevent overheating makes them an invaluable asset in modern power distribution systems. While they may have a slightly higher initial cost, the benefits in performance, reliability, and reduced maintenance often result in lower total cost of ownership.

However, it’s important to note that radiator designs are not a one-size-fits-all solution. Factors such as transformer size, load profile, and environmental conditions should be carefully considered when choosing between standard and radiator tanks. In my experience, radiator tanks show the most benefit in medium to large transformers, particularly in applications with high or variable loads.

As we continue to push for more efficient and reliable power infrastructure, radiator oil tanks are likely to play an increasingly important role in transformer design. Their ability to maintain optimal operating conditions aligns perfectly with the demands of modern electrical grids, where reliability and efficiency are paramount.

Conclusion

Radiator oil tanks significantly enhance transformer cooling, extending lifespan and preventing overheating. While they offer substantial benefits for medium to large transformers, proper application consideration is crucial. Their role in improving power distribution efficiency and reliability makes them a key technology for modern electrical infrastructure.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group