Auto Transformers 101: Understanding the Backbone of Modern Power Distribution?

Are you puzzled by the complexities of power distribution systems? You’re not alone. Many people find electrical systems confusing, but understanding auto transformers can unlock the mysteries of modern power distribution.

Auto transformers are essential components in power systems that efficiently regulate voltage using a single winding. They’re like the unsung heroes of our electrical grid, ensuring stable power delivery while saving space and energy.

In my 20 years as an electrical engineer, I’ve seen auto transformers revolutionize power systems. This guide will walk you through everything you need to know, from basics to advanced applications. Whether you’re a curious beginner or a seasoned professional, you’ll find valuable insights here.

What is an Auto Transformer? A Simple Introduction?

Imagine trying to fill a water bottle from a fire hydrant. That’s the challenge power companies face when delivering electricity to your home. Auto transformers are the solution to this problem.

An auto transformer is a special type of transformer that uses a single winding to adjust voltage levels. It’s like having a universal adapter for electricity, making it possible to "step down" high voltages for safe home use or "step up" lower voltages for efficient power transmission.

Let’s break it down with a simple analogy:

Think of an auto transformer as a long garden hose with multiple taps along its length. The water pressure (voltage) at each tap is different, but it’s all part of the same hose (winding). By choosing different taps, you can get the exact "pressure" you need.

Key components:

- Single Winding: The "hose" that carries electricity.

- Taps: "Outlets" at different points on the winding.

- Core: A metal center that helps direct the electrical energy.

Here’s a simple comparison between auto transformers and regular transformers:

| Feature | Auto Transformer | Regular Transformer |

|---|---|---|

| Windings | One | Two separate |

| Size | Compact | Larger |

| Efficiency | Higher for small changes | Lower for small changes |

| Cost | Lower | Higher |

| Best Use | Small voltage adjustments | Large voltage changes |

The Inner Workings: How Auto Transformers Operate?

Have you ever wondered how auto transformers actually work their magic? Let’s demystify the process.

Auto transformers work by electromagnetic induction, just like regular transformers. The key difference is that they use parts of the same winding for both input and output, allowing for more efficient power transfer.

Here’s a step-by-step breakdown:

- Electricity enters the winding, creating a magnetic field.

- This field induces voltage throughout the entire winding.

- By selecting different taps, we can "pick" the voltage we need.

Imagine a slide at a playground. The higher you start (input voltage), the faster you go at the bottom (output voltage). By choosing different starting points (taps), you control the outcome.

Mathematical Insight (for the technically inclined):

The voltage ratio in an auto transformer is determined by the number of turns between taps. If N₁ is the total number of turns and N₂ is the number of turns between taps:

V₁/V₂ = N₁/N₂

Where V₁ is the input voltage and V₂ is the output voltage.

Key Components of an Auto Transformer Explained?

Understanding the parts of an auto transformer is like knowing the ingredients of your favorite recipe. Each component plays a crucial role.

An auto transformer consists of a winding, core, taps, and terminals. These work together to efficiently transform voltage levels while maintaining a compact design.

Let’s explore each part:

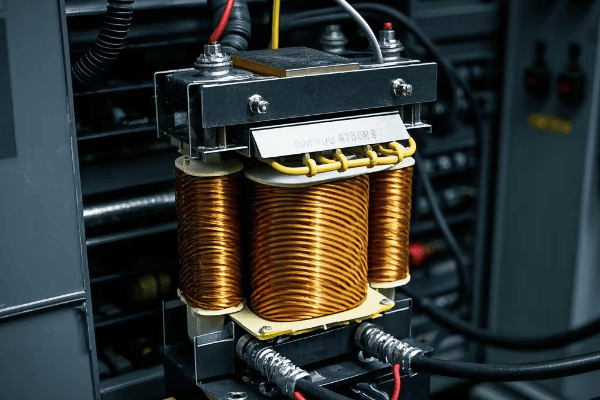

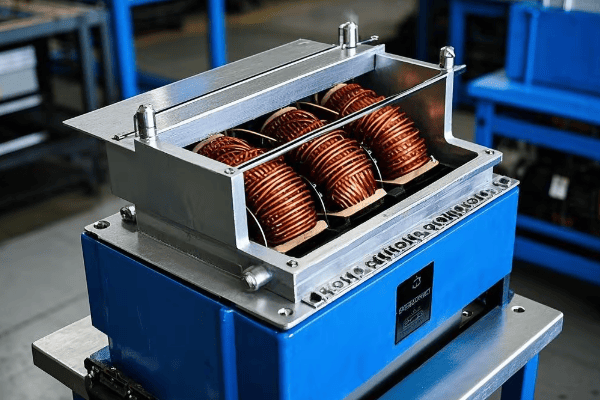

-

Winding:

- The "heart" of the transformer.

- A long coil of copper wire.

- Carries the electrical current.

-

Core:

- Usually made of laminated steel sheets.

- Directs the magnetic field.

- Reduces energy losses.

-

Taps:

- Connection points along the winding.

- Allow for different voltage ratios.

- Like choosing different gears on a bike.

-

Terminals:

- Connection points for external circuits.

- Where power goes in and comes out.

-

Insulation:

- Prevents short circuits.

- Manages heat.

Here’s a table summarizing the components and their functions:

| Component | Function | Analogy |

|---|---|---|

| Winding | Carries current | The water in a hose |

| Core | Directs magnetic field | The hose itself |

| Taps | Select voltage | Faucets along the hose |

| Terminals | Connect to circuits | The nozzle and source |

| Insulation | Prevents shorts | The hose’s rubber coating |

Auto Transformers vs. Traditional Transformers: A Comparison?

Choosing between an auto transformer and a traditional transformer can be tricky. Let’s compare them to help you make the right choice.

Auto transformers excel in efficiency and size for small voltage changes, while traditional transformers offer better isolation and flexibility for large voltage differences.

Key differences:

-

Design:

- Auto: Single winding with taps.

- Traditional: Separate primary and secondary windings.

-

Size:

- Auto: Compact.

- Traditional: Larger.

-

Efficiency:

- Auto: Higher for small voltage changes (up to 99%).

- Traditional: Lower for small changes (95-98%).

-

Isolation:

- Auto: Limited electrical isolation.

- Traditional: Complete electrical isolation.

-

Cost:

- Auto: Lower for small voltage ratios.

- Traditional: Higher overall.

Real-world example:

I once worked on a project where space was tight. By using an auto transformer instead of a traditional one, we reduced the transformer footprint by 40% while maintaining the same power output.

Here’s a comparison table:

| Feature | Auto Transformer | Traditional Transformer |

|---|---|---|

| Size | Smaller | Larger |

| Efficiency (small changes) | 98-99% | 95-98% |

| Electrical Isolation | Limited | Complete |

| Best for Voltage Ratios | Close to 1:1 | Any ratio |

| Initial Cost | Lower for small changes | Higher |

| Typical Applications | Voltage regulation | Wide range transformations |

Choose an auto transformer when:

- You need small voltage adjustments.

- Space is limited.

- High efficiency is crucial.

Choose a traditional transformer when:

- You need large voltage changes.

- Electrical isolation is essential.

- You’re dealing with high fault currents.

Efficiency Matters: The Benefits of Auto Transformers in Power Systems?

In the world of power distribution, efficiency is king. Auto transformers wear the crown when it comes to small voltage adjustments.

Auto transformers can achieve efficiency ratings up to 99% for small voltage changes. This high efficiency translates to reduced energy losses, lower operational costs, and a smaller environmental footprint.

Let’s break down the efficiency benefits:

-

Reduced Losses:

- Less copper used means lower resistance losses.

- Smaller core results in reduced core losses.

-

Energy Savings:

- Higher efficiency means less wasted energy.

- Can lead to significant cost savings over time.

-

Environmental Impact:

- Less energy waste means reduced carbon emissions.

- More efficient use of resources in manufacturing.

Real-world Impact:

In a recent factory upgrade, replacing traditional transformers with auto transformers led to:

- 2% increase in overall system efficiency

- 140,000 kWh annual energy savings

- $14,000 reduction in yearly energy costs

Efficiency Comparison:

| Voltage Change | Auto Transformer Efficiency | Traditional Transformer Efficiency |

|---|---|---|

| 5% | 99.5% | 98% |

| 10% | 99% | 97.5% |

| 20% | 98% | 97% |

| 50% | 96% | 96% |

For small voltage changes, the efficiency advantage of auto transformers is clear. This makes them ideal for applications like voltage regulation in power distribution systems.

Common Applications of Auto Transformers in Industry and Infrastructure?

Auto transformers are versatile devices found in many industries. Let’s explore where they make the biggest impact.

Auto transformers are widely used in power distribution, industrial processes, transportation systems, and even some consumer electronics. They excel in applications requiring efficient voltage regulation and power factor correction.

Key application areas:

-

Power Distribution:

- Voltage regulation in substations

- Compensating for voltage drops in long lines

-

Industrial Processes:

- Motor starting (reducing inrush current)

- Welding equipment (adjusting voltage for different processes)

- Furnace control (precise voltage regulation)

-

Transportation:

- Railway electrification

- Electric vehicle charging stations

-

Renewable Energy:

- Grid integration for solar and wind power

-

Testing and Measurement:

- Laboratory power supplies

- Calibration equipment

Case Study: Rural Power Stabilization

In a recent project, we used auto transformers to solve voltage fluctuation issues in a rural area:

- Problem: 15% voltage fluctuation causing equipment failures

- Solution: Strategically placed auto transformers along the distribution line

- Result: Reduced fluctuations to 3%, improving power quality and reliability

Application Summary Table:

| Industry | Application | Benefit of Auto Transformer |

|---|---|---|

| Power Distribution | Voltage regulation | Stable power supply |

| Manufacturing | Motor starting | Reduced equipment stress |

| Transportation | EV charging | Efficient power conversion |

| Renewable Energy | Grid integration | Smooth power feed-in |

| R&D | Variable voltage source | Precise control for testing |

Safety Considerations: Best Practices for Auto Transformer Usage?

Safety is paramount when working with any electrical equipment, especially auto transformers. Let’s review key safety practices.

Auto transformers require specific safety precautions due to their lack of electrical isolation. Proper grounding, overcurrent protection, and regular maintenance are essential for safe operation.

Essential safety practices:

-

Proper Grounding:

- Ensure the transformer chassis is well-grounded.

- Implement a robust grounding system for the entire installation.

-

Overcurrent Protection:

- Install appropriately sized circuit breakers or fuses.

- Consider the potential for higher fault currents in auto transformers.

-

Regular Maintenance:

- Conduct visual inspections for signs of wear or damage.

- Perform insulation resistance tests annually.

-

Temperature Monitoring:

- Install temperature sensors to detect overheating.

- Implement automatic shutdown for excessive temperatures.

-

Personnel Training:

- Educate staff on proper operation and safety procedures.

- Conduct regular safety refresher courses.

Safety Checklist:

| Safety Aspect | Action | Frequency |

|---|---|---|

| Grounding | Check connections | Monthly |

| Overcurrent Protection | Test breakers/fuses | Quarterly |

| Insulation | Perform resistance test | Annually |

| Temperature | Monitor hot spots | Continuously |

| Visual Inspection | Check for damage | Weekly |

| Staff Training | Conduct safety courses | Annually |

Remember: Safety is not just about following rules; it’s about creating a culture of awareness and responsibility.

Sizing and Selection: Choosing the Right Auto Transformer for Your Needs?

Selecting the right auto transformer is crucial for optimal performance and longevity. Let’s walk through the key factors to consider.

Choosing the correct auto transformer involves considering voltage ratio, power rating, efficiency requirements, cooling method, and environmental factors. The right choice depends on your specific application and operating conditions.

Key selection factors:

-

Voltage Ratio:

- Determine required input and output voltages.

- Consider future voltage change needs.

-

Power Rating:

- Calculate maximum load requirements.

- Add 20-30% for future expansion.

-

Efficiency:

- Consider losses at expected load levels.

- Higher efficiency models may cost more upfront but save in the long run.

-

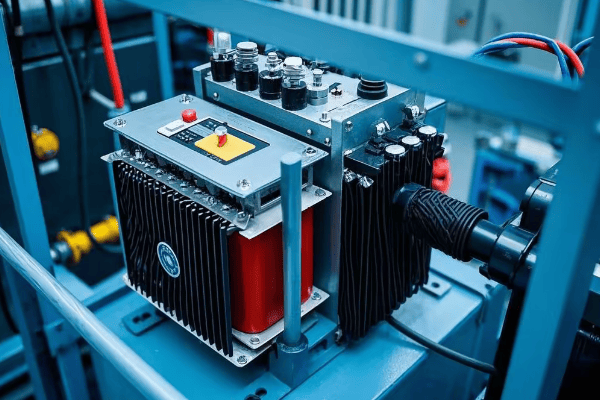

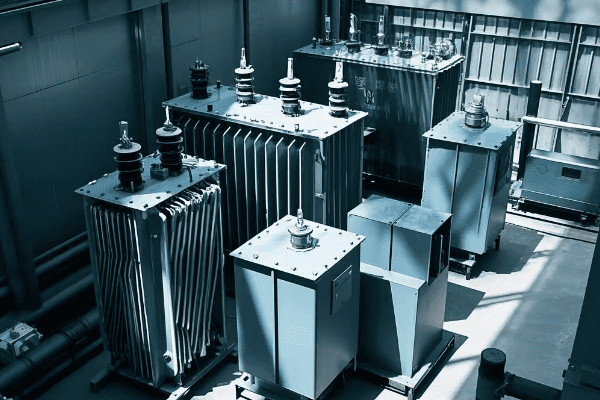

Cooling Method:

- Air-cooled for most indoor applications.

- Oil-immersed for outdoor or high-capacity needs.

-

Environmental Factors:

- Temperature range of installation location.

- Humidity and altitude considerations.

Selection Process:

-

Define Requirements:

- List all electrical and environmental needs.

-

Calculate Load:

- Determine max load and factor in growth.

-

Consider Environment:

- Assess installation location conditions.

-

Evaluate Options:

- Compare models based on your criteria.

-

Consult Experts:

- Seek advice from manufacturers or engineers.

-

Review Specifications:

- Carefully examine technical details.

-

Consider Total Cost:

- Factor in efficiency and maintenance, not just initial price.

Selection Matrix:

| Factor | Options | Considerations |

|---|---|---|

| Voltage Ratio | Fixed / Variable | Future flexibility needs |

| Power Rating | VA range | Current and future loads |

| Efficiency | Standard / High | Operating costs vs. initial investment |

| Cooling | Air / Oil | Environment and capacity |

| Enclosure | Indoor / Outdoor | Installation location |

Pro Tip: Always plan for future growth. I once worked with a client who underestimated their power needs and had to replace their transformers within two years. Proper sizing from the start could have saved them significant costs.

Conclusion

Auto transformers are powerful tools that form the backbone of modern power distribution systems. Their efficiency, compact size, and versatility make them indispensable in various applications. By understanding their principles, benefits, and proper usage, you can make informed decisions to optimize your electrical systems. Remember to prioritize safety and proper maintenance for long-term reliability and performance.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group