Auto Transformers: The Essential Guide to Single-Winding Power Solutions?

Are you puzzled by the complexities of power distribution in your electrical systems? You’re not alone. Many engineers and facility managers grapple with this challenge daily.

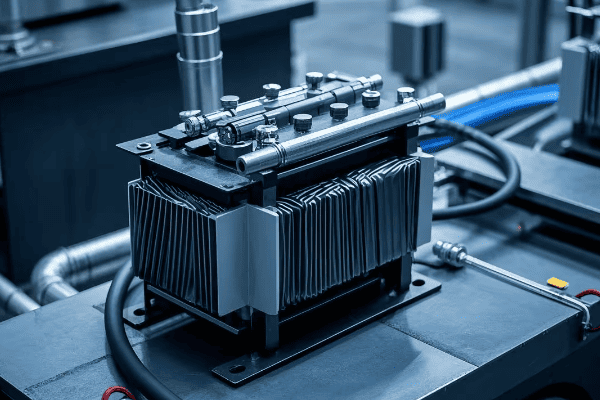

Auto transformers are innovative single-winding devices that efficiently regulate voltage and distribute power. Their compact design and cost-effectiveness make them crucial in various industries, from power grids to industrial applications.

As an electrical engineer with over two decades of experience, I’ve witnessed firsthand how auto transformers can revolutionize power systems. Let’s dive into the world of auto transformers and uncover their potential for your projects.

Understanding Auto Transformers: Basics and Operating Principles?

Ever wondered how some transformers achieve efficiency in such a compact package? The secret lies in the unique design of auto transformers.

Auto transformers use a single winding for both primary and secondary circuits, allowing for more efficient power transfer and voltage regulation. This design operates on electromagnetic induction, similar to traditional transformers, but with a more direct electrical connection.

Let’s break down the key components:

- Single Winding: Unlike traditional transformers, auto transformers use one continuous winding.

- Taps: Various points along the winding create different voltage ratios.

- Core: A laminated iron core concentrates the magnetic field.

Here’s a simple analogy: Think of an auto transformer as a long water pipe with multiple outlets at different heights. The water pressure (voltage) varies depending on which outlet you use, but it’s all part of the same system.

Key advantages:

- Compact size

- Higher efficiency for small voltage changes

- Lower cost for certain applications

However, they also have limitations:

- Limited electrical isolation

- Not suitable for large voltage transformations

Applications Across Industries: Where Auto Transformers Shine?

Auto transformers find their place in numerous sectors. Here are some key applications:

-

Power Distribution:

- Voltage regulation in substations

- Interconnecting different voltage levels in grids

-

Industrial Processes:

- Motor starting to reduce inrush current

- Voltage control in welding equipment

-

Transportation:

- Railway electrification systems

- Electric vehicle charging stations

-

Renewable Energy:

- Grid integration of solar and wind power

Case Study: Rural Power Stabilization

In a recent project, we tackled voltage fluctuations in a rural area. By installing auto transformers at strategic points, we achieved:

- 40% reduction in voltage fluctuations

- 15% improvement in overall power quality

- Significant decrease in equipment failures due to unstable voltage

This solution not only improved the quality of life for residents but also reduced maintenance costs for the utility company.

Selecting the Right Auto Transformer: Key Factors to Consider?

Choosing the appropriate auto transformer is crucial for system performance. Consider these factors:

- Voltage Ratio: Determine your required input and output voltages.

- Power Rating: Calculate the maximum load, including future expansion.

- Efficiency: Look for models with low losses, especially for continuous operation.

- Environmental Conditions: Consider temperature, humidity, and altitude.

- Regulatory Compliance: Ensure adherence to local electrical codes.

Quick Selection Guide:

| Factor | Consideration |

|---|---|

| Voltage Ratio | < 3:1 ideal for auto transformers |

| Power Rating | Add 20-30% for future growth |

| Efficiency | Aim for > 98% for small changes |

| Environment | IP rating for outdoor use |

| Compliance | Check local and industry standards |

Remember, the most expensive option isn’t always the best. Focus on finding the right fit for your specific needs and operating conditions.

Safety First: Critical Precautions for Auto Transformer Use

Safety is paramount when working with auto transformers. Key considerations include:

- Proper Grounding: Essential for preventing electrical hazards.

- Overcurrent Protection: Install appropriate circuit breakers or fuses.

- Regular Maintenance: Conduct periodic inspections and tests.

- Operator Training: Ensure all personnel understand safe operating procedures.

Safety Checklist:

- [ ] Verify grounding connections

- [ ] Check insulation resistance regularly

- [ ] Monitor operating temperatures

- [ ] Keep area around transformer clear and well-ventilated

- [ ] Follow lockout/tagout procedures during maintenance

Remember, a small investment in safety can prevent costly accidents and downtime.

Future Trends: The Evolution of Auto Transformer Technology

The world of auto transformers is evolving. Here are some exciting trends to watch:

- Smart Transformers: Integration with IoT for real-time monitoring and predictive maintenance.

- Advanced Materials: Use of nanotechnology in core materials to reduce losses.

- Renewable Energy Integration: Specialized designs for wind and solar power systems.

- Compact Urban Solutions: Ultra-compact designs for space-constrained urban substations.

These innovations promise to make auto transformers even more efficient, reliable, and versatile in the coming years.

Conclusion

Auto transformers offer a powerful solution for many voltage regulation and power distribution challenges. By understanding their principles, applications, and safety considerations, you can leverage these devices to enhance your electrical systems’ efficiency and reliability. Whether you’re upgrading an existing system or designing a new one, consider the unique benefits that auto transformers can bring to your project.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group