Auto Transformers Unveiled: Efficiency, Safety, and Practical Applications?

Are you struggling to understand the complexities of power distribution systems? You’re not alone. Many engineers and technicians find auto transformers confusing, but they’re essential for modern electrical grids.

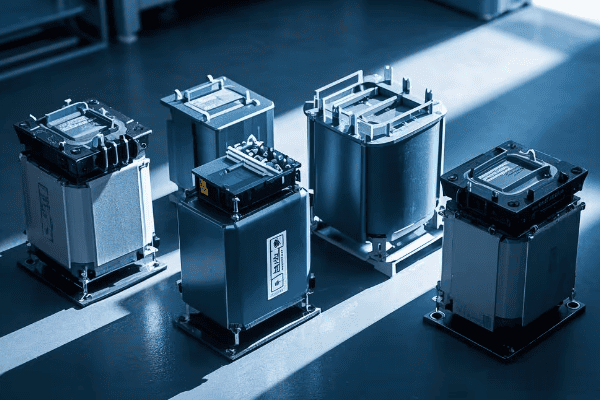

Auto transformers are key components in power systems that efficiently regulate voltage using a single winding. They’re crucial for maintaining stable power delivery while saving space and energy in various applications across industries.

In my 20 years as an electrical engineer, I’ve seen auto transformers revolutionize power systems. This guide will walk you through everything you need to know about auto transformers, from basic principles to practical applications and safety considerations. Whether you’re a curious beginner or a seasoned professional, you’ll find valuable insights here.

The Basics of Auto Transformers: How They Work and Why They Matter?

Imagine trying to fill a water bottle from a fire hydrant. That’s the challenge power companies face when delivering electricity to your home. Auto transformers are the solution to this problem.

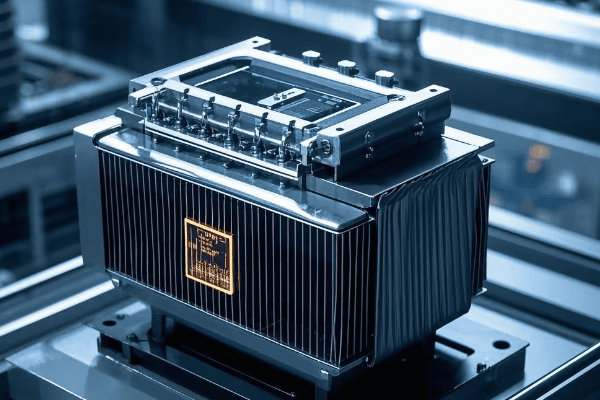

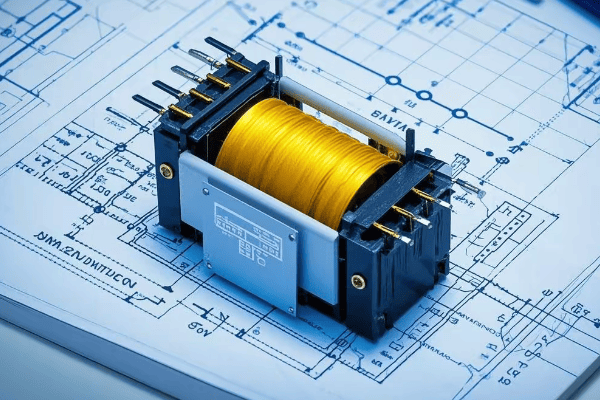

An auto transformer is a special type of transformer that uses a single winding to adjust voltage levels. It’s like having a universal adapter for electricity, making it possible to "step down" high voltages for safe home use or "step up" lower voltages for efficient power transmission.

Let’s break it down with a simple analogy:

Think of an auto transformer as a long garden hose with multiple taps along its length. The water pressure (voltage) at each tap is different, but it’s all part of the same hose (winding). By choosing different taps, you can get the exact "pressure" you need.

Key components:

- Single Winding: The "hose" that carries electricity.

- Taps: "Outlets" at different points on the winding.

- Core: A metal center that helps direct the electrical energy.

Here’s a simple comparison between auto transformers and regular transformers:

| Feature | Auto Transformer | Regular Transformer |

|---|---|---|

| Windings | One | Two separate |

| Size | Compact | Larger |

| Efficiency | Higher for small changes | Lower for small changes |

| Cost | Lower | Higher |

| Best Use | Small voltage adjustments | Large voltage changes |

Beginner’s Tip: Think of an auto transformer as a "smart" extension cord that can adjust the voltage to match your needs, whether you’re plugging in a lamp or a power tool.

Quiz: What’s the main advantage of an auto transformer over a regular transformer?

A) It’s larger

B) It’s more efficient for small voltage changes

C) It always costs more

D) It uses two separate windings

(Answer: B)

Efficiency Gains: Comparing Auto Transformers to Traditional Transformers?

Are you looking to optimize your power system’s efficiency? Auto transformers might be the solution you’re seeking, but how do they stack up against traditional transformers?

Auto transformers offer superior efficiency, especially for small voltage changes. They can achieve efficiency ratings up to 99%, compared to 95-98% for traditional transformers, leading to significant energy savings in power distribution systems.

Let’s dive into a real-world case study to illustrate these efficiency gains:

Case Study: Manufacturing Plant Upgrade

Location: Ontario, Canada

Challenge: High energy costs and limited space for electrical equipment

Before:

- 10 traditional transformers (500 kVA each)

- Average efficiency: 97%

- Annual energy loss: 1,314,000 kWh

- Floor space used: 100 m²

After (Auto Transformer Upgrade):

- 10 auto transformers (500 kVA each)

- Average efficiency: 99%

- Annual energy loss: 438,000 kWh

- Floor space used: 60 m²

Results:

- Energy savings: 876,000 kWh per year

- Cost savings: $87,600 per year (at $0.10/kWh)

- Space savings: 40 m²

- ROI: 2.5 years

This case study demonstrates the significant benefits of auto transformers in terms of energy efficiency, cost savings, and space utilization.

Efficiency Comparison Table:

| Voltage Change | Auto Transformer Efficiency | Traditional Transformer Efficiency |

|---|---|---|

| 5% | 99.5% | 98% |

| 10% | 99% | 97.5% |

| 20% | 98% | 97% |

| 50% | 96% | 96% |

As you can see, auto transformers excel in efficiency, especially for small voltage changes. This makes them ideal for applications like voltage regulation in power distribution systems.

Beginner’s Tip: Higher efficiency means less energy wasted as heat. This not only saves money but also reduces the need for cooling systems, further increasing overall system efficiency.

Quiz: In the case study, how much energy did the auto transformer upgrade save annually?

A) 438,000 kWh

B) 876,000 kWh

C) 1,314,000 kWh

D) 100,000 kWh

(Answer: B)

Safety First: Key Considerations When Working with Auto Transformers?

Safety is paramount when working with any electrical equipment, especially auto transformers. Are you aware of the potential risks and necessary precautions?

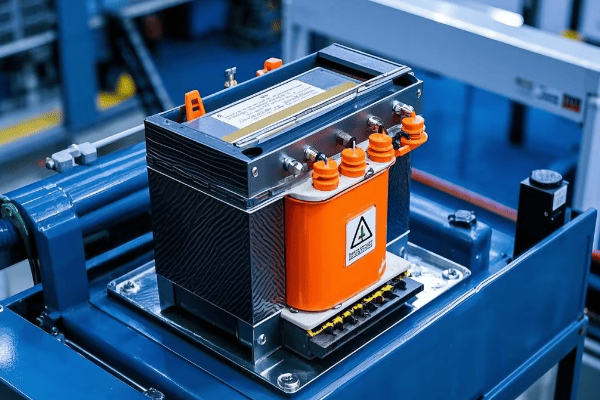

Auto transformers require specific safety measures due to their lack of electrical isolation. Key safety considerations include proper grounding, overcurrent protection, insulation maintenance, and adherence to electrical codes and standards.

Let’s explore essential safety practices through a real-world incident and its resolution:

Case Study: Near-Miss Incident at a Substation

Location: Texas, USA

Incident: Electrical arc flash during maintenance

Situation:

During routine maintenance of an auto transformer at a substation, an electrical arc flash occurred, narrowly missing a technician.

Root Causes:

- Inadequate grounding

- Worn insulation

- Lack of proper personal protective equipment (PPE)

Corrective Actions:

- Implemented comprehensive grounding procedures

- Established regular insulation testing schedule

- Upgraded PPE requirements for all personnel

- Conducted mandatory safety training sessions

Results:

- Zero incidents in the following 3 years

- 30% reduction in near-miss reports

- Improved safety culture among staff

Key Safety Measures:

-

Grounding:

- Ensure proper grounding of the auto transformer chassis.

- Implement a robust grounding system for the entire installation.

-

Overcurrent Protection:

- Install appropriately sized circuit breakers or fuses.

- Consider the potential for higher fault currents in auto transformers.

-

Insulation Maintenance:

- Regularly check insulation resistance.

- Replace or repair damaged insulation promptly.

-

Personal Protective Equipment (PPE):

- Use appropriate voltage-rated gloves and clothing.

- Wear safety glasses and face shields during maintenance.

-

Training and Procedures:

- Conduct regular safety training for all personnel.

- Develop and enforce clear safety procedures.

Safety Checklist:

| Safety Aspect | Action | Frequency |

|---|---|---|

| Grounding | Check connections, measure resistance | Monthly |

| Overcurrent Protection | Inspect and test breakers/fuses | Quarterly |

| Insulation | Perform insulation resistance test | Annually |

| PPE | Inspect and replace as needed | Before each use |

| Staff Training | Conduct safety training sessions | Annually |

Remember, safety is not just about following rules; it’s about creating a culture of awareness and responsibility.

Beginner’s Tip: Always treat auto transformers as live equipment. Never assume they are de-energized without proper verification.

Quiz: What is a key safety consideration specific to auto transformers?

A) They require more frequent oil changes

B) They have a lack of electrical isolation

C) They are always safe to touch

D) They only need grounding every five years

(Answer: B)

Practical Applications: Industries and Scenarios Where Auto Transformers Excel?

Auto transformers find applications across various industries due to their efficiency and compact design. But where do they truly shine?

Auto transformers are widely used in power distribution, industrial processes, transportation systems, and renewable energy integration. They excel in applications requiring efficient voltage regulation, power factor correction, and small voltage transformations.

Let’s explore a real-world application that showcases the versatility of auto transformers:

Case Study: Solar Farm Integration

Location: Arizona, USA

Challenge: Efficiently connecting a large solar farm to the grid

Situation:

A 100 MW solar farm needed to connect to the local power grid. The solar panels produced variable DC voltage that needed to be converted and stepped up to match the grid voltage.

Solution:

Implemented a system using auto transformers in conjunction with inverters:

- Inverters converted DC to AC

- Auto transformers adjusted voltage levels for grid compatibility

- Smart control systems managed voltage fluctuations

Results:

- 99.2% efficiency in power transmission

- 15% reduction in overall system losses compared to traditional methods

- Successful handling of voltage variations from 360V to 440V

- 30% reduction in substation footprint

This case study demonstrates how auto transformers can play a crucial role in renewable energy integration, offering efficiency and flexibility in managing variable power sources.

Key Application Areas:

-

Power Distribution:

- Voltage regulation in substations

- Compensation for voltage drops in long transmission lines

-

Industrial Processes:

- Motor starting (reducing inrush current)

- Welding equipment (adjusting voltage for different processes)

- Furnace control (precise voltage regulation)

-

Transportation Systems:

- Railway electrification

- Electric vehicle charging stations

-

Renewable Energy:

- Solar and wind farm grid integration

- Energy storage system connections

Application Summary Table:

| Industry | Application | Benefits of Auto Transformers |

|---|---|---|

| Power Distribution | Voltage regulation | Stable power supply, reduced losses |

| Manufacturing | Motor starting, welding | Reduced equipment stress, precise control |

| Transportation | Railway power, EV charging | Efficient power conversion, fast charging |

| Renewable Energy | Grid integration | Smooth power feed-in, high efficiency |

Beginner’s Tip: Auto transformers are like the Swiss Army knives of the electrical world – versatile tools that can handle a variety of voltage adjustment tasks efficiently.

Quiz: In the solar farm case study, what was the efficiency achieved in power transmission?

A) 95%

B) 97%

C) 99.2%

D) 100%

(Answer: C)

Conclusion

Auto transformers play a crucial role in modern power systems, offering efficiency, versatility, and adaptability. From power distribution to renewable energy integration, these devices are essential for maintaining stable and efficient electrical grids. By understanding their principles, applications, and safety considerations, we can harness the full potential of auto transformers to build more sustainable and reliable power systems for the future.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group