Choosing the Right Electrical Transformer Box for Your Project?

Are you struggling to select the perfect electrical transformer box for your project? You’re not alone. Many engineers and project managers find this decision challenging. The wrong choice can lead to inefficiency, safety issues, and costly replacements.

Choosing the right electrical transformer box involves assessing your project’s specific needs, understanding different types and applications, considering power and voltage requirements, evaluating environmental factors, and planning for long-term cost-effectiveness. The ideal transformer box balances current demands with future scalability and efficiency.

In this article, I’ll guide you through the process of selecting the best transformer box for your project. We’ll explore key factors to consider, different types and applications, sizing considerations, environmental factors, and long-term planning. Whether you’re working on a small residential project or a large industrial installation, this guide will help you make an informed decision.

Assessing Your Needs: Key Factors in Transformer Box Selection?

Have you ever felt overwhelmed by the sheer number of options when choosing a transformer box? It’s a common challenge. But what if you could narrow down your choices by focusing on the most critical factors for your project?

Assessing your needs for transformer box selection involves analyzing load requirements, voltage levels, installation environment, space constraints, and future expansion plans. Key factors include power capacity, input and output voltages, physical dimensions, cooling requirements, and compatibility with existing systems.

Diving Deeper into Transformer Box Selection Factors

Let’s break down the key factors you need to consider:

1. Load Requirements

Understanding your power needs is crucial:

- Calculate total connected load

- Consider peak demand and load factor

- Factor in potential future load increases

I once worked on a project where the client underestimated their future power needs. Within two years, they had to replace the transformer box, causing significant downtime and extra costs. This experience taught me the importance of thorough load analysis and future-proofing.

2. Voltage Considerations

Matching voltage levels is essential:

- Determine required input and output voltages

- Consider voltage regulation needs

- Evaluate harmonic distortion if applicable

3. Environmental Factors

The installation environment plays a big role:

- Indoor vs. outdoor installation

- Temperature and humidity ranges

- Exposure to contaminants or corrosive elements

4. Space Constraints

Physical limitations can dictate your options:

- Available floor or wall space

- Weight restrictions

- Accessibility for maintenance

Here’s a table summarizing key factors to consider:

| Factor | Considerations | Importance |

|---|---|---|

| Load Requirements | Total load, peak demand, future growth | Critical |

| Voltage Levels | Input/output voltages, regulation | High |

| Environment | Indoor/outdoor, temperature, contaminants | High |

| Space | Available area, weight limits, access | Moderate to High |

| Future Expansion | Scalability, upgradability | Moderate to High |

In my experience, one of the most overlooked aspects of transformer box selection is the consideration of harmonic loads. In a recent industrial project, we initially selected a standard transformer box. However, after a detailed analysis of the client’s equipment, we discovered significant harmonic currents. We had to switch to a K-rated transformer to handle these harmonics, avoiding potential overheating and efficiency losses.

Another crucial factor is the cooling system. I recall a project in a hot, dusty environment where the initial transformer box overheated frequently. We had to retrofit an advanced cooling system, which could have been avoided with proper initial selection. Now, I always carefully evaluate the cooling requirements based on the specific installation environment.

Scalability is becoming increasingly important in transformer box selection. In a recent data center project, we opted for a modular transformer system. This allowed the client to easily add capacity as their computing needs grew, without requiring a complete system overhaul.

The impact of renewable energy integration should not be underestimated. In a commercial building project with extensive solar panel installation, we had to select a transformer box capable of handling bidirectional power flow. This required careful consideration of the transformer’s design and protection systems.

Lastly, don’t forget about noise considerations, especially in urban or residential settings. I once worked on a project where we had to replace a transformer box due to noise complaints from nearby residents. Now, I always factor in noise levels and consider low-noise designs when necessary.

By carefully assessing these key factors, you can significantly narrow down your options and choose a transformer box that not only meets your current needs but also provides flexibility for the future. Remember, the right choice now can save you from headaches and expenses down the road.

Types and Applications: Matching Transformer Boxes to Project Requirements?

Are you confused about which type of transformer box is best suited for your specific project? You’re not alone. The variety of transformer types can be overwhelming, but matching the right one to your project is crucial for optimal performance and efficiency.

Different transformer box types suit various applications. Dry-type transformers are ideal for indoor, moisture-sensitive environments. Oil-filled transformers are better for outdoor, high-capacity needs. Pad-mounted transformers work well in urban settings, while pole-mounted types are common in rural areas. Selecting the right type depends on your project’s specific requirements.

Exploring Transformer Box Types and Their Applications

Let’s break down the main types of transformer boxes and their ideal applications:

1. Dry-Type Transformers

Characteristics and applications:

- No liquid insulation, uses air cooling

- Ideal for indoor installations, especially in buildings

- Commonly used in commercial and light industrial settings

I once worked on a hospital renovation project where we chose dry-type transformers for their fire safety advantages. The absence of oil made them a perfect fit for the sensitive healthcare environment.

2. Oil-Filled Transformers

Features and best uses:

- Use oil for insulation and cooling

- Suitable for outdoor installations and higher capacities

- Common in utility and heavy industrial applications

3. Pad-Mounted Transformers

Attributes and applications:

- Ground-level installation, often in urban areas

- Enclosed in a tamper-resistant housing

- Used in residential and commercial distribution systems

4. Pole-Mounted Transformers

Characteristics and typical uses:

- Mounted on utility poles

- Common in rural and suburban areas

- Used for residential and light commercial power distribution

Here’s a comparison table of different transformer types:

| Type | Environment | Capacity Range | Maintenance | Best For |

|---|---|---|---|---|

| Dry-Type | Indoor | Up to 35 kV | Low | Commercial buildings, hospitals |

| Oil-Filled | Outdoor | Up to 765 kV | Moderate | Utilities, heavy industry |

| Pad-Mounted | Outdoor (ground) | Up to 35 kV | Moderate | Urban residential, commercial |

| Pole-Mounted | Outdoor (elevated) | Up to 35 kV | Moderate | Rural, suburban distribution |

In my experience, selecting the right type of transformer box can make a significant difference in project success. I recall a project for a data center where we initially considered oil-filled transformers for their higher capacity. However, after assessing the fire risk and indoor installation requirements, we opted for high-capacity dry-type transformers. This decision not only met the power needs but also aligned with the facility’s stringent fire safety regulations.

Another important consideration is the environmental impact. In an eco-sensitive project near a water source, we chose dry-type transformers over oil-filled ones to eliminate the risk of oil leaks. This decision, while slightly more expensive initially, provided long-term environmental protection and peace of mind for the client.

The choice between pad-mounted and pole-mounted transformers often comes down to aesthetics and space constraints. In a recent urban renewal project, we replaced old pole-mounted transformers with pad-mounted units. This not only improved the visual appeal of the neighborhood but also allowed for easier maintenance access.

For industrial applications with high harmonic loads, such as those with many variable frequency drives, special consideration is needed. I’ve found that specifying K-rated dry-type transformers or using special oil-filled designs can effectively handle these challenging load profiles.

In areas prone to severe weather, the choice of transformer type can affect system reliability. For a coastal project subject to hurricanes, we selected specially designed pad-mounted transformers with enhanced waterproofing and wind resistance. This choice significantly improved the resilience of the local power distribution system.

Lastly, the trend towards renewable energy integration is influencing transformer selection. In a recent solar farm project, we used specially designed oil-filled transformers capable of handling the variable output of the solar arrays. These transformers included advanced monitoring systems to manage the bidirectional power flow effectively.

By understanding the characteristics and ideal applications of different transformer types, you can make an informed decision that aligns with your project’s specific needs. Remember, the right transformer type not only meets your current requirements but also provides the flexibility and efficiency needed for future demands.

Power and Voltage Considerations: Sizing Your Transformer Box Correctly?

Are you worried about under or oversizing your transformer box? It’s a common concern, and for good reason. Incorrect sizing can lead to inefficiency, increased costs, and even system failures. But how do you determine the right size for your needs?

Correctly sizing a transformer box involves calculating total load demand, considering power factor, and accounting for future growth. Key factors include kVA rating, primary and secondary voltages, and expected load profile. Proper sizing ensures efficient operation, prevents overheating, and allows for potential expansion.

Diving into Power and Voltage Considerations

Let’s explore the key aspects of sizing your transformer box:

1. Load Calculation

Accurate load assessment is crucial:

- Sum up the power requirements of all connected equipment

- Consider diversity factor (not all loads operate simultaneously)

- Factor in potential future load increases

I once worked on a project where we initially undersized the transformer based on connected load alone. After implementing proper load calculation techniques, including diversity factors, we were able to select a more appropriate and cost-effective transformer size.

2. Power Factor Consideration

Power factor affects transformer sizing:

- Lower power factor requires larger transformer capacity

- Consider power factor correction if necessary

- Understand the nature of the loads (resistive, inductive, capacitive)

3. Voltage Requirements

Matching voltage levels is essential:

- Determine required primary and secondary voltages

- Consider voltage regulation needs

- Account for any step-up or step-down requirements

4. Efficiency and Losses

Consider transformer efficiency:

- Evaluate no-load and full-load losses

- Consider energy efficiency standards and regulations

- Balance initial cost with long-term energy savings

Here’s a table summarizing key sizing considerations:

| Factor | Consideration | Impact on Sizing |

|---|---|---|

| Total Load | Sum of all connected equipment | Directly affects kVA rating |

| Diversity Factor | Not all loads operate at once | Allows for smaller sizing |

| Power Factor | Relationship between real and apparent power | Lower PF requires larger size |

| Voltage Levels | Primary and secondary voltage requirements | Determines transformer ratio |

| Future Growth | Anticipated load increases | May require oversizing |

In my experience, one of the most common mistakes in transformer sizing is failing to account for harmonic loads. In a recent industrial project, we initially sized the transformer based on standard calculations. However, after conducting a harmonic analysis, we discovered that the high harmonic content required a 20% increase in transformer capacity to prevent overheating.

Another crucial aspect is considering the starting current of large motors. I recall a water treatment plant project where the initial transformer size was inadequate to handle the inrush current of large pump motors. We had to upsize the transformer and implement soft starters to manage these high starting currents effectively.

The impact of non-linear loads, such as variable frequency drives and LED lighting, on transformer sizing is often underestimated. In a modern office building project, we had to specify a K-rated transformer to handle the harmonic loads generated by the abundance of electronic equipment. This decision prevented potential overheating and efficiency losses.

Climate considerations also play a role in transformer sizing. In a project located in an extremely hot environment, we had to oversize the transformer slightly to account for the reduced cooling efficiency. This approach ensured reliable operation even during the hottest months of the year.

The trend towards electric vehicle (EV) charging is introducing new challenges in transformer sizing. In a recent residential development project, we had to factor in the potential widespread adoption of EV charging. This led us to choose a larger transformer size with the capability to handle future load growth from EV chargers.

Lastly, the integration of renewable energy sources can significantly impact transformer sizing. In a project involving a large solar installation, we had to carefully size the transformer to handle both the building’s load and the potential power backfeed from the solar array. This required a bi-directional capable transformer with specific protection features.

By carefully considering these power and voltage factors, you can ensure that your transformer box is correctly sized for your current needs while also providing flexibility for future growth. Remember, proper sizing is not just about meeting immediate demands – it’s about creating a robust and efficient electrical system for the long term.

Environmental and Safety Factors: Choosing a Transformer Box for Optimal Performance?

Have you considered how environmental conditions and safety requirements might affect your transformer box choice? Many people overlook these crucial factors, leading to performance issues and potential hazards. But how do you ensure your transformer box is both safe and optimally performing in its specific environment?

Choosing a transformer box for optimal performance involves considering environmental factors like temperature, humidity, altitude, and exposure to contaminants. Safety considerations include fire resistance, noise levels, and compliance with local regulations. The right choice balances these factors to ensure reliability, efficiency, and safety in the specific installation environment.

Exploring Environmental and Safety Considerations

Let’s delve into the key environmental and safety factors for transformer box selection:

1. Temperature Considerations

Temperature greatly affects transformer performance:

- Consider ambient temperature range at the installation site

- Evaluate cooling requirements (air-cooled vs. oil-cooled)

- Factor in temperature rise under load

I once worked on a project in a desert climate where standard transformers were overheating. We had to specify custom-designed units with enhanced cooling systems to withstand the extreme temperatures.

2. Humidity and Moisture

Moisture can be a transformer’s enemy:

- Assess humidity levels and potential for condensation

- Consider sealed designs for high-humidity environments

- Evaluate need for dehumidifiers or moisture absorbers

3. Altitude Effects

High altitude can impact transformer performance:

- Air density affects cooling efficiency

- May require derating at high altitudes

- Consider special designs for extreme elevations

4. Contaminants and Corrosion

Environmental pollutants can degrade transformers:

- Evaluate presence of corrosive elements (e.g., salt spray in coastal areas)

- Consider special coatings or enclosures for harsh environments

- Plan for regular maintenance in contaminated areas

5. Safety Considerations

Safety is paramount in transformer selection:

- Fire resistance ratings for indoor installations

- Noise levels for urban or residential areas

- Compliance with local electrical codes and standards

Here’s a table summarizing environmental and safety considerations:

| Factor | Consideration | Potential Solution |

|---|---|---|

| High Temperature | Reduced cooling efficiency | Enhanced cooling systems |

| High Humidity | Risk of moisture ingress | Sealed designs, dehumidifiers |

| High Altitude | Reduced air density | Altitude-specific designs |

| Corrosive Environment | Accelerated degradation | Special coatings, enclosures |

| Fire Safety | Risk in indoor settings | Fire-resistant materials |

| Noise | Disturbance in urban areas | Low-noise designs, enclosures |

In my experience, one of the most overlooked aspects of environmental considerations is the impact of solar radiation. In a recent project in a high-altitude, sunny location, we found that direct sunlight was causing significant temperature increases in outdoor transformers. We had to implement special sun shields and reflective coatings to mitigate this issue.

Seismic activity is another critical factor in certain regions. I worked on a project in an earthquake-prone area where we had to specify transformers with enhanced structural reinforcement and special mounting systems. These modifications ensured the transformers could withstand potential seismic events without failure or oil leakage.

The challenge of wildlife interference is often underestimated. In a rural project, we encountered frequent issues with animals causing short circuits and damage to transformers. We implemented wildlife guards and strategically placed deterrents to protect the equipment while maintaining ecological balance.

In urban environments, electromagnetic interference (EMI) can be a significant concern. I recall a project near a sensitive research facility where we had to design custom shielding for the transformers to prevent EMI from affecting nearby equipment. This required careful coordination with the facility’s scientists to ensure their work remained unaffected.

Climate change is increasingly influencing transformer design and selection. In a coastal project, we had to factor in potential sea-level rise and increased storm intensity. This led to selecting transformers with enhanced waterproofing and elevated installations to ensure long-term reliability.

Lastly, the growing focus on environmental sustainability is shaping transformer choices. In a recent green building project, we specified biodegradable transformer oil and implemented an advanced oil containment system. This not only met stringent environmental regulations but also aligned with the client’s sustainability goals.

When considering environmental and safety factors, it’s crucial to think long-term. A transformer that performs well in current conditions may struggle as environmental factors change over time. For instance, in an area experiencing increasing temperatures due to climate change, we’ve started specifying transformers with higher temperature ratings and more efficient cooling systems to ensure they remain effective for their entire lifespan.

Another important consideration is the potential for natural disasters. In flood-prone areas, I’ve implemented elevated transformer installations and waterproof designs. Similarly, in regions susceptible to wildfires, we’ve used fire-resistant materials and created defensible spaces around transformer installations.

The issue of noise pollution is becoming increasingly important, especially in urban environments. In a recent project in a densely populated area, we had to use specially designed low-noise transformers and implement sound-absorbing enclosures to meet strict local noise regulations. This not only ensured compliance but also improved the quality of life for nearby residents.

Safety considerations extend beyond the transformer itself to maintenance and emergency procedures. I always emphasize the importance of clear signage, easy access for maintenance, and well-designed safety features like automatic shutoffs and fire suppression systems. In one industrial project, we implemented a remote monitoring system that could detect potential issues early, reducing the need for frequent on-site inspections in a hazardous environment.

By carefully considering these environmental and safety factors, you can select a transformer box that not only performs optimally in its specific environment but also ensures the safety of personnel and surrounding areas. Remember, a well-chosen transformer is one that operates efficiently, safely, and reliably throughout its entire lifecycle, regardless of environmental challenges.

Cost-Effectiveness and Future-Proofing: Long-Term Considerations in Transformer Box Selection?

Are you concerned about making a cost-effective choice that won’t become obsolete in a few years? It’s a common worry when selecting transformer boxes. How do you balance immediate budget constraints with long-term efficiency and adaptability?

Selecting a cost-effective and future-proof transformer box involves considering initial costs, operational efficiency, maintenance requirements, and potential for upgrades. Key factors include energy efficiency ratings, smart monitoring capabilities, scalability, and compatibility with emerging technologies. The goal is to minimize total cost of ownership while ensuring adaptability to future needs.

Exploring Long-Term Considerations in Transformer Selection

Let’s delve into the key aspects of cost-effectiveness and future-proofing:

1. Energy Efficiency

Efficiency directly impacts long-term costs:

- Look for high-efficiency models with low losses

- Consider the impact of efficiency on operating costs over time

- Evaluate payback period for higher-efficiency models

I once worked on a project where we chose a slightly more expensive, high-efficiency transformer. The energy savings paid for the price difference in just three years, providing significant cost benefits over the transformer’s lifespan.

2. Smart Monitoring and Diagnostics

Advanced monitoring can prevent costly failures:

- Consider transformers with built-in monitoring systems

- Look for predictive maintenance capabilities

- Evaluate compatibility with existing or planned smart grid systems

3. Scalability and Upgradability

Future-proofing often means planning for growth:

- Choose designs that allow for easy capacity upgrades

- Consider modular systems for flexibility

- Evaluate the potential for adding features like renewable energy integration

4. Total Cost of Ownership (TCO)

Look beyond the initial price tag:

- Calculate long-term energy costs

- Factor in maintenance and potential repair costs

- Consider the lifespan of the transformer

Here’s a table comparing factors affecting long-term costs:

| Factor | Impact on Cost | Consideration |

|---|---|---|

| Energy Efficiency | High | Lower operating costs over time |

| Smart Monitoring | Moderate | Reduced maintenance costs, improved reliability |

| Scalability | Moderate to High | Avoids costly replacements for expansion |

| Initial Cost | High | Must be balanced against long-term savings |

| Maintenance Requirements | Moderate | Regular maintenance can extend lifespan |

In my experience, one of the most overlooked aspects of cost-effectiveness is the impact of power quality on transformer lifespan. In a recent industrial project, we initially chose a standard transformer. However, after analyzing the harmonic-rich environment, we opted for a K-rated transformer. While more expensive upfront, this choice prevented premature failure and costly downtime, ultimately saving money in the long run.

The trend towards renewable energy integration is another crucial consideration for future-proofing. I worked on a commercial building project where we selected a transformer with bi-directional power flow capabilities. This foresight allowed for easy integration of rooftop solar panels years later without needing to replace the transformer.

Adaptability to smart grid technologies is becoming increasingly important. In a recent urban development project, we chose transformers with advanced communication capabilities. This allowed for seamless integration with the city’s smart grid initiative, providing benefits like real-time load management and improved outage response.

The potential for regulatory changes should also be considered. I’ve seen cases where transformers became non-compliant due to new efficiency standards. Now, I always recommend selecting transformers that not only meet but exceed current standards to ensure long-term compliance and avoid costly early replacements.

Environmental considerations can significantly impact long-term costs. In a project near an environmentally sensitive area, we chose a transformer with biodegradable oil. While more expensive initially, this decision prevented potential environmental cleanup costs and aligned with the client’s sustainability goals.

Lastly, the importance of proper sizing for cost-effectiveness cannot be overstated. I’ve seen many cases where oversized transformers led to unnecessary capital expenditure and ongoing efficiency losses. Conversely, undersized units often require premature replacement. Careful load analysis and growth projections are crucial for selecting the right size that balances current needs with future expansion.

By carefully considering these long-term factors, you can select a transformer box that not only meets your immediate needs but also provides cost-effective and adaptable service for years to come. Remember, the cheapest option upfront isn’t always the most economical in the long run. Investing in efficiency, adaptability, and quality can lead to significant savings and improved performance over the transformer’s lifetime.

Conclusion

Choosing the right electrical transformer box requires careful consideration of project needs, environmental factors, safety requirements, and long-term cost-effectiveness. By assessing these aspects thoroughly, you can select a transformer that ensures optimal performance, safety, and efficiency for your specific project, both now and in the future.

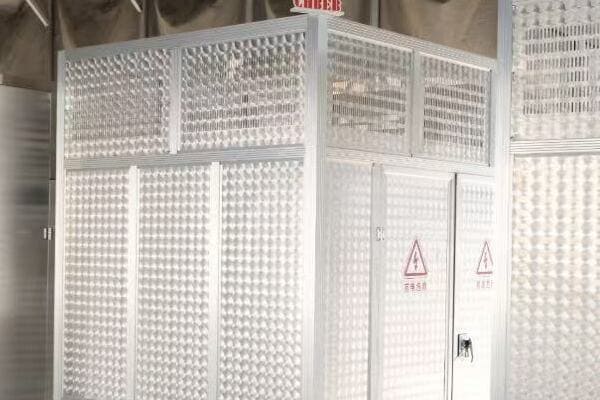

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group