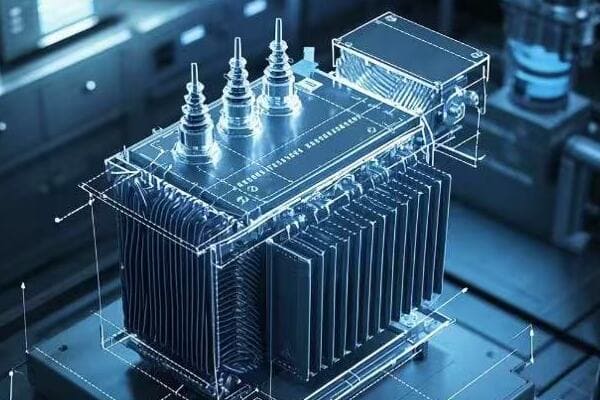

Designing Excellence: Key Considerations for Pad Mounted Transformers?

Have you ever wondered what goes into designing those green boxes you see in your neighborhood? These pad mounted transformers are crucial for power distribution, but their design is far from simple.

Designing pad mounted transformers involves careful consideration of voltage class, kVA rating, insulation systems, cooling methods, environmental factors, safety features, aesthetics, maintenance accessibility, smart grid compatibility, and regulatory compliance. Each aspect plays a vital role in creating efficient and reliable transformers.

As an electrical engineer with over 20 years of experience, I’ve seen firsthand how crucial proper design is for pad mounted transformers. These aren’t just metal boxes; they’re complex systems that require careful planning and expertise. Let’s dive into the key considerations that go into designing these essential components of our power distribution system.

Voltage Class Selection: Matching Distribution System Requirements?

Have you ever plugged a 110V appliance into a 220V outlet? The results can be disastrous. The same principle applies on a much larger scale when selecting the voltage class for pad mounted transformers.

Voltage class selection is crucial in pad mounted transformer design. It ensures the transformer can handle the primary distribution voltage and step it down to the required secondary voltage. Proper selection prevents equipment damage and ensures efficient power distribution.

Let’s explore the intricacies of voltage class selection:

Finding the Right Fit

-

Primary Voltage Considerations:

- Must match the distribution system voltage

- Typically ranges from 4.16 kV to 34.5 kV

-

Secondary Voltage Requirements:

- Determined by end-user needs

- Common levels include 120/240V for residential and 277/480V for commercial

-

Insulation Levels:

- Basic Impulse Level (BIL) must be appropriate for the voltage class

- Higher voltage classes require higher BIL ratings

I remember a project where we were upgrading a suburban area’s power distribution. The existing transformers were 15 kV class, but the utility was planning to upgrade their system to 25 kV in the near future. We decided to install 25 kV class transformers with dual voltage primaries. This foresight saved the utility from having to replace the transformers again in just a few years.

Here’s a comparison of common voltage classes:

| Voltage Class | Typical Primary Voltage | Common Applications | BIL Rating |

|---|---|---|---|

| 5 kV | 4160V | Small residential areas | 60 kV |

| 15 kV | 12470V | Residential and light commercial | 95 kV |

| 25 kV | 24940V | Suburban and rural distribution | 125 kV |

| 35 kV | 34500V | Heavy commercial and light industrial | 150 kV |

kVA Rating Determination: Balancing Capacity and Demand?

Have you ever tried to power your entire house with a single extension cord? It’s a recipe for disaster. Similarly, choosing the right kVA rating for a pad mounted transformer is crucial to meet power demands without overloading the system.

kVA rating determination involves analyzing current and future power needs of the area served. It requires balancing between having enough capacity for peak loads and avoiding oversized, inefficient transformers. Proper sizing ensures reliable power supply and cost-effective operation.

Let’s delve into the process of determining the right kVA rating:

Sizing Up Power Needs

-

Load Analysis:

- Study current power consumption patterns

- Consider future growth and development plans

-

Diversity Factor:

- Account for the fact that not all connected loads operate simultaneously

- Helps in avoiding oversizing

-

Load Factor:

- Ratio of average load to peak load

- Influences the transformer’s efficiency and lifespan

I once worked on a project for a new residential development. Initially, the developer wanted to install 500 kVA transformers throughout. After conducting a thorough load analysis and considering the area’s growth projections, we determined that a mix of 300 kVA and 500 kVA units would be more appropriate. This tailored approach saved on initial costs and improved overall system efficiency.

Here’s a breakdown of typical kVA ratings and their applications:

| kVA Rating | Typical Application | Estimated Number of Homes Served |

|---|---|---|

| 25-75 kVA | Rural residential | 1-10 homes |

| 100-167 kVA | Suburban residential | 10-30 homes |

| 300-500 kVA | Dense residential/Light commercial | 30-100 homes or small businesses |

| 750-2500 kVA | Heavy commercial/Light industrial | Shopping centers, small factories |

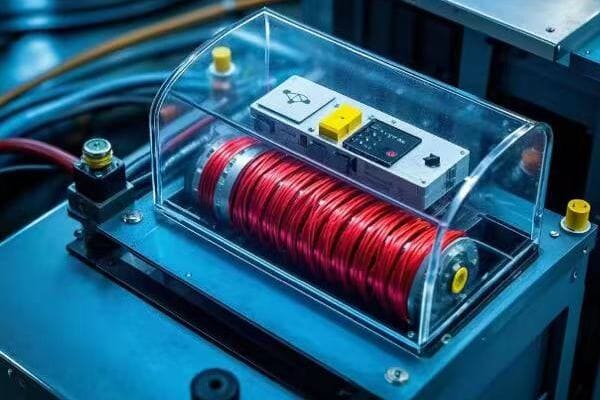

Insulation Systems: Ensuring Long-Term Reliability?

Have you ever wondered why transformers don’t short circuit despite the high voltages inside them? The answer lies in their insulation systems. Choosing the right insulation is crucial for the longevity and reliability of pad mounted transformers.

Insulation systems in pad mounted transformers prevent electrical breakdown and ensure long-term reliability. They involve selecting appropriate materials for both liquid and solid insulation, considering factors like dielectric strength, thermal stability, and environmental impact.

Let’s explore the key aspects of insulation systems:

Layers of Protection

-

Liquid Insulation:

- Typically mineral oil or natural ester fluids

- Provides both insulation and cooling

-

Solid Insulation:

- Materials like cellulose paper and pressboard

- Used for winding insulation and structural support

-

Insulation Coordination:

- Ensures proper distribution of electrical stress

- Prevents partial discharges and premature aging

I remember a project where we were designing transformers for a coastal area with high humidity and salt content in the air. We opted for a hybrid insulation system using natural ester fluid and upgraded solid insulation materials. This combination provided excellent moisture tolerance and extended the transformer’s expected lifespan by nearly 20%.

Here’s a comparison of common insulation materials:

| Insulation Type | Material | Advantages | Disadvantages |

|---|---|---|---|

| Liquid | Mineral Oil | High dielectric strength, Good heat transfer | Environmental concerns |

| Liquid | Natural Ester | Biodegradable, High fire point | Higher cost |

| Solid | Cellulose Paper | Good electrical properties, Cost-effective | Moisture sensitive |

| Solid | Nomex | High temperature resistance | Expensive |

Cooling Methods: Optimizing Performance and Efficiency?

Have you ever touched a transformer and felt how warm it is? Managing this heat is crucial for the transformer’s performance and lifespan. The choice of cooling method can make a significant difference in both efficiency and reliability.

Cooling methods in pad mounted transformers are essential for maintaining optimal operating temperatures. They range from natural oil circulation to forced air cooling, each with its own advantages. Proper cooling ensures efficient operation, extends transformer life, and prevents premature failures.

Let’s dive into the various cooling methods and their applications:

Keeping Cool Under Pressure

-

Oil Natural Air Natural (ONAN):

- Relies on natural convection of oil and air

- Suitable for smaller transformers in moderate climates

-

Oil Natural Air Forced (ONAF):

- Uses fans to enhance air cooling

- Increases cooling capacity without changing transformer size

-

Oil Forced Air Forced (OFAF):

- Employs pumps for oil circulation and fans for air cooling

- Used in larger transformers with higher heat generation

I once worked on a project in a hot, arid climate where standard ONAN cooling was insufficient. We implemented an ONAF system with temperature-controlled fans. This solution not only prevented overheating but also improved the transformer’s efficiency by allowing it to operate at optimal temperatures even during peak load times.

Here’s a comparison of cooling methods:

| Cooling Method | Heat Dissipation | Suitable for | Maintenance Needs |

|---|---|---|---|

| ONAN | Low | Small to medium transformers | Minimal |

| ONAF | Medium | Medium to large transformers | Regular fan maintenance |

| OFAF | High | Large transformers | Higher (pumps and fans) |

Environmental Factors: Designing for Diverse Climates and Conditions?

Have you ever wondered why the same transformer design isn’t used everywhere? From scorching deserts to freezing tundras, environmental factors play a crucial role in pad mounted transformer design.

Environmental factors significantly influence pad mounted transformer design. Considerations include temperature extremes, humidity levels, altitude, seismic activity, and pollution levels. Adapting designs to these factors ensures reliable operation and longevity in diverse climates and conditions.

Let’s explore how environmental factors shape transformer design:

Adapting to Nature’s Challenges

-

Temperature Extremes:

- Cold climates: Special low-temperature oil, heaters for start-up

- Hot climates: Enhanced cooling systems, heat-resistant materials

-

Humidity and Rainfall:

- Sealed designs to prevent moisture ingress

- Corrosion-resistant materials and coatings

-

Altitude Considerations:

- Reduced air density affects cooling and insulation

- Adjusted ratings and cooling designs for high-altitude installations

-

Seismic Activity:

- Reinforced structures and mounting systems

- Flexible connections to withstand vibrations

I remember a project in a coastal area prone to flooding. We designed the transformers with submersible features, including watertight seals and special pressure relief devices. During a severe storm surge, these transformers continued to operate even when partially submerged, proving the value of environmental adaptation in design.

Here’s a comparison of design adaptations for different environments:

| Environmental Factor | Design Adaptation | Impact on Performance |

|---|---|---|

| Extreme Heat | Enhanced cooling, Special oils | Prevents overheating, Extends lifespan |

| Extreme Cold | Low-temp oils, Heaters | Ensures start-up, Maintains viscosity |

| High Humidity | Sealed designs, Dehumidifiers | Prevents moisture ingress, Reduces corrosion |

| High Altitude | Adjusted ratings, Enhanced insulation | Maintains cooling efficiency, Prevents partial discharge |

| Seismic Activity | Reinforced structures, Flexible mounts | Withstands vibrations, Prevents oil leaks |

Safety Features: Incorporating Protective Measures for Public and Workers?

Have you ever walked past a transformer and wondered if it’s safe? Safety is paramount in pad mounted transformer design, not just for utility workers but for the general public too.

Safety features in pad mounted transformers include tamper-resistant enclosures, internal fault protection, grounding systems, and arc flash mitigation. These features protect both the public from accidental contact and workers during maintenance, ensuring safe operation in various environments.

Let’s delve into the critical safety features:

Layers of Protection

-

Tamper-Resistant Enclosures:

- Locked cabinets with penta-head bolts

- Warning signs and labels

-

Internal Fault Protection:

- Fuses and circuit breakers

- Pressure relief devices

-

Grounding Systems:

- Equipotential grounding to prevent step and touch potentials

- Proper bonding of all metal parts

-

Arc Flash Mitigation:

- Arc-resistant designs

- Remote racking and switching capabilities

I once worked on upgrading transformers in a public park. We implemented a double-lock system and added smart sensors that could detect and report any tampering attempts. A few months later, the utility reported that these measures had completely eliminated the vandalism issues they previously faced.

Here’s a breakdown of safety features and their purposes:

| Safety Feature | Purpose | Benefit |

|---|---|---|

| Tamper-Resistant Enclosure | Prevent unauthorized access | Protects public from accidental contact |

| Internal Fusing | Interrupt fault currents | Prevents catastrophic failures |

| Grounding System | Eliminate voltage differences | Protects against electric shock |

| Arc-Resistant Design | Contain internal arcing faults | Enhances worker safety during maintenance |

| Remote Operation Capabilities | Allow operation from a safe distance | Reduces exposure to potential hazards |

Aesthetic Considerations: Blending Function with Community Aesthetics?

Have you ever noticed how some transformers seem to disappear into their surroundings while others stick out like a sore thumb? Aesthetic design in pad mounted transformers is more important than you might think.

Aesthetic considerations in pad mounted transformer design focus on blending the units with their surroundings. This involves color selection, shape design, and even artistic wraps. Good aesthetic design not only improves community acceptance but can also add value to the urban landscape.

Let’s explore how we can make transformers look good while doing their job:

Beauty in Function

-

Color Selection:

- Standard green often used to blend with vegetation

- Custom colors to match architectural schemes

-

Shape and Size Optimization:

- Low-profile designs to minimize visual impact

- Rounded corners for a softer appearance

-

Artistic Wraps:

- Vinyl wraps featuring local art or landscapes

- Camouflage designs to blend with specific environments

-

Landscaping Integration:

- Designing placement to work with existing or planned landscaping

- Using transformers as part of urban design elements

I remember a project in a historic district where standard green boxes were deemed too modern-looking. We worked with a local artist to create custom wraps featuring scenes from the town’s history. The transformers became talking points, blending utility with public art. The city council was so impressed that they requested similar treatments for other utility equipment.

Here’s a comparison of aesthetic approaches:

| Approach | Application | Community Impact | Cost |

|---|---|---|---|

| Standard Green | Residential areas | Blends with vegetation | Low |

| Custom Colors | Architectural integration | Enhances urban design | Moderate |

| Artistic Wraps | Public spaces, tourist areas | Creates visual interest | High |

| Camouflage Design | Natural settings, parks | Minimizes visual presence | Moderate |

| Sculptural Design | Urban centers, plazas | Doubles as public art | Very High |

Maintenance Accessibility: Facilitating Easy Servicing and Repairs?

Have you ever tried to fix something that’s hard to reach? It’s frustrating, right? Now imagine trying to maintain a complex electrical device like a transformer. That’s why maintenance accessibility is a crucial aspect of pad mounted transformer design.

Maintenance accessibility in pad mounted transformers involves designing for easy inspection, servicing, and repair. This includes features like removable panels, clearly labeled components, and strategically placed access points. Good accessibility design reduces downtime, lowers maintenance costs, and extends the transformer’s lifespan.

Let’s dive into the key aspects of designing for maintenance accessibility:

Making Maintenance Manageable

-

Removable Panels:

- Large, easy-to-remove panels for access to internal components

- Lightweight materials for easier handling

-

Component Layout:

- Logical arrangement of parts for easy identification

- Adequate space around components for tool access

-

Labeling and Documentation:

- Clear, durable labels on all major components

- Easily accessible wiring diagrams and maintenance instructions

-

Safety Features for Maintenance:

- Built-in grounding points for safe work

- Lockout-tagout compatibility for energy isolation

I once worked on redesigning a series of transformers that had a reputation for being maintenance nightmares. We implemented a modular design with plug-and-play components and color-coded wiring. The utility’s maintenance team reported that routine tasks that used to take hours could now be completed in minutes. This not only saved money but also significantly reduced downtime during repairs.

Here’s a comparison of maintenance-friendly features:

| Feature | Purpose | Impact on Maintenance | |||

|---|---|---|---|---|---|

| Hinged Doors | Easy access to components | Reduces time for routine checks | |||

| Modular Design | Quick component replacement | Minimizes downtime during repairs | |||

| External Gauges | Monitoring without opening | Enables quick visual inspections | Standardized Parts | Simplified inventory management | Reduces repair time and costs |

| Built-in Diagnostics | Early problem detection | Enables preventive maintenance |

Smart Grid Compatibility: Integrating Advanced Monitoring and Control?

Ever wondered how power companies manage to keep the lights on so consistently? Smart grid technology is the answer, and modern pad mounted transformers are a key part of this intelligent network.

Smart grid compatibility in pad mounted transformers involves integrating sensors, communication systems, and control capabilities. This allows for real-time monitoring, remote operation, and advanced analytics, enabling more efficient and reliable power distribution.

Let’s explore how we’re making transformers smarter:

Transformers Get a Brain

-

Sensor Integration:

- Temperature, load, and oil quality sensors

- Voltage and current monitoring devices

-

Communication Systems:

- Cellular, Wi-Fi, or power line communication capabilities

- Secure data transmission protocols

-

Advanced Analytics:

- Real-time performance analysis

- Predictive maintenance algorithms

-

Remote Control Capabilities:

- Ability to adjust tap settings remotely

- Remote disconnection for safety or load shedding

I recently worked on a project to upgrade an entire suburban network with smart transformers. During a heatwave, the utility was able to remotely adjust transformer loads to prevent overheating. They even predicted and prevented a potential failure by analyzing data trends. The result was zero outages during a period when neighboring areas experienced multiple blackouts.

Here’s a breakdown of smart features and their benefits:

| Smart Feature | Function | Benefit |

|---|---|---|

| Load Monitoring | Tracks power usage in real-time | Optimizes distribution efficiency |

| Fault Detection | Identifies issues quickly | Reduces outage duration |

| Voltage Regulation | Maintains stable voltage levels | Improves power quality |

| Data Analytics | Predicts maintenance needs | Prevents unexpected failures |

| Remote Control | Allows for remote operation | Reduces field visits |

Regulatory Compliance: Meeting Industry Standards and Local Regulations?

Have you ever wondered why electrical equipment seems to work the same way everywhere? That’s largely due to regulatory standards. For pad mounted transformers, compliance isn’t just about following rules—it’s about ensuring safety, reliability, and interoperability.

Regulatory compliance for pad mounted transformers involves adhering to industry standards like IEEE, ANSI, and IEC, as well as local regulations. This ensures safety, performance, and compatibility across different power systems. Compliance covers aspects from design and manufacturing to installation and operation.

Let’s dive into the world of transformer regulations:

Navigating the Regulatory Landscape

-

Safety Standards:

- IEEE C57.12.00 for general requirements

- ANSI C57.12.26 for pad mounted transformers

- NFPA 70 (National Electrical Code) for installation

-

Performance Standards:

- IEEE C57.12.90 for test code

- IEC 60076 for power transformers

-

Environmental Regulations:

- EPA guidelines for oil containment

- RoHS compliance for hazardous substances

-

Energy Efficiency Standards:

- DOE energy conservation standards

- ENERGY STAR certification (where applicable)

I remember a project where we were designing transformers for export to multiple countries. We had to navigate a complex web of international and local standards. By creating a comprehensive compliance matrix and working closely with regulatory experts, we developed a design that met or exceeded standards in all target markets. This attention to regulatory detail opened up new markets for our client and set a new benchmark in the industry.

Here’s an overview of key standards and their impacts:

| Standard | Focus Area | Key Requirements | Impact of Non-Compliance |

|---|---|---|---|

| IEEE C57.12.00 | General Requirements | Design, materials, testing | Safety risks, performance issues |

| ANSI C57.12.26 | Pad Mounted Specifics | Dimensions, connections | Incompatibility, installation problems |

| NFPA 70 | Installation | Wiring, grounding, clearances | Legal issues, safety hazards |

| EPA Guidelines | Environmental | Oil containment, spill prevention | Environmental damage, fines |

| DOE Standards | Energy Efficiency | Minimum efficiency levels | Higher operating costs, potential fines |

Conclusion

Designing excellence in pad mounted transformers requires careful consideration of multiple factors, from technical specifications to aesthetic and environmental concerns. By addressing these key aspects, we can create transformers that are efficient, reliable, safe, and future-ready.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group