Distribution Transformer Price: Balancing Cost, Efficiency, and Long-Term Value in Modern Power Infrastructure Investments?

Are you struggling to justify the cost of new distribution transformers? You’re not alone. Many utilities find it challenging to balance upfront expenses with long-term benefits in today’s complex energy landscape.

Distribution transformer pricing involves balancing initial costs with long-term efficiency and value. Key factors include material costs, energy efficiency ratings, smart grid compatibility, and regulatory compliance. Utilities must consider total cost of ownership, including energy losses and maintenance, to make informed investment decisions in modern power infrastructure.

As someone who has spent years in the power distribution industry, I’ve seen firsthand how crucial it is to make the right decisions when it comes to transformer investments. In this article, I’ll guide you through the complexities of distribution transformer pricing and help you understand how to make choices that benefit your utility both now and in the future.

What Key Factors Drive Distribution Transformer Pricing in Today’s Market?

Are you puzzled by the wide range of prices for distribution transformers? Understanding the key pricing factors can help you make more informed decisions for your utility.

Key factors driving distribution transformer pricing include raw material costs, design complexity, efficiency ratings, manufacturing processes, and market demand. Advanced features like smart grid compatibility and environmental considerations also impact pricing. The balance of these factors determines the final cost of transformers in today’s competitive market.

Let’s dive deeper into the factors that influence distribution transformer pricing:

Raw Material Costs

The cost of materials plays a significant role in transformer pricing.

Impact of Materials:

- Copper and aluminum prices for windings

- Electrical steel costs for the core

- Insulation material expenses

Design Complexity

More advanced designs often come with higher price tags.

Design Factors Affecting Cost:

- Core design (e.g., wound core vs. stacked laminations)

- Winding configuration

- Cooling system complexity

Efficiency Ratings

Higher efficiency transformers typically cost more upfront but offer long-term savings.

Efficiency Considerations:

- No-load loss ratings

- Load loss ratings

- Compliance with efficiency standards (e.g., DOE regulations)

Manufacturing Processes

The production method can significantly impact the final price.

Manufacturing Influences:

- Automation level in production

- Quality control processes

- Production volume and economies of scale

| Factor | Low-Cost Impact | High-Cost Impact |

|---|---|---|

| Raw Materials | Standard materials | Premium, high-performance materials |

| Design | Basic, traditional designs | Advanced, optimized designs |

| Efficiency | Standard efficiency | High-efficiency, low-loss designs |

| Manufacturing | High-volume, standardized production | Low-volume, customized production |

In my experience, navigating these pricing factors requires a deep understanding of both the technical aspects of transformers and the current market conditions. I remember working on a project where we were tasked with upgrading a utility’s transformer fleet. Initially, the focus was solely on finding the lowest upfront cost. However, after a comprehensive analysis of efficiency ratings and long-term energy savings, we were able to justify investing in higher-priced, more efficient models that ultimately saved the utility millions in operating costs over the transformers’ lifespans.

It’s important to note that while these factors all play a role in pricing, their relative importance can vary depending on market conditions and specific utility needs. I’ve seen cases where fluctuations in copper prices have dramatically shifted the competitive landscape among transformer manufacturers. Staying informed about these market dynamics is crucial for making cost-effective procurement decisions.

Don’t overlook the impact of regulatory changes on pricing. In one project, we had to quickly adapt our transformer specifications to meet new efficiency standards. This led to a short-term increase in prices but ultimately resulted in more energy-efficient and cost-effective operations for our clients.

Another crucial aspect is the role of technology in pricing. I’m currently involved in a project exploring the integration of smart features into distribution transformers. While these advanced capabilities increase the upfront cost, they offer significant benefits in terms of grid management and predictive maintenance, potentially reducing overall lifecycle costs.

Lastly, it’s exciting to see how innovations in materials science are influencing transformer pricing. I recently visited a research facility where they’re developing new core materials that promise to dramatically reduce losses. While still in the experimental stage, these advancements could significantly impact future pricing structures in the industry.

Understanding the key factors driving distribution transformer pricing is essential for making informed investment decisions. By carefully considering these elements and their long-term implications, utilities can strike the right balance between upfront costs and long-term value, ensuring their power infrastructure is both cost-effective and future-ready.

How Does Energy Efficiency Impact the Total Cost of Ownership for Distribution Transformers?

Are you focusing too much on the initial price tag of transformers and overlooking long-term costs? Many utilities make this mistake, potentially leading to higher expenses over time.

Energy efficiency significantly impacts the total cost of ownership for distribution transformers. Higher efficiency models, while more expensive upfront, reduce energy losses over the transformer’s lifespan. This results in lower operating costs, decreased environmental impact, and potential regulatory compliance benefits. The energy savings often outweigh the initial price difference.

Let’s explore how energy efficiency affects the total cost of ownership:

Reduced Energy Losses

Efficient transformers minimize both no-load and load losses.

Benefits of Lower Losses:

- Decreased energy waste

- Lower operating costs

- Reduced strain on the power grid

Longer Lifespan

Efficient transformers often have improved thermal management.

Lifespan Advantages:

- Reduced thermal stress on components

- Slower degradation of insulation

- Potential for extended service life

Regulatory Compliance

Energy-efficient transformers help meet and exceed regulatory standards.

Compliance Benefits:

- Avoidance of penalties

- Eligibility for incentives or rebates

- Future-proofing against stricter regulations

Environmental Impact

Efficiency translates to reduced carbon footprint.

Environmental Considerations:

- Lower greenhouse gas emissions

- Alignment with sustainability goals

- Potential for improved corporate image

| Efficiency Level | Initial Cost | Energy Savings | Long-Term Cost |

|---|---|---|---|

| Standard | Lower | Minimal | Higher |

| High Efficiency | Higher | Significant | Lower |

| Ultra-High Efficiency | Highest | Maximal | Lowest |

In my experience, the impact of energy efficiency on total cost of ownership cannot be overstated. I recall a project where we replaced a utility’s aging transformer fleet with high-efficiency models. The initial investment was 20% higher, but our calculations showed a break-even point within just four years. Over the 25-year lifespan of the transformers, the utility is projected to save millions in energy costs.

It’s important to note that the benefits of energy efficiency extend beyond just cost savings. In one case, a utility’s investment in high-efficiency transformers allowed them to defer costly upgrades to their generation capacity. The reduced losses across their distribution network effectively created "negawatts," freeing up capacity for growth without additional infrastructure investment.

Don’t overlook the role of proper sizing in maximizing efficiency benefits. I’ve worked with utilities to implement advanced load forecasting and transformer sizing strategies. By ensuring transformers operate closer to their optimal efficiency point, we’ve been able to squeeze even more value out of high-efficiency units.

Another crucial aspect is the consideration of future energy costs. In a recent consultation, we developed a model that factored in projected increases in electricity prices. This analysis made the case for ultra-high efficiency transformers even more compelling, as the energy savings compound over time with rising energy costs.

Lastly, it’s exciting to see how advancements in materials and design are pushing the boundaries of transformer efficiency. I’m currently involved in a pilot project testing new amorphous core transformers that promise even lower losses than current high-efficiency models. While still more expensive, these cutting-edge units could redefine our understanding of lifecycle costs for distribution transformers.

Considering energy efficiency in the context of total cost of ownership is crucial for making sound investment decisions in distribution transformers. By looking beyond the initial price tag and considering long-term energy savings, utilities can not only reduce their operating costs but also contribute to a more sustainable and efficient power grid.

What Are the Price Variations Among Different Types of Distribution Transformers and Their Applications?

Are you confused by the wide range of prices for different types of distribution transformers? It’s a common challenge for many utilities trying to optimize their infrastructure investments.

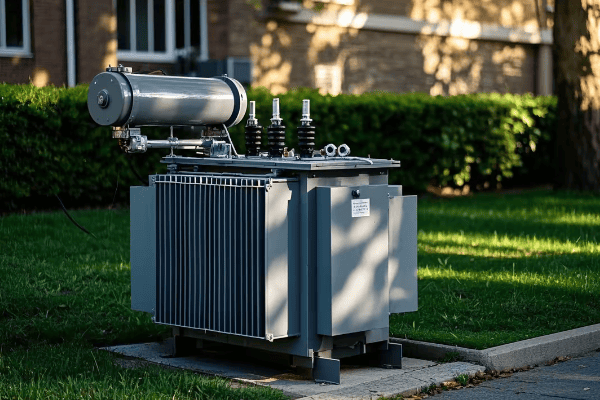

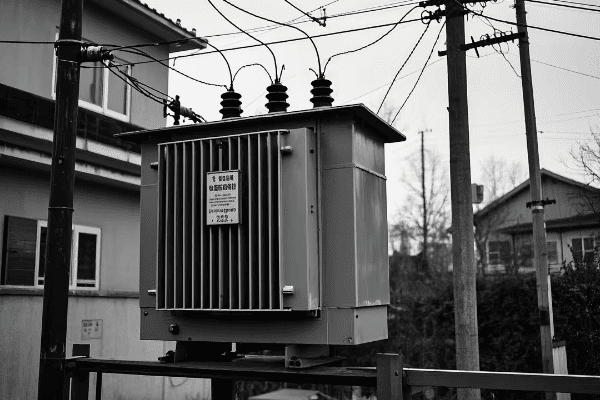

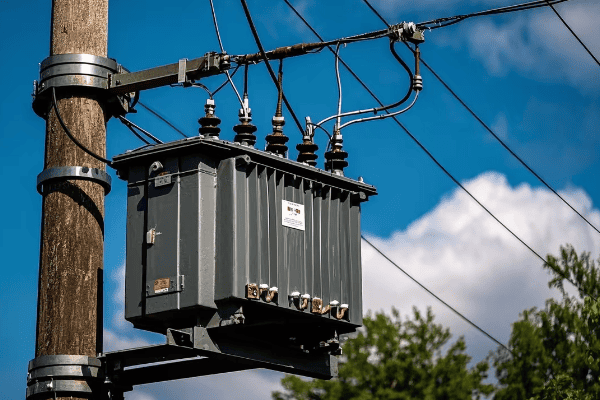

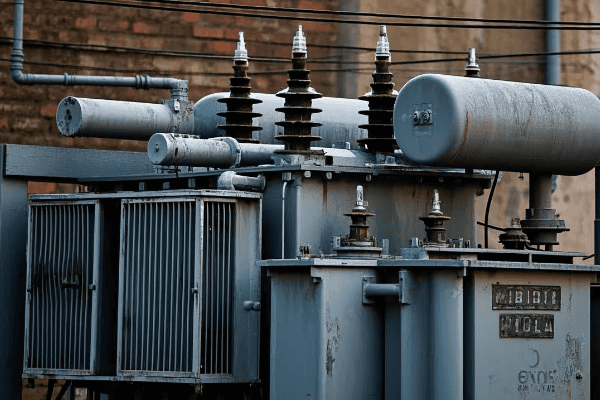

Price variations among distribution transformers are significant and depend on type, capacity, and application. Dry-type transformers are generally more expensive than oil-filled ones but offer benefits in certain environments. Pole-mounted transformers are typically less costly than pad-mounted units. Specialized applications like solar or wind farm integration often command premium prices due to unique requirements.

Let’s break down the price variations among different transformer types:

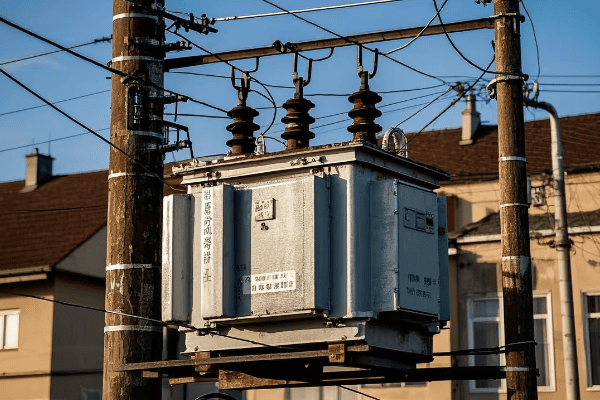

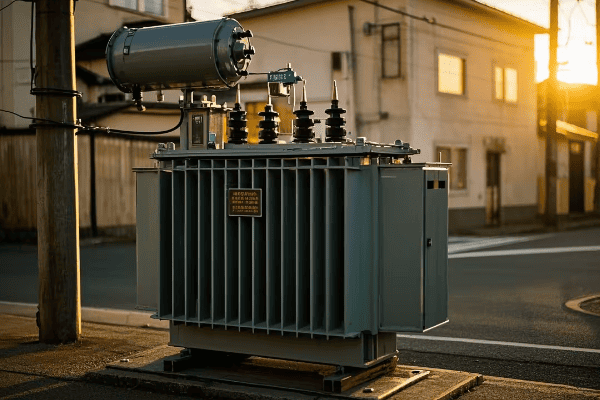

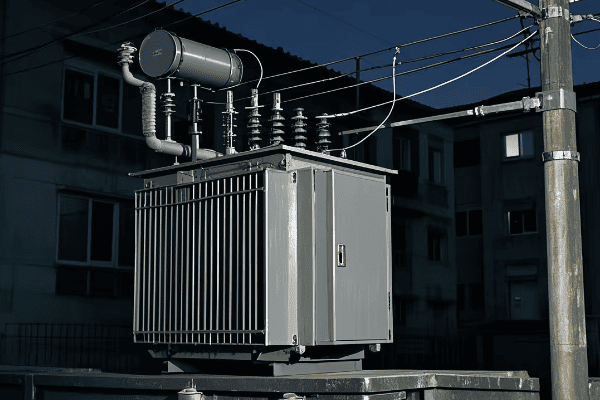

Oil-Filled vs. Dry-Type Transformers

These two main categories have distinct price points and applications.

Price Comparison:

- Oil-filled: Generally lower initial cost

- Dry-type: Higher upfront cost but potentially lower maintenance expenses

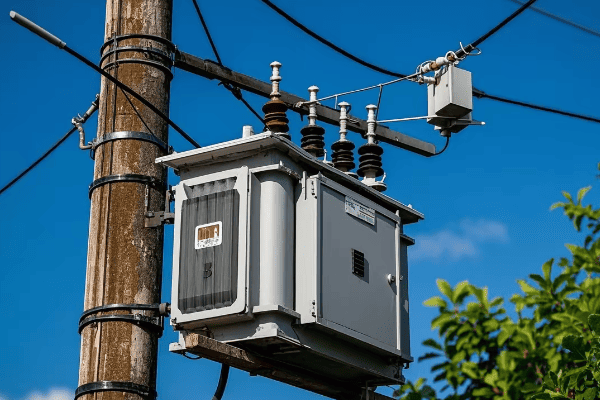

Pole-Mounted vs. Pad-Mounted Transformers

Installation method affects both price and suitability for different environments.

Cost Factors:

- Pole-mounted: Lower material costs but higher installation expenses

- Pad-mounted: Higher unit cost but often easier to maintain and service

Standard vs. Specialized Applications

Transformers for specific uses often come with premium price tags.

Specialized Transformer Costs:

- Solar farm integration transformers: Higher due to specific voltage requirements

- Wind farm transformers: Premium pricing for robust design to handle variable loads

- Urban network transformers: Increased cost for compact design and enhanced safety features

Single-Phase vs. Three-Phase Transformers

The number of phases impacts both price and application suitability.

Phase-Based Pricing:

- Single-phase: Generally less expensive, suitable for residential areas

- Three-phase: Higher cost but necessary for industrial and commercial applications

| Transformer Type | Relative Cost | Best Application |

|---|---|---|

| Oil-filled | Lower | General purpose, high capacity |

| Dry-type | Higher | Indoor, environmentally sensitive areas |

| Pole-mounted | Moderate | Rural, residential areas |

| Pad-mounted | Higher | Urban, commercial areas |

| Specialized (e.g., renewable energy) | Highest | Specific industrial or energy production needs |

In my years of experience, I’ve seen how choosing the right type of transformer for each application can make a significant difference in both initial costs and long-term performance. I remember a project where a utility was initially leaning towards dry-type transformers for an urban redevelopment area due to environmental concerns. However, after a detailed analysis of lifecycle costs and the specific site requirements, we found that modern, environmentally friendly oil-filled units were actually the more cost-effective and suitable choice.

It’s important to note that while initial price is a key factor, it shouldn’t be the only consideration. In one case, I worked with a utility that opted for higher-priced, specialized transformers for a new industrial park. The premium paid for these units was quickly offset by their ability to handle the unique load profiles of the incoming businesses, avoiding costly upgrades down the line.

Don’t overlook the impact of location and environment on transformer selection and pricing. I’ve been involved in projects in coastal areas where the corrosive sea air necessitated the use of specially designed (and more expensive) transformers. The higher upfront cost was justified by the extended lifespan and reduced maintenance needs in these challenging conditions.

Another crucial aspect is the consideration of future needs. I’m currently advising a utility on a grid modernization project where we’re factoring in the potential for increased electric vehicle adoption. This forward-thinking approach has led us to select slightly more expensive transformers with higher capacity and smart features, anticipating the changing load patterns of the future.

Lastly, it’s exciting to see how innovations in transformer design are creating new price-performance paradigms. I recently visited a manufacturer developing a hybrid transformer that combines the best features of both dry-type and oil-filled designs. While still in the prototype stage, this technology promises to offer new options for utilities looking to balance cost, performance, and environmental considerations.

Understanding the price variations among different types of distribution transformers is crucial for making informed investment decisions. By carefully considering the specific needs of each application and looking beyond just the initial price tag, utilities can select transformers that offer the best long-term value and performance for their unique situations.

How Do Initial Costs Compare to Long-Term Benefits in Distribution Transformer Investments?

Are you struggling to justify higher upfront costs for advanced transformers? It’s a common dilemma that many utilities face when balancing budget constraints with long-term infrastructure needs.

Initial costs of distribution transformers often contrast sharply with their long-term benefits. Higher-priced, efficient models typically offer significant savings in energy losses, maintenance, and lifespan extension. While budget-friendly options may seem attractive initially, they often result in higher total costs over time. The key is to evaluate investments based on lifecycle cost analysis.

Let’s delve into the comparison between initial costs and long-term benefits:

Energy Loss Reduction

More efficient transformers can significantly cut energy losses over time.

Long-Term Savings:

- Lower no-load losses for 24/7 savings

- Reduced load losses during peak operation times

- Cumulative savings that often exceed initial price differences

Maintenance and Reliability

Higher quality transformers often require less maintenance and have fewer failures.

Lifecycle Benefits:

- Reduced frequency of maintenance interventions

- Lower risk of unexpected failures and outages

- Extended operational lifespan

Adaptability to Future Needs

Advanced transformers can be more adaptable to changing grid requirements.

Future-Proofing Advantages:

- Better compatibility with smart grid technologies

- Improved ability to handle evolving load profiles

- Easier integration of renewable energy sources

Environmental and Regulatory Compliance

Investing in efficient transformers can yield long-term regulatory benefits.

Compliance Benefits:

- Meeting or exceeding current and future efficiency standards

- Potential for incentives or rebates for high-efficiency equipment

- Reduced carbon footprint and improved corporate sustainability

| Aspect | Low Initial Cost | High Initial Cost |

|---|---|---|

| Energy Efficiency | Higher losses, increased operating costs | Lower losses, significant long-term savings |

| Maintenance | More frequent, higher lifetime costs | Less frequent, lower lifetime costs |

| Adaptability | Limited future compatibility | Better prepared for future grid needs |

| Compliance | May require earlier replacement | Likely to meet future standards |

In my experience, the contrast between initial costs and long-term benefits can be stark. I recall a project where a utility was hesitant to invest in premium, high-efficiency transformers due to budget constraints. We conducted a detailed 20-year lifecycle cost analysis, which revealed that the more expensive units would save the utility over $2 million in energy costs alone, far outweighing the additional upfront investment of $500,000.

It’s important to note that the benefits of higher-quality transformers extend beyond just financial savings. In one case, I worked with a utility that invested in advanced transformers with remote monitoring capabilities. While more expensive initially, these units allowed for predictive maintenance, significantly reducing downtime and improving overall grid reliability. The resulting improvement in customer satisfaction and reduction in regulatory penalties provided value that was hard to quantify but undeniably significant.

Don’t overlook the impact of evolving technology on this cost-benefit equation. I’m currently involved in a project evaluating the integration of solid-state transformers into a distribution network. While substantially more expensive upfront, these cutting-edge units offer unprecedented flexibility and efficiency. Our preliminary analysis suggests they could be game-changers in areas with high renewable energy penetration or rapidly changing load profiles.

Another crucial aspect is the consideration of risk and resilience. In a recent consultation, we factored in the potential costs of transformer failure in critical infrastructure areas. The analysis showed that investing in higher-quality, more reliable transformers in these locations was justified even if their efficiency benefits alone didn’t offset the higher initial cost.

Lastly, it’s exciting to see how new financial models are changing the way utilities approach these investments. I’ve been working with a utility exploring a "Transformer-as-a-Service" model, where a third party owns and maintains high-efficiency transformers, charging the utility based on performance. This approach aligns the incentives for long-term efficiency with more manageable short-term costs.

Balancing initial costs with long-term benefits in distribution transformer investments requires a comprehensive approach. By considering factors like energy efficiency, maintenance needs, future adaptability, and regulatory compliance, utilities can make investment decisions that not only make financial sense but also contribute to a more reliable, efficient, and sustainable power grid.

What Impact Do Energy Regulations Have on Distribution Transformer Pricing and Selection Criteria?

Are you finding it challenging to navigate the complex landscape of energy regulations when selecting transformers? You’re not alone. Many utilities struggle to balance regulatory compliance with cost-effective equipment choices.

Energy regulations significantly impact distribution transformer pricing and selection criteria. They set minimum efficiency standards, influencing design and manufacturing processes. This often leads to higher initial costs but ensures long-term energy savings. Regulations also affect material choices and testing requirements, further influencing pricing and selection decisions for utilities.

Let’s explore the various ways energy regulations impact transformer pricing and selection:

Minimum Efficiency Standards

Regulations often set baseline efficiency requirements for transformers.

Regulatory Impacts:

- Higher manufacturing costs to meet efficiency targets

- Increased use of premium materials (e.g., low-loss steel)

- More rigorous testing and certification processes

Material Restrictions

Some regulations limit the use of certain materials in transformer construction.

Material Compliance Effects:

- Phasing out of environmentally harmful substances

- Adoption of alternative, often more expensive materials

- Research and development costs for new material solutions

Testing and Certification Requirements

Regulations mandate specific testing procedures and certifications.

Testing Impacts:

- Additional costs for extensive efficiency testing

- Investments in advanced testing equipment

- Potential delays in product release due to certification processes

Environmental Considerations

Many regulations focus on reducing the environmental impact of transformers.

Environmental Compliance Costs:

- Development of more eco-friendly insulation materials

- Enhanced oil containment systems for oil-filled transformers

- End-of-life disposal and recycling considerations

| Regulatory Aspect | Impact on Pricing | Impact on Selection Criteria |

|---|---|---|

| Efficiency Standards | Increased base price | Focus on total cost of ownership |

| Material Restrictions | Higher material costs | Limited options in some categories |

| Testing Requirements | Added certification costs | Preference for pre-certified models |

| Environmental Rules | Eco-design cost increases | Emphasis on sustainable options |

In my years working with utilities and manufacturers, I’ve seen firsthand how energy regulations can reshape the transformer market. I remember when the U.S. Department of Energy introduced new efficiency standards a few years ago. Initially, there was concern about rising costs, but it ultimately drove innovation in the industry. One manufacturer I worked with invested heavily in redesigning their core transformer line. While it increased their production costs by about 15%, they were able to achieve efficiency levels that exceeded the standards, giving them a competitive edge in the market.

It’s important to note that while regulations often lead to higher upfront costs, they can result in significant long-term savings. In a recent project, we helped a utility transition to transformers that met the latest efficiency standards. The initial investment was higher, but our analysis showed that the energy savings over the transformers’ lifespans would more than offset the increased cost, with the added benefit of reduced carbon emissions.

Don’t overlook the impact of regional variations in regulations. I’ve worked on international projects where navigating different standards across countries added complexity to procurement decisions. In one case, we had to create a matrix of regulatory requirements for a utility operating across three countries to ensure all their transformer purchases were compliant in each jurisdiction.

Another crucial aspect is how regulations are driving innovation in transformer design. I’m currently advising a manufacturer on the development of a new line of transformers that not only meet current standards but are designed to be easily upgradable to meet future regulations. This forward-thinking approach, while adding to the initial cost, offers utilities a way to future-proof their investments.

Lastly, it’s exciting to see how some utilities are turning regulatory compliance into a competitive advantage. I recently worked with a utility that went beyond compliance, investing in transformers that significantly exceeded efficiency standards. They were able to market themselves as a green energy provider, attracting environmentally conscious customers and improving their public image.

Energy regulations have a profound impact on distribution transformer pricing and selection criteria. While they often lead to higher initial costs, they also drive innovation, improve efficiency, and contribute to long-term sustainability goals. Utilities that approach these regulations strategically can turn compliance into an opportunity for improvement and differentiation in the market.

How Can Utilities Develop Cost-Effective Strategies for Distribution Transformer Procurement?

Are you struggling to balance budget constraints with the need for high-quality, efficient transformers? This is a common challenge for many utilities in today’s competitive and rapidly evolving energy landscape.

Utilities can develop cost-effective procurement strategies by implementing lifecycle cost analysis, leveraging bulk purchasing power, exploring leasing options, and adopting predictive maintenance approaches. Additionally, standardizing specifications, considering remanufactured units, and staying informed about market trends and technological advancements can lead to more economical transformer investments.

Let’s dive into some strategies for cost-effective transformer procurement:

Lifecycle Cost Analysis

Look beyond initial purchase price to total ownership costs.

Key Considerations:

- Energy efficiency over the transformer’s lifespan

- Maintenance and repair costs

- Expected operational life and replacement timing

Bulk Purchasing and Framework Agreements

Leverage economies of scale to reduce per-unit costs.

Procurement Approaches:

- Multi-year purchasing agreements with suppliers

- Collaborative buying with other utilities or through consortiums

- Standardization of specifications to increase order volumes

Leasing and Alternative Financing Models

Explore options beyond traditional purchasing.

Financial Strategies:

- Transformer leasing to reduce upfront capital expenditure

- Performance-based contracts with manufacturers

- Energy savings-funded procurement models

Predictive Maintenance and Smart Asset Management

Use data-driven approaches to optimize transformer lifecycles.

Smart Management Benefits:

- Extended transformer lifespan through timely interventions

- Reduced unexpected failures and associated costs

- More accurate forecasting of replacement needs

| Strategy | Short-Term Impact | Long-Term Benefit |

|---|---|---|

| Lifecycle Analysis | Higher initial investment | Lower total cost of ownership |

| Bulk Purchasing | Reduced per-unit costs | Streamlined procurement process |

| Leasing Models | Lower upfront costs | Flexibility in asset management |

| Predictive Maintenance | Investment in monitoring systems | Extended asset life, reduced failures |

In my experience, developing a cost-effective procurement strategy requires a holistic approach. I recall working with a mid-sized utility that was struggling with rising transformer costs. We implemented a comprehensive strategy that combined lifecycle cost analysis with a new bulk purchasing agreement. The result was a 15% reduction in their overall transformer expenditure over five years, while also improving the average efficiency of their transformer fleet.

It’s important to note that what works for one utility may not be ideal for another. I’ve seen cases where smaller utilities benefited greatly from joining procurement consortiums, allowing them to access pricing typically reserved for larger entities. On the other hand, I worked with a large utility that found significant savings by bringing some of their transformer refurbishment in-house, a strategy that wouldn’t be feasible for smaller operations.

Don’t overlook the potential of remanufactured or refurbished transformers. In a recent project, we helped a utility develop a hybrid procurement strategy that included a mix of new high-efficiency units for critical locations and carefully selected remanufactured units for less demanding applications. This approach allowed them to stretch their budget further while still meeting their performance and reliability targets.

Another crucial aspect is staying informed about market trends and technological advancements. I’m currently advising several utilities on how to incorporate flexibility into their procurement strategies to take advantage of emerging technologies like solid-state transformers. While these units are currently more expensive, we’re developing phased adoption plans that allow for pilot deployments without overcommitting resources.

Lastly, it’s exciting to see how some utilities are leveraging data analytics to optimize their procurement strategies. I recently worked on a project implementing an AI-driven asset management system that analyzes performance data from the entire transformer fleet. This system not only helps in predicting maintenance needs but also informs procurement decisions by identifying the most cost-effective transformer specifications for different parts of the network.

Developing cost-effective strategies for distribution transformer procurement is an ongoing process that requires a balance of short-term cost considerations and long-term strategic planning. By adopting a comprehensive approach that considers lifecycle costs, explores alternative procurement models, and leverages technological advancements, utilities can optimize their investments in this critical infrastructure.

What Role Does Technology Play in Balancing Price and Performance of Modern Distribution Transformers?

Are you wondering how to leverage the latest technologies to get the best value from your transformer investments? You’re not alone. Many utilities are grappling with the challenge of balancing advanced features with budget constraints.

Technology plays a crucial role in balancing price and performance of modern distribution transformers. Advancements in materials science, design software, and manufacturing processes are enabling the production of more efficient and reliable transformers at competitive prices. Smart monitoring systems and IoT integration are also enhancing performance and longevity, justifying higher initial investments through improved lifecycle value.

Let’s explore how technology is influencing the price-performance balance in transformers:

Advanced Materials

New materials are improving efficiency and reducing costs.

Material Innovations:

- Amorphous metal cores for lower no-load losses

- Advanced insulation materials for better thermal management

- Nano-engineered fluids for improved cooling and insulation

Design Optimization Software

Sophisticated software tools are revolutionizing transformer design.

Software Benefits:

- Rapid prototyping and testing of designs

- Optimization for specific performance criteria

- Reduction in material waste and manufacturing costs

Smart Monitoring and Diagnostics

Integrated sensors and analytics improve transformer management.

Smart Features:

- Real-time monitoring of key parameters

- Predictive maintenance capabilities

- Remote diagnostics and control

Advanced Manufacturing Techniques

New production methods are enhancing quality while controlling costs.

Manufacturing Innovations:

- 3D printing for complex components

- Automated winding and assembly processes

- Precision laser cutting for core materials

| Technology | Impact on Price | Impact on Performance |

|---|---|---|

| Advanced Materials | Initially higher, long-term savings | Significant efficiency improvements |

| Design Software | Reduced development costs | Optimized designs for specific needs |

| Smart Monitoring | Higher upfront cost | Extended lifespan, improved reliability |

| Advanced Manufacturing | Potential for cost reduction | Consistent quality, customization options |

In my years of experience in the power industry, I’ve witnessed firsthand how technology has transformed the landscape of transformer design and manufacturing. I remember visiting a transformer factory a decade ago and comparing it to a recent visit to a state-of-the-art facility. The difference was striking. The modern factory used advanced robotics and AI-driven quality control systems, producing transformers with unprecedented precision and consistency.

It’s important to note that while these technological advancements often come with higher initial costs, they frequently lead to significant long-term savings. In a recent project, we helped a utility upgrade to transformers with advanced monitoring systems. The initial investment was 20% higher than traditional models, but the predictive maintenance capabilities have already prevented two major failures in the first year, potentially saving millions in repair costs and avoided outages.

Don’t overlook the role of software in driving both performance improvements and cost reductions. I worked with a manufacturer who implemented advanced electromagnetic field simulation software in their design process. This allowed them to optimize their transformer designs for specific customer requirements, reducing material usage by 8% while improving efficiency. The result was a more competitive product that balanced performance and price effectively.

Another crucial aspect is the integration of smart technologies. I’m currently advising a utility on a grid modernization project where we’re deploying transformers with built-in IoT capabilities. These units can communicate real-time performance data, load profiles, and even environmental conditions. While more expensive upfront, these smart transformers are proving invaluable in optimizing grid operations and extending asset lifespans.

Lastly, it’s exciting to see how emerging technologies like artificial intelligence are poised to further revolutionize the industry. I recently visited a research lab where they’re developing AI algorithms that can predict transformer failures with unprecedented accuracy. This technology promises to dramatically reduce maintenance costs and improve reliability, potentially reshaping how we value and price transformers in the future.

The role of technology in balancing price and performance of modern distribution transformers is continually evolving. By staying informed about these advancements and strategically incorporating new technologies, utilities can make transformer investments that offer the best combination of upfront affordability and long-term value. As we move towards smarter, more efficient grids, the transformers that leverage these technologies will play a crucial role in shaping the future of power distribution.

How Are Smart Grid Requirements Influencing the Pricing Landscape of Distribution Transformers?

Are you finding it challenging to justify the costs of smart grid-compatible transformers? You’re not alone. Many utilities are grappling with the balance between traditional transformer pricing and the added value of smart features.

Smart grid requirements are significantly influencing distribution transformer pricing. The integration of communication capabilities, sensors, and advanced monitoring systems increases initial costs. However, these features enable improved grid management, predictive maintenance, and enhanced reliability. The pricing landscape is shifting towards valuing long-term benefits and grid integration capabilities over just upfront costs.

Let’s explore how smart grid needs are reshaping transformer pricing:

Communication Capabilities

Smart transformers need to be part of a connected grid ecosystem.

Communication Features Impact:

- Integration of communication modules (e.g., cellular, Wi-Fi, power line carrier)

- Cybersecurity measures to protect against digital threats

- Compatibility with various smart grid protocols

Advanced Monitoring Systems

Real-time data collection and analysis are key smart grid features.

Monitoring System Costs:

- Sensor integration for various parameters (temperature, load, oil condition)

- Data processing and storage capabilities

- Software for data analysis and reporting

Power Quality Management

Smart transformers play a role in maintaining grid stability.

Power Quality Features:

- Voltage regulation capabilities

- Harmonic mitigation technologies

- Fault detection and isolation systems

Adaptability to Renewable Integration

Smart transformers need to handle bidirectional power flows.

Renewable Integration Costs:

- Enhanced control systems for variable loads

- Energy storage integration capabilities

- Advanced protection mechanisms for reverse power flow

| Smart Feature | Impact on Price | Grid Benefit |

|---|---|---|

| Communication | Moderate increase | Enhanced grid visibility and control |

| Monitoring | Significant increase | Predictive maintenance, reduced outages |

| Power Quality | High increase | Improved grid stability and efficiency |

| Renewable Adaptability | Substantial increase | Facilitates clean energy integration |

In my experience, the influence of smart grid requirements on transformer pricing has been profound. I recall a project where we were upgrading a utility’s urban distribution network. The initial sticker shock of smart transformers was significant – they were about 40% more expensive than traditional units. However, our cost-benefit analysis over a 15-year period showed that the smart features would result in a 25% reduction in outage minutes and a 10% improvement in overall grid efficiency, more than justifying the additional upfront cost.

It’s important to note that the value of smart transformers extends beyond just operational improvements. In one case, I worked with a utility that was able to defer a costly substation upgrade by deploying smart transformers with load management capabilities. The enhanced visibility and control these units provided allowed for more efficient use of existing infrastructure, saving millions in capital expenditure.

Don’t overlook the role of data in driving value from smart transformer investments. I’m currently advising a utility on implementing a data analytics platform that leverages information from their smart transformer fleet. This system is not only optimizing maintenance schedules but also providing insights for future grid planning, adding significant value beyond the transformers’ basic function.

Another crucial aspect is the adaptability of smart transformers to future grid needs. I recently consulted on a project where we specified transformers with modular communication systems. This design allows for easier upgrades as communication technologies evolve, protecting the utility’s investment and ensuring long-term compatibility with smart grid advancements.

Lastly, it’s exciting to see how smart transformer technologies are enabling new business models. I’ve been working with a group exploring the concept of "grid-as-a-service," where utilities can offer advanced power quality and reliability options to customers willing to pay a premium. The smart capabilities of modern transformers are key to making these innovative service models possible.

The influence of smart grid requirements on distribution transformer pricing is reshaping how utilities approach their infrastructure investments. While the upfront costs are higher, the long-term benefits in terms of grid management, reliability, and adaptability are driving a shift in how we value these critical assets. As smart grid technologies continue to evolve, transformers that can seamlessly integrate into this intelligent network will become increasingly valuable, despite their higher initial price tags.

Conclusion

Distribution transformer pricing involves a complex balance of initial costs, long-term efficiency, and smart grid capabilities. By considering total cost of ownership, leveraging technology, and adapting to regulatory and smart grid requirements, utilities can make informed investment decisions that ensure reliable, efficient, and future-ready power distribution systems.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group