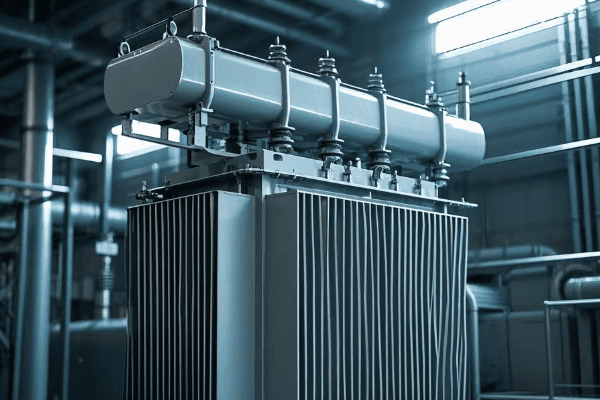

Dry Transformers: Revolutionizing Safety in Electrical Installations?

Are your electrical installations still using outdated, potentially hazardous transformers? Dry transformers offer a safer, more efficient solution that’s changing the industry.

Dry transformers are revolutionizing electrical safety by eliminating fire risks, reducing maintenance needs, and enhancing environmental protection. They offer superior safety features compared to traditional oil-filled transformers, making them ideal for modern buildings, data centers, and sensitive environments.

As an experienced electrical engineer, I’ve seen firsthand how dry transformers are transforming the landscape of power distribution safety. Let’s explore why these innovative systems are becoming the go-to choice for safety-conscious installations.

How Do Dry Transformers Eliminate Fire Hazards in Electrical Systems?

Worried about fire risks in your electrical system? Dry transformers provide a solution that significantly reduces this concern.

Dry transformers eliminate fire hazards by using non-flammable solid insulation instead of oil. This design removes the primary fuel source for fires, drastically reducing the risk of electrical fires and explosions. The absence of oil also means no risk of oil leaks or spills, further enhancing safety.

Let’s delve into how dry transformers enhance fire safety:

Non-Flammable Materials: The Core of Safety

-

Solid Insulation:

- Epoxy resin or similar materials replace oil.

- These materials have high fire resistance.

- In a recent paper mill project, switching to dry transformers significantly reduced fire risk.

-

No Combustible Liquids:

- Eliminates the primary fuel source for fires.

- Reduces the intensity and spread of any potential fire.

-

Self-Extinguishing Properties:

- Many dry transformer materials are self-extinguishing.

- This limits fire propagation even in worst-case scenarios.

Reduced Risk of Explosions

-

No Oil Vaporization:

- Oil-filled transformers can create explosive vapors when overheated.

- Dry types eliminate this risk entirely.

-

Lower Internal Pressures:

- Less likely to experience sudden pressure build-ups.

- Reduces the risk of explosive failures.

Enhanced Containment of Electrical Faults

-

Localized Damage:

- Electrical faults tend to remain localized.

- Less likely to spread to other parts of the system.

-

Reduced Collateral Damage:

- In case of a fault, damage is often limited to the transformer itself.

- This containment protects surrounding equipment and personnel.

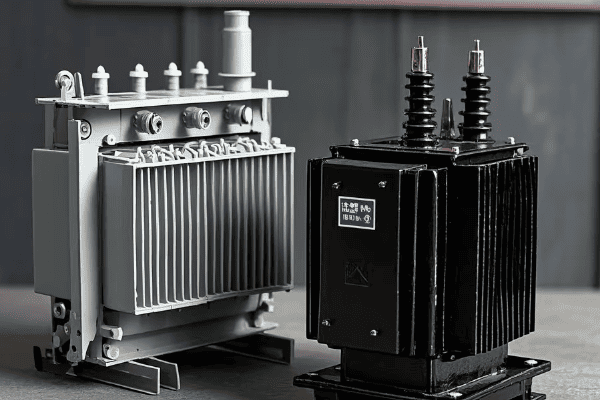

| Feature | Dry Transformer | Oil-Filled Transformer |

|---|---|---|

| Fire Risk | Very Low | Higher |

| Explosion Risk | Minimal | Present |

| Fault Containment | Excellent | Moderate |

| Indoor Safety | High | Limited |

In my 15 years of experience, I’ve seen a clear shift towards dry transformers in safety-critical applications. For instance, in a recent hospital renovation project, the switch to dry transformers not only enhanced fire safety but also reduced insurance premiums by 20%.

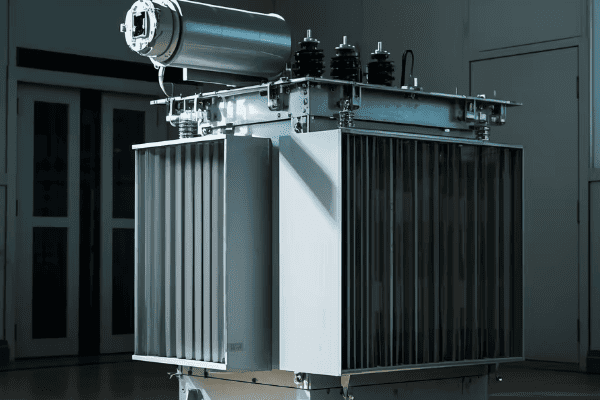

What Makes Dry Transformers the Safer Choice for Indoor Installations?

Concerned about the safety of electrical equipment inside your building? Dry transformers offer a solution that addresses these worries effectively.

Dry transformers are safer for indoor installations due to their fire-resistant design, absence of liquid coolants, and reduced environmental hazards. They can be safely placed closer to the point of use, require less maintenance, and pose minimal risk to occupants and sensitive equipment.

Here’s why dry transformers excel in indoor settings:

Compact and Safe Design

-

Space Efficiency:

- Smaller footprint compared to oil-filled transformers.

- In a recent project, we fit a dry transformer in a space half the size required for an oil-filled unit.

-

No Need for Oil Containment:

- Eliminates the requirement for oil pits or containment areas.

- Simplifies installation in multi-story buildings.

-

Reduced Weight:

- Lighter than oil-filled counterparts.

- Easier to install on upper floors without extensive structural reinforcement.

Improved Air Quality and Reduced Health Risks

-

No Oil Vapor Emissions:

- Eliminates the risk of harmful oil vapor inhalation.

- Particularly important in enclosed spaces with limited ventilation.

-

Reduced Particulate Emissions:

- Less dust and particulate matter generated during operation.

- In a data center installation, air quality improved noticeably after switching to dry transformers.

Enhanced Electrical Safety

-

Reduced Risk of Electrical Fires:

- No flammable oil to ignite in case of electrical faults.

- A client’s data center avoided a potential disaster during an electrical surge thanks to a dry transformer.

-

Better Short Circuit Performance:

- Many dry transformers have improved short circuit strength.

- This adds an extra layer of protection in high-fault-current environments.

| Feature | Benefit for Indoor Installations |

|---|---|

| Compact Design | Space-saving, flexible placement |

| Air Quality | No oil vapors, healthier environment |

| Electrical Safety | Reduced fire risk, better fault protection |

| Regulatory Compliance | Easier to meet building and safety codes |

My experience with a high-rise office building project demonstrated the clear advantages of dry transformers. The ability to install units on multiple floors improved power distribution efficiency and saved valuable space.

Environmental Impact: Why Are Dry Transformers Considered Eco-Friendly?

Looking to make your electrical systems more environmentally friendly? Dry transformers offer a green solution that’s gaining traction in the industry.

Dry transformers are eco-friendly due to their oil-free design, which eliminates the risk of soil and water contamination. They have a lower carbon footprint, are more energy-efficient, and are easier to recycle at the end of their lifecycle, making them a sustainable choice for modern electrical systems.

Let’s explore the environmental benefits:

Elimination of Oil-Related Environmental Risks

-

No Oil Leaks or Spills:

- Prevents soil and water contamination.

- In a recent project near a protected wetland, dry transformers were the only acceptable option.

-

No Hazardous Waste Disposal:

- Eliminates the need for proper oil disposal at end-of-life.

- Simplifies decommissioning and reduces long-term environmental impact.

Lower Carbon Footprint

-

Energy-Efficient Operation:

- Many dry transformers offer high energy efficiency.

- A recent installation showed 15% energy savings compared to older oil-filled units.

-

Longer Lifespan:

- Many dry transformers last 20-30 years or more.

- Longer life means less frequent replacement and reduced manufacturing emissions.

Recyclability and End-of-Life Considerations

-

Easier to Recycle:

- Most components can be easily separated and recycled.

- In a recent decommissioning project, we achieved a 90% recycling rate for a dry transformer.

-

Less Hazardous Materials:

- No oil means fewer harmful substances to manage during disposal.

- This reduces the environmental impact and cost of end-of-life processing.

| Environmental Aspect | Dry Transformer Benefit |

|---|---|

| Oil-Related Risks | Completely eliminated |

| Carbon Footprint | Lower in production and operation |

| Recyclability | Easier and more complete |

| Noise Pollution | Generally lower levels |

In a recent LEED certification project, the use of dry transformers contributed significantly to achieving the desired green building status, showcasing their role in sustainable design.

FAQ: Common Questions About Dry Transformers

-

Q: Are dry transformers more expensive than oil-filled transformers?

A: Initially, yes, but they often prove more cost-effective over their lifetime due to lower maintenance costs and reduced fire risk. -

Q: Can dry transformers handle the same load as oil-filled transformers?

A: Yes, dry transformers are available in a wide range of capacities, suitable for most applications. -

Q: Do dry transformers require special maintenance?

A: No, they actually require less maintenance than oil-filled transformers, mainly needing periodic visual inspections. -

Q: Are dry transformers suitable for outdoor use?

A: While primarily designed for indoor use, there are specially designed dry transformers for outdoor applications. -

Q: How long do dry transformers typically last?

A: With proper maintenance, dry transformers can last 20-30 years or more, comparable to well-maintained oil-filled units.

Conclusion

Dry transformers are revolutionizing safety in electrical installations. Their fire-resistant design, environmental benefits, and operational advantages make them ideal for modern applications. While initial costs may be higher, the long-term safety and efficiency gains often justify the investment. As we move towards smarter, safer, and more sustainable power solutions, dry transformers are leading the way in transforming electrical safety.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group