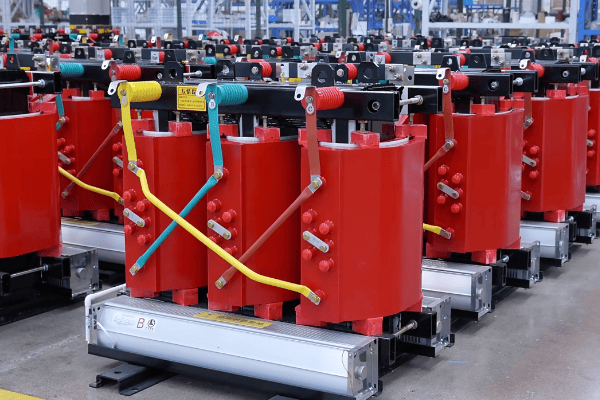

Dry Type Distribution Transformer Applications: From Industrial to Residential Settings?

Are you wondering why dry type transformers are becoming so popular? From factories to homes, these transformers are changing how we distribute power.

Dry type distribution transformers are versatile power solutions used in various settings. They offer advantages in safety, maintenance, and environmental protection. These transformers are ideal for indoor installations, areas with moisture concerns, and locations where fire safety is paramount.

I’ve worked with dry type transformers in many different projects. I’ve seen firsthand how they can solve unique power distribution challenges. Let’s explore how these transformers are making a difference across different settings.

Industrial Power Solutions: Optimizing Performance with Dry Type Distribution Transformers?

Have you ever wondered how factories manage their complex power needs? Dry type transformers are often the unsung heroes in these industrial settings.

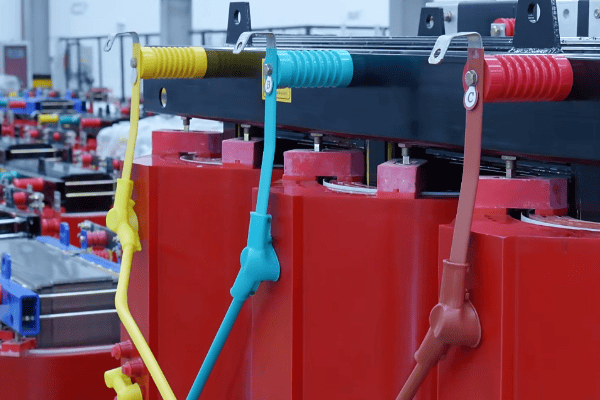

Dry type distribution transformers play a crucial role in industrial power solutions. They offer reliable performance, minimal maintenance, and enhanced safety features. These transformers are particularly well-suited for harsh industrial environments with dust, chemicals, or high temperatures.

In my years of experience, I’ve seen dry type transformers revolutionize industrial power distribution. Here’s why they’re so effective:

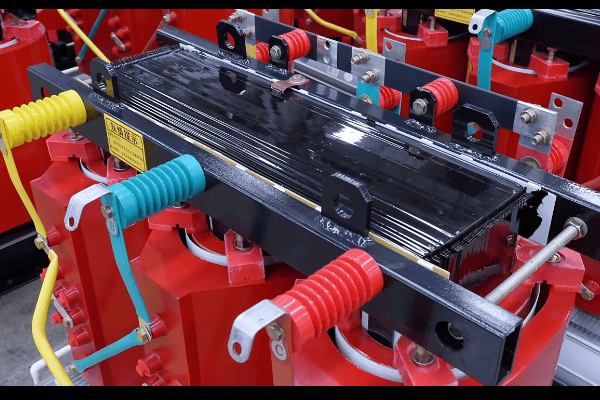

Reliability in Harsh Conditions

Dry type transformers can handle tough industrial environments:

- Dust Resistance: No oil means less risk of contamination.

- Chemical Resistance: Suitable for areas with corrosive atmospheres.

- High Temperature Tolerance: Can operate in hot industrial settings.

I once installed a dry type transformer in a steel mill. The high temperatures and dust would have quickly degraded an oil-filled unit, but the dry type transformer performed flawlessly for years.

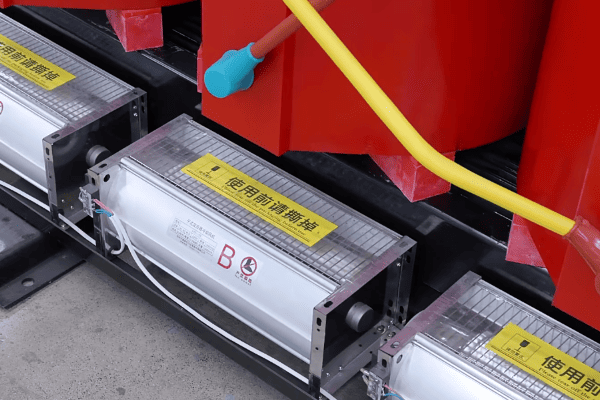

Minimal Maintenance Requirements

These transformers are designed for easy upkeep:

| Feature | Benefit |

|---|---|

| No Oil Changes | Reduces maintenance time and costs |

| Sealed Design | Prevents ingress of contaminants |

| Simple Inspection | Easy visual checks without complex procedures |

In a food processing plant, we replaced oil-filled transformers with dry types. The maintenance team was thrilled – no more oil sampling or leak checks, just simple periodic inspections.

Enhanced Safety Features

Safety is paramount in industrial settings:

- Fire Resistant: Reduced fire hazard compared to oil-filled units.

- Non-Toxic: No risk of oil spills or environmental contamination.

- Compact Design: Easier to install in tight spaces or on higher floors.

I remember a project in a chemical plant where safety was the top priority. The dry type transformer’s fire-resistant properties made it the only acceptable choice for their indoor substation.

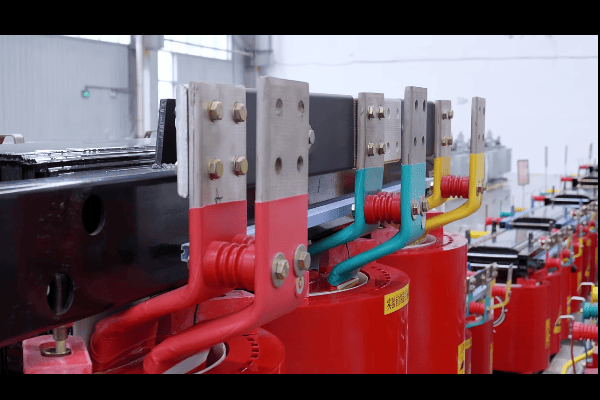

Load Management and Efficiency

Dry type transformers can handle industrial power demands:

- High Overload Capacity: Can manage short-term load spikes.

- Efficient at Varying Loads: Maintains performance across different demand levels.

- Multiple Tap Settings: Allows for voltage adjustment to optimize efficiency.

In a manufacturing facility, we used a dry type transformer with multiple tap settings. It allowed the plant to adjust voltage levels as production demands changed throughout the day, improving overall energy efficiency.

Commercial Energy Efficiency: Leveraging Dry Type Transformers in Business Environments?

Are you looking to cut energy costs in your commercial building? Dry type transformers might be the solution you haven’t considered.

Dry type transformers are increasingly used in commercial settings to improve energy efficiency. They offer low losses, compact design, and the ability to handle varying loads typical in business environments. These transformers are ideal for office buildings, shopping centers, and other commercial spaces.

I’ve helped many businesses upgrade their power systems with dry type transformers. The results are often surprising. Here’s what makes them so effective in commercial settings:

Energy Efficiency and Cost Savings

Dry type transformers can significantly reduce energy losses:

- Low No-Load Losses: Efficient even during periods of low demand.

- Reduced Core Losses: Advanced core materials minimize energy waste.

- Optimized for Partial Loads: Maintains efficiency during typical business hours.

I once helped a large office complex switch to dry type transformers. Their energy bills dropped by 15% in the first year alone.

Space-Saving Design

Commercial real estate is valuable, and dry type transformers help maximize it:

| Feature | Benefit |

|---|---|

| Compact Size | Fits in small electrical rooms |

| Vertical Installation Option | Utilizes wall space efficiently |

| No Oil Pit Required | Simplifies installation in multi-story buildings |

In a retrofit project for a downtown high-rise, we replaced bulky oil-filled transformers with compact dry types. It freed up enough space to add a small storage area, which the building manager was thrilled about.

Noise Reduction

Quiet operation is crucial in commercial environments:

- Low Audible Sound: Minimal disruption to work environments.

- Vibration Dampening: Reduces structural noise transmission.

- Enclosure Options: Further sound reduction for sensitive areas.

I installed a dry type transformer in a library once. The staff couldn’t believe how quiet it was compared to their old unit. It made a big difference in maintaining a peaceful atmosphere.

Smart Grid Compatibility

Modern businesses need transformers that can keep up with smart technology:

- Monitoring Capabilities: Easy integration with building management systems.

- Power Quality Management: Helps maintain clean power for sensitive equipment.

- Load Balancing: Supports efficient distribution across varying business loads.

In a recent project for a tech company, we used dry type transformers with built-in monitoring. It allowed them to track power usage in real-time and optimize their energy consumption patterns.

Residential Power Management: Benefits and Considerations of Dry Type Transformers in Homes?

Ever thought about the transformer that powers your home? Dry type transformers are making their way into residential settings, and for good reasons.

Dry type transformers offer several benefits for residential power management. They provide enhanced safety, reduced maintenance, and improved reliability for home electrical systems. These transformers are particularly useful in apartment buildings, large homes, and areas with specific environmental concerns.

I’ve seen an increasing number of homeowners and residential developers opt for dry type transformers. Here’s why they’re becoming a popular choice:

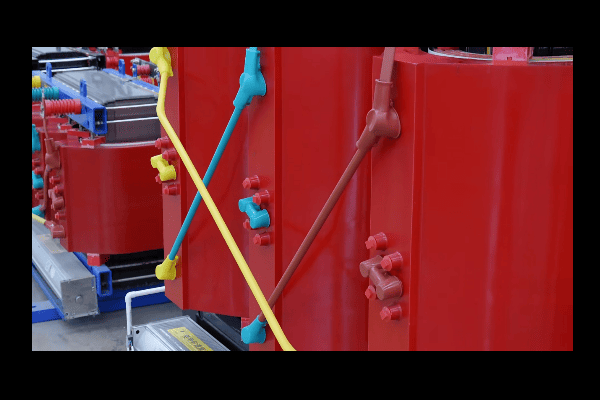

Safety First

Safety is a top priority in residential settings:

- Fire Resistant: Minimizes fire risks in densely populated areas.

- No Oil Leaks: Eliminates the risk of soil or water contamination.

- Touch-Safe Design: Safer for curious children or pets.

I once installed a dry type transformer in a large family home. The parents were relieved to know there was no risk of oil leaks near their children’s play area.

Quiet Operation

Peace and quiet are important at home:

| Feature | Benefit |

|---|---|

| Low Noise Emissions | Doesn’t disturb living spaces |

| Minimal Vibration | Reduces structural noise transmission |

| Enclosure Options | Further sound reduction for sensitive areas |

In an upscale apartment complex, we replaced the old transformers with dry types. The residents immediately noticed how much quieter their homes became.

Reliability and Longevity

Homeowners want power solutions that last:

- Resistant to Environmental Factors: Performs well in various climates.

- Stable Performance: Maintains efficiency over time.

- Long Lifespan: Often outlasts oil-filled counterparts.

I worked on a project in a coastal area where salt air was a major concern. The dry type transformer we installed has been running smoothly for years, while the old oil-filled units needed frequent maintenance.

Energy Efficiency

Energy savings matter in residential settings too:

- Low Losses: Helps reduce overall energy consumption.

- Efficient at Varying Loads: Handles the ups and downs of residential power use.

- Smart Home Compatible: Can integrate with home energy management systems.

For a large smart home project, we used dry type transformers that could communicate with the home’s energy management system. The homeowners loved being able to monitor and optimize their power usage.

Selection Criteria: Matching Dry Type Distribution Transformers to Specific Application Needs?

Choosing the right transformer can be tricky. How do you know which dry type transformer is best for your specific needs?

Selecting the right dry type distribution transformer involves considering various factors such as load requirements, environmental conditions, space constraints, and regulatory standards. Proper matching ensures optimal performance, energy efficiency, and longevity of the transformer in its specific application.

Over the years, I’ve helped many clients choose the right dry type transformer. Here’s what I consider when making a selection:

Load Profile Analysis

Understanding power needs is crucial:

- Peak Load Requirements: Ensures the transformer can handle maximum demand.

- Load Factor: Helps determine the most efficient transformer size.

- Future Growth: Allows for potential increases in power needs.

I once worked with a growing tech startup. We chose a transformer with extra capacity to accommodate their rapid expansion plans. It saved them from needing an upgrade just a year later.

Environmental Considerations

The installation environment plays a big role:

| Factor | Consideration |

|---|---|

| Temperature | Affects cooling and efficiency |

| Humidity | Influences insulation requirements |

| Altitude | Impacts cooling and insulation |

For a high-altitude installation in Colorado, we had to select a transformer with special insulation and cooling designs to handle the thin air and temperature extremes.

Space and Installation Constraints

Physical limitations can dictate transformer choice:

- Available Floor Space: Determines the maximum transformer size.

- Weight Limits: Important for rooftop or upper floor installations.

- Access Routes: Affects the feasibility of installation and future replacement.

In a renovation project for an old city building, we had to choose a compact, lightweight transformer that could be moved through narrow hallways and fit in a small electrical room.

Regulatory Compliance

Meeting standards and regulations is non-negotiable:

- Energy Efficiency Standards: Varies by region and application.

- Noise Regulations: Particularly important in residential or mixed-use areas.

- Safety Codes: Must meet local and national requirements.

For a project in California, we had to select transformers that met the state’s strict energy efficiency standards. It was challenging, but it resulted in significant long-term energy savings for the client.

Safety and Sustainability: Advantages of Dry Type Transformers Across Various Settings?

Are you concerned about safety and environmental impact? Dry type transformers offer solutions that address both these crucial aspects.

Dry type transformers provide significant safety and sustainability advantages across various settings. They eliminate the risk of oil leaks, reduce fire hazards, and have a lower environmental impact. These features make them ideal for environmentally sensitive areas and locations with strict safety requirements.

Throughout my career, I’ve seen dry type transformers make a real difference in safety and sustainability. Here’s why they’re so advantageous:

Enhanced Fire Safety

Dry type transformers significantly reduce fire risks:

- No Flammable Oil: Eliminates a major fire hazard.

- Self-Extinguishing Materials: Many designs use flame-retardant components.

- Lower Operating Temperatures: Reduces the risk of heat-related fires.

I once installed dry type transformers in a hospital. The fire safety officers were impressed by how much these units reduced the overall fire risk in the building.

Environmental Protection

These transformers are eco-friendly:

| Aspect | Benefit |

|---|---|

| No Oil Leaks | Prevents soil and water contamination |

| Recyclable Materials | Easier to dispose of at end-of-life |

| Lower Carbon Footprint | Often more energy-efficient over their lifespan |

In an environmentally sensitive project near a protected wetland, dry type transformers were the only option that met the strict environmental regulations.

Reduced Maintenance and Increased Reliability

Less maintenance means fewer safety risks and more sustainable operations:

- No Oil Handling: Eliminates the need for potentially hazardous oil changes.

- Sealed Design: Prevents ingress of dust and moisture, reducing maintenance.

- Longer Lifespan: Reduces the frequency of replacements and associated waste.

I worked with a remote mining operation that switched to dry type transformers. The reduced maintenance needs were a game-changer for their operations in a challenging, isolated environment.

Improved Air Quality

Dry type transformers contribute to better indoor air quality:

- No Oil Vapor Emissions: Important in enclosed or poorly ventilated areas.

- Reduced Particulate Generation: Less dust and debris compared to oil-filled units.

- Lower Heat Emissions: Can reduce HVAC load in buildings.

For a project in a large indoor shopping mall, the switch to dry type transformers noticeably improved the air quality in the service areas, making a healthier environment for maintenance staff.

Conclusion

Dry type distribution transformers offer versatile, safe, and efficient power solutions across industrial, commercial, and residential settings. Their benefits in safety, maintenance, and environmental protection make them an excellent choice for various applications.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group