Dry Type Transformers: The Future of Indoor Power Distribution?

I’ve seen many changes in the power industry over the years. But nothing has impressed me more than the rise of dry type transformers. They’re changing how we think about indoor power distribution.

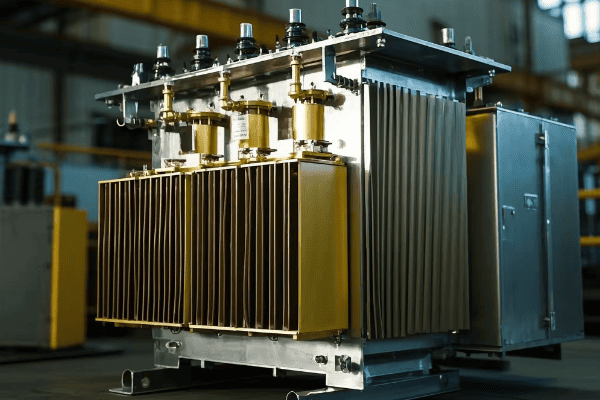

Dry type transformers are becoming the go-to choice for indoor power distribution. They offer improved safety, lower maintenance, and better environmental performance compared to traditional oil-filled transformers. These benefits make them ideal for use in buildings, hospitals, and data centers.

I remember when I first learned about dry type transformers. I was amazed by their potential. Let’s explore why these transformers are shaping the future of indoor power distribution.

What is a Dry Type Distribution Transformer and How Does it Work?

Have you ever wondered how power safely reaches different parts of a building? The answer often lies in a dry type distribution transformer. It’s a key player in modern power systems.

A dry type distribution transformer is an electrical device that changes voltage levels without using oil for insulation or cooling. It uses air and solid materials instead. This transformer works by electromagnetic induction, transferring electrical energy between two or more circuits through a shared magnetic field.

Let’s dive deeper into how these transformers work and why they’re so important for indoor power distribution.

The Basic Structure

Dry type transformers have a simple yet effective structure:

- Core: This is usually made of silicon steel laminations. It provides a path for the magnetic flux.

- Windings: These are typically made of copper or aluminum. They’re wrapped around the core.

- Insulation: Instead of oil, dry type transformers use solid insulation materials like epoxy resin.

How It Works

The working principle of a dry type transformer is fascinating:

- Primary Winding: When AC power enters the primary winding, it creates a changing magnetic field in the core.

- Magnetic Field: This field extends to the secondary winding.

- Secondary Winding: The changing magnetic field induces a voltage in the secondary winding.

- Voltage Change: The voltage change depends on the number of turns in each winding.

I once had to explain this to a client who was skeptical about switching to dry type transformers. I used a simple analogy: "Imagine the transformer as a gear system. The primary winding is like the input gear, the core is the connecting shaft, and the secondary winding is the output gear. The number of teeth on each gear determines the speed (or in our case, voltage) change."

Types of Dry Type Transformers

There are several types of dry type transformers:

- Cast Resin Transformers: These use epoxy resin for insulation.

- VPI (Vacuum Pressure Impregnated) Transformers: These are impregnated with varnish under vacuum.

- Open Wound Transformers: These have exposed windings and are used in specific industrial applications.

| Type | Insulation | Typical Use | Advantages |

|---|---|---|---|

| Cast Resin | Epoxy resin | Indoor, high moisture areas | Excellent moisture resistance |

| VPI | Varnish | General indoor use | Cost-effective, good performance |

| Open Wound | Air | Industrial, low humidity | Simple design, easy maintenance |

Understanding these types helps in choosing the right transformer for specific needs. In my experience, cast resin transformers are often the best choice for critical indoor applications due to their superior moisture resistance and fire safety.

Why Are Dry Type Transformers Gaining Popularity in Modern Buildings?

I’ve noticed a growing trend in modern building design. More and more architects and engineers are choosing dry type transformers. There’s a good reason for this shift.

Dry type transformers are gaining popularity in modern buildings due to their enhanced safety features, lower maintenance requirements, and eco-friendly design. They eliminate fire risks associated with oil-filled transformers, require less space, and align with green building standards.

Let’s explore the reasons behind this growing popularity and why it matters for modern building design.

Safety First

Safety is always my top priority when designing power systems. Dry type transformers excel in this area:

- Fire Safety: They don’t use flammable oil, greatly reducing fire risk.

- No Oil Leaks: This eliminates the risk of oil spills and associated hazards.

- Indoor Friendly: They can be safely installed close to the point of use.

I once worked on a project for a high-rise office building. The client was concerned about fire safety. When I explained how dry type transformers eliminate the risk of oil fires, they were immediately sold on the idea.

Space Efficiency

In modern buildings, space is often at a premium. Dry type transformers offer significant advantages:

- Compact Design: They’re generally smaller than oil-filled transformers.

- No Oil Containment: This saves even more space in the installation area.

- Flexible Installation: They can be installed in various orientations.

Low Maintenance

Building managers appreciate the low maintenance requirements of dry type transformers:

- No Oil Checks: There’s no need for regular oil testing or replacement.

- Simple Inspections: Visual checks are often sufficient.

- Longer Life: With proper care, they can last for decades.

Eco-Friendly Design

Modern buildings often aim for green certifications. Dry type transformers can help:

- No Oil Disposal: This eliminates a potential environmental hazard.

- Energy Efficient: Many models offer high efficiency ratings.

- Recyclable Materials: Many components can be recycled at end-of-life.

| Feature | Benefit for Modern Buildings |

|---|---|

| Fire Safety | Reduces insurance costs, meets strict safety codes |

| Space Efficiency | Allows for more rentable space in the building |

| Low Maintenance | Reduces operational costs over time |

| Eco-Friendly | Helps achieve green building certifications |

In my experience, the combination of these factors makes dry type transformers an attractive choice for modern building designers. They align well with the goals of safety, efficiency, and sustainability that are so important in contemporary architecture.

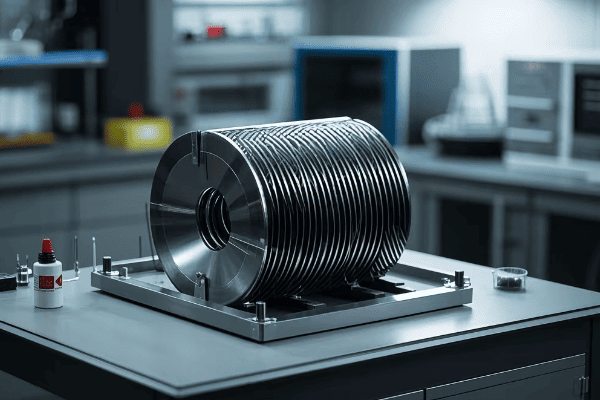

The Core of Dry Type Transformers: Understanding Its Critical Role?

The core of a dry type transformer might not be visible, but it’s the heart of the device. I’ve found that many people overlook its importance. Let’s change that.

The core of a dry type transformer plays a critical role in its operation. It provides a path for the magnetic flux, enabling the transfer of energy between the primary and secondary windings. The core’s design and material significantly impact the transformer’s efficiency, size, and performance.

Let’s dive deeper into the world of transformer cores and why they’re so crucial for the performance of dry type transformers.

Core Materials

The choice of core material is crucial:

- Silicon Steel: This is the most common material. It offers a good balance of performance and cost.

- Amorphous Metal: This newer material can reduce energy losses by up to 70% compared to silicon steel.

- Nanocrystalline Materials: These offer even better performance but are currently very expensive.

I once worked on a project where we used amorphous metal cores. The energy savings were impressive, and the client was thrilled with the reduced operating costs.

Core Designs

There are several core designs, each with its own advantages:

- Core Type: The windings surround the core limbs.

- Shell Type: The core surrounds the windings.

- Toroidal: A ring-shaped core with windings wrapped around it.

The Role of the Core

The core serves several critical functions:

- Magnetic Flux Path: It provides a low-reluctance path for the magnetic flux.

- Energy Transfer: It enables the transfer of energy between the primary and secondary windings.

- Efficiency: A well-designed core minimizes energy losses.

Core Losses

Understanding core losses is crucial for optimizing transformer performance:

- Hysteresis Loss: This occurs due to the changing magnetic field.

- Eddy Current Loss: This is caused by currents induced in the core material.

To minimize these losses, cores are often made of thin laminations stacked together.

| Core Type | Advantages | Best For |

|---|---|---|

| Core Type | Good cooling, easy maintenance | General purpose |

| Shell Type | Better short-circuit strength | High current applications |

| Toroidal | Very low stray magnetic field | Sensitive electronic equipment |

In my experience, the choice of core design and material can make a significant difference in transformer performance. I always pay close attention to these factors when designing or specifying transformers for a project.

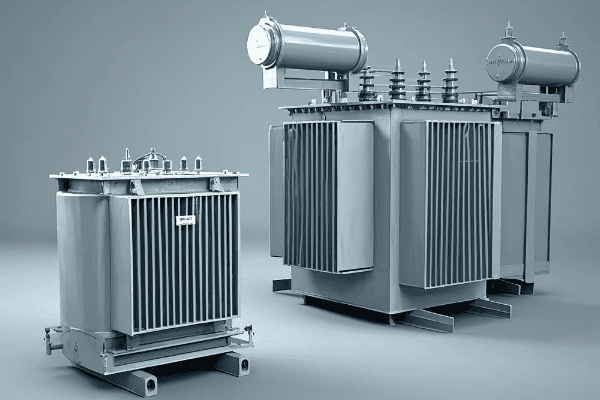

Dry vs. Oil Type Transformers: A Comprehensive Comparison?

I’ve worked with both dry and oil type transformers throughout my career. Each has its strengths and weaknesses. Let’s compare them to see which might be best for your needs.

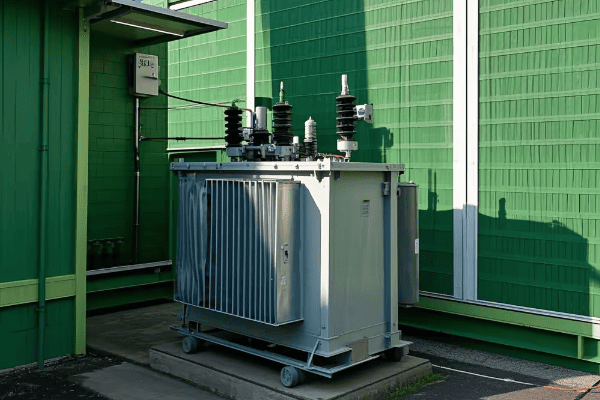

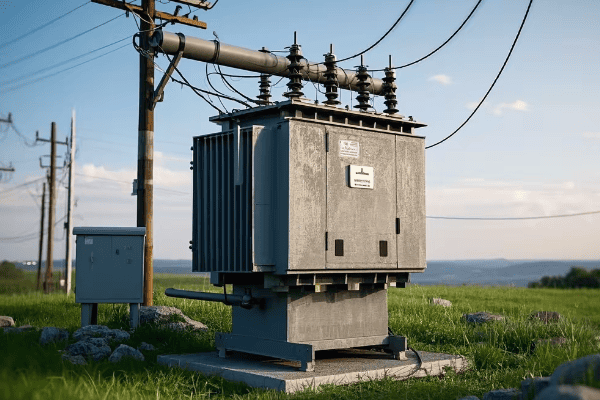

Dry type transformers offer better fire safety and environmental protection, while oil type transformers generally have better cooling and overload capacity. Dry types are preferred for indoor and environmentally sensitive locations, while oil types are often used for outdoor and high-capacity applications.

Let’s dive deeper into the key differences between these two transformer types.

Safety Considerations

Safety is always my top priority:

-

Fire Risk:

- Dry Type: Low fire risk due to absence of flammable oil.

- Oil Type: Higher fire risk due to presence of flammable oil.

-

Environmental Risk:

- Dry Type: No risk of oil leaks or spills.

- Oil Type: Potential for oil leaks, requiring containment measures.

I once worked on a project for a hospital where we chose dry type transformers specifically for their superior fire safety.

Performance and Efficiency

Performance can vary depending on the application:

-

Cooling Efficiency:

- Dry Type: Air-cooled, less efficient for heat dissipation.

- Oil Type: Oil provides excellent cooling, allowing for better overload capacity.

-

Noise Levels:

- Dry Type: Generally quieter operation.

- Oil Type: Can be noisier, especially with cooling fans.

-

Efficiency:

- Dry Type: Slightly less efficient, especially at partial loads.

- Oil Type: Often more efficient, particularly in larger sizes.

Maintenance and Lifespan

Maintenance needs can significantly impact long-term costs:

-

Routine Maintenance:

- Dry Type: Lower maintenance requirements, no oil testing needed.

- Oil Type: Regular oil testing and potential oil replacement required.

-

Lifespan:

- Dry Type: Typical lifespan of 20-30 years.

- Oil Type: Can last 30-40 years or more with proper maintenance.

Installation and Space Requirements

Space considerations are often crucial:

-

Space Needs:

- Dry Type: Generally more compact, no need for oil containment.

- Oil Type: Requires more space, including area for oil containment.

-

Weight:

- Dry Type: Typically lighter.

- Oil Type: Heavier, may require additional structural support.

| Feature | Dry Type | Oil Type |

|---|---|---|

| Fire Safety | High | Lower |

| Environmental Risk | Low | Higher |

| Cooling Efficiency | Lower | High |

| Maintenance | Low | Higher |

| Lifespan | 20-30 years | 30-40+ years |

| Space Requirements | Lower | Higher |

| Best For | Indoor, sensitive environments | Outdoor, high capacity |

In my experience, the choice between dry and oil type transformers often comes down to the specific needs of the project. For indoor applications, especially in sensitive environments, I usually recommend dry type transformers. For outdoor substations or very high capacity needs, oil type transformers might be the better choice.

Key Advantages of Dry Type Transformers for Indoor Applications?

When it comes to indoor power distribution, dry type transformers have some clear advantages. I’ve seen these benefits firsthand in many projects.

Dry type transformers excel in indoor applications due to their enhanced safety, reduced maintenance needs, and environmental friendliness. They eliminate fire and environmental risks associated with oil, require less space, and align well with green building standards. These factors make them ideal for use in commercial buildings, hospitals, and data centers.

Let’s explore these advantages in more detail and see why they matter for indoor applications.

Enhanced Safety

Safety is paramount in indoor environments:

- Fire Resistance: The absence of oil significantly reduces fire risk.

- No Oil Leaks: Eliminates the risk of oil spills and associated hazards.

- Reduced Explosion Risk: Lower risk of explosive failure compared to oil-filled transformers.

I once worked on a project for a large library. The client was particularly concerned about fire safety. The choice of dry type transformers gave them peace of mind.

Space Efficiency

In indoor settings, space is often at a premium:

- Compact Design: Generally smaller than equivalent oil-filled units.

- No Oil Containment Needed: Saves additional space.

- Flexible Installation: Can be installed closer to the load, saving on cable costs.

Low Maintenance Requirements

Building managers appreciate the ease of maintenance:

- No Oil Testing: Eliminates the need for regular oil testing and replacement.

- Simpler Inspections: Visual inspections are often sufficient.

- Longer Intervals Between Services: Reduces downtime and maintenance costs.

Environmental Benefits

Dry type transformers align well with green building initiatives:

- No Oil Disposal: Eliminates the need for hazardous waste disposal.

- Recyclable Materials: Many components can be recycled at end-of-life.

- Energy Efficiency: Many models offer high efficiency ratings.

Noise Reduction

Quiet operation is crucial in many indoor settings:

- Lower Noise Levels: Generally quieter than oil-filled transformers.

- No Cooling Fans: Many designs don’t require noisy cooling fans.

| Advantage | Benefit for Indoor Applications |

|---|---|

| Fire Safety | Crucial for occupied buildings |

| Space Efficiency | Maximizes usable floor space |

| Low Maintenance | Reduces operational costs |

| Environmental Benefits | Helps achieve green certifications |

| Noise Reduction | Improves occupant comfort |

In my experience, these advantages make dry type transformers the preferred choice for most indoor applications. They offer a combination of safety, efficiency, and environmental benefits that are hard to match with other transformer types.

Common Misconceptions About Dry Type Transformers: Debunking the Myths?

Throughout my career, I’ve encountered many misconceptions about dry type transformers. These myths can lead to poor decisions in power system design. Let’s clear up some of these misunderstandings.

Common misconceptions about dry type transformers include beliefs that they are less efficient, more expensive, and less durable than oil-filled types. In reality, modern dry type transformers are highly efficient, often more cost-effective in the long run, and can last for decades with proper care.

Let’s examine some of these myths in detail and see why they don’t hold up to scrutiny.

Myth 1: Dry Type Transformers Are Less Efficient

This is a common misconception I often hear:

Reality: While it’s true that some older dry type models were less efficient, modern designs have significantly improved. Many dry type transformers now offer efficiency levels comparable to or even exceeding oil-filled types.

Key Points:

- Advanced Materials: Use of materials like amorphous metal cores has greatly reduced losses.

- Design Improvements: Better winding techniques and insulation have improved efficiency.

- Regulation Compliance: Many dry type transformers meet or exceed efficiency standards.

I once worked on a project where we replaced old oil-filled transformers with modern dry types. The energy savings were substantial, surprising even the skeptical facility manager.

Myth 2: Dry Type Transformers Are Always More Expensive

Initial cost is often a concern:

Reality: While the upfront cost of dry type transformers can be higher, they often prove more cost-effective over their lifetime.

Key Points:

- Lower Maintenance Costs: No oil testing or replacement needed.

- Reduced Installation Costs: No need for oil containment systems.

- Longer Lifespan: Many dry type transformers last for decades with proper care.

- Lower Insurance Costs: Reduced fire risk can lead to lower insurance premiums.

Myth 3: Dry Type Transformers Can’t Handle Overloads

This misconception canThis misconception can lead to overdesign:

Reality: While it’s true that dry type transformers generally have lower overload capacity than oil-filled types, they can still handle short-term overloads when properly designed.

Key Points:

- Design Flexibility: Dry type transformers can be designed for specific overload requirements.

- Temperature Monitoring: Advanced monitoring systems can safely manage overload conditions.

- Cooling Options: Some designs incorporate forced air cooling for better overload handling.

In a data center project I worked on, we successfully used dry type transformers with forced air cooling to handle the variable loads typical in such environments.

Myth 4: Dry Type Transformers Are Not Suitable for Harsh Environments

This myth often limits their use:

Reality: While it’s true that standard dry type transformers are designed for indoor use, there are specially designed models for harsh environments.

Key Points:

- Enclosures: Dry type transformers can be housed in protective enclosures for outdoor use.

- Special Designs: Some models are specifically designed for high humidity or corrosive environments.

- Temperature Range: Many dry type transformers can operate in a wide temperature range.

I once specified a specially designed dry type transformer for a coastal industrial plant. It performed excellently despite the salty, humid environment.

| Myth | Reality |

|---|---|

| Less Efficient | Modern designs are highly efficient |

| More Expensive | Often more cost-effective over lifetime |

| Can’t Handle Overloads | Can be designed for overload capacity |

| Not for Harsh Environments | Special designs available for challenging conditions |

Debunking these myths is crucial for making informed decisions about transformer selection. In my experience, understanding the true capabilities of dry type transformers often leads to better, more efficient power system designs.

The Environmental Impact: How Dry Type Transformers Contribute to Sustainability?

As an engineer, I’ve always been interested in the environmental impact of the systems I design. Dry type transformers have a lot to offer in this regard. Let’s explore how they contribute to sustainability.

Dry type transformers contribute to sustainability through their eco-friendly design, energy efficiency, and long lifespan. They eliminate the risk of oil leaks, reduce the need for hazardous waste disposal, and often use recyclable materials. Their efficiency and durability also contribute to reduced energy consumption over time.

Let’s dive deeper into the environmental benefits of dry type transformers and why they matter in our increasingly eco-conscious world.

Elimination of Oil-Related Environmental Risks

This is perhaps the most obvious environmental benefit:

- No Oil Leaks: Eliminates the risk of soil and water contamination.

- No Oil Disposal: Removes the need for hazardous waste management.

- Reduced Fire Risk: Lowers the chance of environmentally damaging fires.

I once worked on a project near a protected wetland. The choice of dry type transformers was crucial in getting environmental approval for the development.

Energy Efficiency

Efficiency is key to reducing environmental impact:

- Low Losses: Modern dry type transformers have very low core and winding losses.

- Consistent Performance: Efficiency remains high even at partial loads.

- Cool Operation: Less energy wasted as heat compared to some oil-filled types.

Long Lifespan and Recyclability

Sustainability is about more than just operation:

- Durability: Many dry type transformers last 20-30 years or more.

- Recyclable Materials: Core and windings are often made of recyclable metals.

- Less Frequent Replacement: Longer lifespan means less frequent manufacturing and disposal.

Reduced Carbon Footprint

The overall impact on carbon emissions is significant:

- Manufacturing: Often requires less energy-intensive processes than oil-filled types.

- Transportation: Lighter weight can mean lower transport-related emissions.

- Operation: High efficiency leads to lower energy consumption over time.

Alignment with Green Building Standards

Dry type transformers can help achieve green certifications:

- LEED Points: Can contribute to LEED certification for buildings.

- Energy Star: Many models meet Energy Star efficiency requirements.

- Green Grid Initiatives: Align well with efforts to create more sustainable power grids.

| Environmental Aspect | Benefit of Dry Type Transformers |

|---|---|

| Oil-Related Risks | Eliminated |

| Energy Efficiency | High, reducing overall energy consumption |

| Lifespan | Long, reducing manufacturing and disposal impacts |

| Recyclability | High, especially for core and windings |

| Green Building Compliance | Often contributes to certifications |

In my experience, the environmental benefits of dry type transformers are becoming increasingly important. As sustainability becomes a key focus in many industries, the choice of transformer type can play a significant role in reducing a project’s overall environmental impact.

Conclusion

Dry type transformers are revolutionizing indoor power distribution. They offer enhanced safety, efficiency, and environmental benefits. As we move towards more sustainable and smart buildings, dry type transformers will play a crucial role in shaping our power systems.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group