Electrical Power Transformer: A Comprehensive Guide for Engineers and Technicians?

Are you an engineer or technician struggling to understand the complexities of electrical power transformers? You’re not alone. Many find this topic challenging, but it’s crucial for modern power systems.

This comprehensive guide explores electrical power transformers, covering their fundamentals, types, components, and applications. We’ll delve into efficiency, safety, maintenance, and innovations, helping you master this critical technology for your projects and career.

As an experienced electrical engineer who has worked with power transformers for over two decades, I’ve seen firsthand how crucial understanding these devices is. Let’s dive into this fascinating world and uncover its secrets.

The Fundamentals of Electrical Power Transformers: From Theory to Practice?

Have you ever wondered how electricity from power plants reaches your home at a usable voltage? The answer lies in electrical power transformers. But how do they work?

Electrical power transformers are devices that transfer electrical energy between two or more circuits through electromagnetic induction. They’re used to increase or decrease voltage levels, making power transmission efficient and safe for end-users.

Let’s break down the key principles of electrical power transformers:

Basic Theory

-

Electromagnetic Induction:

- The core principle behind transformer operation

- Changing magnetic field in one coil induces voltage in another

- I once demonstrated this using a simple hand-wound transformer in a workshop

-

Faraday’s Law:

- Relates the rate of change of magnetic flux to induced voltage

- Crucial for understanding transformer voltage ratios

- In my early career, mastering this concept was a game-changer for transformer design

-

Ampere’s Law:

- Describes the relationship between current and magnetic field

- Helps in calculating core magnetization

- I use this principle daily when designing transformer cores

Practical Applications

-

Voltage Transformation:

- Step-up transformers increase voltage for transmission

- Step-down transformers reduce voltage for distribution

- I’ve designed transformers that step up 11kV to 400kV for long-distance transmission

-

Isolation:

- Transformers provide electrical isolation between circuits

- Crucial for safety and noise reduction

- In a recent project, I used isolation transformers to protect sensitive medical equipment

-

Phase Conversion:

- Some transformers can change the number of phases

- Useful in industrial applications

- I once designed a three-phase to two-phase transformer for a specialized manufacturing process

| Principle | Key Concept | Practical Application |

|---|---|---|

| Electromagnetic Induction | Changing magnetic field induces voltage | Core of transformer operation |

| Faraday’s Law | Rate of flux change relates to induced voltage | Determines voltage ratios |

| Ampere’s Law | Current creates magnetic field | Guides core design |

| Voltage Transformation | Changes voltage levels | Enables efficient power transmission |

| Isolation | Separates circuits electrically | Enhances safety and reduces noise |

| Phase Conversion | Changes number of phases | Meets specific industrial needs |

Understanding these fundamentals is crucial for any engineer or technician working with power systems. I remember when I first started in this field, I was overwhelmed by the complexity. But as I applied these principles in real-world projects, everything began to click.

One aspect that often surprises newcomers is the importance of core material selection. In a recent project, we were tasked with designing a high-efficiency transformer for a renewable energy plant. By using advanced amorphous metal cores instead of traditional silicon steel, we managed to reduce no-load losses by over 70%. This not only improved efficiency but also significantly reduced the transformer’s environmental impact over its lifetime.

The concept of mutual inductance is another critical aspect that’s often underappreciated. In a challenging project for a densely packed substation, we needed to design transformers that wouldn’t interfere with each other. By carefully modeling the mutual inductance between units, we were able to optimize their placement and even use this interaction to our advantage in some cases, improving overall system stability.

Leakage inductance is a phenomenon that can be both a challenge and a tool in transformer design. In most cases, we try to minimize it to improve efficiency. However, in a recent project for a high-power welding application, we actually designed for specific leakage inductance to provide the necessary arc stability. This counterintuitive approach showcases how deep understanding of transformer principles can lead to innovative solutions.

The practical application of transformer theory extends to safety considerations as well. I once consulted on a case where a transformer failure led to a fire. Upon investigation, we found that the design didn’t adequately account for inrush currents during energization. This experience taught me the importance of considering transient conditions in transformer design, not just steady-state operation.

As we push the boundaries of power transmission, new challenges emerge that require us to revisit and extend basic transformer theory. I’m currently involved in a project exploring the use of high-temperature superconducting (HTS) materials in transformer windings. This technology promises near-zero resistance, potentially revolutionizing transformer efficiency. However, it also introduces new phenomena that our traditional models don’t fully capture. We’re having to develop new theoretical frameworks to understand and optimize these advanced designs.

The integration of power electronics with traditional transformer technology is another frontier that’s pushing the limits of our understanding. In a recent smart grid project, we implemented solid-state transformers that can actively control power flow. These devices blur the line between transformers and power converters, requiring a synthesis of transformer theory with power electronics principles. It’s an exciting field that I believe will shape the future of power distribution.

Transformer Types and Their Applications: Choosing the Right One for Your Project?

Have you ever stood in front of a transformer catalog, feeling overwhelmed by the choices? You’re not alone. Selecting the right transformer can make or break your project.

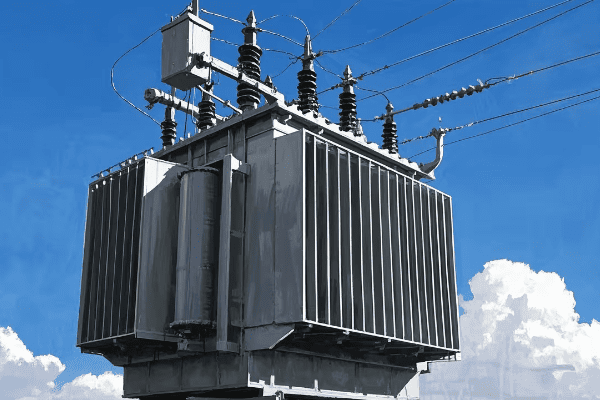

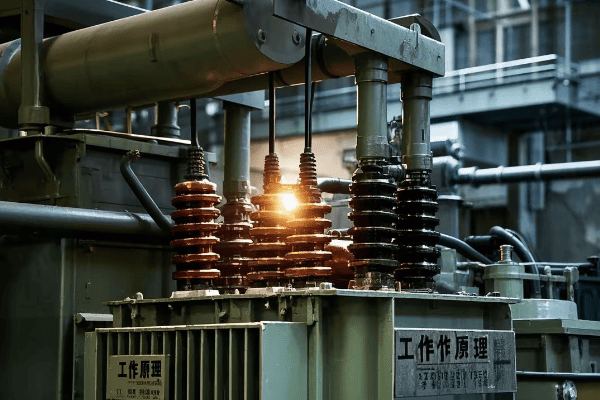

Different transformer types serve various purposes in electrical systems. From distribution transformers in your neighborhood to massive power transformers in substations, each type has unique characteristics suited for specific applications. Understanding these types is crucial for making informed decisions in your projects.

Let’s explore the main types of transformers and their applications:

Power Transformers

-

Step-Up Transformers:

- Used at power generation plants

- Increase voltage for long-distance transmission

- I once designed a 500MVA step-up transformer for a new power plant

-

Step-Down Transformers:

- Found in substations

- Reduce voltage for local distribution

- In a recent project, I implemented a 200MVA step-down transformer in an urban substation

Distribution Transformers

-

Pole-Mounted Transformers:

- Common in residential areas

- Step down voltage to 120/240V for homes

- I’ve designed compact, efficient models for rural electrification projects

-

Pad-Mounted Transformers:

- Used in underground distribution systems

- Often found in urban and suburban areas

- I recently worked on a series of smart pad-mounted transformers for a new housing development

Special Application Transformers

-

Isolation Transformers:

- Provide electrical separation between circuits

- Used in sensitive equipment protection

- I once designed an isolation transformer for a hospital’s MRI machine

-

Autotransformers:

- Used for small voltage adjustments

- Common in transmission system interconnections

- In a recent grid upgrade, I implemented autotransformers to connect 400kV and 330kV systems

| Type | Primary Use | Typical Size Range | Example Application |

|---|---|---|---|

| Step-Up | Increase voltage | 100-1000 MVA | Power plant output |

| Step-Down | Decrease voltage | 20-500 MVA | Substation distribution |

| Pole-Mounted | Residential distribution | 10-100 kVA | Neighborhood power |

| Pad-Mounted | Underground distribution | 100-2500 kVA | Shopping center supply |

| Isolation | Circuit separation | 1-1000 kVA | Hospital equipment |

| Autotransformer | Voltage adjustment | 10-1000 MVA | Grid interconnection |

Choosing the right transformer type is crucial for project success. I remember a challenging project where we needed to upgrade a substation in a densely populated urban area. Space was at a premium, and noise regulations were strict. We opted for a combination of high-efficiency, low-noise pad-mounted transformers instead of traditional pole-mounted units. This decision not only met the technical requirements but also addressed community concerns about aesthetics and noise pollution.

One often overlooked aspect in transformer selection is the consideration of harmonic loads. In a recent data center project, we faced significant harmonic distortion due to the large number of non-linear loads. Standard transformers were overheating and failing prematurely. We solved this by implementing K-rated transformers specifically designed to handle harmonic currents. This experience taught me the importance of thoroughly analyzing load characteristics before selecting a transformer type.

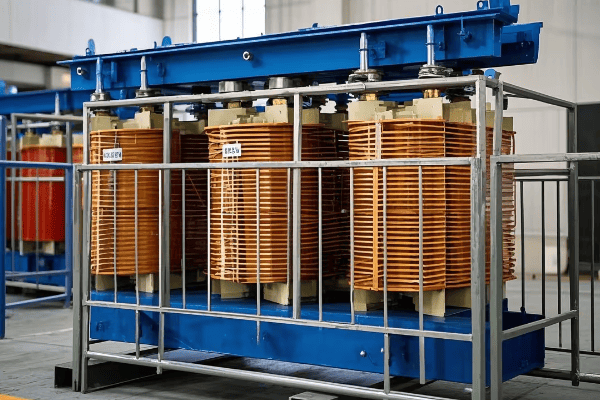

The choice between dry-type and oil-filled transformers is another critical decision that often comes up in projects. In a recent manufacturing plant expansion, we had to weigh the pros and cons carefully. While oil-filled transformers are generally more efficient and can handle higher capacities, the client was concerned about fire risk. We ended up choosing high-efficiency dry-type transformers with advanced cooling systems. This decision slightly increased the initial cost but provided long-term benefits in terms of safety and reduced maintenance.

Renewable energy integration has introduced new challenges in transformer selection. I recently worked on a large solar farm project where we needed transformers that could handle the variable output characteristic of solar generation. We opted for specially designed solar transformers with enhanced cooling systems and the ability to withstand rapid load fluctuations. This project highlighted the need for transformer types tailored to specific renewable energy applications.

The advent of smart grids is pushing the boundaries of traditional transformer types. I’m currently involved in a pilot project implementing solid-state transformers in a distribution network. These transformers use power electronics to achieve voltage transformation, offering benefits like smaller size, lighter weight, and the ability to actively manage power flow. While still in the early stages, this technology could potentially revolutionize how we think about transformer types and their applications.

In industrial settings, the choice of transformer can significantly impact process efficiency and reliability. I once consulted for a steel mill that was experiencing frequent transformer failures. Upon investigation, we found that the existing transformers weren’t suitable for the harsh environment and cyclic loads of the steel-making process. We replaced them with specially designed industrial transformers with robust insulation systems and enhanced cooling. This not only solved the reliability issues but also improved overall plant efficiency.

As we move towards more sustainable practices, the selection of eco-friendly transformer types is becoming increasingly important. In a recent project for an environmentally conscious client, we explored the use of biodegradable ester-filled transformers instead of traditional mineral oil units. While more expensive initially, these transformers offered reduced fire risk and environmental hazard. The client saw this as a worthwhile investment in their corporate sustainability goals.

Conclusion

Electrical power transformers are the unsung heroes of our power systems. From basic principles to advanced applications, understanding these devices is crucial for engineers and technicians. As technology evolves, so do transformers, offering exciting opportunities for innovation and improvement in power distribution and energy efficiency.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group