Exploring the Diverse World of Pad Mounted Transformers: Types and Configurations?

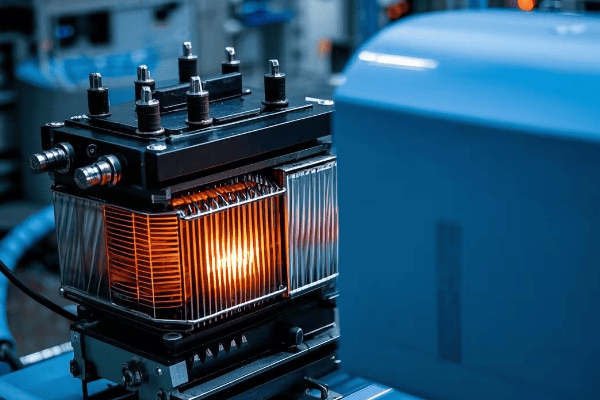

Have you ever wondered about those green boxes in your neighborhood? They’re not just for decoration. These pad mounted transformers come in various types and configurations, each serving a unique purpose in our power distribution system.

Pad mounted transformers are available in single-phase and three-phase designs, with loop feed or radial feed configurations. They come in different voltage classes and kVA ratings, use various cooling methods, and can be customized for special applications, including smart grid integration.

As an electrical engineer with over 20 years of experience, I’ve worked with a wide range of pad mounted transformers. Each type has its own strengths and ideal applications. Understanding these differences is crucial for designing efficient and reliable power distribution systems. Let’s dive into the diverse world of pad mounted transformers and explore their types and configurations.

Single-Phase vs. Three-Phase: Understanding the Basics?

Ever noticed that some transformers are smaller than others? The difference often lies in whether they’re single-phase or three-phase. But what does this mean for power distribution?

Single-phase transformers are used for residential and light commercial loads, while three-phase transformers power industrial and heavy commercial applications. The choice between them depends on the power requirements and the nature of the connected loads.

Let’s break down the key differences:

Powering Different Needs

-

Single-Phase Transformers:

- Used primarily in residential areas

- Suitable for lighting, heating, and small appliances

- Typically smaller and less expensive

-

Three-Phase Transformers:

- Common in industrial and large commercial settings

- Ideal for heavy machinery and high-power equipment

- More efficient for large loads

-

Power Distribution:

- Single-phase: Two wires (one phase and neutral)

- Three-phase: Three or four wires (three phases and sometimes neutral)

I remember a project where we were upgrading a small town’s power distribution. Most of the residential areas used single-phase transformers. But when a new manufacturing plant moved in, we had to install three-phase transformers to meet their power needs. The difference in size and capacity was striking.

Here’s a comparison table:

| Feature | Single-Phase | Three-Phase |

|---|---|---|

| Typical Applications | Homes, Small Shops | Factories, Large Buildings |

| Power Capacity | Lower | Higher |

| Efficiency | Good for small loads | Better for large loads |

| Size | Smaller | Larger |

| Cost | Less expensive | More expensive |

| Voltage Stability | Good | Excellent |

Loop Feed vs. Radial Feed: Configurations for Different Needs?

Have you ever experienced a power outage that affected only part of your neighborhood? The difference might be due to loop feed versus radial feed configurations. These setups play a crucial role in power reliability and maintenance.

Loop feed configurations allow power to flow from two directions, providing redundancy and easier maintenance. Radial feed setups have a single power source, which is simpler but less reliable. The choice depends on the area’s needs for reliability and the utility’s maintenance practices.

Let’s explore these configurations in detail:

Balancing Reliability and Simplicity

-

Loop Feed Configuration:

- Power can flow from two directions

- Allows isolation of sections for maintenance without interrupting service

- More complex and expensive to install

-

Radial Feed Configuration:

- Single power source

- Simpler and less expensive to install

- Any fault or maintenance requires a complete outage

-

Hybrid Systems:

- Combine elements of both for optimal performance

- Used in areas with mixed reliability needs

I once worked on a project to upgrade a suburban area prone to storm-related outages. We switched from a radial feed to a loop feed configuration. After the upgrade, when a tree fell on one line, power was quickly rerouted through the loop. What could have been a day-long outage was reduced to just a few minutes of flickering lights.

Here’s a comparison of these configurations:

| Feature | Loop Feed | Radial Feed |

|---|---|---|

| Reliability | Higher | Lower |

| Installation Cost | Higher | Lower |

| Maintenance Flexibility | Better | Limited |

| Fault Isolation | Easier | More Difficult |

| Typical Use | Urban Areas, Critical Infrastructure | Rural Areas, Simple Systems |

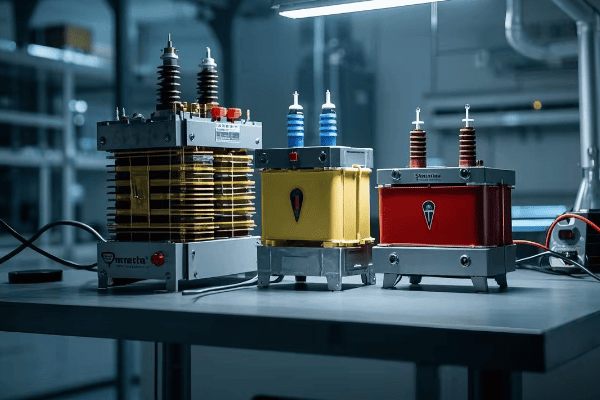

Voltage Classes: From Distribution to Sub-Transmission?

Ever wondered why some transformers are bigger than others? The size often relates to their voltage class. Pad mounted transformers come in various voltage classes to suit different parts of the power grid.

Pad mounted transformers are available in voltage classes ranging from distribution levels (up to 35 kV) to sub-transmission levels (up to 69 kV). The choice of voltage class depends on the transformer’s position in the power distribution chain and the specific needs of the area it serves.

Let’s break down the voltage classes:

From Neighborhood to Industrial Power

-

Distribution Class:

- Typically 5 kV to 35 kV

- Used in residential and commercial areas

- Steps down voltage for end-user consumption

-

Sub-Transmission Class:

- Usually 35 kV to 69 kV

- Acts as a link between transmission and distribution systems

- Often used in large industrial settings or substations

-

Special Classes:

- Some transformers designed for unique voltage requirements

- Can handle non-standard voltages for specific applications

I remember a project where we were setting up power distribution for a new industrial park. We needed a mix of voltage classes. Near the main substation, we used sub-transmission class transformers to handle the incoming high voltage. Then, we stepped down to distribution class transformers to power individual factories and offices.

Here’s a comparison of voltage classes:

| Voltage Class | Typical Use | Size | Insulation Requirements |

|---|---|---|---|

| 5 kV – 15 kV | Residential, Small Commercial | Smaller | Standard |

| 15 kV – 35 kV | Large Commercial, Light Industrial | Medium | Enhanced |

| 35 kV – 69 kV | Heavy Industrial, Sub-Transmission | Large | Specialized |

kVA Ratings: Matching Capacity to Demand?

Have you ever wondered how utilities know what size transformer to use? It all comes down to kVA ratings. These ratings are crucial for ensuring that transformers can handle the power demands of the areas they serve.

kVA (kilovolt-ampere) ratings in pad mounted transformers range from 25 kVA for small residential loads to 5000 kVA or more for large industrial applications. Selecting the right kVA rating is essential for efficient power distribution and preventing overloads or underutilization.

Let’s dive into the world of kVA ratings:

Sizing Up Power Needs

-

Small Ratings (25-167 kVA):

- Typically used in residential areas

- Suitable for powering homes and small businesses

-

Medium Ratings (225-1000 kVA):

- Common in commercial and light industrial settings

- Can handle larger buildings or small manufacturing facilities

-

Large Ratings (1500-5000+ kVA):

- Used in heavy industrial applications

- Capable of powering large factories or commercial complexes

I once worked on a project to upgrade the power distribution in a growing suburban area. We started with 100 kVA transformers, but as more homes were built and energy usage increased, we had to replace them with 250 kVA units. It was a valuable lesson in planning for future growth.

Here’s a breakdown of kVA ratings and their typical applications:

| kVA Rating | Typical Application | Number of Homes/Businesses Served |

|---|---|---|

| 25-75 kVA | Small residential | 1-10 homes |

| 100-167 kVA | Large residential/Small commercial | 10-30 homes or 1-5 small businesses |

| 225-500 kVA | Medium commercial | 1-2 large stores or office buildings |

| 750-2000 kVA | Large commercial/Light industrial | Shopping centers or small factories |

| 2500-5000+ kVA | Heavy industrial | Large manufacturing plants |

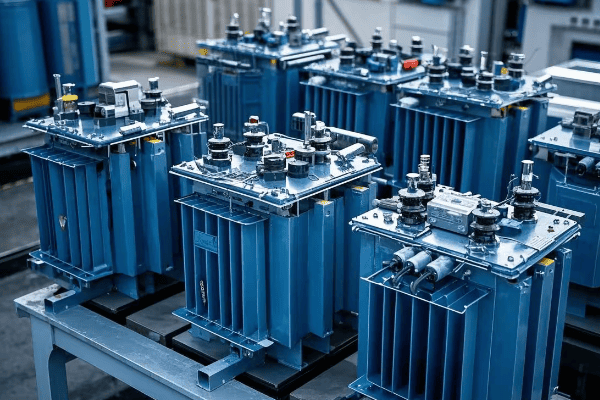

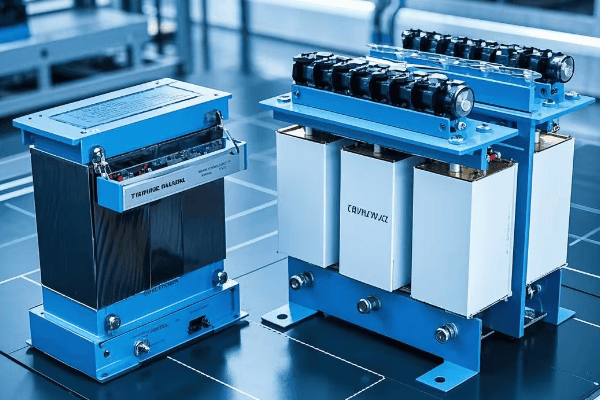

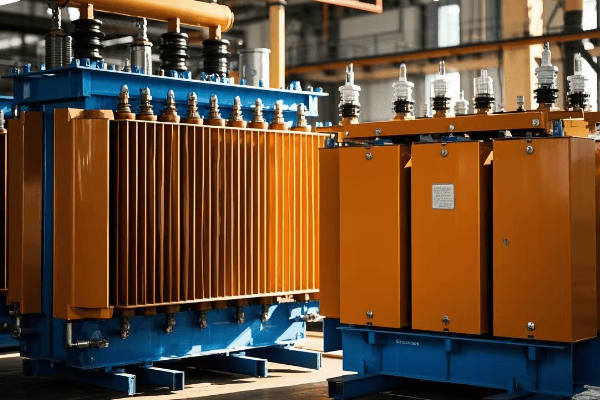

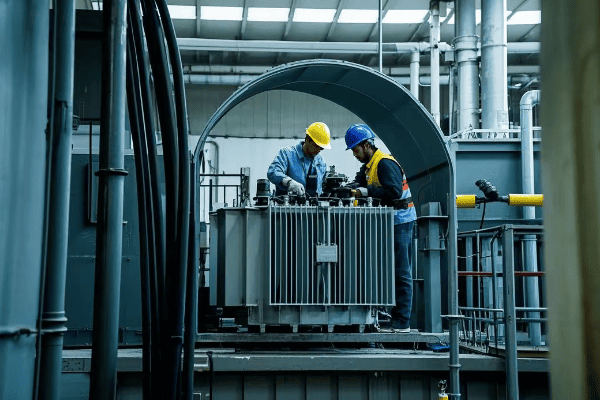

Cooling Methods: Oil-Immersed and Dry-Type Designs?

Ever wondered how transformers stay cool under all that electrical stress? The cooling method is a critical aspect of transformer design, affecting everything from efficiency to maintenance needs.

Pad mounted transformers primarily use two cooling methods: oil-immersed and dry-type. Oil-immersed transformers use insulating oil for cooling and insulation, while dry-type transformers use air and solid insulating materials. Each has its advantages and ideal applications.

Let’s explore these cooling methods in detail:

Keeping Cool Under Pressure

-

Oil-Immersed Transformers:

- Use mineral oil or synthetic fluids for cooling and insulation

- Excellent heat dissipation properties

- Require less space for the same power rating

-

Dry-Type Transformers:

- Use air and solid insulation materials

- No risk of oil leaks or fires

- Often preferred in environmentally sensitive areas

-

Hybrid Cooling Systems:

- Some designs combine elements of both for specific applications

- Can offer a balance of efficiency and environmental safety

I remember a project where we were installing transformers in a water treatment plant. The facility managers were concerned about potential oil leaks contaminating the water supply. We opted for dry-type transformers, which eliminated the risk of oil spills and provided peace of mind for the operators.

Here’s a comparison of these cooling methods:

| Feature | Oil-Immersed | Dry-Type |

|---|---|---|

| Cooling Efficiency | Higher | Lower |

| Environmental Risk | Potential oil leaks | Minimal |

| Fire Risk | Higher (but rare) | Lower |

| Maintenance | Regular oil testing needed | Less maintenance |

| Noise Level | Generally quieter | Can be noisier |

| Cost | Often less expensive | More expensive for high ratings |

| Lifespan | Typically longer | Shorter in harsh environments |

Special Applications: Submersible and Vault-Type Transformers?

Have you ever seen a transformer underwater or hidden underground? These special types of pad mounted transformers are designed for unique environments where standard designs just won’t cut it.

Submersible transformers are designed to operate while fully submerged, ideal for flood-prone areas. Vault-type transformers are installed underground in urban settings where space is at a premium. Both types offer unique solutions for challenging installation environments.

Let’s dive into these special applications:

Transformers in Extreme Environments

-

Submersible Transformers:

- Designed to operate while completely underwater

- Used in areas prone to flooding or high water tables

- Sealed construction to prevent water ingress

-

Vault-Type Transformers:

- Installed in underground vaults in urban areas

- Save valuable above-ground space

- Require special ventilation and access considerations

-

Challenges and Solutions:

- Cooling in confined spaces

- Maintenance access in difficult locations

- Enhanced safety features for public areas

I once worked on a project in a coastal city where we installed submersible transformers in a flood-prone area. During a major storm surge, these transformers continued to operate even when partially submerged, maintaining power to critical infrastructure when it was needed most.

Here’s a comparison of these special transformer types:

| Feature | Submersible | Vault-Type |

|---|---|---|

| Environment | Flood-prone areas | Urban underground |

| Space Efficiency | Moderate | High |

| Installation Complexity | High | Very High |

| Maintenance Accessibility | Challenging | Very Challenging |

| Cost | Higher than standard | Significantly higher |

| Cooling Method | Specially designed | Often forced air or dry-type |

| Safety Features | Waterproof seals | Fire suppression, ventilation |

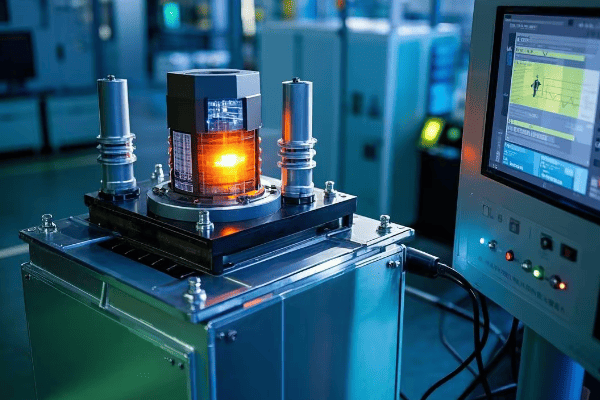

Smart Transformers: Integrating Intelligence into the Grid?

Ever imagined a transformer that could think for itself? Welcome to the world of smart transformers. These high-tech devices are revolutionizing how we manage and monitor our power distribution systems.

Smart transformers incorporate advanced sensors, communication capabilities, and control systems. They can monitor their own performance, adjust to changing load conditions, and communicate with the smart grid. This intelligence leads to improved efficiency, reliability, and grid management.

Let’s explore the features of smart transformers:

The Brains Behind the Power

-

Real-Time Monitoring:

- Continuous tracking of voltage, current, and temperature

- Early detection of potential issues

-

Load Management:

- Ability to adjust to changing power demands

- Optimizes power flow for efficiency

-

Communication Capabilities:

- Integration with smart grid systems

- Remote monitoring and control

-

Predictive Maintenance:

- Uses data analytics to predict when maintenance is needed

- Reduces unexpected outages

I recently worked on upgrading a suburban power network with smart transformers. The utility company was amazed at how quickly they could identify and respond to issues. In one instance, the system detected an impending failure and alerted technicians before any outage occurred, saving thousands in potential repair costs and customer inconvenience.

Here’s a breakdown of smart transformer features:

| Feature | Function | Benefit |

|---|---|---|

| Voltage Regulation | Automatically adjusts output voltage | Improved power quality |

| Load Monitoring | Tracks power usage patterns | Better load forecasting |

| Fault Detection | Quickly identifies and isolates faults | Faster outage response |

| Power Factor Correction | Optimizes power factor | Increased efficiency |

| Data Analytics | Analyzes performance data | Predictive maintenance |

| Remote Control | Allows for remote operation | Reduced field visits |

Customization Options: Tailoring Transformers to Specific Requirements?

Have you ever needed a tool that’s just right for a specific job? Pad mounted transformers are no different. Customization options allow these vital components to be tailored for unique applications and environments.

Customizable features in pad mounted transformers include special voltage ratings, unique physical dimensions, enhanced protection systems, and specific cooling methods. These options allow utilities and industries to get transformers that perfectly fit their needs, improving efficiency and reliability.

Let’s explore the world of transformer customization:

Tailoring Power to Perfection

-

Voltage and Power Ratings:

- Non-standard voltage options for specific applications

- Custom kVA ratings to match exact load requirements

-

Physical Customization:

- Unique cabinet designs for special installation locations

- Compact designs for space-constrained areas

-

Enhanced Protection:

- Additional surge arresters for lightning-prone areas

- Special corrosion protection for harsh environments

-

Cooling Customization:

- Hybrid cooling systems for extreme temperatures

- Low-noise designs for residential areas

I once worked with a solar farm that needed transformers with very specific voltage ratings to match their inverter outputs. We designed custom units that not only met their voltage needs but also included enhanced monitoring capabilities for their unique load patterns. The result was a more efficient and reliable power conversion system for the entire solar installation.

Here’s a table of common customization options:

| Customization Area | Options | Typical Applications |

|---|---|---|

| Voltage Class | Non-standard ratings | Renewable energy, Industrial processes |

| Physical Design | Slim profile, Underground | Urban areas, Aesthetically sensitive locations |

| Protection Features | Enhanced surge protection | Lightning-prone areas, Critical infrastructure |

| Cooling System | Ultra-quiet, High-efficiency | Residential zones, Energy-conscious facilities |

| Monitoring | Advanced sensors, Smart grid integration | Utilities with remote management needs |

| Environmental | Biodegradable fluids, Extra containment | Environmentally sensitive areas |

Conclusion

Pad mounted transformers come in a diverse range of types and configurations, from basic single-phase units to advanced smart transformers.This diversity allows for tailored solutions in various power distribution scenarios, ensuring efficient and reliable electricity supply across different environments and applications.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group