How Are Transformer Winding Structures Classified? A Simple Guide

Have you ever wondered why some transformers look different from others? The secret lies in their winding structures, a crucial aspect of transformer design that often goes unnoticed.

Transformer winding structures are classified into three main categories: based on the number of phases, the number of windings, and the connections between windings. These classifications include single-phase vs. three-phase, single-winding vs. two-winding, and autotransformers vs. isolation transformers. Each type serves specific purposes in power systems.

As an electrical engineer with years of experience in power systems, I’ve seen firsthand how the right winding structure can make or break a transformer’s performance. Let’s dive into the fascinating world of transformer windings and uncover why they’re so crucial in our modern electrical grid.

What Are the Different Types of Transformer Winding Structures Based on the Number of Phases?

Have you ever noticed the three large wires running into most industrial buildings? Those are typically for three-phase power, but why do we use different phase configurations in transformers?

Transformers are classified into single-phase, two-phase, and three-phase based on the number of phases. Single-phase transformers have one primary and one secondary winding. Two-phase transformers, now obsolete, had two windings 90 degrees apart. Three-phase transformers, the most common in power systems, have three sets of primary and secondary windings.

Let’s break down each type:

Single-Phase Transformers

- Structure: One primary and one secondary winding

- Use: Common in residential areas and for small electrical appliances

- Advantage: Simple design, suitable for low power applications

Two-Phase Transformers

- Structure: Two identical windings spaced 90 degrees apart

- Use: Obsolete, replaced by three-phase systems

- Historical note: Once used in early power distribution systems

Three-Phase Transformers

- Structure: Three sets of primary and secondary windings

- Use: Most common in power distribution and industrial applications

- Advantage: Provides constant power supply, more efficient for high power transmission

I remember working on a project to upgrade a small town’s power distribution. We replaced several old single-phase transformers with a new three-phase system. The improvement in power quality and efficiency was remarkable, with fewer voltage fluctuations and reduced energy losses.

Here’s a quick comparison table:

| Type | Number of Windings | Common Applications | Efficiency for High Power |

|---|---|---|---|

| Single-Phase | 2 (1 primary, 1 secondary) | Residential, Small appliances | Lower |

| Two-Phase | 4 (2 sets of primary and secondary) | Obsolete | N/A |

| Three-Phase | 6 (3 sets of primary and secondary) | Industrial, Power distribution | Higher |

Understanding these phase-based classifications is crucial for anyone working with electrical systems. The choice between single-phase and three-phase transformers can significantly impact power quality, efficiency, and the overall performance of an electrical system.

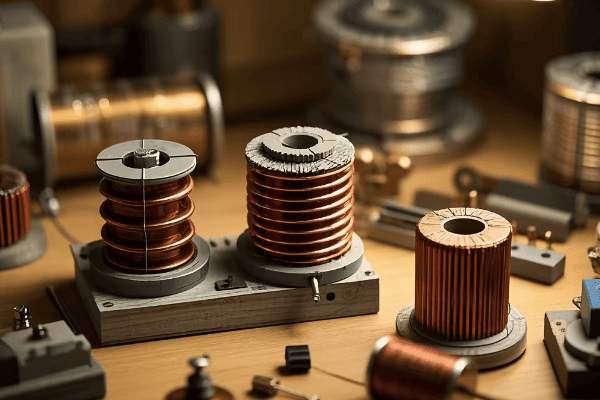

How Do Transformer Winding Structures Differ Based on the Number of Windings?

When you look at a transformer, it might not be immediately obvious how many windings it has. But did you know that the number of windings can tell you a lot about a transformer’s purpose?

Transformers are classified as single-winding or two-winding based on their structure. Single-winding transformers have both primary and secondary on the same core, used mainly for isolation. Two-winding transformers have separate cores for primary and secondary, allowing for voltage transformation. The choice depends on the specific application requirements.

Let’s explore these types in more detail:

Single-Winding Transformers

- Structure: Primary and secondary windings on the same core

- Primary Use: Electrical isolation without voltage change

- Advantages:

- Compact design

- Lower cost

- Efficient for small voltage adjustments

- Applications:

- Power line carrier communication

- Some types of voltage regulators

Two-Winding Transformers

- Structure: Separate cores for primary and secondary windings

- Primary Use: Voltage transformation and isolation

- Advantages:

- Greater flexibility in voltage ratios

- Better isolation between primary and secondary

- Suitable for large voltage transformations

- Applications:

- Power distribution transformers

- Isolation transformers in sensitive electronic equipment

I once worked on a project in a hospital where we needed to protect sensitive medical equipment from power line disturbances. We chose a two-winding isolation transformer because it provided both the necessary voltage adjustment and excellent electrical isolation, ensuring the safety and accuracy of the medical devices.

Here’s a comparison table to summarize the key differences:

| Aspect | Single-Winding Transformer | Two-Winding Transformer |

|---|---|---|

| Core Structure | Shared core | Separate cores |

| Main Function | Isolation | Voltage transformation and isolation |

| Efficiency for Small Voltage Changes | Higher | Lower |

| Isolation Quality | Good | Excellent |

| Typical Applications | Voltage regulation, Line conditioning | Power distribution, Equipment protection |

| Cost | Lower | Higher |

Understanding these differences is crucial when selecting transformers for specific applications. The choice between single-winding and two-winding transformers can impact not only the performance of your electrical system but also its safety and reliability.

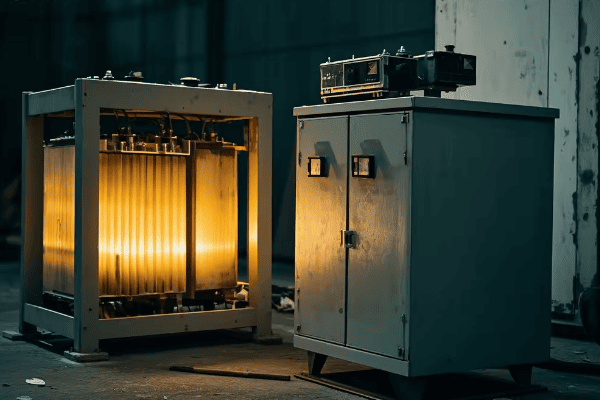

How Do Connections Between Windings Affect Transformer Classification?

Have you ever wondered why some transformers can change voltage so efficiently while others provide better isolation? The secret lies in how their windings are connected.

Transformers are classified as autotransformers or isolation transformers based on the connections between their windings. Autotransformers have electrically connected primary and secondary windings, sharing a common portion. Isolation transformers have completely separate primary and secondary windings, providing electrical isolation. Each type has unique advantages for specific applications.

Let’s examine these two types in detail:

Autotransformers

- Structure: Primary and secondary windings are electrically connected

- Primary Use: Efficient voltage adjustment with a small transformation ratio

- Advantages:

- Higher efficiency for small voltage changes

- Smaller size and lower cost

- Less copper required in construction

- Applications:

- Voltage regulators in power systems

- Motor starting applications

- Interconnecting systems with slightly different voltages

Isolation Transformers

- Structure: Primary and secondary windings are electrically isolated

- Primary Use: Providing galvanic isolation between circuits

- Advantages:

- Complete electrical separation between primary and secondary

- Protection against electric shock and ground faults

- Reduction of electrical noise and interference

- Applications:

- Medical equipment

- Sensitive electronic devices

- Safety-critical industrial processes

I recall a project at a manufacturing plant where we needed to connect two systems operating at slightly different voltages. We used an autotransformer because it provided the necessary voltage adjustment efficiently and cost-effectively. However, for the plant’s control room equipment, we installed isolation transformers to protect against electrical noise and potential ground faults.

Here’s a comparison table highlighting the key differences:

| Aspect | Autotransformer | Isolation Transformer |

|---|---|---|

| Winding Connection | Electrically connected | Electrically isolated |

| Primary Function | Efficient voltage adjustment | Electrical isolation |

| Size and Cost | Smaller and less expensive | Larger and more expensive |

| Efficiency for Small Voltage Changes | Very high | Lower |

| Safety in High Voltage Applications | Lower (no isolation) | Higher (complete isolation) |

| Typical Applications | Voltage regulation, Motor starting | Medical equipment, Sensitive electronics |

The choice between autotransformers and isolation transformers depends on the specific requirements of your application. While autotransformers offer efficiency and cost savings for small voltage adjustments, isolation transformers provide crucial safety and noise reduction features for sensitive or critical equipment.

Conclusion

Transformer winding structures play a crucial role in power systems, affecting efficiency, safety, and functionality. By understanding the classifications based on phases, number of windings, and connections, engineers and technicians can make informed decisions in designing and maintaining electrical systems. Whether you’re working with residential power supplies or industrial equipment, the right transformer winding structure can make all the difference in ensuring reliable, efficient, and safe power distribution.

FAQs: Common Questions About Transformer Winding Structures

- Why are three-phase transformers more common in power distribution?

Three-phase transformers are more common in power distribution for several reasons:

- Efficiency: They provide a more constant and balanced power flow, resulting in higher efficiency in power transmission and distribution.

- Cost-effectiveness: One three-phase transformer is generally cheaper and requires less space than three single-phase transformers of equivalent power rating.

- Power density: Three-phase systems can transmit more power with less conductor material compared to single-phase systems.

- Smooth power delivery: They provide a smoother power delivery for large motors and industrial equipment, reducing vibration and wear.

In my experience, upgrading from single-phase to three-phase systems in industrial areas has consistently led to improved power quality and reduced energy losses. However, single-phase transformers still have their place in residential areas and for smaller loads.

- Can a single-winding transformer be used for voltage transformation?

Yes, a single-winding transformer can be used for voltage transformation, but with limitations:

- Autotransformer configuration: Single-winding transformers used for voltage transformation are typically configured as autotransformers.

- Limited range: They are most efficient and practical for small voltage adjustments, usually within a ratio of 2:1 or less.

- No isolation: Unlike two-winding transformers, they don’t provide electrical isolation between input and output.

- Applications: Common uses include voltage regulators, motor starters, and interconnecting systems with slight voltage differences.

I once worked on a project where we used a single-winding autotransformer to adjust the voltage in a small industrial facility. It was perfect for our needs because we only needed a 10% voltage boost and isolation wasn’t a concern. However, for larger voltage changes or where isolation is required, a two-winding transformer would be the better choice.

- What are the safety advantages of isolation transformers?

Isolation transformers offer several important safety advantages:

- Electrical isolation: They provide complete galvanic isolation between primary and secondary circuits, preventing the transfer of DC voltages and fault currents.

- Ground fault protection: They can break ground loops and provide protection against electric shock from ground faults.

- Noise reduction: They attenuate common-mode noise and transients, protecting sensitive equipment.

- Voltage stabilization: Some isolation transformers include voltage regulation features, providing stable output voltage.

In a hospital project I worked on, we installed isolation transformers for all critical medical equipment. This not only protected the equipment from power line disturbances but also enhanced patient safety by reducing the risk of electric shock. The investment in isolation transformers paid off in terms of equipment longevity and reliability.

- How do autotransformers differ from regular transformers in terms of efficiency?

Autotransformers generally offer higher efficiency compared to regular (two-winding) transformers, especially for small voltage transformations:

- Reduced losses: Only a portion of the power is transformed, resulting in lower copper losses.

- Size and cost: They are smaller and use less material, which can lead to cost savings.

- Limitation: The efficiency advantage diminishes as the voltage transformation ratio increases.

For example, in a project where we needed to adjust voltage by just 10%, an autotransformer was about 99% efficient, compared to about 97% for a comparable two-winding transformer. However, for large voltage changes or where isolation is needed, regular transformers are often the better choice despite slightly lower efficiency.

- Are there any special maintenance considerations for different winding structures?

Yes, different winding structures have specific maintenance considerations:

- Three-phase transformers: Require balanced load monitoring and phase-to-phase insulation checks.

- Autotransformers: Need careful monitoring of the common winding for signs of overheating or insulation breakdown.

- Isolation transformers: Regular testing of insulation resistance between primary and secondary windings is crucial.

- All types: Require routine oil analysis (for oil-filled types), thermal imaging, and power quality measurements.

In my maintenance experience, I’ve found that autotransformers often require more frequent inspections due to their compact design and shared windings. For isolation transformers, we pay extra attention to maintaining the integrity of the isolation barrier. Regular maintenance tailored to each type of winding structure is key to ensuring long-term reliability and safety of transformer installations.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group