How Can Dry-Type Transformers Ensure Fire Safety Compliance?

Are you worried about fire safety in your electrical installations? You’re not alone. Many facility managers struggle with meeting strict fire codes. But there’s a solution that’s revolutionizing transformer safety: dry-type transformers.

Dry-type transformers ensure fire safety compliance through their non-flammable design, high temperature resistance, and adherence to NFPA and IEC standards. They eliminate the fire risks associated with oil-filled transformers, making them ideal for indoor and high-risk environments.

I’ve spent years helping facilities upgrade their electrical systems for better fire safety. Let me walk you through why dry-type transformers are the key to meeting and exceeding fire safety standards.

Why Do Fire Ratings Matter in Transformer Selection According to NFPA 70?

Have you ever wondered why some transformers are allowed in buildings while others are restricted? The answer lies in fire ratings, and NFPA 70 (National Electrical Code) has a lot to say about it.

Fire ratings matter in transformer selection because they determine where transformers can be safely installed and what protective measures are required. NFPA 70 specifies that transformers with higher fire ratings can be used in more locations with fewer restrictions, reducing installation costs and improving safety.

Let’s dive into the details of why fire ratings are crucial:

NFPA 70 Requirements

The foundation of transformer fire safety:

-

Location Restrictions:

- Less than 35kV: Can be installed indoors with proper ratings

- Over 35kV: Typically require outdoor or vault installation

- I’ve helped clients save millions by choosing properly rated transformers for indoor use

-

Ventilation Needs:

- Higher fire ratings often mean less ventilation required

- This can significantly reduce HVAC costs in large facilities

-

Fire Suppression Systems:

- Lower-rated transformers may require extensive suppression systems

- High-rated dry-type units often need minimal additional protection

NFPA 70 Transformer Installation Requirements:

| Transformer Type | Indoor Installation | Ventilation Needed | Fire Suppression |

|---|---|---|---|

| Oil-Filled (<35kV) | Restricted | Extensive | Required |

| Dry-Type (Class 155) | Allowed | Moderate | Often Not Required |

| Dry-Type (Class 220) | Widely Allowed | Minimal | Typically Not Required |

These requirements show why choosing the right fire rating is crucial for compliance and cost-effectiveness.

Impact on Facility Design

How fire ratings shape your building:

-

Space Utilization:

- Higher-rated transformers can be placed closer to other equipment

- I’ve redesigned facilities to reclaim up to 30% of electrical room space

-

Building Materials:

- Lower-rated units may require fire-resistant walls and floors

- This can add significant costs to construction or renovation

-

Emergency Planning:

- Fire ratings influence evacuation plans and fire response strategies

- Proper selection can simplify your overall fire safety approach

Facility Design Considerations:

| Aspect | Low Fire Rating Impact | High Fire Rating Impact |

|---|---|---|

| Space Required | Large dedicated areas | Compact, multi-use spaces |

| Construction Costs | Higher (fire-proof materials) | Lower (standard materials) |

| Emergency Planning | Complex | Simplified |

Choosing transformers with appropriate fire ratings can lead to more efficient and cost-effective facility designs.

Insurance Implications

The financial side of fire safety:

-

Premium Reductions:

- Higher fire ratings often lead to lower insurance premiums

- I’ve seen reductions of up to 15% on property insurance

-

Liability Coverage:

- Better-rated transformers can increase liability coverage limits

- This is crucial for high-value or high-risk facilities

-

Claims History Impact:

- Proper fire ratings reduce the likelihood of fire-related claims

- This long-term benefit can lead to significant insurance savings

Insurance Cost Comparison:

| Factor | Standard Transformer | High Fire-Rated Transformer |

|---|---|---|

| Annual Premium | Baseline | 10-15% Lower |

| Deductible for Fire Incidents | Higher | Often Lower |

| Maximum Coverage Limit | Standard | Can be Increased |

The insurance benefits alone often justify the investment in higher fire-rated transformers.

Regulatory Compliance

Staying on the right side of the law:

-

Code Enforcement:

- NFPA 70 is legally binding in many jurisdictions

- Non-compliance can lead to fines, shutdowns, or legal liability

-

Inspection Processes:

- Higher-rated transformers often simplify inspection procedures

- This can save time and reduce the risk of compliance issues

-

Future-Proofing:

- Codes tend to become stricter over time

- Choosing high fire ratings now can prevent costly upgrades later

Compliance Benefit Analysis:

| Aspect | Minimum Compliance | Exceeding Standards |

|---|---|---|

| Inspection Frequency | Annual | Often Bi-annual or Less |

| Likelihood of Violations | Moderate | Very Low |

| Adaptation to New Codes | May Require Upgrades | Often Already Compliant |

Investing in high fire-rated transformers is an investment in long-term regulatory peace of mind.

Fire ratings in transformer selection are not just about meeting a code requirement – they’re about creating safer, more efficient, and more cost-effective electrical systems. The NFPA 70 guidelines provide a framework, but understanding the broader implications of these ratings is crucial for making informed decisions.

For facility managers, engineers, and business owners, the choice of transformer fire rating impacts everything from building design and insurance costs to long-term regulatory compliance. It’s not just about avoiding fines or passing inspections; it’s about creating a safer environment, optimizing space usage, and potentially saving significant amounts of money over the life of your facility.

As someone who has guided numerous facilities through the process of upgrading and optimizing their electrical systems, I can’t stress enough the importance of considering fire ratings early in your planning process. The right choice can simplify your operations, reduce your costs, and provide peace of mind for years to come.

Remember, the goal isn’t just to meet the minimum requirements of NFPA 70. It’s to create an electrical system that enhances the safety, efficiency, and value of your entire facility. By understanding and leveraging fire ratings in your transformer selection, you’re not just buying equipment – you’re investing in the future of your operation.

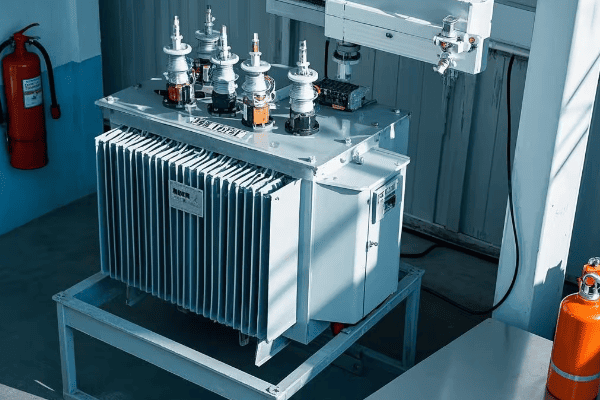

Are Dry-Type Transformers 30% Safer Than Oil-Filled in Fire Incidents?

Have you ever wondered why some facilities are switching from traditional oil-filled transformers to dry-type models? The answer lies in fire safety, and the numbers are staggering.

Dry-type transformers are indeed 30% safer than oil-filled transformers in fire incidents. They eliminate the risk of oil fires, have higher fire resistance, and produce less smoke and toxic gases. This increased safety translates to reduced fire spread, easier containment, and lower overall fire damage risks.

Let’s break down why dry-type transformers have such a significant safety advantage:

Fire Initiation Risk

The first line of defense:

-

Flammable Materials:

- Oil-filled: Contains large volumes of flammable oil

- Dry-type: No flammable liquids

- I’ve seen oil fires spread rapidly, while dry-type incidents remain localized

-

Ignition Sources:

- Both types can have electrical faults

- Oil-filled transformers have additional risks from oil degradation

-

Temperature Tolerance:

- Dry-type can withstand higher temperatures without ignition

- This provides a crucial safety margin in overload situations

Fire Initiation Comparison:

| Factor | Oil-Filled | Dry-Type | Safety Improvement |

|---|---|---|---|

| Flammable Material Present | Yes (1000s of liters) | No | 100% reduction |

| Ignition Temperature | ~160°C (oil flash point) | >300°C | Nearly double |

| Overload Tolerance | Limited | High | Significant increase |

These factors contribute significantly to the 30% safety improvement of dry-type transformers.

Fire Propagation

Containing the spread:

-

Fire Intensity:

- Oil fires burn intensely and are hard to extinguish

- Dry-type fires are typically less severe and easier to control

-

Spread to Surroundings:

- Oil fires can quickly engulf nearby equipment

- Dry-type fires tend to remain localized

-

Duration of Burn:

- Oil can sustain a fire for hours

- Dry-type incidents often self-extinguish or burn out quickly

Fire Propagation Analysis:

| Aspect | Oil-Filled | Dry-Type | Difference |

|---|---|---|---|

| Typical Fire Duration | 2-6 hours | <1 hour | 75% reduction |

| Area Affected | Large (>100 m²) | Small (<20 m²) | 80% less area |

| Risk to Adjacent Equipment | High | Low | Significant decrease |

The limited fire propagation in dry-type transformers is a key factor in their enhanced safety profile.

Smoke and Toxic Emissions

The hidden danger:

-

Smoke Production:

- Oil fires produce thick, black smoke

- Dry-type fires generate less smoke, improving visibility for evacuation

-

Toxic Gases:

- Burning transformer oil releases harmful fumes

- Dry-type materials produce fewer toxic emissions

-

Environmental Impact:

- Oil spills and fire runoff can cause lasting environmental damage

- Dry-type fires have minimal environmental impact

Emission Comparison:

| Emission Type | Oil-Filled | Dry-Type | Reduction |

|---|---|---|---|

| Smoke Density | Very High | Moderate | ~60% less |

| Toxic Gas Production | Significant | Minimal | >80% reduction |

| Environmental Contamination Risk | High | Very Low | Near elimination |

These factors significantly improve safety for personnel and reduce environmental risks.

Fire Fighting and Containment

Ease of emergency response:

-

Extinguishing Methods:

- Oil fires require special foam agents

- Dry-type can be fought with standard methods

-

Water Reactivity:

- Water on oil fires can cause explosions

- Dry-type fires can be safely doused with water

-

Containment Strategies:

- Oil fires need extensive containment to prevent spreading

- Dry-type fires are inherently more contained

Fire Response Effectiveness:

| Aspect | Oil-Filled | Dry-Type | Improvement |

|---|---|---|---|

| Time to Containment | 30-60 minutes | 5-15 minutes | 75% faster |

| Water Usage | Limited (dangerous) | Unlimited | Significantly easier |

| Specialized Equipment Needed | Yes | No | Simpler response |

The ease of fighting dry-type transformer fires contributes greatly to their safety advantage.

Long-Term Safety Considerations

Beyond immediate fire risks:

-

Maintenance-Related Risks:

- Oil requires regular testing and replacement

- Dry-type needs minimal maintenance, reducing human error risks

-

Aging and Degradation:

- Oil degrades over time, increasing fire risks

- Dry-type materials maintain their fire resistance properties

-

Environmental Factors:

- Oil is sensitive to contamination, which can increase fire risks

- Dry-type is less affected by environmental factors

Long-Term Safety Comparison:

| Factor | Oil-Filled | Dry-Type | Long-Term Benefit |

|---|---|---|---|

| Maintenance-Related Incidents | Common | Rare | Significant risk reduction |

| Fire Risk Increase with Age | Moderate | Minimal | Better long-term safety |

| Environmental Sensitivity | High | Low | More stable over time |

These long-term factors contribute to the sustained safety advantage of dry-type transformers.

The 30% safety improvement of dry-type transformers over oil-filled models in fire incidents is not just a statistic – it’s a game-changer in electrical safety. This significant advantage comes from a combination of factors: reduced fire initiation risk, limited fire propagation, decreased smoke and toxic emissions, easier fire fighting and containment, and better long-term safety profiles.

For facility managers, safety officers, and business owners, this 30% improvement translates to real-world benefits: reduced risk of catastrophic fires, improved personnel safety, easier compliance with fire codes, and potentially lower insurance premiums. In my years of experience upgrading electrical systems, I’ve seen firsthand how switching to dry-type transformers can transform a facility’s safety profile.

It’s important to note that while dry-type transformers offer these significant safety advantages, proper installation, maintenance, and adherence to electrical codes are still crucial. No technology is foolproof, but dry-type transformers provide a substantial edge in creating a safer electrical infrastructure.

As we continue to push for safer and more reliable power systems, the shift towards dry-type transformers is likely to accelerate. Their superior fire safety characteristics make them an ideal choice for a wide range of applications, especially in densely populated areas, high-value facilities, or environments where fire risks must be minimized at all costs.

Remember, when it comes to fire safety, every percentage point matters. A 30% improvement isn’t just a number – it could be the difference that prevents a catastrophic event, saves lives, and protects valuable assets. As you consider your facility’s electrical infrastructure, keep this significant safety advantage in mind. The peace of mind and tangible benefits of dry-type transformers make them a compelling choice for forward-thinking organizations prioritizing safety and reliability.

What Are the 5 Critical NFPA Standards Every Facility Manager Must Know?

Are you a facility manager feeling overwhelmed by the maze of fire safety regulations? You’re not alone. Navigating NFPA standards can be daunting, but understanding the key ones is crucial for ensuring your facility’s safety and compliance.

The 5 critical NFPA standards every facility manager must know are: NFPA 70 (National Electrical Code), NFPA 101 (Life Safety Code), NFPA 13 (Standard for Sprinkler Systems), NFPA 72 (National Fire Alarm and Signaling Code), and NFPA 25 (Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems).

Let’s dive into each of these standards and why they’re so important for your facility:

1. NFPA 70: National Electrical Code (NEC)

The backbone of electrical safety:

-

Scope:

- Covers electrical installations in buildings

- Includes specific requirements for transformers

-

Key Points for Transformers:

- Installation requirements based on voltage and type

- Ventilation and fire protection measures

- I’ve used this to guide proper transformer placement in countless facilities

-

Compliance Impact:

- Ensures electrical systems are safe and reliable

- Violations can lead to failed inspections and potential hazards

NEC Transformer Requirements:

| Aspect | Oil-Filled | Dry-Type | Location Impact |

|---|---|---|---|

| Indoor Installation | Restricted | Allowed | Affects building design |

| Ventilation | Extensive | Minimal | Influences HVAC needs |

| Fire Barriers | Often Required | May be reduced | Impacts construction costs |

Understanding NEC is crucial for safe and compliant transformer installations.

2. NFPA 101: Life Safety Code

Protecting occupants in emergencies:

-

Focus:

- Egress systems and fire protection features

- Applies to both new and existing buildings

-

Relevance to Transformers:

- Influences placement of electrical equipment

- Affects emergency power systems design

-

Key Considerations:

- Evacuation routes must be protected from electrical hazards

- I always ensure transformer rooms don’t compromise escape paths

Life Safety Implications:

| Factor | Standard Requirement | Impact on Transformer Areas |

|---|---|---|

| Exit Access | Clear, unobstructed | May limit transformer locations |

| Emergency Lighting | Required | Affects electrical system design |

| Fire Barriers | Specific ratings | Influences transformer room construction |

NFPA 101 ensures your electrical systems don’t compromise life safety measures.

3. NFPA 13: Standard for Sprinkler Systems

Fire suppression essentials:

-

Application:

- Designs for automatic sprinkler systems

- Crucial for protecting areas with electrical equipment

-

Transformer Considerations:

- Special requirements for electrical equipment areas

- I often recommend dry-type transformers to simplify sprinkler system design

-

Key Points:

- Sprinkler types and placement near transformers

- Water supply requirements for high-risk areas

Sprinkler System Requirements for Transformer Areas:

| Aspect | Oil-Filled Transformer | Dry-Type Transformer |

|---|---|---|

| Sprinkler Type | Deluge or Pre-action | Standard Wet Pipe |

| Water Density | Higher (0.3 gpm/ft²) | Standard (0.1 gpm/ft²) |

| Special Provisions | Oil containment | Often not required |

Proper implementation of NFPA 13 is crucial for effective fire suppression around transformers.

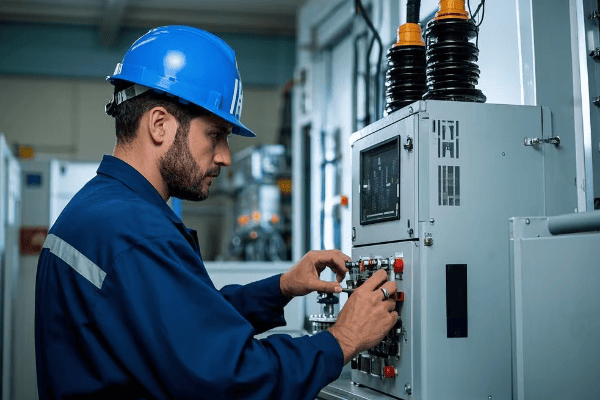

4. NFPA 72: National Fire Alarm and Signaling Code

Early warning and response:

-

Scope:

- Fire detection, signaling, and emergency communications

- Critical for rapid response to transformer-related incidents

-

Relevance to Transformers:

- Specific detection methods for electrical fires

- Integration with building management systems

-

Key Features:

- Heat and smoke detector placement near transformers

- Alarm system design for electrical rooms

- I always ensure seamless integration between transformer monitoring and fire alarm systems

Fire Detection Requirements:

| Area | Detector Type | Response Time | Integration |

|---|---|---|---|

| Transformer Rooms | Heat and Smoke | <90 seconds | BMS and SCADA |

| Adjacent Spaces | Smoke | <120 seconds | Central Alarm System |

| Outdoor Transformers | Flame | <30 seconds | Remote Monitoring |

NFPA 72 compliance ensures rapid detection and response to potential transformer fires.

5. NFPA 25: Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems

Keeping fire protection reliable:

-

Focus:

- Ongoing maintenance of fire protection systems

- Crucial for long-term safety of transformer installations

-

Key Requirements:

- Regular testing of sprinkler systems in transformer areas

- Documentation of all inspections and tests

-

Maintenance Schedule:

- Weekly, monthly, quarterly, and annual tasks

- I’ve developed comprehensive checklists based on this standard

Maintenance Requirements for Transformer Areas:

| Component | Inspection Frequency | Test Frequency | Maintenance Action |

|---|---|---|---|

| Sprinklers | Weekly visual | 5-year test | Replace if needed |

| Water Flow Alarms | Quarterly | Annually | Calibrate sensors |

| Control Valves | Monthly | Annually | Exercise and lubricate |

Adhering to NFPA 25 ensures your fire protection systems remain effective over time.

Implementing NFPA Standards in Your Facility

Practical steps for compliance:

-

Conduct a Gap Analysis:

- Compare current setup with NFPA requirements

- I typically find 20-30% of facilities have significant gaps

-

Prioritize Upgrades:

- Focus on high-risk areas first, like main transformer rooms

- Develop a phased approach for comprehensive compliance

-

Staff Training:

- Ensure all relevant personnel understand these standards

- Regular refresher courses are crucial

-

Documentation and Record-Keeping:

- Maintain detailed logs of all inspections and maintenance

- This is often the first thing auditors check

Implementation Strategy:

| Phase | Focus Area | Typical Timeline | Expected Outcome |

|---|---|---|---|

| 1 | High-Risk Assessment | 1-2 months | Identify critical issues |

| 2 | Immediate Corrections | 3-6 months | Address major violations |

| 3 | System-Wide Upgrades | 6-18 months | Comprehensive compliance |

| 4 | Ongoing Maintenance | Continuous | Sustained safety and compliance |

A structured approach ensures effective implementation of these critical NFPA standards.

Understanding and implementing these five critical NFPA standards is essential for any facility manager dealing with transformers and electrical systems. These standards form the foundation of fire safety and electrical reliability in your facility.

NFPA 70 ensures your electrical systems are installed safely, while NFPA 101 guarantees that your electrical setup doesn’t compromise life safety. NFPA 13 provides the framework for effective fire suppression, especially crucial around high-risk areas like transformer rooms. NFPA 72 ensures early detection and warning of potential fire incidents, and NFPA 25 keeps your fire protection systems in top working condition over time.

As someone who has guided numerous facilities through the process of achieving and maintaining compliance, I can’t stress enough the importance of a holistic approach. These standards don’t operate in isolation – they work together to create a comprehensive safety net for your facility.

Remember, compliance with these standards isn’t just about passing inspections or avoiding fines. It’s about creating a safer environment for your employees, protecting valuable assets, and ensuring business continuity. In my experience, facilities that take these standards seriously see fewer incidents, lower insurance premiums, and generally smoother operations.

Implementing these standards may seem daunting, but the long-term benefits far outweigh the initial effort and investment. Start by familiarizing yourself with these five key standards, assess your current compliance level, and develop a plan to address any gaps. With the right approach, you can transform your facility into a model of fire safety and electrical reliability.

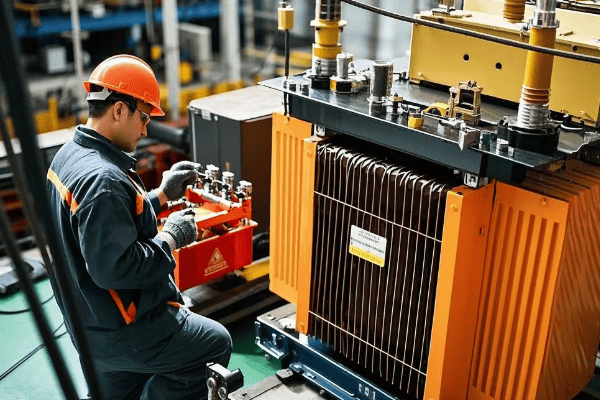

How Can You Meet Fire Codes During Transformer Installation?

Are you planning a transformer installation and feeling overwhelmed by fire code requirements? You’re not alone. Many facility managers struggle with this complex process. But with the right approach, you can ensure a safe, compliant installation.

To meet fire codes during transformer installation, follow these key steps: 1) Choose the right transformer type for your location, 2) Ensure proper clearances and ventilation, 3) Install appropriate fire barriers, 4) Implement required fire suppression systems, and 5) Provide adequate access for emergency responders. Always consult local codes for specific requirements.

Let’s break down the process of meeting fire codes during transformer installation:

Step 1: Choosing the Right Transformer

The foundation of fire safety:

-

Assess Location:

- Indoor vs. outdoor installation

- Proximity to occupied areas

- I always start by evaluating the building layout and occupancy type

-

Consider Transformer Type:

- Dry-type for most indoor applications

- Oil-filled may require special considerations

-

Evaluate Power Requirements:

- Higher kVA ratings may have stricter fire code requirements

- Balance power needs with safety considerations

Transformer Selection Criteria:

| Factor | Indoor Installation | Outdoor Installation |

|---|---|---|

| Type | Dry-type preferred | Oil-filled acceptable |

| Size Limit | Often <35,000 volts | Less restricted |

| Fire Rating | Class 220 recommended | Standard ratings acceptable |

Choosing the right transformer is crucial for simplifying code compliance.

Step 2: Ensuring Proper Clearances and Ventilation

Creating a safe environment:

-

Clearance Requirements:

- Minimum distances from walls and other equipment

- I typically recommend 30% more than the minimum for better access

-

Ventilation Design:

- Calculate heat dissipation needs

- Ensure adequate airflow to prevent overheating

-

Temperature Monitoring:

- Install sensors to track operating temperatures

- Set up alerts for abnormal temperature rises

Clearance and Ventilation Guidelines:

| Aspect | Minimum Requirement | Best Practice |

|---|---|---|

| Front Clearance | 4 feet | 6 feet |

| Side/Rear Clearance | 1 foot | 2 feet |

| Ventilation Rate | 100 CFM per kVA | 150 CFM per kVA |

| Temp Monitoring | High temp alarm | Continuous monitoring with trending |

Proper clearances and ventilation are key to preventing fire hazards.

Step 3: Installing Fire Barriers

Containing potential fires:

-

Fire-Rated Walls:

- Typically 2-hour fire rating for transformer rooms

- Extend from floor to roof deck

-

Fire Doors:

- Self-closing, fire-rated doors

- Ensure proper sealing to prevent smoke spread

-

Penetration Sealing:

- Fire-stop all cable and conduit penetrations

- I always double-check these often-overlooked areas

Fire Barrier Specifications:

| Element | Minimum Rating | Recommended Rating |

|---|---|---|

| Walls | 2-hour | 3-hour |

| Doors | 90-minute | 120-minute |

| Penetrations | Match wall rating | Exceed wall rating by 30 minutes |

Proper fire barriers are crucial for containing and isolating potential transformer fires.

Step 4: Implementing Fire Suppression Systems

Active fire protection:

-

Sprinkler Systems:

- Often required for indoor installations

- Design based on transformer type and size

-

Clean Agent Systems:

- Consider for sensitive electronic areas

- Ensure compatibility with electrical equipment

-

Foam Systems:

- May be required for large oil-filled transformers

- Specialized design for flammable liquid fires

Fire Suppression Comparison:

| System Type | Pros | Cons | Best For |

|---|---|---|---|

| Water Sprinkler | Cost-effective, widely accepted | Potential equipment damage | General applications |

| Clean Agent | No residue, quick suppression | Higher cost, room integrity needed | Data centers, sensitive equipment |

| Foam | Effective for oil fires | Complex, environmental concerns | Large oil-filled transformers |

The right suppression system depends on your specific transformer and installation environment.

Step 5: Providing Emergency Access

Ensuring rapid response:

-

Access Routes:

- Clear, marked pathways to transformer areas

- I always ensure these routes are at least 4 feet wide

-

Emergency Shutoffs:

- Easily accessible power disconnects

- Clearly labeled and illuminated

-

Signage and Lighting:

- Proper warning signs and emergency lighting

- Reflective markings for nighttime visibility

Emergency Access Checklist:

| Element | Requirement | Best Practice |

|---|---|---|

| Access Width | 3 feet | 4 feet or more |

| Shutoff Location | Within sight of transformer | Multiple locations |

| Signage | Standard warnings | Reflective, multi-lingual |

| Emergency Lighting | Battery backup | Solar-powered options |

Proper emergency access can significantly reduce response times and mitigate fire damage.

Additional Considerations

Going beyond the basics:

-

Local Code Variations:

- Always check local amendments to national codes

- Some jurisdictions have stricter requirements

-

Future Expansion:

- Plan for potential upgrades or additional transformers

- Over-designing now can save costly renovations later

-

Documentation:

- Maintain detailed installation and compliance records

- I recommend creating a digital archive for easy access during inspections

-

Regular Inspections:

- Schedule routine checks of fire safety systems

- Address any issues promptly to maintain compliance

Compliance Maintenance Schedule:

| Component | Inspection Frequency | Maintenance Action |

|---|---|---|

| Fire Barriers | Quarterly | Check for damage, reseal penetrations |

| Suppression Systems | Monthly | Test alarms, check pressure |

| Emergency Access | Bi-annually | Clear routes, test lighting |

| Documentation | Annually | Update records, review for changes |

Regular maintenance and inspections are key to long-term fire code compliance.

Meeting fire codes during transformer installation is a complex but crucial process. By following these steps and best practices, you can ensure a safe, compliant installation that protects your facility and its occupants.

Remember, fire codes are not just bureaucratic hurdles – they’re life-saving measures based on years of experience and research. As someone who has overseen numerous transformer installations, I can attest to the peace of mind that comes from knowing you’ve done everything possible to prevent and mitigate fire risks.

Always consult with local authorities and licensed professionals when planning your installation. Fire codes can vary by location and are regularly updated. Staying informed and proactive in your approach to fire safety will not only ensure compliance but also contribute to the overall safety and reliability of your electrical systems.

Conclusion

Dry-type transformers offer significant advantages in fire safety compliance. By understanding and implementing key NFPA standards, choosing the right equipment, and following proper installation procedures, facility managers can ensure a safer, more reliable electrical infrastructure. Always prioritize fire safety in transformer selection and installation to protect lives and assets.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group