How Do Power Transformers and Distribution Transformers Differ in Modern Electrical Systems?

Have you ever wondered how electricity reaches your home safely? The journey from power plants to your outlets is fascinating. It involves two key players: power transformers and distribution transformers.

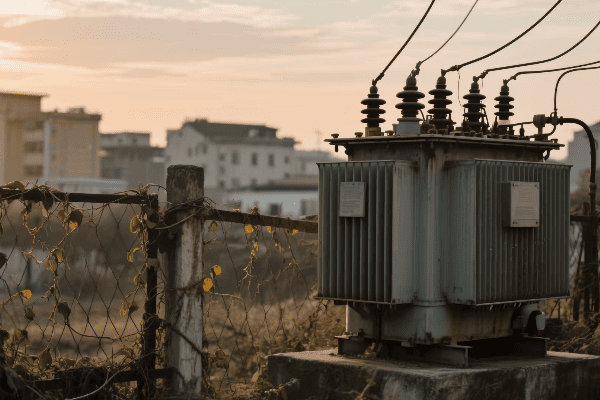

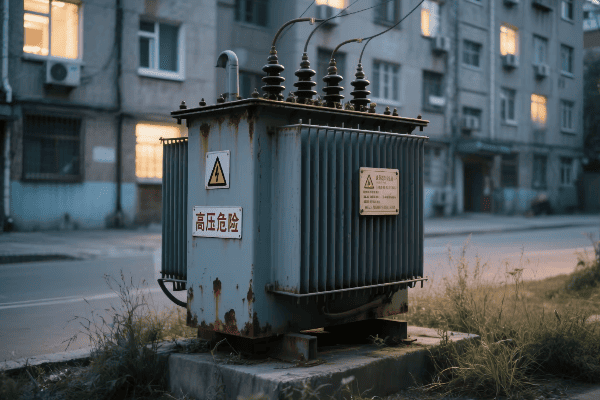

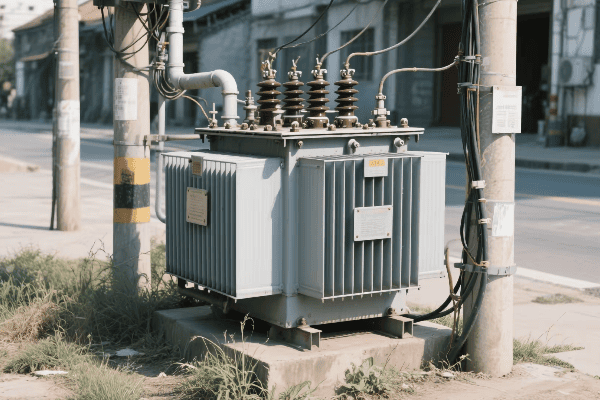

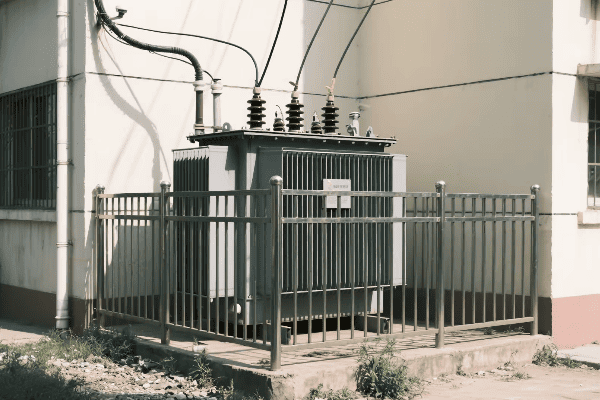

Power transformers and distribution transformers are essential components in electrical systems. They differ in size, capacity, and function. Power transformers handle high voltages at generation and transmission levels, while distribution transformers step down voltage for end-user consumption.

As an electrical engineer with years of experience in the power industry, I’ve worked extensively with both types of transformers. I’ve seen firsthand how crucial they are to our modern electrical infrastructure. Let’s dive deeper into their differences and why they matter.

What Are the Core Functions and Voltage Levels of Power vs. Distribution Transformers?

Imagine trying to drink from a fire hose. That’s what using electricity straight from a power plant would be like. Power and distribution transformers work together to make electricity usable for us.

Power transformers handle high voltages, typically 69 kV and above. They work at power generation sites and substations. Distribution transformers deal with lower voltages, usually below 35 kV. They’re the last step before electricity reaches consumers.

I remember my first visit to a major substation. The size of the power transformers amazed me. They were massive compared to the distribution transformers I was used to seeing in neighborhoods. This experience helped me understand their different roles better.

Power Transformer Functions

Power transformers have three main jobs:

- Step up voltage for long-distance transmission

- Step down voltage at substations

- Provide isolation between different voltage systems

Distribution Transformer Functions

Distribution transformers have two primary functions:

- Step down voltage to levels safe for consumer use

- Distribute electricity to end-users

Voltage Level Comparison

| Transformer Type | Input Voltage | Output Voltage |

|---|---|---|

| Power | 69 kV – 765 kV | 69 kV – 138 kV |

| Distribution | 4 kV – 35 kV | 120 V – 600 V |

The voltage levels show why we need both types. Power transformers handle the "bulk" electricity. Distribution transformers make it safe for our homes and businesses. Without this two-stage process, our electrical systems wouldn’t be practical or safe.

How Do Size and Capacity Differentiate Power Transformers from Distribution Transformers?

Size matters in the transformer world. When I first started in this field, I was struck by the vast difference in size between power and distribution transformers. It’s not just about physical size, though. Capacity plays a huge role too.

Power transformers are giants, often weighing hundreds of tons with capacities reaching 1000 MVA or more. Distribution transformers are much smaller, typically under 5 tons, with capacities usually below 3000 kVA. This size difference reflects their roles in the power system.

I once worked on a project to upgrade a substation. The new power transformer we installed was so large it required special transportation and a team of experts to set up. It was a stark contrast to the distribution transformers I’d helped install in residential areas.

Size Comparison

Let’s break down the size differences:

-

Physical Dimensions

- Power transformers can be as large as a house

- Distribution transformers are often no bigger than a large refrigerator

-

Weight

- Power transformers: 100 to 400 tons or more

- Distribution transformers: Usually under 5 tons

Capacity Comparison

Capacity is measured in volt-amperes (VA) or kilovolt-amperes (kVA):

| Transformer Type | Typical Capacity Range |

|---|---|

| Power | 5 MVA to 1000 MVA |

| Distribution | 5 kVA to 3000 kVA |

The huge capacity difference is due to their roles. Power transformers need to handle electricity for entire cities or regions. Distribution transformers serve smaller areas like neighborhoods or individual buildings.

These size and capacity differences affect everything from design to maintenance. Power transformers require specialized equipment for installation and maintenance. Distribution transformers, being smaller, are easier to replace and maintain.

What Unique Roles Do Power and Distribution Transformers Play in the Electrical Grid?

Understanding the roles of power and distribution transformers is like understanding the difference between highways and local roads. Both are crucial, but they serve different purposes in getting you to your destination.

Power transformers are the backbone of the transmission system. They handle bulk power transfer and voltage regulation at the grid level. Distribution transformers are the final link to consumers. They ensure safe, usable voltage levels for homes and businesses.

I’ve seen this difference in action many times. Once, during a major grid upgrade project, I witnessed how power transformers at substations managed the flow of electricity across vast distances. Later, in a residential development project, I saw how distribution transformers brought that power directly to individual homes.

Power Transformer Roles

-

Transmission System Support

- Enable long-distance power transmission

- Maintain voltage stability in the grid

-

Substation Operations

- Step down voltage for further distribution

- Provide isolation between transmission and distribution systems

-

Grid Interconnection

- Facilitate power exchange between different grid sections

- Support grid stability during load changes

Distribution Transformer Roles

-

Local Power Distribution

- Deliver electricity to end-users

- Maintain consistent voltage for consumer appliances

-

Voltage Regulation

- Adjust voltage levels to compensate for line losses

- Ensure power quality for sensitive electronic devices

-

Safety and Isolation

- Provide electrical isolation between the grid and consumer premises

- Protect consumer equipment from high voltage surges

Comparative Impact on Grid Stability

| Aspect | Power Transformers | Distribution Transformers |

|---|---|---|

| Voltage Control | Grid-wide impact | Localized impact |

| Load Management | Large-scale balancing | Small-scale load handling |

| Fault Protection | System-wide protection | End-user protection |

The roles of these transformers complement each other. Power transformers ensure the overall health and stability of the grid. Distribution transformers make sure this stability translates into reliable power for end-users.

In my career, I’ve seen how crucial both types are. A failure in a power transformer can affect an entire region. A problem with a distribution transformer might only impact a few households. But both are equally important for a functioning electrical system.

How Do Design Features Vary Between Power and Distribution Transformers?

Design differences between power and distribution transformers fascinate me. These differences aren’t just about size. They reflect the unique challenges each type faces in the electrical system.

Power transformers are designed for high efficiency and reliability at high voltages. They often have complex cooling systems and advanced monitoring. Distribution transformers focus on cost-effectiveness and ease of maintenance. They’re built to withstand frequent load changes.

I remember a project where we were comparing designs for a new substation. The power transformer specifications were incredibly detailed, focusing on things like harmonics and short-circuit strength. In contrast, when I worked on a residential project, the distribution transformer designs prioritized factors like noise reduction and compact size.

Core Design Differences

-

Cooling Systems

- Power transformers: Often use oil with forced cooling (fans or pumps)

- Distribution transformers: Usually rely on natural oil or air cooling

-

Insulation

- Power transformers: High-grade insulation for extreme voltages

- Distribution transformers: Simpler insulation suitable for lower voltages

-

Tap Changers

- Power transformers: Often have on-load tap changers for voltage regulation

- Distribution transformers: Usually have off-load taps, if any

-

Monitoring and Control

- Power transformers: Advanced monitoring systems (temperature, gas, oil level)

- Distribution transformers: Basic overload and short-circuit protection

Comparative Design Features

| Feature | Power Transformers | Distribution Transformers |

|---|---|---|

| Core Material | High-grade steel | Standard electrical steel |

| Winding Material | Copper (usually) | Aluminum or Copper |

| Efficiency | Very high (>99%) | High (>95%) |

| Size/Weight | Large and heavy | Compact and lighter |

| Noise Level | Higher | Lower |

These design differences reflect their operating conditions. Power transformers need to handle massive amounts of energy consistently. Distribution transformers need to be reliable under varying load conditions.

In my experience, understanding these design differences is crucial for proper installation and maintenance. I’ve seen cases where misunderstanding these differences led to inefficiencies or even failures in the electrical system.

What Are the Distinct Maintenance and Operational Considerations for Each Transformer Type?

Maintenance and operation of transformers are critical for a reliable power supply. Over the years, I’ve learned that power and distribution transformers have very different needs in this area.

Power transformers require complex, scheduled maintenance and continuous monitoring. They often have advanced diagnostic systems. Distribution transformers need less frequent maintenance but more regular inspections. Their maintenance is often reactive rather than preventive.

I recall a time when a power transformer at a major substation needed maintenance. It was a huge operation involving a team of specialists and days of planning. In contrast, when a distribution transformer in a residential area failed, we simply replaced it with a spare unit in a matter of hours.

Maintenance Considerations

-

Frequency of Maintenance

- Power transformers: Regular, scheduled maintenance (often annually)

- Distribution transformers: Less frequent, often based on inspections or issues

-

Complexity of Maintenance

- Power transformers: Highly complex, requiring specialized skills and equipment

- Distribution transformers: Simpler, often focusing on external inspections and basic tests

-

Monitoring Systems

- Power transformers: Continuous monitoring of various parameters (temperature, gas levels, oil quality)

- Distribution transformers: Basic overload and fault indicators

-

Lifespan and Replacement

- Power transformers: Longer lifespan (30-40 years), major refurbishment possible

- Distribution transformers: Shorter lifespan (20-30 years), often replaced rather than repaired

Operational Considerations

| Aspect | Power Transformers | Distribution Transformers |

|---|---|---|

| Load Management | Critical, constant monitoring | Less critical, designed for load variations |

| Efficiency | Crucial due to high power handling | Important but less critical |

| Fault Response | Immediate action required | Can often be temporarily bypassed |

| Environmental Impact | Higher due to size and oil volume | Lower, but more units in populated areas |

In my experience, the key to effective transformer management is understanding these differences. For power transformers, we focus on preventing issues before they occur. With distribution transformers, we prepare for quick replacements and have spare units ready.

I’ve found that regular training for maintenance teams is crucial. The skills needed for power transformer maintenance are very different from those for distribution transformers. This specialized knowledge can make a huge difference in the reliability of the electrical system.

Conclusion

Power and distribution transformers are both vital for our electrical systems. They differ in size, function, design, and maintenance needs. Understanding these differences is key to maintaining a reliable and efficient power grid.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group