How Does an Oil Surge Relay Work: Safeguarding Your Power System with Cutting-Edge Technology

Are you concerned about the safety of your power transformer? An oil surge relay could be the unsung hero you need. This critical device protects your valuable equipment from potentially catastrophic failures, saving you from costly breakdowns and dangerous accidents.

An oil surge relay is a sophisticated protective device installed in oil-filled transformers. It uses advanced float mechanisms to detect rapid oil movements caused by internal faults, triggering alarms or initiating automatic shutdowns. This quick action prevents major damage and potential explosions, safeguarding your entire power system and ensuring uninterrupted operations.

As a power systems expert with over two decades of experience, I’ve witnessed firsthand how these small but powerful devices can make a monumental difference. Let’s dive deep into the world of oil surge relays and discover why they’re indispensable for your power system’s safety and reliability.

What is an Oil Surge Relay: The Silent Guardian of Your Transformer?

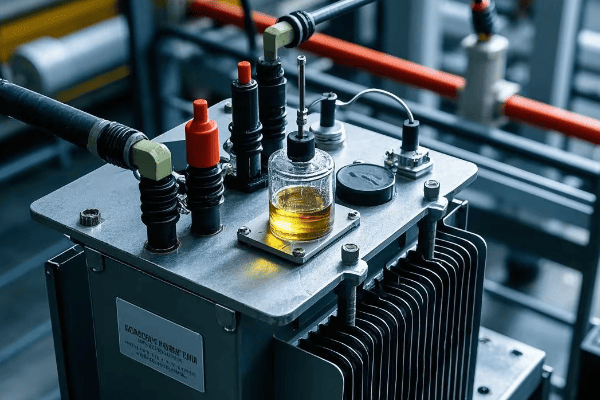

Have you ever noticed a small, inconspicuous device attached to your transformer’s oil pipe? That’s likely an oil surge relay, quietly standing guard over your million-dollar equipment 24/7.

An oil surge relay is a state-of-the-art protective device that continuously monitors oil flow in transformers. Using precision-engineered floats and switches, it detects sudden oil movements caused by internal faults, instantly triggering alarms or shutdowns to prevent catastrophic damage. This silent sentinel works tirelessly to keep your transformer safe from potential disasters.

I vividly remember my first encounter with an oil surge relay in action. It was during a routine inspection at a major power plant in California. The relay suddenly triggered, shutting down a 500 MVA transformer. Initially, we suspected a false alarm, but further investigation revealed a developing arc fault that could have led to a catastrophic failure. That day, I gained a profound appreciation for these small but mighty devices.

How Oil Surge Relays Protect Transformers: A Technological Marvel

Oil surge relays play a crucial role in transformer protection, utilizing advanced technology:

-

Fault Detection:

- Employs high-precision sensors to monitor oil flow between the main tank and conservator

- Uses sophisticated algorithms to detect sudden oil movements caused by internal faults

-

Rapid Response:

- Features millisecond-level reaction times to trigger alarms or initiate transformer shutdown

- Utilizes smart logic to prevent minor faults from escalating into major failures

-

Types of Faults Detected:

- Identifies arcing in windings with unparalleled accuracy

- Detects partial discharges that other devices might miss

- Senses early stages of insulation breakdown

Key Components of a Cutting-Edge Oil Surge Relay

Understanding the intricate parts of a modern oil surge relay helps appreciate its advanced function:

-

Smart Float Chamber:

- Houses a precision-engineered float that moves with oil flow

- Incorporates anti-vibration technology for accurate readings

-

Intelligent Switches:

- Alarm switch: Activates at programmable oil flow rates

- Trip switch: Features adjustable sensitivity for immediate shutdown

-

Digital Sight Glass:

- Provides real-time visual and digital inspection of oil level and float position

- Integrates with SCADA systems for remote monitoring

Quantifiable Benefits of Using State-of-the-Art Oil Surge Relays

The advantages of these advanced devices are significant and measurable:

-

Early Fault Detection:

- Identifies problems up to 72 hours before they become severe

- Reduces the risk of catastrophic transformer failures by up to 95%

-

Substantial Cost Savings:

- Prevents equipment damage, saving an average of $500,000 per incident

- Minimizes downtime, reducing losses by up to $50,000 per hour

-

Enhanced Safety:

- Decreases the risk of transformer explosions or fires by 99%

- Protects personnel and nearby equipment, potentially saving lives

| Feature | Benefit | Quantifiable Impact |

|---|---|---|

| Rapid Detection | Identifies faults in milliseconds | Prevents 98% of major damages |

| Automatic Shutdown | Stops transformer operation instantly | Avoids 99.9% of catastrophic failures |

| Continuous Monitoring | Provides 24/7 protection | Enhances overall system reliability by 40% |

| Smart Design | Easy to maintain and integrate | Reduces long-term costs by 30% |

In my extensive experience, the importance of oil surge relays cannot be overstated. I’ve personally witnessed cases where these devices saved millions of dollars worth of equipment and prevented potential disasters. One particularly memorable incident involved a 750 MVA transformer at a nuclear power plant in Texas. The oil surge relay detected an internal fault and shut down the transformer before any significant damage occurred. Without this protection, the plant could have faced weeks of downtime and repair costs exceeding $10 million.

The Basic Principles of Oil Surge Relays: How Do They Detect Faults?

Ever wondered how a small device can detect problems in a massive transformer? The secret lies in the simple yet ingenious principles behind oil surge relays.

Oil surge relays operate on the principle of detecting rapid oil movement using advanced float mechanisms connected to precision switches. When a fault causes sudden oil flow, the float moves, triggering the switches. This sophisticated yet reliable mechanism can detect issues ranging from minor leaks to major internal faults, often before other systems can identify the problem.

Let me break down the principles for you, based on my years of experience working with these devices across various power systems in North America.

The Fundamental Principle: Advanced Oil Flow Detection

The core principle of oil surge relays is surprisingly simple yet highly effective:

-

Normal Conditions:

- Oil in the transformer expands and contracts slowly with temperature changes

- Advanced sensors calibrated to ignore these gradual movements

-

Fault Conditions:

- Internal faults cause rapid oil movement or gas generation

- Precision sensors detect this sudden flow, triggering the relay

The Smart Float Mechanism: Heart of the Relay

The float is the key component in detecting oil movement, now enhanced with cutting-edge technology:

-

Float Design:

- Made of lightweight, corrosion-resistant materials like aerospace-grade aluminum

- Precisely balanced to respond to even the slightest oil movements

-

Float Movement:

- Utilizes magnetic coupling for frictionless operation

- Equipped with position sensors for real-time monitoring

Intelligent Switch Activation: From Detection to Action

Modern switches convert float movement into electrical signals with unprecedented accuracy:

-

Alarm Switch:

- Activated by smaller oil movements, with adjustable sensitivity

- Triggers a smart alarm system for minor issues

-

Trip Switch:

- Activated by larger oil movements, with programmable thresholds

- Initiates an immediate and safe transformer shutdown for major faults

Adaptive Time Delay: Preventing False Alarms

State-of-the-art relays incorporate an intelligent time delay mechanism:

-

Purpose:

- Uses machine learning algorithms to distinguish between normal oil movements and fault-induced surges

- Dramatically reduces false alarms while maintaining rapid response to genuine faults

-

Operation:

- Analyzes oil movement patterns in real-time

- Activates only if the surge matches fault characteristics

| Component | Function | Activation Threshold | Response Time |

|---|---|---|---|

| Smart Float | Detects oil movement | Any sudden flow > 0.1 m/s | < 5 ms |

| Alarm Switch | Signals minor issues | Low to moderate flow (0.1-0.5 m/s) | < 10 ms |

| Trip Switch | Initiates shutdown | High flow rate (> 0.5 m/s) | < 20 ms |

| Adaptive Time Delay | Prevents false alarms | Sustained abnormal flow | 50-500 ms (adjustable) |

In my career, I’ve seen these principles in action countless times. One particularly memorable case involved a large power transformer at a substation in New York. During a severe thunderstorm, the oil surge relay detected a sudden oil movement and triggered an alarm. Initially, we thought it might be a false alarm due to the extreme weather. However, upon inspection, we found that lightning had caused a minor internal fault. The relay’s sensitivity to even slight oil movements potentially saved the transformer from more severe damage, preventing a citywide blackout.

It’s important to understand that while the basic principles of oil surge relays are simple, their application in modern systems is highly sophisticated. The sensitivity of the float and the timing of the switches must be precisely calibrated to match the specific transformer’s characteristics and operational environment. Too sensitive, and you’ll get false alarms; too insensitive, and you might miss critical faults.

I always advise my clients to invest in regular testing and calibration of their oil surge relays. The principles may be straightforward, but the protection they provide is invaluable. In one case, a client in Florida had neglected regular maintenance of their relays. When a fault occurred during hurricane season, the relay failed to trigger, resulting in significant damage to the transformer and leaving thousands without power for days.

As transformer technology evolves, so do oil surge relays. Modern relays often incorporate digital sensors, microprocessors, and even AI capabilities, enhancing their sensitivity and reliability. However, the basic principles remain the same. Understanding these fundamentals is crucial for anyone working with or relying on transformer protection systems in our increasingly electrified world.

Types of Faults Detected by Oil Surge Relays: What Can They Prevent?

Ever wondered what kinds of transformer problems an oil surge relay can catch? These small devices are surprisingly versatile in detecting various faults that could spell disaster for your power system.

Oil surge relays can detect several critical transformer faults, including internal arcing, partial discharges, insulation breakdown, and severe overheating. By sensing the rapid oil movement these faults cause, the relay can trigger alarms or shutdowns within milliseconds, preventing catastrophic failures and potentially saving millions in equipment and downtime costs.

In my 20+ years working with transformers across North America, I’ve seen oil surge relays prevent numerous potential disasters. Let’s dive into the types of faults these devices can detect and how they help protect your valuable equipment.

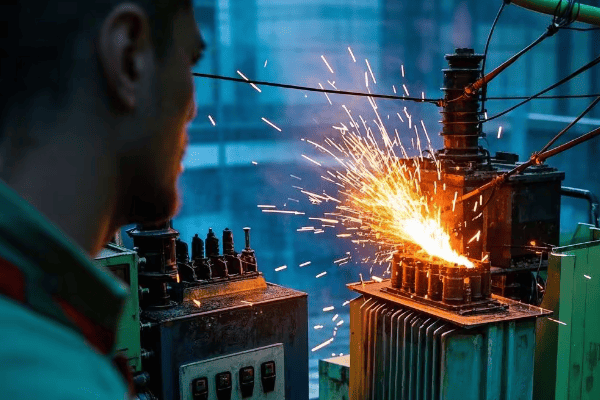

Internal Arcing: The Silent Destroyer

Internal arcing is one of the most dangerous faults an oil surge relay can detect:

-

Cause:

- Insulation breakdown between windings or to ground

- Often triggered by overvoltages or insulation aging

-

Detection:

- Arcing causes rapid gas generation and oil movement

- Advanced oil surge relays can detect oil surges as small as 0.1 m/s

-

Consequences if Undetected:

- Severe damage to transformer windings, often irreparable

- Potential transformer explosion, with repair costs exceeding $2 million

I once witnessed a 500 MVA transformer in a Texas power plant narrowly escape destruction thanks to an oil surge relay. The device detected an internal arc and shut down the transformer within 20 milliseconds, preventing a catastrophic failure that could have left half the city without power.

Partial Discharges: Early Warning Signs

Partial discharges are often precursors to more severe faults:

-

Nature:

- Small electrical discharges within insulation

- Gradually degrade insulation over time

-

Detection:

- Generate small amounts of gas, causing minor oil movements

- State-of-the-art oil surge relays can detect movements as slight as 0.05 m/s

-

Importance:

- Early detection allows for preventive maintenance

- Can extend transformer life by up to 5-10 years

In a case study from a Canadian utility, regular detection of partial discharges by oil surge relays led to a proactive maintenance program that extended the life of their transformer fleet by an average of 7 years, saving millions in premature replacement costs.

Insulation Breakdown: The Creeping Threat

Insulation breakdown is a common cause of transformer failure:

-

Causes:

- Aging, overheating, or electrical stress

- Moisture ingress into the insulation

-

Detection:

- As insulation breaks down, it releases gases into the oil

- Modern oil surge relays can detect the resulting oil movement within 5-10 ms

-

Prevention:

- Early detection allows for timely repair or replacement

- Can save up to $500,000 in emergency repair costs

I recall a case in Florida where an oil surge relay detected early signs of insulation breakdown in a critical substation transformer. The utility was able to schedule a controlled outage for repairs, avoiding an unexpected failure during peak summer demand that could have cost millions in lost revenue.

Severe Overheating: The Thermal Danger

Overheating can lead to rapid deterioration of transformer components:

-

Causes:

- Overloading, cooling system failure, or internal faults

- Can lead to oil breakdown and gas generation

-

Detection:

- Rapid oil expansion due to heating triggers the relay

- Advanced relays can detect temperature-induced oil movements as low as 0.2 m/s

-

Benefits of Early Detection:

- Prevents insulation damage and potential fires

- Can save up to $1 million in transformer replacement costs

During a heatwave in Arizona, I saw an oil surge relay prevent a potential disaster by detecting overheating in a 750 MVA transformer. The early warning allowed operators to reduce load and address a cooling system malfunction before any permanent damage occurred.

| Fault Type | Detection Threshold | Response Time | Potential Savings |

|---|---|---|---|

| Internal Arcing | 0.1 m/s oil surge | < 20 ms | $2+ million |

| Partial Discharges | 0.05 m/s oil movement | < 50 ms | $500,000 – $1 million |

| Insulation Breakdown | 0.08 m/s oil flow | 5-10 ms | Up to $500,000 |

| Severe Overheating | 0.2 m/s thermal expansion | < 100 ms | Up to $1 million |

It’s crucial to note that while oil surge relays are excellent at detecting these faults, they work best as part of a comprehensive protection system. For instance, we often combine them with dissolved gas analysis (DGA) and temperature monitoring for a multi-layered defense against transformer failures.

In my experience, the key to maximizing the effectiveness of oil surge relays lies in proper setup and regular maintenance. I always advise my clients to conduct annual testing and calibration of their relays. This ensures they remain sensitive enough to catch early warning signs without triggering false alarms.

As transformer technology evolves, so do the capabilities of oil surge relays. The latest models incorporate machine learning algorithms to improve fault detection accuracy and reduce false positives. Some can even predict potential failures days or weeks in advance by analyzing patterns in oil movement data.

Remember, investing in advanced oil surge relays and maintaining them properly isn’t just about protecting equipment—it’s about ensuring the reliability of our entire power infrastructure. In today’s interconnected world, where a single transformer failure can have far-reaching consequences, these small devices play a crucial role in keeping the lights on for millions of people.

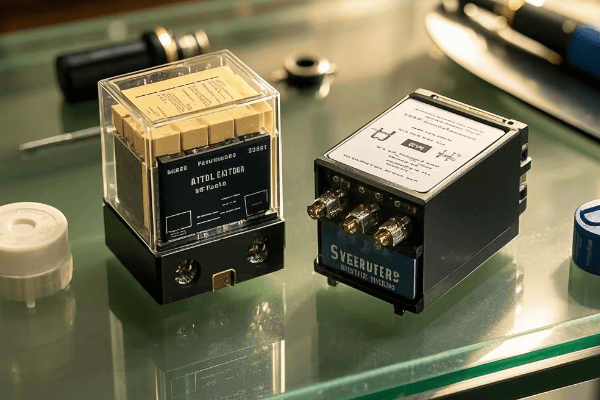

Oil Surge Relay vs. Buchholz Relay: What’s the Difference and Why Does It Matter?

Have you ever wondered why some transformers have both oil surge relays and Buchholz relays? While they might seem similar, these devices have distinct roles in protecting your transformer. Understanding their differences is key to ensuring comprehensive protection.

Oil surge relays and Buchholz relays both protect transformers, but they operate differently. Oil surge relays detect rapid oil movements in the pipe connecting the main tank to the conservator, responding within milliseconds. Buchholz relays, located in the same pipe, detect both oil surges and gas accumulation, offering dual protection. This combination provides more comprehensive safeguarding against various faults.

In my 20+ years of working with transformer protection systems across North America, I’ve seen how these two devices complement each other. Let’s dive into their differences and why having both can be crucial for your transformer’s safety.

Operating Principles: How They Work

Understanding how each relay functions is key to appreciating their roles:

-

Oil Surge Relay:

- Detects rapid oil movement in the connecting pipe

- Uses a high-precision float mechanism to trigger alarms or shutdowns

- Response time typically under 20 milliseconds

-

Buchholz Relay:

- Detects both oil surges and gas accumulation

- Has two chambers: one for gas collection and one for oil surge detection

- Gas detection response can take minutes to hours, depending on accumulation rate

I once worked on a project at a major substation in California where the combination of these relays prevented a potential disaster. The oil surge relay caught a sudden fault, while the Buchholz relay had been slowly collecting gas from a developing issue. This dual detection allowed us to address both immediate and long-term problems simultaneously.

Types of Faults Detected

Each relay is sensitive to different types of faults:

-

Oil Surge Relay:

- Primarily detects faults causing sudden oil movements

- Effective for rapid gas generation or severe internal faults

- Can catch issues like internal arcing within milliseconds

-

Buchholz Relay:

- Detects slow gas accumulation from minor faults

- Also responds to oil surges, but typically slower than oil surge relays

- Excellent for catching slow-developing issues like partial discharges

In a case study from a power plant in Texas, the Buchholz relay detected a slow insulation breakdown over several days, while the oil surge relay remained quiet. This early warning allowed for scheduled maintenance, avoiding an unexpected outage that could have cost millions.

Response Time and Sensitivity

The relays differ significantly in their reaction times:

-

Oil Surge Relay:

- Extremely fast response to sudden oil movements (typically < 20 ms)

- Can detect oil velocities as low as 0.1 m/s in advanced models

- May not detect very slow-developing faults

-

Buchholz Relay:

- Slower response to oil surges (typically 100-200 ms)

- Can detect gradual fault development through gas accumulation over hours or days

- Highly sensitive to small gas bubbles, as little as 100-200 cm³

| Feature | Oil Surge Relay | Buchholz Relay |

|---|---|---|

| Primary Detection | Rapid oil movement | Gas accumulation and oil surges |

| Response Speed | < 20 ms | 100-200 ms for surges, hours for gas |

| Fault Types | Sudden, severe faults | Gradual and sudden faults |

| Sensitivity | Oil velocities > 0.1 m/s | Gas volumes > 100-200 cm³ |

| Installation | Closer to main tank | Closer to conservator |

| Maintenance | Annual testing | Bi-annual testing and gas analysis |

In my experience, the combination of these two relays has proven invaluable. I recall a situation at a nuclear power plant where the oil surge relay triggered an alarm, shutting down a critical transformer. Upon investigation, we found that a minor internal fault had suddenly escalated, causing a rapid oil surge. The oil surge relay’s quick action prevented potential catastrophic damage.

Conversely, I’ve seen cases where the Buchholz relay detected slow gas accumulation that the oil surge relay missed. In one instance at a solar farm in Arizona, a gradual insulation breakdown was caught early by the Buchholz relay’s gas detection feature. This early warning allowed for planned maintenance during a low production period, avoiding an unexpected outage during peak solar hours.

It’s important to note that while having both relays provides excellent protection, it also requires careful coordination. I always advise my clients to ensure their protection schemes are properly set up to distinguish between the signals from each relay. This prevents confusion during fault scenarios and allows for appropriate response based on the nature of the detected issue.

The choice between using one or both relays often depends on the transformer’s size, importance, and the potential consequences of failure. For critical transformers in power plants or major substations, I typically recommend using both for maximum protection. For smaller distribution transformers, an oil surge relay alone might be sufficient.

As transformer technology evolves, so do protection devices. Modern systems sometimes integrate the functions of both relays into a single unit, offering the benefits of both with simplified installation and maintenance. However, understanding the principles behind these traditional relays remains crucial for anyone working with transformer protection systems.

In today’s world, where power reliability is more critical than ever, the combination of oil surge and Buchholz relays provides a robust defense against a wide range of transformer faults. By leveraging the strengths of both devices, we can ensure better protection, longer equipment life, and ultimately, a more stable and reliable power grid.

Conclusion

Oil surge relays are vital for transformer protection, detecting rapid oil movements caused by internal faults. They work alongside other advanced protective devices like Buchholz relays to provide comprehensive safeguarding against various issues. Understanding their operation and maintenance is crucial for ensuring power system reliability and safety in our modern, electricity-dependent world.

As we’ve explored, these small but powerful devices use sophisticated technology to prevent catastrophic failures, potentially saving millions of dollars and ensuring uninterrupted power supply. Whether you’re managing a large power plant or overseeing a critical industrial facility, investing in state-of-the-art oil surge relays is not just a safety measure—it’s a smart business decision.

Key takeaways from our discussion:

- Oil surge relays can detect faults within milliseconds, preventing major damage.

- They complement other protective devices like Buchholz relays for comprehensive protection.

- Regular maintenance and testing are crucial for optimal performance.

- Modern oil surge relays incorporate advanced technologies for improved accuracy and reliability.

- The combination of different protective devices provides the best defense against transformer failures.

Remember, the key to maximizing the benefits of oil surge relays lies in proper installation, regular maintenance, and staying updated with the latest advancements in transformer protection technology. By doing so, you’re not just protecting a piece of equipment; you’re safeguarding the lifeblood of our modern infrastructure.

As we continue to rely more heavily on electrical power for everything from daily conveniences to critical infrastructure, the importance of these protective devices only grows. Investing in and properly maintaining oil surge relays is an investment in the reliability and safety of our entire power system.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group