How Does Power Transformer Work: A Comprehensive Guide for Beginners?

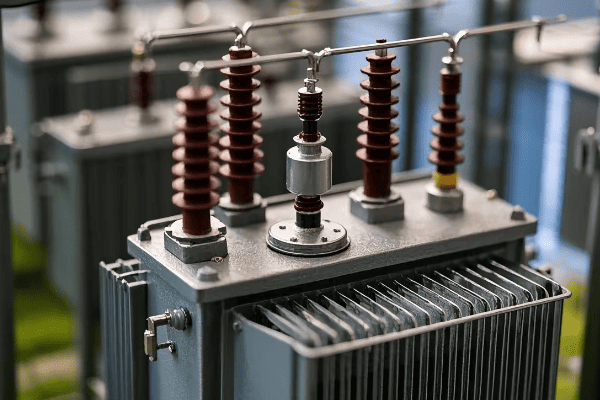

Have you ever wondered how electricity travels from power plants to your home? The answer lies in power transformers. These devices are crucial but often misunderstood.

Power transformers are essential devices in electrical systems. They change voltage levels, allowing efficient power transmission over long distances. Understanding how they work is key for anyone interested in electricity or engineering.

In this guide, I’ll break down the complexities of power transformers. We’ll explore their basic concepts, working principles, types, construction, and applications. Let’s dive in and demystify these important devices.

What is a Power Transformer: Basic Concepts and Components?

Are you confused about what a power transformer really is? You’re not alone. Many people find this concept challenging, but it’s simpler than you might think.

A power transformer is an electrical device that transfers energy between circuits using electromagnetic induction. It has two main parts: the primary winding and the secondary winding, both wrapped around a magnetic core.

Let’s dive deeper into the world of power transformers. Understanding their basic concepts and components is crucial for grasping how our electrical systems work.

Key Components

-

Core

- Made of laminated steel sheets

- Provides a path for magnetic flux

-

Windings

- Primary winding: Connected to the power source

- Secondary winding: Connected to the load

- Made of copper or aluminum wire

-

Insulation

- Prevents short circuits between windings and core

- Often uses oil or special paper

Basic Concepts

-

Turns Ratio

- Ratio of turns in primary to secondary winding

- Determines voltage transformation

-

Electromagnetic Induction

- Principle behind transformer operation

- Changing magnetic field induces voltage in nearby conductor

| Component | Function | Material |

|---|---|---|

| Core | Magnetic flux path | Laminated steel |

| Primary Winding | Receives input power | Copper/Aluminum wire |

| Secondary Winding | Delivers output power | Copper/Aluminum wire |

| Insulation | Prevents short circuits | Oil/Paper |

Understanding these components and concepts is essential for grasping how power transformers work. The core provides a path for the magnetic flux, which is crucial for the energy transfer process. The windings are where the actual transformation of voltage occurs, with the number of turns in each winding determining the voltage change.

The insulation is a critical component that ensures the safe operation of the transformer. Without proper insulation, the high voltages involved could lead to dangerous short circuits or electrical breakdowns.

The turns ratio is a fundamental concept in transformer theory. It’s this ratio that allows transformers to step voltage up or down. For example, if the secondary winding has twice as many turns as the primary, the output voltage will be twice the input voltage.

Electromagnetic induction, discovered by Michael Faraday in 1831, is the key principle behind transformer operation. When an alternating current flows through the primary winding, it creates a changing magnetic field in the core. This changing field then induces a voltage in the secondary winding.

In my early days of studying electrical engineering, I found these concepts challenging. But once I understood how they all work together, it opened up a whole new world of understanding about our electrical systems.

The Principle of Electromagnetic Induction: The Heart of Transformer Operation?

Have you ever wondered how a transformer can change voltage without any moving parts? The secret lies in a principle discovered nearly 200 years ago: electromagnetic induction.

Electromagnetic induction is the core principle behind transformer operation. When a changing magnetic field passes through a conductor, it induces a voltage. This principle allows transformers to transfer energy between circuits and change voltage levels.

Let’s explore this fascinating principle in more detail. Understanding electromagnetic induction is key to grasping how transformers work and why they’re so important in our electrical systems.

Faraday’s Law of Induction

-

Changing Magnetic Field

- Creates an electromotive force (EMF)

- Rate of change affects induced voltage

-

Lenz’s Law

- Induced current opposes the change causing it

- Ensures energy conservation

Application in Transformers

-

Primary Winding

- Alternating current creates changing magnetic field

- Field strength varies with input voltage and frequency

-

Magnetic Core

- Concentrates and directs magnetic field

- Improves coupling between windings

-

Secondary Winding

- Changing field induces voltage

- Voltage depends on number of turns and rate of field change

| Concept | Description | Importance in Transformers |

|---|---|---|

| Changing Magnetic Field | Varying field strength over time | Creates the basis for energy transfer |

| Induced Voltage | Voltage created by changing field | Allows voltage transformation |

| Mutual Inductance | Interaction between two nearby coils | Enables energy transfer between windings |

Electromagnetic induction is truly the heart of transformer operation. When an alternating current flows through the primary winding, it creates a changing magnetic field. This field is concentrated and directed by the magnetic core, which is why transformer cores are made of materials with high magnetic permeability like silicon steel.

The changing magnetic field then passes through the secondary winding. According to Faraday’s Law, this changing field induces a voltage in the secondary winding. The magnitude of this induced voltage depends on two main factors: the rate of change of the magnetic field and the number of turns in the secondary winding.

This is where the concept of turns ratio becomes crucial. If the secondary winding has more turns than the primary, the induced voltage will be higher than the input voltage, creating a step-up transformer. Conversely, if the secondary has fewer turns, we get a step-down transformer.

Lenz’s Law, which is a consequence of the conservation of energy, ensures that the induced current in the secondary winding creates a magnetic field that opposes the change in the original field. This opposition is what creates the "back EMF" in the primary winding, which limits the current draw when the secondary circuit is open.

I remember being fascinated by this concept during my studies. The idea that we could transfer energy and change voltage levels without any moving parts seemed almost magical. It’s this elegant application of a fundamental physical principle that makes transformers so efficient and reliable.

Understanding electromagnetic induction not only helps us grasp how transformers work, but it also provides insight into many other electrical devices and phenomena. From electric motors to wireless charging, this principle is at work all around us, quietly enabling much of our modern technology.

Types of Power Transformers: Step-Up, Step-Down, and Isolation Transformers?

Are you confused about the different types of power transformers? You’re not alone. Many people struggle to understand the distinctions, but knowing these types is crucial for anyone working with electrical systems.

Power transformers come in three main types: step-up, step-down, and isolation transformers. Step-up transformers increase voltage, step-down transformers decrease it, and isolation transformers transfer power between circuits without changing voltage.

Let’s explore each type of power transformer in more detail. Understanding these distinctions is key to grasping how our power systems work and how electricity is managed from generation to consumption.

Step-Up Transformers

-

Function

- Increase voltage for long-distance transmission

- Reduce current to minimize power losses

-

Applications

- Power plants

- Substations at beginning of transmission lines

Step-Down Transformers

-

Function

- Decrease voltage for distribution and end-use

- Increase current for power delivery

-

Applications

- Substations near populated areas

- Pole-mounted transformers in neighborhoods

Isolation Transformers

-

Function

- Transfer power between circuits without direct connection

- Provide safety and noise reduction

-

Applications

- Medical equipment

- Audio systems

| Type | Voltage Change | Primary Use | Common Locations |

|---|---|---|---|

| Step-Up | Increases | Power transmission | Power plants, substations |

| Step-Down | Decreases | Power distribution | Substations, neighborhoods |

| Isolation | No change | Safety, noise reduction | Hospitals, recording studios |

Each type of power transformer plays a crucial role in our electrical systems. Step-up transformers are essential for efficient power transmission over long distances. By increasing the voltage, they allow power companies to reduce the current in transmission lines. This is important because power loss in a conductor is proportional to the square of the current. So, by stepping up the voltage and reducing the current, we can significantly reduce transmission losses.

I remember visiting a power plant early in my career and being amazed by the size of the step-up transformers. These massive devices were taking the 20,000 volts produced by the generators and stepping it up to 400,000 volts for long-distance transmission. It was a vivid illustration of the importance of these devices in our power grid.

Step-down transformers, on the other hand, are what bring that high-voltage power down to levels we can use in our homes and businesses. You’ve probably seen these as large cylinders on poles in your neighborhood or as pad-mounted boxes in newer developments. These transformers take the several thousand volts in distribution lines and step it down to the 120/240 volts we use in our homes.

Isolation transformers are a bit different. While they don’t change voltage levels, they serve a crucial safety function by providing galvanic isolation between circuits. This means there’s no direct electrical connection between the primary and secondary sides of the transformer. This is particularly important in medical settings, where it can protect patients from electrical faults.

I once worked on a project installing isolation transformers in a hospital’s operating rooms. The extra layer of safety they provided was crucial in an environment where even a small electrical fault could have serious consequences.

Understanding these different types of transformers and their applications is essential for anyone working in electrical engineering or related fields. Each type serves a specific purpose, and together they form the backbone of our electrical distribution system, ensuring that power is transmitted efficiently and used safely.

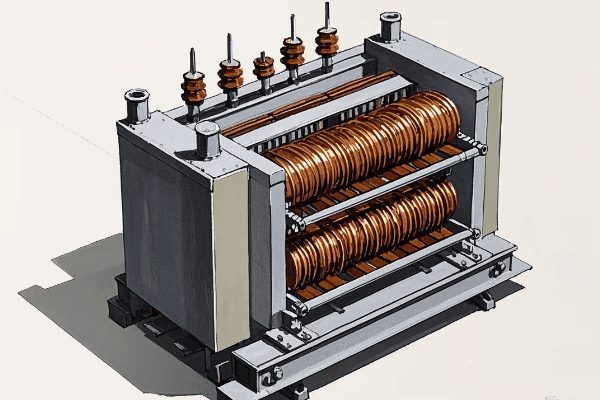

Power Transformer Construction: Core, Windings, and Insulation?

Have you ever wondered what’s inside a power transformer? The construction of these devices is a marvel of engineering, combining simple principles with precise design. Let’s unpack the mystery.

Power transformers are built with three main components: the core, windings, and insulation. The core provides a path for magnetic flux, the windings transfer energy, and the insulation prevents short circuits and manages heat.

Let’s dive deeper into the construction of power transformers. Understanding how these components work together is key to grasping the efficiency and reliability of these crucial devices.

Core Construction

-

Material

- Silicon steel laminations

- Grain-oriented for better magnetic properties

-

Types

- Core-type: Windings surround the core

- Shell-type: Core surrounds the windings

-

Assembly

- Stacked in layers to reduce eddy currents

- Clamped tightly to minimize vibration

Winding Construction

-

Materials

- Copper: Higher conductivity, more expensive

- Aluminum: Lighter, less expensive

-

Types

- Disc windings: For high-voltage applications

- Helical windings: For low-voltage, high-current applications

-

Arrangement

- Concentric: One winding inside the other

- Sandwich: Alternating primary and secondary discs

Insulation System

-

Solid Insulation

- Paper wrapping on conductors

- Pressboard barriers between windings

-

Liquid Insulation

- Mineral oil: Most common

- Synthetic esters: More environmentally friendly

-

Gas Insulation

- SF6 (Sulfur Hexafluoride): For special applications

| Component | Function | Common Materials |

|---|---|---|

| Core | Magnetic flux path | Silicon steel laminations |

| Windings | Energy transfer | Copper or aluminum wire |

| Insulation | Prevent short circuits, manage heat | Paper, oil, pressboard |

The construction of a power transformer is a fascinating blend of electrical and mechanical engineering. Each component plays a crucial role in the transformer’s operation and efficiency.

The core is the magnetic heart of the transformer. It’s typically made from thin laminations of silicon steel, each insulated from the others to reduce eddy currents. The grain orientation of the steel is crucial – it’s aligned to provide the easiest path for magnetic flux. This attention to detail in the core construction is what allows transformers to operate with such high efficiency.

I remember visiting a transformer manufacturing plant and being amazed at the precision involved in assembling the core. Each lamination was carefully stacked and clamped to ensure minimal gaps and vibration. It’s this level of care that ensures transformers can operate reliably for decades.

The windings are where the actual voltage transformation occurs. The choice between copper and aluminum is often a balance between performance and cost. Copper has better conductivity, but aluminum is lighter and less expensive. The type of winding – disc, helical, or layer – depends on the voltage and current requirements of the transformer.

The arrangement of the windings is also crucial. In a core-type transformer, the windings are wrapped around the legs of the core. In a shell-type, the core envelops the windings. Each design has its advantages, and the choice often depends on the specific application and size of the transformer.

Insulation is the unsung hero of transformer construction. It not only prevents short circuits between windings and between windings and the core, but it also plays a crucial role in heat management. The paper insulation wrapped around the conductors is impregnated with oil, which serves both as an insulator and a coolant.

I once worked on a project to retrofit an old transformer with a new insulation system. The improvement in performance and lifespan was remarkable, highlighting just how important proper insulation is to a transformer’s operation.

The liquid insulation, typically mineral oil, serves multiple purposes. It insulates, it cools, and it even provides valuable diagnostic information. By analyzing the oil, engineers can detect potential problems before they become serious.

Understanding the construction of power transformers is crucial for anyone working in the field of electrical engineering. It’s not just about the electrical principles – the mechanical design, the materials used, and the assembly techniques all play a part in creating these remarkably efficient and reliable devices that form the backbone of our electrical grid.

Applications and Importance of Power Transformers in Electrical Systems?

Have you ever stopped to think about how electricity gets from power plants to your home? Power transformers are the unsung heroes of this journey. They’re everywhere in our electrical systems, but their importance is often overlooked.

Power transformers are crucial in electrical systems for voltage conversion, power distribution, and electrical isolation. They enable efficient long-distance power transmission, safe voltage levels for end-users, and protect equipment from power surges and faults.

Let’s explore the wide-ranging applications and critical importance of power transformers in our electrical systems. Understanding this will give you a new appreciation for these devices that silently keep our world powered.

Power Generation and Transmission

-

Step-Up Transformers at Power Plants

- Increase voltage for long-distance transmission

- Reduce current and power losses

-

Substation Transformers

- Step down voltage for distribution networks

- Enable power routing and system protection

Industrial Applications

-

Arc Furnace Transformers

- Provide high current at low voltage for steel production

- Handle extreme load fluctuations

-

Rectifier Transformers

- Supply power to DC systems in industries

- Used in electrolysis processes, like aluminum production

Commercial and Residential Use

-

Distribution Transformers

- Step down voltage to usable levels for buildings

- Provide isolation between utility and customer systems

-

Isolation Transformers

- Protect sensitive equipment from power disturbances

- Used in hospitals, data centers, and audio equipment

| Application | Transformer Type | Key Function |

|---|---|---|

| Power Plants | Step-Up | Increase voltage for transmission |

| Substations | Step-Down | Reduce voltage for distribution |

| Steel Mills | Arc Furnace | Provide high current at low voltage |

| Neighborhoods | Distribution | Supply usable voltage to homes |

| Hospitals | Isolation | Protect sensitive medical equipment |

The applications of power transformers are vast and varied, touching almost every aspect of our electrified world. Their importance cannot be overstated – without transformers, our modern electrical systems simply wouldn’t be possible.

In power generation and transmission, transformers play a crucial role. At power plants, step-up transformers increase the voltage to levels suitable for long-distance transmission, often to hundreds of thousands of volts. This high voltage is what makes it economically feasible to transmit power over long distances. Without these transformers, we’d need impossibly thick cables to carry the current, or we’d lose most of the power to heat in the transmission lines.

I once visited a major substation where transmission voltages of 500kV were being stepped down to 132kV for regional distribution. The size and complexity of these transformers were awe-inspiring. It really drove home how crucial these devices are in managing our power grid.

In industrial applications, transformers take on specialized roles. Arc furnace transformers, for example, are designed to handle the extreme load fluctuations in steel production. These transformers need to supply enormous currents at relatively low voltages, and they must do so while withstanding the harsh electrical environment of an arc furnace.

Rectifier transformers are another specialized type, used in industries that require large amounts of DC power. I’ve seen these in action in aluminum smelters, where they supply the power for the electrolysis process. The ability of these transformers to handle high currents and non-linear loads is crucial for these industrial processes.

In commercial and residential settings, distribution transformers are the workhorses that bring power to our homes and businesses. These are the transformers you might see mounted on poles or in green boxes in your neighborhood. They take the medium voltage from distribution lines (typically 4-34kV) and step it down to the 120/240V we use in our homes.

Isolation transformers hold a special place in my heart. Early in my career, I worked on a project installing these in a hospital’s operating rooms. These transformers provide a crucial safety function by isolating sensitive medical equipment from the main power supply. This not only protects the equipment from power disturbances but, more importantly, protects patients from potential electrical faults.

The importance of power transformers extends beyond just moving electricity around. They play a crucial role in system protection and power quality management. By providing points of isolation in the grid, transformers allow for the implementation of various protection schemes that keep our power system stable and reliable.

Moreover, transformers are key to integrating renewable energy sources into our grid. Wind farms and solar plants often use specialized transformers to match their output to grid requirements. As we move towards a more sustainable energy future, the role of transformers in managing these diverse and distributed energy sources will only grow in importance.

In data centers, transformers are critical for maintaining the uninterrupted power supply that keeps our digital world running. They not only provide the necessary voltage levels but also help in managing power quality and protecting sensitive equipment from disturbances.

Even in our homes, small transformers are everywhere – in our phone chargers, laptops, and various electronic devices. These might not be as impressive as their larger cousins, but they perform the same fundamental function of voltage conversion and electrical isolation.

The ubiquity and importance of power transformers in our electrical systems cannot be overstated. From enabling the long-distance transmission of power to ensuring the safe and efficient use of electricity in our homes and industries, transformers are truly the unsung heroes of our electrified world.

Conclusion

Power transformers are the backbone of our electrical systems. They enable efficient power transmission, safe distribution, and countless applications across industries. Understanding their operation is key to appreciating our modern electrified world.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group