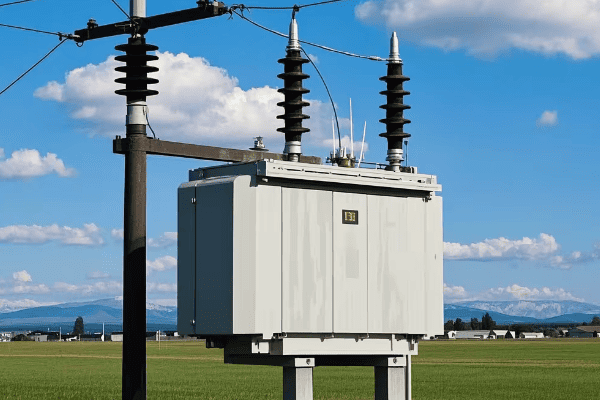

How to Select the Perfect High-Voltage Lightning Arrester: A Guide for Transformer Protection

Have you ever wondered what would happen if lightning struck your power transformer? The consequences could be devastating without proper protection.

Selecting the perfect high-voltage lightning arrester for transformer protection involves considering five key factors: voltage rating, arrester type, energy rating, operating voltage, and environmental conditions. By carefully evaluating these aspects, you can ensure optimal protection for your transformer against lightning strikes and power surges.

As someone who’s spent years in the power industry, I’ve seen firsthand the importance of choosing the right lightning arrester. Let’s dive into the key factors you need to consider to keep your transformers safe and your power flowing.

What Voltage Rating Do You Need for Your Lightning Arrester?

Imagine buying a fire extinguisher that can’t handle the heat of your kitchen fire. That’s what happens when you choose a lightning arrester with the wrong voltage rating.

The voltage rating of your lightning arrester should be at least 1.2 times the maximum operating voltage of your transformer. This ensures adequate protection against voltage surges. For example, if your transformer operates at 100 kV, your lightning arrester should have a voltage rating of at least 120 kV.

Let’s break down the process of determining the right voltage rating:

Factors to Consider When Choosing Voltage Rating

-

Transformer’s Maximum Operating Voltage

- This is your starting point. Always check the transformer’s specifications.

- Remember, it’s the maximum voltage, not the nominal voltage.

-

System’s Highest Voltage Level

- Consider any potential voltage fluctuations in your power system.

- It’s better to err on the side of caution here.

-

Temporary Overvoltage Conditions

- Account for any known overvoltage scenarios in your system.

- This could be due to load rejection or other system anomalies.

-

Safety Margin

- The 1.2 multiplier we mentioned earlier? That’s your safety margin.

- It accounts for unexpected voltage spikes and system variations.

Here’s a simple table to help you visualize the process:

| Transformer Operating Voltage (kV) | Minimum Arrester Voltage Rating (kV) |

|---|---|

| 69 | 83 |

| 138 | 166 |

| 230 | 276 |

| 345 | 414 |

| 500 | 600 |

I remember a case where a client insisted on using a lower-rated arrester to save costs. Despite my warnings, they went ahead. Six months later, a lightning strike caused significant damage to their transformer. The repair costs far exceeded what they would have spent on a properly rated arrester. It was a costly lesson in the importance of correct voltage rating.

When selecting your arrester’s voltage rating, always consult with the manufacturer and consider any unique aspects of your power system. It’s better to have a slightly over-rated arrester than one that can’t handle the job when you need it most.

Metal Oxide vs. Gap Type: Which Arrester is Right for Your Transformer?

Choosing between metal oxide and gap type arresters is like deciding between a smartphone and a flip phone. Both make calls, but one offers significantly more advanced protection.

Metal oxide arresters are generally superior to gap type arresters for transformer protection. They offer faster response times, better energy handling capabilities, and more consistent performance. However, gap type arresters may still be suitable in certain low-risk or budget-constrained situations.

Let’s dive deeper into the characteristics of each type:

Understanding Metal Oxide Arresters

-

Fast Response Time

- Metal oxide arresters react in nanoseconds to voltage surges.

- This rapid response is crucial for protecting sensitive equipment.

-

Excellent Energy Handling

- They can absorb large amounts of energy without damage.

- This makes them ideal for areas with frequent lightning strikes.

-

No Follow Current

- Metal oxide arresters don’t produce a follow current after operation.

- This reduces stress on the power system and improves reliability.

-

Compact Design

- These arresters are smaller and lighter than gap types.

- This makes installation and maintenance easier.

Gap Type Arresters: The Old Guard

-

Simple Construction

- Gap type arresters have a straightforward design.

- This can make them more affordable in some cases.

-

Visible Operation

- You can often see when a gap type arrester has operated.

- This can be helpful for maintenance and troubleshooting.

-

Limited Performance

- They have slower response times compared to metal oxide arresters.

- Energy handling capabilities are generally lower.

-

Follow Current Issues

- Gap type arresters can produce a follow current after operation.

- This can stress the power system and potentially cause issues.

Here’s a comparison table to help you decide:

| Feature | Metal Oxide Arrester | Gap Type Arrester |

|---|---|---|

| Response Time | Nanoseconds | Microseconds |

| Energy Handling | High | Moderate |

| Follow Current | None | Yes |

| Size | Compact | Bulky |

| Cost | Higher | Lower |

| Lifespan | Longer | Shorter |

I once worked on a project upgrading a substation’s protection system. The client was using old gap type arresters and experiencing frequent issues with follow currents and occasional equipment damage. We replaced them with metal oxide arresters, and the improvement was immediate. Not only did we see a reduction in equipment stress, but the overall reliability of the substation increased significantly.

When choosing between metal oxide and gap type arresters, consider these factors:

- The criticality of the equipment you’re protecting

- The lightning activity in your area

- Your budget constraints

- The expected lifespan of your installation

In most cases, I recommend metal oxide arresters for their superior performance and reliability. However, if you’re dealing with a low-risk installation or severe budget constraints, gap type arresters might still be a viable option. Always consult with a protection expert to make the best choice for your specific situation.

How to Determine the Ideal Energy Rating for Your Lightning Arrester?

Choosing the right energy rating for your lightning arrester is like picking the right size fire extinguisher. Too small, and it won’t handle the job. Too big, and you’re wasting money.

The ideal energy rating for your lightning arrester depends on factors like the lightning activity in your area, the importance of the protected equipment, and the system voltage. A higher energy rating means better protection but also higher cost. For most transformer applications, an energy rating between 5-20 kJ/kV is typical.

Let’s break down how to determine the right energy rating:

Factors Influencing Energy Rating Selection

-

Lightning Activity Level

- Areas with frequent and severe lightning require higher energy ratings.

- Consider both the frequency and intensity of lightning strikes.

-

System Voltage

- Higher voltage systems generally require arresters with higher energy ratings.

- This is due to the increased energy in potential surges.

-

Equipment Criticality

- More critical equipment justifies higher energy ratings for better protection.

- Consider the cost and importance of the protected transformer.

-

System Grounding

- Effectively grounded systems may allow for lower energy ratings.

- Poorly grounded systems require higher ratings to compensate.

-

Arrester Location

- Arresters at line entrances may need higher ratings than those deeper in the system.

- This is due to the higher exposure to direct lightning strikes.

Here’s a table to guide your energy rating selection:

| System Voltage (kV) | Minimum Energy Rating (kJ/kV) | Recommended Energy Rating (kJ/kV) |

|---|---|---|

| Up to 69 | 3 | 5-10 |

| 69-230 | 5 | 10-15 |

| Above 230 | 8 | 15-20 |

I recall a project where we were protecting a critical transformer for a data center. Despite the higher cost, we opted for an arrester with a 20 kJ/kV energy rating due to the area’s high lightning activity and the critical nature of the load. During a particularly severe thunderstorm season, this decision paid off. The arrester successfully protected the transformer from multiple severe strikes, preventing what could have been catastrophic downtime for the data center.

When selecting your arrester’s energy rating, consider these tips:

- Always err on the side of caution for critical equipment.

- Consider future system expansions or voltage upgrades.

- Consult local weather data for lightning activity information.

- Don’t forget to factor in switching surges, not just lightning.

Remember, while a higher energy rating provides better protection, it also comes with a higher price tag. Balance the need for protection with your budget constraints, but never compromise on safety for critical equipment.

What Operating Voltage Range Should You Consider for Optimal Protection?

Selecting the right operating voltage range for your lightning arrester is like tuning a radio. Too low, and you’ll get unwanted noise. Too high, and you’ll miss the important signals.

The operating voltage range of a lightning arrester should be carefully matched to your system’s normal operating voltage and potential temporary overvoltages. Typically, the arrester’s maximum continuous operating voltage (MCOV) should be about 5-10% higher than the system’s maximum continuous operating voltage.

Let’s explore how to determine the optimal operating voltage range:

Key Considerations for Operating Voltage Range

-

System’s Normal Operating Voltage

- This is your baseline. Start by knowing your system’s typical voltage.

- Remember, this can fluctuate within a certain range.

-

Temporary Overvoltage Conditions

- Account for known overvoltage scenarios in your system.

- These could be due to load rejection, switching operations, or other factors.

-

Arrester’s Protective Level

- The arrester must operate below the insulation withstand level of the protected equipment.

- This ensures the arrester acts before equipment damage occurs.

-

Margin of Safety

- Allow for a safety margin above normal system voltage.

- This prevents nuisance operations during minor voltage fluctuations.

Here’s a table to guide your operating voltage range selection:

| System Voltage (kV) | Recommended MCOV Range (kV) | Typical Protective Level (kV) |

|---|---|---|

| 69 | 70-76 | 220-240 |

| 138 | 140-152 | 350-380 |

| 230 | 233-253 | 540-580 |

| 345 | 349-379 | 750-810 |

| 500 | 506-549 | 1050-1150 |

I once worked on a project where we were experiencing frequent arrester operations in a 138 kV system. After investigation, we found that the arrester’s MCOV was set too close to the system’s normal operating voltage. By selecting an arrester with a slightly higher MCOV, we eliminated the nuisance operations while still maintaining adequate protection.

When selecting your arrester’s operating voltage range, keep these points in mind:

- Always consult your system’s voltage profile, including any known overvoltage scenarios.

- Consider future system upgrades that might increase operating voltages.

- Balance protection level with the need to avoid nuisance operations.

- Remember that higher MCOV ratings often come with higher protective levels, so there’s a trade-off to consider.

The right operating voltage range ensures your arrester provides reliable protection without unnecessary operations. It’s a critical factor in maximizing the effectiveness and lifespan of your lightning protection system.

How Do Environmental Factors Influence Your Lightning Arrester Choice?

Choosing a lightning arrester without considering environmental factors is like buying a car without thinking about the roads you’ll drive on. The environment can make or break your protection strategy.

Environmental factors such as pollution, humidity, temperature extremes, and altitude can significantly impact the performance and lifespan of lightning arresters. These factors influence the choice of housing material, creepage distance, and even the internal components of the arrester.

Let’s explore how different environmental factors affect your arrester choice:

Key Environmental Considerations

-

Pollution Level

- High pollution areas require arresters with higher creepage distances.

- Special coatings or designs may be necessary to prevent flashover.

-

Humidity and Rainfall

- High humidity can lead to corrosion and degradation of arrester components.

- Proper sealing and moisture-resistant materials are crucial in wet environments.

-

Temperature Extremes

- Both very high and very low temperatures can affect arrester performance.

- Choose arresters rated for your specific temperature range.

-

Altitude

- Higher altitudes require derating of arrester voltage ratings.

- This is due to the reduced air density at high elevations.

-

UV Radiation

- Strong sunlight can degrade certain housing materials over time.

- UV-resistant housings are important in areas with high sun exposure.

Here’s a table summarizing environmental factors and their impacts:

| Environmental Factor | Impact on Arrester | Mitigation Strategy |

|---|---|---|

| High Pollution | Increased risk of flashover | Higher creepage distance, special coatings |

| High Humidity | Corrosion, internal degradation | Enhanced sealing, moisture-resistant materials |

| Extreme Temperatures | Altered performance, material stress | Temperature-rated designs, special materials |

| High Altitude | Reduced voltage withstand | Voltage derating, special designs |

| Strong UV Radiation | Housing degradation | UV-resistant materials |

I remember a project in a coastal industrial area where standard arresters were failing prematurely. The combination of salt spray, industrial pollution, and high humidity was wreaking havoc on the arrester housings. We switched to arresters with silicon rubber housings and increased creepage distances. The result was a dramatic improvement in reliability and lifespan.

When considering environmental factors, keep these tips in mind:

- Always conduct a thorough site survey before selecting arresters.

- Consider seasonal variations in environmental conditions.

- Don’t forget about micro-environments (e.g., near cooling towers or in valleys).

- Consult with arrester manufacturers about their recommendations for specific environments.

Remember, the most advanced arrester technology is useless if it can’t withstand the environment it’s placed in. Proper environmental consideration ensures your lightning protection system remains effective year after year, regardless of the conditions it faces.

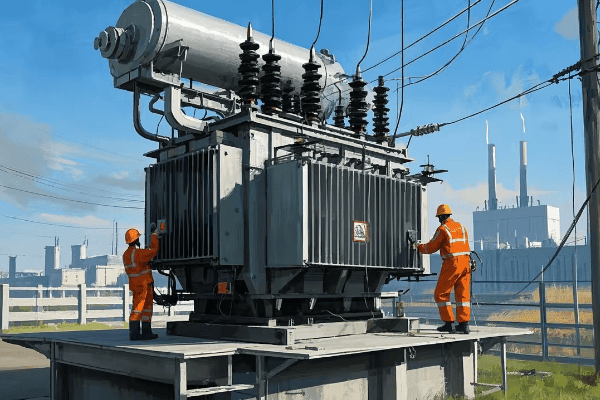

Installation and Maintenance: Best Practices for Lightning Arrester Effectiveness

Installing a lightning arrester isn’t a "set it and forget it" task. Proper installation and regular maintenance are like servicing your car – essential for long-term performance and reliability.

Correct installation and consistent maintenance are crucial for the effectiveness of lightning arresters. This includes proper grounding, secure mounting, regular inspections, and timely replacements. Good practices can significantly extend the life of your arresters and ensure they perform when you need them most.

Let’s dive into the best practices for installation and maintenance:

Installation Best Practices

-

Proper Grounding

- Ensure a low-impedance path to ground.

- Use short, straight leads with minimal bends.

-

Secure Mounting

- Mount arresters vertically unless otherwise specified.

- Ensure they’re securely fastened to withstand environmental forces.

-

Lead Length

- Keep lead lengths as short as possible.

- Long leads can reduce the effectiveness of the arrester.

-

Clearances

- Maintain proper clearances from other equipment.

- This prevents flashover and ensures safe operation.

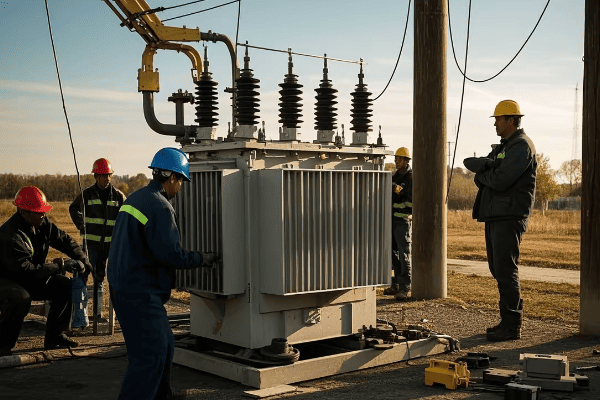

Maintenance Best Practices

-

Regular Visual Inspections

- Check for physical damage, corrosion, or signs of previous operations.

- Inspect at least annually, more frequently in harsh environments.

-

Electrical Testing

- Conduct periodic tests to ensure proper operation.

- This may include insulation resistance and leakage current tests.

-

Thermal Imaging

- Use thermal cameras to detect hot spots or abnormal heating.

- This can identify potential issues before they become critical.

-

Record Keeping

- Maintain detailed records of inspections and tests. – This helps track performance over time and predict potential issues.

-

Timely Replacement

- Replace arresters that show signs of degradation or have reached their end of life.

- Don’t wait for failure – proactive replacement is key.

Here’s a maintenance schedule table to help you stay on track:

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Visual Inspection | Every 6 months | High |

| Electrical Testing | Annually | Critical |

| Thermal Imaging | Annually | Medium |

| Record Update | After each inspection/test | High |

| Full System Review | Every 3-5 years | Critical |

I recall a situation where a client was experiencing frequent arrester failures. Upon investigation, we found that their installation practices were subpar – long ground leads and improper mounting were compromising the arresters’ effectiveness. After correcting these issues and implementing a rigorous maintenance schedule, their failure rate dropped dramatically.

When it comes to installation and maintenance, keep these tips in mind:

- Always follow manufacturer guidelines for installation and maintenance.

- Train your staff on proper inspection techniques.

- Invest in quality testing equipment for accurate assessments.

- Don’t neglect seemingly minor issues – they can lead to major problems.

- Consider the environment when planning maintenance schedules.

Remember, even the best lightning arrester is only as good as its installation and maintenance. A well-maintained system not only protects your equipment but also provides peace of mind during those stormy nights.

Conclusion

Selecting the perfect high-voltage lightning arrester for your transformer is a critical task that requires careful consideration of voltage ratings, arrester types, energy ratings, operating voltage ranges, and environmental factors. Proper installation and maintenance are equally important for long-term effectiveness. By following these guidelines, you can ensure optimal protection for your valuable transformer assets.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group