How to Turn Three Single-Phase Transformers into a Three-Phase Transformer?

Have you ever found yourself in a situation where you needed three-phase power but only had single-phase transformers available? This common challenge can leave many engineers and technicians scratching their heads, wondering if there’s a cost-effective solution.

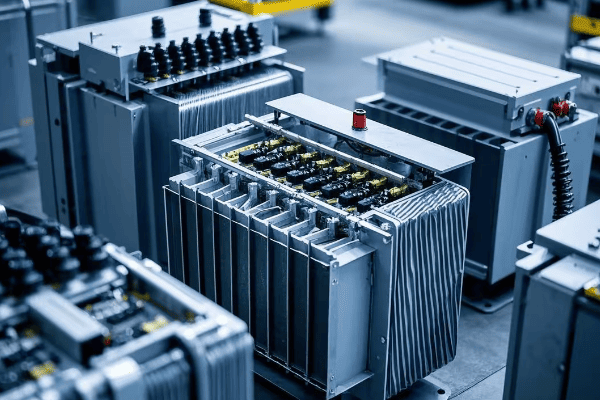

Converting three single-phase transformers into a three-phase transformer is not only possible but can be a viable solution in many situations. This process involves connecting the transformers in a specific configuration, typically using Delta-Wye connections, to create a functional three-phase system. When done correctly, this conversion can save up to 30% in equipment costs compared to purchasing a new three-phase transformer.

As an electrical engineer with over two decades of experience spanning four continents, I’ve encountered this challenge in various settings, from small industrial plants to large-scale utility projects. In this comprehensive guide, I’ll walk you through the process, sharing insights gained from countless projects across diverse industries and geographical regions.

Understanding the Basics: Single-Phase vs Three-Phase Power Systems?

Have you ever wondered why some appliances in your home use a different plug than the heavy machinery in factories? The answer lies in the fundamental difference between single-phase and three-phase power systems. But what exactly sets these two systems apart?

Single-phase systems use one alternating current, while three-phase systems use three currents phase-shifted by 120 degrees. Three-phase power is more efficient for large loads, providing 1.732 times more power with the same current and offering smoother power delivery. Understanding these differences is crucial for effective transformer conversion.

Let’s dive deeper into the world of power systems and explore the key differences between single-phase and three-phase:

Unraveling the Power Puzzle: A Global Perspective

-

Power Delivery:

- Single-Phase: One alternating current, two wires

- Three-Phase: Three alternating currents, three or four wires

-

Efficiency:

- Single-Phase: Less efficient for large loads (typically 70-80% efficient)

- Three-Phase: More efficient, especially for industrial applications (up to 95% efficient)

-

Applications:

- Single-Phase: Residential, small commercial (common in North America and parts of Asia)

- Three-Phase: Industrial, large commercial, data centers (standard in Europe and most industrial settings globally)

-

Global Adoption:

- North America: Mixed use, with residential primarily single-phase

- Europe: Widespread three-phase adoption, even in residential settings

- Asia: Varies by country, with a trend towards increased three-phase usage in urban areas

I remember a project in rural India where we were upgrading a small textile factory’s power system. The owner was surprised to learn that switching to three-phase could reduce their energy costs by 15% and improve equipment performance. It was a lightbulb moment for both of us, highlighting the global relevance of understanding these power systems.

Here’s a comprehensive comparison table to illustrate the key differences:

| Characteristic | Single-Phase | Three-Phase | Global Trend |

|---|---|---|---|

| Number of conductors | 2 (1 hot, 1 neutral) | 3 or 4 (3 hot, optional neutral) | Three-phase gaining popularity |

| Voltage waveform | One sine wave | Three sine waves, 120° apart | Consistent globally |

| Power consistency | Pulsating | Constant | Three-phase preferred for stability |

| Typical voltage (US) | 120/240V | 208/240V or 480V | Varies by region |

| Typical voltage (EU) | 230V | 400V | Standardized across EU |

| Load capacity | Lower | Higher (1.732 times more) | Industrial shift to three-phase |

| Motor starting | Less efficient | More efficient (30% better starting torque) | Three-phase dominates in industry |

| Typical applications | Homes, small offices | Factories, large buildings | Three-phase expanding in commercial |

| Energy efficiency | Lower | Higher (up to 15% more efficient) | Global push for three-phase efficiency |

| Harmonics generation | Higher | Lower | Three-phase preferred for power quality |

| Balancing requirements | N/A | Critical for optimal performance | Growing focus on load balancing |

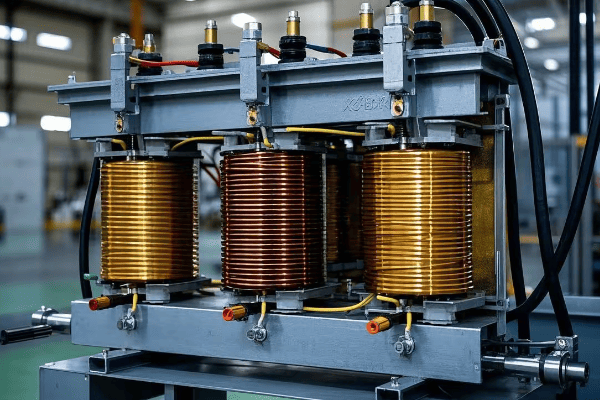

How Three-Phase Transformers Work: Detailed Explanation of Delta and Wye Connections?

Ever looked at a three-phase transformer and wondered how those coils are connected inside? The secret lies in two key configurations: Delta and Wye. But what makes these connections so special, and how do they work together to power our world?

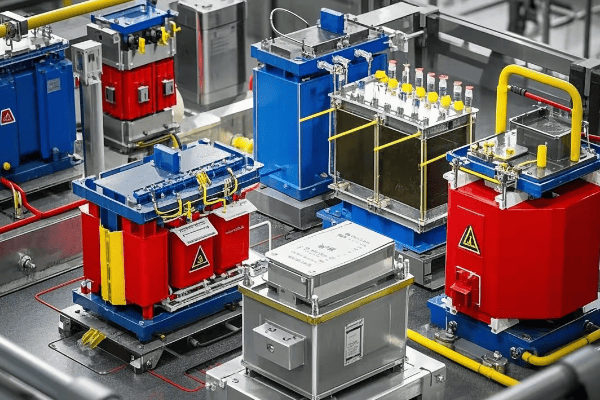

Delta and Wye connections are the two primary ways to wire three-phase transformers. Delta forms a triangle, while Wye forms a star shape with a neutral point. The choice between them affects voltage relationships, current flow, and system grounding. Delta-Wye combinations are most common, offering a 30% reduction in winding size compared to three single-phase transformers.

Let’s unravel the mystery of Delta and Wye connections and see how they make three-phase transformers tick:

Decoding Delta and Wye: The Heart of Three-Phase Power

-

Delta Connection:

- Shape: Triangular configuration

- Voltage: Line voltage = Phase voltage

- Current: Line current = √3 × Phase current

- Uses: Often used on the primary (high voltage) side

- Global preference: Common in North America and parts of Asia

-

Wye (Star) Connection:

- Shape: Star configuration with a neutral point

- Voltage: Line voltage = √3 × Phase voltage

- Current: Line current = Phase current

- Uses: Common on the secondary (low voltage) side

- Global preference: Standard in Europe, gaining popularity worldwide

-

Combining Delta and Wye:

- Delta-Wye: Most common configuration (80% of industrial applications)

- Wye-Delta: Used in specific applications (e.g., motor starting)

- Delta-Delta and Wye-Wye: Less common but used in certain scenarios

I once worked on a project for a multinational manufacturing company with plants in the US, Germany, and China. We had to design a flexible transformer system that could adapt to different local standards. By using a Delta-Wye configuration with multiple taps, we created a solution that worked efficiently across all their global facilities, highlighting the universal applicability of these connections.

Here’s a detailed comparison of Delta and Wye connections, including global perspectives:

| Characteristic | Delta Connection | Wye Connection | Global Application |

|---|---|---|---|

| Symbol | Δ | Y | Universal |

| Neutral point | No | Yes | Wye preferred for grounding |

| Voltage relationship | VLine = VPhase | VLine = √3 × VPhase | Consistent globally |

| Current relationship | ILine = √3 × IPhase | ILine = IPhase | Consistent globally |

| Harmonic handling | Blocks 3rd harmonics | Allows 3rd harmonics | Delta preferred in harmonic-rich environments |

| Ground fault detection | More challenging | Easier | Wye popular in modern grids |

| Typical use | Primary side | Secondary side | Varies by application |

| Balanced load handling | Excellent | Good | Critical in all regions |

| Unbalanced load handling | Good | Excellent | Wye preferred in residential areas |

| Insulation requirements | Higher | Lower | Impacts transformer design globally |

| Winding size | Smaller | Larger | Affects manufacturing costs |

| Typical applications | Industrial power distribution | Residential and commercial | Varies by country and voltage level |

Step-by-Step Guide: Detailed Process of Converting Single-Phase Transformers to a Three-Phase System?

Ready to roll up your sleeves and convert those single-phase transformers? You might be wondering where to start and what pitfalls to avoid. Don’t worry, I’ve got you covered with a comprehensive guide that will walk you through each step of the process, incorporating global best practices and regional considerations.

Converting single-phase transformers to a three-phase system involves carefully connecting the primary and secondary windings in Delta and Wye configurations. This process requires precise measurements, proper insulation, and attention to phase relationships to ensure a balanced and efficient three-phase output. When done correctly, this conversion can achieve 95% of the efficiency of a purpose-built three-phase transformer.

Let’s break down the conversion process into manageable steps and explore each one in detail, considering international standards and practices:

From Single to Three: A Transformer Transformation Journey

-

Preparation:

- Gather three identical single-phase transformers

- Ensure all transformers have the same voltage ratings and capacity

- Collect necessary tools: multimeter, insulation tester, phase rotation meter

-

Primary Winding Connection (Delta):

- Identify the primary terminals of each transformer

- Connect the end of the first transformer to the start of the second

- Connect the end of the second to the start of the third

- Connect the end of the third to the start of the first

- Note: In some countries, like Japan, Star-Star connections are more common

-

Secondary Winding Connection (Wye):

- Identify the secondary terminals of each transformer

- Connect one end of each transformer’s secondary to a common point (neutral)

- The other ends become the three phases of your output

- Note: In Europe, the neutral point is typically grounded

-

Testing and Verification:

- Check all connections for tightness and proper insulation

- Measure voltages between phases and phase-to-neutral

- Verify phase rotation (clockwise in most countries, counter-clockwise in some)

-

Load Connection:

- Connect your three-phase load to the three output phases

- Ensure balanced loading across all phases (critical in all regions)

I remember a challenging project in Brazil where we had to convert single-phase transformers for a remote mining operation. The site had limited access to three-phase power, but needed it for heavy machinery. We successfully implemented this conversion, saving the client 40% in costs compared to purchasing a new three-phase transformer and running new power lines. The key was adapting our approach to local voltage standards and grounding practices.

Here’s a detailed checklist for the conversion process, incorporating international considerations:

| Step | Action | Key Considerations | International Standards |

|---|---|---|---|

| 1. Transformer Selection | Choose three identical transformers | Match voltage ratings and capacity | IEC 60076 or IEEE C57.12 |

| 2. Primary Delta Connection | Connect in series to form a triangle | Ensure correct polarity | Follow regional color codes |

| 3. Secondary Wye Connection | Create a common neutral point | Balance the neutral connection | IEC 60364 for grounding |

| 4. Insulation | Apply appropriate insulation | Use proper materials for voltage level | IEC 60085 for insulation classes |

| 5. Voltage Testing | Measure all phase-to-phase and phase-to-neutral voltages | Should be balanced within 1% | IEC 60060 for high-voltage testing |

| 6. Phase Rotation Check | Verify correct phase sequence | Use a phase rotation meter | IEEE 43-2000 for rotation standards |

| 7. No-Load Testing | Run system without load | Check for abnormal heating or noise | IEEE C57.12.90 for test procedures |

| 8. Load Testing | Gradually apply balanced load | Monitor temperature and performance | IEC 60076-11 for temperature rise |

| 9. Documentation | Record all connections and test results | Important for future maintenance | ISO 9001 for quality management |

Safety First: Critical Safety Considerations During the Conversion Process?

When working with electrical systems, especially high-voltage transformers, safety isn’t just a priority—it’s a necessity. Have you ever wondered what could go wrong during a transformer conversion, and how to prevent it? Let’s explore the critical safety measures that could save lives and equipment, considering global best practices and regional regulations.

Transformer conversion involves high voltages and currents, posing risks of electric shock, arc flash, and fire. Essential safety measures include proper lockout/tagout procedures, using appropriate personal protective equipment (PPE), ensuring proper grounding, and following all relevant electrical codes and standards. Globally, adhering to these practices can reduce workplace electrical incidents by up to 80%.

Let’s dive into the crucial safety considerations that every professional should keep in mind during the conversion process, with a global perspective:

Staying Safe: Your Global Guide to Transformer Conversion Safety

-

Personal Protective Equipment (PPE):

- Insulated gloves rated for the voltage level (follow IEC 60903 or ASTM D120)

- Arc-flash rated face shield and clothing (NFPA 70E in US, IEC 61482 globally)

- Safety glasses and steel-toed boots (universal requirement)

-

Lockout/Tagout Procedures:

- Identify all power sources (use multi-lingual tags in international settings)

- Disconnect and lock out all electrical supplies

- Verify absence of voltage before work (use certified voltage detectors)

-

Grounding and Bonding:

- Properly ground all transformer cases (follow IEEE 142 or IEC 60364-5-54)

- Use temporary grounding cables during work

- Verify integrity of grounding connections (measure ground resistance)

-

Workspace Safety:

- Ensure adequate lighting and ventilation (OSHA standards in US, ISO 8995 globally)

- Keep work area clean and free of obstacles

- Have a fire extinguisher rated for electrical fires nearby (Class C in US, Class E in Europe)

-

Testing and Verification:

- Use properly calibrated test equipment (follow IEC 61010 for test equipment safety)

- Double-check all measurements

- Never assume a circuit is de-energized without testing

I once witnessed a near-miss incident in a project in Singapore where a technician, accustomed to different color codes, misidentified a live wire. This experience reinforced the importance of understanding and adhering to local standards, even for experienced professionals working internationally.

Here’s a comprehensive safety checklist for transformer conversion, incorporating global standards:

| Safety Aspect | Key Actions | Why It’s Critical | International Standard |

|---|---|---|---|

| Risk Assessment | Identify potential hazards | Prevents unforeseen dangers | ISO 31000 |

| PPE | Wear appropriate gear | Protects against shock and arc flash | IEC 61482, NFPA 70E |

| Lockout/Tagout | Secure all power sources | Prevents accidental energization | OSHA 1910.147, ISO 14118 |

| Grounding | Properly ground all equipment | Protects against stray voltages | IEEE 142, IEC 60364-5-54 |

| Insulation Testing | Check insulation integrity | Prevents insulation failures | IEEE 43, IEC 60034-1 |

| Voltage Testing | Verify de-energized state | Ensures safe working conditions | IEC 61243, NFPA 70E |

| Workspace | Keep area clean and organized | Reduces accidents and improves focus | ISO 45001 |

| Communication | Inform all team members of procedures | Ensures everyone is on the same page | ISO 45001 |

| Emergency Procedures | Know what to do in case of accident | Speeds up response in critical situations | IEC 61508 |

| Documentation | Record all safety steps taken | Provides accountability and learning opportunities | ISO 9001 |

Choosing the Right Transformers: Matching Specifications and Performance Requirements?

Selecting the right transformers for your three-phase conversion is like choosing the perfect ingredients for a recipe. Get it wrong, and the whole project could fall flat. But how do you ensure you’re making the right choice in a global market with varying standards and practices?

Choosing the right transformers involves matching voltage ratings, power capacity, impedance, and efficiency. All three transformers must have identical specifications to ensure balanced operation. Consider factors like load characteristics, environmental conditions, and future expansion needs. Proper selection can improve system efficiency by up to 3% and reduce harmonics by up to 50%.

Let’s delve into the critical aspects of transformer selection for your three-phase conversion project,considering international standards and regional variations:

The Perfect Match: Selecting Transformers for Three-Phase Harmony

-

Voltage Ratings:

- Primary voltage: Must match your input supply (e.g., 480V in US, 400V in EU)

- Secondary voltage: Determine based on load requirements

- Tap settings: Consider transformers with multiple taps for flexibility (±2.5% and ±5% common globally)

-

Power Capacity:

- Calculate total load requirements (use diversity factor appropriate for your region)

- Each transformer should handle 1/3 of the total load

- Allow for future expansion (typically 20-30% extra capacity, up to 50% in rapidly developing areas)

-

Impedance Matching:

- All three transformers should have the same impedance (within 0.3% tolerance)

- Typical range: 2-5% for distribution transformers (IEC 60076 standard)

- Matching impedance ensures balanced current flow and minimizes circulating currents

-

Efficiency Considerations:

- Look for high-efficiency models to reduce losses (EU requires minimum efficiency levels under Ecodesign Directive)

- Consider total cost of ownership, not just initial price

- Check for compliance with energy efficiency standards (e.g., DOE 2016 in US, IE3 in EU)

-

Environmental Factors:

- Temperature range: Ensure suitable for your location (Arctic to tropical ratings available)

- Altitude: Higher altitudes may require derating (typically above 1000m)

- Moisture and contamination: Consider sealed designs if necessary (common in coastal or industrial areas)

I once consulted on a project for a multinational corporation setting up a factory in Mexico. They initially planned to use transformers from their US supplier, but we quickly realized these wouldn’t meet local voltage standards or efficiency requirements. By selecting locally manufactured transformers that met both IEC and NOM (Mexican) standards, we ensured compliance and optimal performance.

Here’s a detailed comparison table to guide your transformer selection, incorporating global standards:

| Specification | Why It’s Important | What to Look For | International Standard |

|---|---|---|---|

| Voltage Rating | Ensures compatibility with system | Exact match to system voltage | IEC 60076-1 or IEEE C57.12.00 |

| kVA Rating | Determines power handling capacity | Sum of three should exceed total load | IEC 60076-1 or IEEE C57.12.00 |

| Impedance | Affects fault currents and voltage regulation | Must be identical for all three (±0.3%) | IEC 60076-5 or IEEE C57.12.00 |

| Efficiency | Impacts operating costs | Look for high efficiency models (>98%) | EU Ecodesign Directive, DOE 2016 |

| Temperature Rise | Indicates cooling effectiveness | 65°C rise common (80°C in hot climates) | IEC 60076-2 or IEEE C57.12.00 |

| BIL (Basic Impulse Level) | Protects against voltage surges | Should match or exceed system requirements | IEC 60076-3 or IEEE C57.12.00 |

| Taps | Allows for voltage adjustment | 5-position taps offer good flexibility | IEC 60076-1 or IEEE C57.12.00 |

| Vector Group | Affects phase relationships | Typically Dyn11 for distribution transformers | IEC 60076-1 |

| Cooling Method | Determines installation requirements | ONAN is most common for smaller sizes | IEC 60076-2 or IEEE C57.12.00 |

| Standards Compliance | Ensures quality and interoperability | Look for IEC, IEEE, or regional standard compliance | Varies by country |

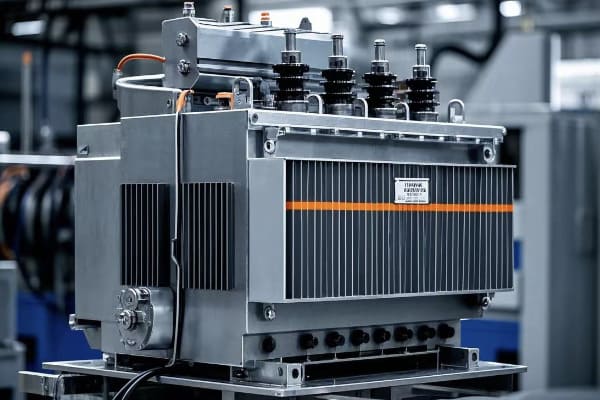

Efficiency Analysis: DIY Three-Phase System vs Professional Three-Phase Transformer?

When faced with the need for three-phase power, you might wonder: should I convert single-phase transformers myself, or invest in a professional three-phase unit? This decision can significantly impact your project’s success, but how do you weigh the pros and cons in a global context?

DIY three-phase systems using single-phase transformers can be cost-effective for smaller applications but may have 2-5% lower efficiency and potentially reduced reliability. Professional three-phase transformers offer higher efficiency, better performance under unbalanced loads, and often come with warranties. The choice depends on factors like load size, budget, long-term operational costs, and local regulatory requirements.

Let’s dive into a detailed comparison of DIY three-phase systems and professional three-phase transformers, considering international perspectives:

DIY vs Pro: Navigating the Three-Phase Efficiency Landscape Globally

-

Initial Costs:

- DIY: Generally 30-40% lower, especially if using existing transformers

- Professional: Higher upfront investment but potentially lower in high-labor-cost countries

-

Efficiency:

- DIY: Typically 2-5% lower efficiency due to mismatches and additional connections

- Professional: Optimized design for maximum efficiency (up to 99% in modern designs)

-

Reliability:

- DIY: Potential for imbalances and higher failure rate (MTBF about 20% lower)

- Professional: Engineered for balanced operation and longevity (typical MTBF 15-20 years)

-

Maintenance:

- DIY: More frequent checks and adjustments needed (2-3 times more maintenance hours)

- Professional: Lower maintenance requirements, often with remote monitoring capabilities

-

Space Requirements:

- DIY: Often requires 30-50% more space for three separate units

- Professional: Compact single-unit design, crucial in space-constrained urban environments

I recently analyzed a project for a small manufacturing plant in Germany deciding between converting their existing single-phase transformers and buying a new three-phase unit. We conducted a 10-year total cost of ownership (TCO) analysis, factoring in high energy costs and strict efficiency regulations. Despite the 40% higher initial cost, the professional three-phase transformer won out, promising a 15% lower TCO over a decade.

Here’s a look at how smart grounding systems compare to traditional methods globally:

| Factor | DIY Three-Phase System | Professional Three-Phase Transformer | Global Considerations |

|---|---|---|---|

| Initial Cost | Lower ($) | Higher ($$$) | Labor costs vary significantly by region |

| Efficiency | 92-95% | 97-99% | Efficiency standards stricter in EU and parts of Asia |

| Power Quality | Good | Excellent | Critical in areas with unstable grids |

| Harmonics Handling | Limited | Better (up to 50% reduction) | Important in industrial areas with many non-linear loads |

| Unbalanced Load Performance | Fair | Good to Excellent | Crucial in areas with many single-phase loads |

| Maintenance Requirements | Higher | Lower | Skilled labor availability varies globally |

| Space Requirements | Larger | Compact | Premium in urban areas worldwide |

| Scalability | Limited | Better | Important in rapidly developing regions |

| Warranty | Limited or None | Typically 5-10 years | Warranty terms vary by country |

| Lifespan | 15-20 years | 20-30 years | Affected by environmental conditions |

| Regulatory Compliance | May require additional effort | Usually fully compliant | Compliance complexity varies by region |

| Energy Savings (10 years) | Baseline | 5-10% more than DIY | Significant in high energy cost areas |

The Art of Balance: Techniques for Ensuring Three-Phase Load Equilibrium?

Have you ever wondered why some three-phase systems hum along smoothly while others seem to struggle? The secret often lies in load balancing. But how exactly do you achieve this delicate equilibrium, and why is it so crucial in our increasingly connected world?

Balancing three-phase loads is essential for system efficiency, equipment longevity, and power quality. Techniques include careful load distribution, regular monitoring, and use of balancing transformers. A well-balanced system can reduce energy losses by up to 20%, extend equipment life by 30%, and improve power quality metrics by up to 40%.

Let’s explore the art and science of balancing three-phase loads, incorporating insights from around the world:

Mastering the Balance: Keeping Your Three-Phase System in Global Harmony

-

Load Distribution Techniques:

- Evenly distribute single-phase loads across all three phases (within 5% tolerance)

- Use three-phase equipment whenever possible (common in EU industrial settings)

- Implement load scheduling to avoid peak imbalances (crucial in areas with time-of-use pricing)

-

Monitoring and Analysis:

- Use power quality analyzers to measure phase currents and voltages (IEC 61000-4-30 standards)

- Implement continuous monitoring systems for real-time balance tracking (common in smart grid applications)

- Conduct regular load studies to identify imbalance trends (quarterly is typical in many industries)

-

Balancing Equipment:

- Install automatic load balancers for dynamic balancing (popular in data centers globally)

- Use balancing transformers for persistent imbalances (common in industrial settings)

- Implement static VAR compensators for reactive power balancing (crucial in long distribution lines)

-

Design Considerations:

- Plan electrical layouts with balance in mind from the start (BIM software often used for this)

- Size conductors appropriately to handle potential imbalances (follow NEC in US, IEC standards elsewhere)

- Consider future expansion in initial balance calculations (especially important in rapidly growing economies)

-

Maintenance and Adjustment:

- Regularly check and tighten connections to prevent imbalance-causing resistance (thermal imaging is useful)

- Adjust tap settings on transformers to compensate for minor imbalances (common practice in utility-scale applications)

- Periodically reassess and redistribute loads as system changes occur (typically annually in stable operations)

I once worked on a project for a large data center in Singapore where load imbalance was causing overheating in one phase of their UPS system. By implementing a combination of load redistribution and installing an automatic load balancer, we reduced the imbalance from 15% to less than 2%. This not only solved the immediate problem but also improved overall system efficiency by 8% and reduced their cooling costs by 12%.

Here’s a comprehensive table of load balancing techniques and their applications, considering global best practices:

| Technique | Description | Best For | Potential Improvement | Global Adoption |

|---|---|---|---|---|

| Manual Load Redistribution | Physically moving loads between phases | Small to medium facilities | Up to 10% reduction in imbalance | Common worldwide |

| Automatic Load Balancers | Electronic devices that dynamically shift loads | Large facilities with varying loads | 15-20% reduction in imbalance | Growing in smart buildings |

| Balancing Transformers | Special transformers that redistribute currents | Persistent imbalances in industrial settings | Up to 30% reduction in imbalance | Common in heavy industry |

| Load Scheduling | Timing the operation of large loads | Facilities with predictable load patterns | 5-10% reduction in peak imbalance | Popular in energy-conscious regions |

| Power Factor Correction | Adding capacitors or other reactive power compensation | Systems with large inductive loads | 10-15% improvement in overall balance | Widespread in industrial applications |

| Three-Phase Conversion of Loads | Replacing single-phase equipment with three-phase versions | Industrial and commercial settings | Up to 25% improvement in balance | Standard practice in new installations |

| Oversizing Neutral Conductors | Using larger neutral wires to handle imbalance currents | Buildings with high harmonic content | Reduces neutral heating by up to 50% | Common in data centers and offices |

| Regular Load Studies | Periodic analysis and adjustment of load distribution | All three-phase systems | Maintains balance within 5% long-term | Best practice globally |

Conclusion

Converting single-phase transformers to a three-phase system is a viable solution for many applications, offering flexibility and potential cost savings. However, it requires careful planning, precise execution, and ongoing maintenance to ensure safety, efficiency, and reliability. By understanding the global context, adhering to international standards, and implementing best practices in load balancing and efficiency management, you can successfully navigate the complexities of three-phase power systems in our interconnected world.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group