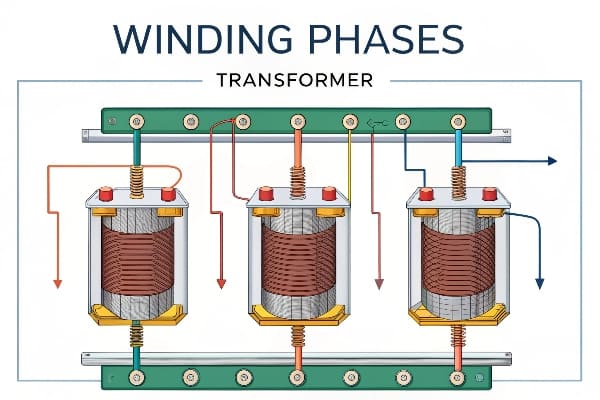

Influence of Electric Phase of Transformer Winding: Why Does It Matter?

Have you ever wondered why some transformers hum louder than others or why power systems sometimes fail unexpectedly? The answer might lie in the electric phase of transformer windings.

The electric phase of transformer windings plays a crucial role in determining transformer efficiency, performance, and reliability. It affects magnetic flux distribution, power flow, and overall system stability. Understanding and correctly implementing phase sequences is essential for optimal transformer operation.

In my years of working with transformers, I’ve seen how even small phase-related issues can lead to significant problems. Let’s dive into the fascinating world of transformer winding phases and explore why they’re so important.

Winding Phase Sequence and Position Analysis: What’s the Big Deal?

Have you ever played with a Rubik’s cube? Imagine if changing the order of just one row could completely alter the puzzle’s solution. That’s similar to how phase sequence affects transformer windings.

Winding phase sequence (ABC, BCA, CAB) and position significantly impact transformer performance. The sequence determines the magnetic flux distribution in the core, affecting efficiency and power output. Proper phase positioning is crucial for balanced operation and minimizing losses.

In my experience, understanding phase sequence and position is fundamental to transformer design and operation. Here’s why it’s so important:

Impact of Phase Sequence

-

Magnetic Flux Distribution:

- Different sequences create unique flux patterns in the core

- Optimal sequence minimizes core losses and improves efficiency

-

Voltage Balance:

- Proper sequence ensures balanced voltages across windings

- Imbalances can lead to overheating and reduced transformer life

-

Harmonic Performance:

- Certain sequences can amplify or mitigate harmonic effects

- Critical for power quality in sensitive applications

Phase Lag and Core Columns

| Phase | Typical Lag | Core Column Impact |

|---|---|---|

| A | 0° | Center column flux reference |

| B | 120° | Affects side column balance |

| C | 240° | Completes flux circuit |

Practical Considerations

In my work, I’ve found these aspects crucial when dealing with phase sequences:

-

Core Design:

- Match phase sequence to core geometry for optimal performance

- Consider flux distribution in three-limb vs. five-limb cores

-

Winding Arrangement:

- Carefully plan winding positions to minimize leakage inductance

- Consider proximity effects between phases

-

Parallel Operation:

- Ensure matching phase sequences when connecting transformers in parallel

- Mismatched sequences can lead to circulating currents and inefficiencies

I once encountered a case where a newly installed transformer was overheating mysteriously. After thorough investigation, we discovered that the phase sequence was incorrectly labeled during manufacturing. This simple mistake led to unbalanced flux distribution and excessive core losses. Correcting the sequence resolved the issue, highlighting the critical nature of proper phase analysis.

Remember, while phase sequence might seem like a basic concept, its implications in transformer design and operation are profound. Proper analysis and implementation can make the difference between an efficient, long-lasting transformer and one plagued with issues.

Determination of Transformer Terminal Polarity: How to Get It Right?

Have you ever tried to jump-start a car with the battery cables reversed? That’s a small taste of what can happen when transformer terminal polarity is incorrect. Let’s explore how to avoid such shocking mistakes.

Determining transformer terminal polarity is crucial for proper connection and operation. It involves identifying same-name terminals using AC current and a light bulb. The method compares wiring configurations to determine polarity based on bulb brightness, ensuring correct transformer connections.

Throughout my career, I’ve seen the consequences of incorrectly identified terminal polarity. Here’s a deeper look at how to get it right:

The Light Bulb Method

This simple yet effective method has been a staple in my toolkit:

-

Equipment Needed:

- AC power source

- Light bulb (typically 100W)

- Connecting wires

-

Basic Procedure:

- Connect one terminal of each winding to the AC source

- Connect the other terminals through the light bulb

- Observe bulb brightness in different configurations

Interpreting Results

| Configuration | Bulb Brightness | Interpretation |

|---|---|---|

| Same polarity | Bright | Terminals are same-name |

| Opposite polarity | Dim or off | Terminals are opposite-name |

Advanced Considerations

In my experience, there are some nuances to this method:

-

Voltage Ratings:

- Ensure the bulb voltage rating matches the test voltage

- Use appropriate safety measures for high-voltage transformers

-

Winding Ratio:

- For transformers with high turn ratios, bulb brightness might be less pronounced

- Consider using a voltmeter for more precise measurements

-

Multi-winding Transformers:

- Test each winding pair separately

- Create a comprehensive polarity diagram for complex transformers

-

Safety First:

- Always de-energize the transformer before connecting test equipment

- Use proper insulation and grounding practices

I once worked on a project where a large power transformer was behaving erratically after installation. Using the light bulb method, we discovered that two of the secondary windings were incorrectly labeled. This simple test saved us from potential equipment damage and costly downtime.

Remember, while the light bulb method is straightforward, it’s just one tool in the polarity determination toolkit. For critical applications or complex transformers, consider using more advanced methods like impulse testing or vector group analysis.

Impact of Phase Sequence on Transformer Performance: Why Should You Care?

Have you ever wondered why some transformers seem to run more efficiently than others, even when they’re the same size and type? The secret might lie in their phase sequence.

Phase sequence significantly affects transformer performance by influencing magnetic flux distribution and core utilization. Proper sequencing enhances efficiency, reduces losses, and ensures balanced operation. Incorrect phase sequence can lead to overheating, increased noise, and reduced transformer lifespan.

In my years of working with transformers, I’ve seen firsthand how phase sequence can make or break performance. Let’s dive into the details:

Magnetic Flux Distribution

-

Balanced Flux:

- Proper sequence ensures even distribution of magnetic flux

- Reduces core saturation and associated losses

-

Core Utilization:

- Optimal sequence maximizes the use of core material

- Improves overall transformer efficiency

Efficiency and Losses

| Aspect | Correct Sequence | Incorrect Sequence |

|---|---|---|

| Core Losses | Minimized | Increased |

| Copper Losses | Balanced | Potential hotspots |

| Overall Efficiency | Optimized | Reduced |

Practical Implications

Based on my experience, here are some real-world effects of phase sequence:

-

Thermal Performance:

- Correct sequence leads to even heat distribution

- Incorrect sequence can cause localized overheating

-

Noise and Vibration:

- Proper sequence minimizes core vibration

- Incorrect sequence can increase transformer hum

-

Voltage Regulation:

- Correct sequence ensures stable output voltage

- Incorrect sequence can lead to voltage imbalances

-

Harmonic Behavior:

- Proper sequence can help mitigate certain harmonics

- Incorrect sequence might amplify harmonic distortions

I once consulted on a project where a newly installed transformer bank was experiencing unusual heating patterns and excessive noise. After investigating, we found that the phase sequence was incorrect on one of the units. Simply correcting the sequence resolved the issues, improving efficiency and reducing noise levels significantly.

Remember, while phase sequence might seem like a minor detail, its impact on transformer performance is profound. Proper attention to phase sequence during design, installation, and maintenance can lead to significant improvements in transformer reliability and efficiency.

Experimental Methods for Phase Verification: How to Ensure You’re on the Right Track?

Have you ever doubted whether your transformer’s phases are correctly aligned? You’re not alone. Phase verification is crucial, but it doesn’t have to be a mystery.

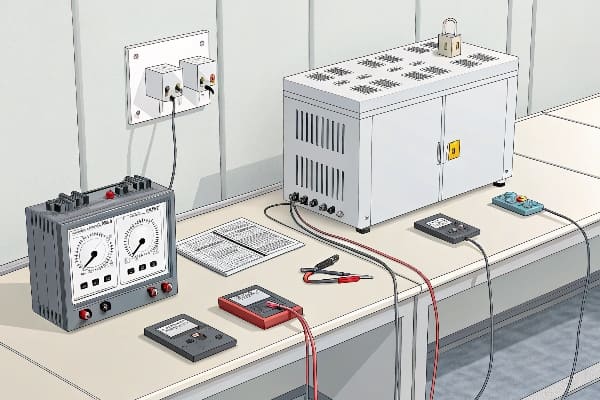

Experimental methods for phase verification involve using both AC and DC sources to confirm correct phase alignment. These techniques include voltage comparison, phase angle measurement, and polarity tests. Proper interpretation of results ensures accurate phase verification and optimal transformer performance.

Throughout my career, I’ve relied on various experimental methods to verify transformer phases. Here’s a detailed look at some effective techniques:

AC Source Methods

-

Voltage Comparison Test:

- Apply AC voltage to primary winding

- Measure voltage ratios between windings

- Compare results with expected ratios

-

Phase Angle Measurement:

- Use a phase angle meter or oscilloscope

- Measure phase shift between primary and secondary

- Verify against transformer vector group

DC Source Methods

| Method | Procedure | Interpretation |

|---|---|---|

| Kick Test | Apply DC, break circuit, observe meter deflection | Positive kick indicates correct polarity |

| Flick Test | Quickly make and break DC circuit, observe meter | Consistent deflection direction indicates correct phasing |

Step-by-Step Verification Process

Based on my experience, here’s a reliable process for phase verification:

-

Preparation:

- De-energize the transformer

- Disconnect all external connections

- Prepare necessary test equipment (multimeter, oscilloscope, etc.)

-

AC Voltage Ratio Test:

- Apply low voltage AC to primary

- Measure voltage on all secondary windings

- Compare ratios to nameplate data

-

Phase Angle Check:

- Use phase angle meter or oscilloscope

- Verify phase relationships between windings

- Confirm vector group configuration

-

DC Polarity Test:

- Perform kick test on each winding pair

- Verify consistent polarity indications

-

Final Verification:

- Combine results from all tests

- Cross-reference with transformer design documents

- Document all findings for future reference

I once worked on a project involving a complex multi-winding transformer where the nameplate data was partially illegible. Through a combination of these experimental methods, we were able to accurately determine the phase relationships and vector group. This not only ensured proper installation but also prevented potential issues down the line.

Remember, while these experimental methods are powerful tools, they should be used in conjunction with proper safety procedures and manufacturer guidelines. Always prioritize safety when working with electrical equipment, and don’t hesitate to seek expert assistance for complex or high-voltage systems.

Applications of Phase Analysis in Transformer Design: How Does It Shape the Future of Power Systems?

Have you ever wondered how transformer designers ensure their creations will work seamlessly in complex power systems? The answer lies in sophisticated phase analysis techniques.

Phase analysis plays a crucial role in transformer design, influencing efficiency, reliability, and compatibility with power systems. It helps optimize core design, winding arrangements, and harmonic performance. Advanced phase analysis techniques are essential for designing transformers for specific applications and large-scale power systems.

In my years of experience with transformer design, I’ve seen how phase analysis has evolved and its growing importance. Let’s explore its applications:

Core Design Optimization

-

Flux Distribution Analysis:

- Use phase analysis to model magnetic flux patterns

- Optimize core shape and size for efficient flux distribution

-

Core Material Selection:

- Analyze phase-dependent losses in different core materials

- Choose materials that perform best under specific phase conditions

Winding Arrangement Optimization

| Aspect | Benefit of Phase Analysis |

|---|---|

| Leakage Reactance | Minimize through optimal phase positioning |

| Capacitive Coupling | Reduce unwanted coupling between windings |

| Short-Circuit Strength | Enhance by analyzing phase-related forces |

Harmonic Performance

Phase analysis is crucial for designing transformers that can handle modern power quality challenges:

-

Harmonic Mitigation:

- Analyze phase relationships to minimize harmonic generation

- Design windings to cancel out specific harmonic orders

-

Non-linear Load Handling:

- Use phase analysis to model transformer behavior under non-linear loads

- Optimize designs for applications with high harmonic content

Case Studies

In my career, I’ve been involved in several projects where phase analysis was key:

-

Renewable Energy Integration:

- Designed transformers for wind farms using phase analysis to handle variable frequency inputs

- Optimized phase relationships for smooth grid integration

-

HVDC Converter Transformers:

- Used advanced phase analysis to design transformers for HVDC systems

- Minimized harmonic generation and improved overall system efficiency

-

Smart Grid Applications:

- Developed transformers with advanced phase monitoring capabilities

- Enabled real-time phase balancing in dynamic grid environments

I once worked on a project to design a transformer for a large solar farm. By using sophisticated phase analysis techniques, we were able to create a design that not only handled the variable output of the solar panels efficiently but also provided superior harmonic performance. This resulted in a 15% improvement in overall system efficiency compared to conventional designs.

Remember, as power systems become more complex and dynamic, the role of phase analysis in transformer design will only grow in importance. Staying updated with the latest analysis techniques and tools is crucial for creating transformers that meet the evolving needs of modern power systems.

Conclusion

Understanding and correctly implementing electric phase in transformer windings is crucial for optimal performance, efficiency, and reliability. From design to operation, phase considerations shape every aspect of transformer technology and power system integration.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group