Key Features of Pad Mounted Transformers: Powering Communities Safely and Efficiently?

Have you ever wondered how electricity reaches your home safely and efficiently? The answer might be hiding in plain sight. Pad mounted transformers are the unsung heroes of our power distribution system.

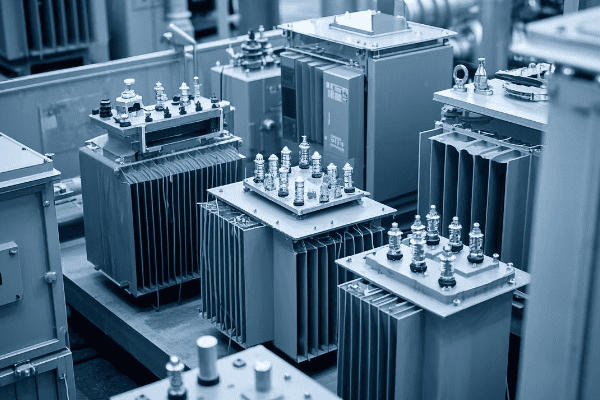

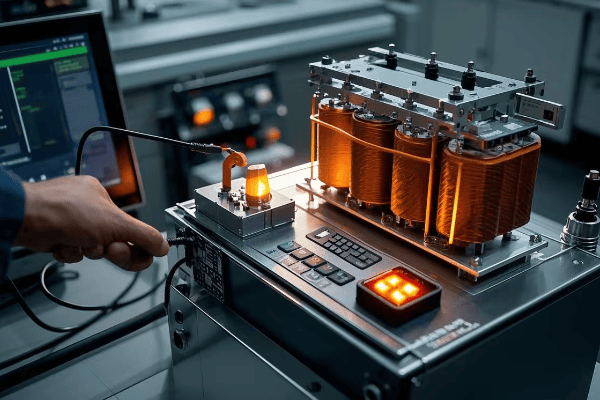

Pad mounted transformers are compact, ground-level electrical devices that convert high-voltage electricity to lower voltages for homes and businesses. They offer key features like noise reduction, customizable configurations, eco-friendly designs, easy maintenance, scalability, and high reliability.

As an electrical engineer with over 20 years of experience, I’ve seen firsthand how pad mounted transformers have revolutionized power distribution. They’re not just another piece of equipment; they’re a game-changer in how we deliver electricity to our communities. Let’s dive into the key features that make these transformers so crucial for powering our communities safely and efficiently.

Noise Reduction: Ensuring Quiet Operation in Residential Areas?

Have you ever been kept awake by a humming transformer? It’s a common complaint in many neighborhoods. But pad mounted transformers are changing the game when it comes to noise pollution.

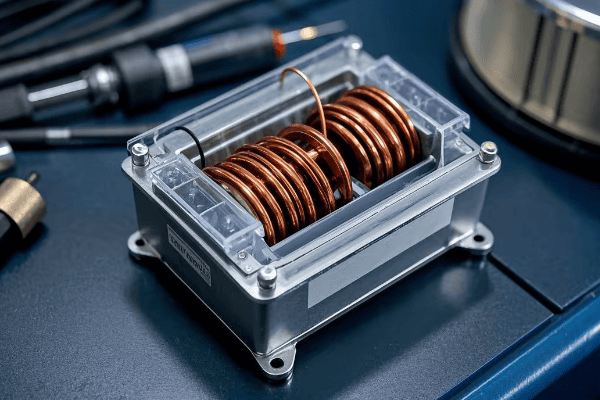

Pad mounted transformers use advanced design techniques to minimize operational noise. These include improved core materials, vibration dampening, and acoustic enclosures. The result is a transformer that can operate quietly in residential areas without disturbing the peace.

Let’s dive deeper into how pad mounted transformers achieve quiet operation:

Silencing the Hum

-

Advanced Core Materials:

- Use of grain-oriented silicon steel

- Reduces magnetostriction, a major source of transformer hum

-

Vibration Dampening:

- Rubber pads between core and tank

- Absorbs vibrations before they can create noise

-

Acoustic Enclosures:

- Special sound-absorbing materials line the transformer cabinet

- Traps and dissipates sound waves

I remember a project where we replaced old, noisy transformers in a suburban area with new pad mounted units. The residents were skeptical at first, but after installation, they couldn’t believe the difference. One homeowner told me he could finally enjoy quiet evenings on his porch again.

Here’s a comparison of noise levels:

| Transformer Type | Typical Noise Level (dB) | Equivalent Sound |

|---|---|---|

| Old Pole-Mounted | 60-70 dB | Vacuum cleaner |

| Standard Pad Mounted | 50-60 dB | Quiet office |

| Advanced Pad Mounted | 40-50 dB | Soft rainfall |

| Ultra-Quiet Pad Mounted | <40 dB | Whisper |

Customizable Configurations: Meeting Diverse Community Needs?

One size fits all? Not when it comes to power distribution. Every community has unique energy needs. That’s where the customizable nature of pad mounted transformers shines.

Pad mounted transformers offer a range of configurations to meet diverse community needs. From single-phase units for residential areas to three-phase designs for industrial zones, these transformers can be tailored to specific voltage requirements, load profiles, and space constraints.

Let’s explore the flexibility of pad mounted transformers:

Tailoring Power to Needs

-

Phase Configurations:

- Single-phase: Ideal for residential and light commercial use

- Three-phase: Perfect for industrial and heavy commercial applications

-

Voltage Classes:

- Distribution class: Typically 5 kV to 35 kV

- Sub-transmission class: Up to 69 kV

-

kVA Ratings:

- Range from 25 kVA to 5000 kVA or more

- Allows for precise matching to load requirements

-

Mounting Options:

- Standard pad mount

- Vault-style for underground installations

- Submersible designs for flood-prone areas

I once worked on a mixed-use development project that required a variety of transformer configurations. We used single-phase units for the residential areas, three-phase for the commercial spaces, and even included some high-capacity units for a small manufacturing zone. The flexibility of pad mounted transformers allowed us to create a tailored solution that met everyone’s needs efficiently.

Here’s a breakdown of common configurations:

| Configuration | Typical Use | Advantages | Considerations |

|---|---|---|---|

| Single-phase, 25-167 kVA | Residential | Cost-effective, Compact | Limited capacity |

| Three-phase, 150-2500 kVA | Commercial, Industrial | High capacity, Efficient for motors | Higher cost, Larger size |

| Single-phase, submersible | Flood-prone areas | Water-resistant | Special installation required |

| Three-phase, vault-style | Urban areas with limited space | Space-saving | More complex installation |

Environmental Considerations: Eco-Friendly Designs and Materials?

Worried about the environmental impact of power distribution? You’re not alone. As we push for greener energy solutions, pad mounted transformers are stepping up to the plate with eco-friendly designs and materials.

Modern pad mounted transformers incorporate eco-friendly features like biodegradable oils, recyclable materials, and energy-efficient designs. These innovations reduce environmental risks, lower carbon footprints, and align with sustainable energy goals.

Let’s dive into the green features of pad mounted transformers:

Going Green with Power Distribution

-

Biodegradable Insulating Oils:

- Vegetable-based oils replace traditional mineral oils

- Faster biodegradation if spilled

- Lower toxicity to wildlife

-

Recyclable Materials:

- Use of recyclable metals in core and windings

- Plastic components made from recycled materials

- Designed for easy disassembly at end-of-life

-

Energy-Efficient Designs:

- High-efficiency cores reduce energy losses

- Advanced winding techniques minimize copper losses

- Better cooling systems for improved efficiency

-

Reduced Carbon Footprint:

- Longer lifespan means less frequent replacements

- Smaller size reduces material use

- Lower losses contribute to overall grid efficiency

I recently worked on a project for a eco-conscious tech company. They wanted their new campus to be as green as possible. We installed pad mounted transformers with vegetable-based oils and high-efficiency cores. The company was thrilled to learn that these transformers would not only reduce their environmental risk but also contribute to their overall energy efficiency goals.

Here’s a comparison of environmental factors:

| Feature | Traditional Transformer | Eco-Friendly Pad Mounted | Environmental Benefit |

|---|---|---|---|

| Insulating Oil | Mineral oil | Vegetable-based oil | Biodegradable, Less toxic |

| Core Material | Standard silicon steel | Amorphous metal | 70-80% lower core losses |

| Lifespan | 25-30 years | 35-40 years | Less frequent replacement |

| Recyclability | Partial | Nearly 100% | Reduced landfill waste |

| Efficiency | 98-99% | 99.5%+ | Lower energy waste |

Maintenance Accessibility: Simplifying Upkeep and Repairs?

Ever wondered why some power outages last longer than others? Often, it’s due to how easy (or difficult) it is to maintain and repair the equipment. This is where pad mounted transformers shine.

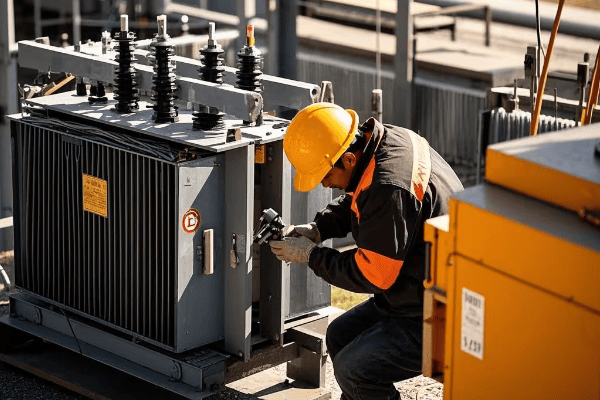

Pad mounted transformers are designed for easy maintenance and quick repairs. Their ground-level installation, accessible compartments, and modular components allow technicians to perform routine checks and repairs efficiently, minimizing downtime and improving overall reliability.

Let’s explore how pad mounted transformers simplify maintenance:

Keeping the Power Flowing

-

Ground-Level Access:

- No need for bucket trucks or climbing

- Safer for technicians

- Quicker response times for emergencies

-

Compartmentalized Design:

- Separate high-voltage and low-voltage sections

- Allows for safer partial access during some maintenance tasks

-

Modular Components:

- Easy replacement of individual parts

- Reduces repair time and costs

-

Built-in Diagnostic Features:

- Temperature and pressure gauges

- Oil level indicators

- Some models include smart monitoring systems

I remember a storm that hit our area a few years back. While many neighborhoods were without power for days due to damaged pole-mounted transformers, areas with pad mounted units were back online much faster. The ease of access and quick repair capabilities made a huge difference in restoration times.

Here’s a comparison of maintenance aspects:

| Aspect | Pole-Mounted Transformer | Pad Mounted Transformer | Benefit of Pad Mounted |

|---|---|---|---|

| Access Method | Bucket truck or climbing | Ground-level | Safer, Faster |

| Inspection Time | 1-2 hours | 30 minutes – 1 hour | More frequent checks |

| Component Replacement | Often requires full unit replacement | Modular replacement possible | Faster, More cost-effective |

| Safety During Maintenance | Exposed to heights and weather | Protected environment | Reduced accident risk |

| Diagnostic Capability | Limited | Advanced, often with smart features | Earlier problem detection |

Scalability: Adapting to Growing Power Demands?

Is your community growing? Are you worried about your power infrastructure keeping up? Scalability is a key feature of pad mounted transformers that addresses these concerns.

Pad mounted transformers offer excellent scalability to meet increasing power demands. They can be easily upgraded or replaced with higher capacity units without significant infrastructure changes. This flexibility allows utilities to adapt to community growth efficiently.

Let’s dive into how pad mounted transformers provide scalable solutions:

Growing with Your Community

-

Modular Design:

- Easy to swap out for higher capacity units

- Minimal changes to surrounding infrastructure

-

Standardized Footprints:

- Larger capacity transformers often fit in the same space

- Reduces need for site modifications during upgrades

-

Parallel Operation:

- Multiple units can be installed side-by-side

- Allows for incremental capacity increases

-

Future-Ready Features:

- Some models designed with extra capacity for future growth

- Smart grid compatibility for advanced load management

I once worked on a project in a rapidly growing suburban area. We initially installed 500 kVA pad mounted transformers but designed the pads to accommodate up to 2500 kVA units. Five years later, when the community’s power needs had increased, we were able to upgrade the transformers quickly and with minimal disruption.

Here’s a look at scalability options:

| Initial Capacity | Upgrade Options | Time for Upgrade | Infrastructure Changes |

|---|---|---|---|

| 100 kVA | Up to 500 kVA | 4-8 hours | Minimal to none |

| 500 kVA | Up to 2500 kVA | 8-12 hours | Minor pad modifications |

| 1000 kVA | Parallel installation | 1-2 days | Additional pad needed |

| Any capacity | Smart grid integration | Varies | Software/control upgrades |

Reliability: Ensuring Consistent Power Supply to Communities?

Have you ever experienced a power outage during a critical moment? Reliability in power distribution is not just a convenience; it’s a necessity. Pad mounted transformers play a crucial role in ensuring a consistent power supply to our communities.

Pad mounted transformers are designed for high reliability. Their robust construction, protection from environmental factors, and advanced monitoring capabilities contribute to fewer outages and quicker restorations. This reliability is crucial for maintaining quality of life and supporting critical infrastructure.

Let’s explore the reliability features of pad mounted transformers:

Keeping the Lights On

-

Robust Construction:

- Sealed, tamper-resistant enclosures

- Corrosion-resistant materials

- Designed to withstand extreme weather conditions

-

Advanced Protection Systems:

- Built-in circuit breakers and fuses

- Surge arresters to protect against lightning strikes

- Automatic voltage regulators for stable output

-

Environmental Shielding:

- Protected from wildlife interference

- Less susceptible to tree falls compared to overhead lines

- Better performance in high wind and ice conditions

-

Monitoring and Diagnostics:

- Real-time monitoring of key parameters

- Early warning systems for potential issues

- Some models include self-healing capabilities

I recall a project where we replaced old, unreliable transformers in a small town prone to frequent outages. After installing new pad mounted units with advanced monitoring systems, the town saw a 70% reduction in outage frequency. The local hospital, which used to rely heavily on backup generators, reported significant improvements in their operations.

Here’s a comparison of reliability factors:

| Factor | Traditional Transformer | Modern Pad Mounted | Impact on Reliability |

|---|---|---|---|

| Weather Resistance | Moderate | High | Fewer weather-related outages |

| Animal Protection | Low | High | Reduced wildlife-caused failures |

| Monitoring Capability | Basic | Advanced | Early problem detection |

| Lifespan | 20-25 years | 30-35 years | Less frequent replacements |

| Maintenance Needs | Frequent | Less frequent | Reduced downtime for maintenance |

| Fault Recovery Time | Hours to days | Minutes to hours | Faster power restoration |

Conclusion

Pad mounted transformers offer a powerful combination of features that make them ideal for modern power distribution. From their quiet operation and customizable configurations to their eco-friendly designs and easy maintenance, these transformers are built to meet the diverse needs of growing communities while ensuring reliability and efficiency.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group