Pad Mounted Transformer Concrete Pad First Energy: Installation Best Practices for Utility Companies?

Have you ever wondered why some power transformers seem to last forever while others fail prematurely? The secret often lies beneath the surface, in the concrete pad they’re installed on.

Proper installation of concrete pads for pad mounted transformers is crucial for utility companies. It ensures transformer stability, longevity, and safety. Best practices include correct pad design, proper site preparation, adherence to safety regulations, and consideration of environmental factors.

In this article, I’ll share my insights on concrete pad installation for pad mounted transformers. I’ve seen firsthand how a well-designed pad can make all the difference in transformer performance and maintenance.

What Are the Key Considerations for Designing and Preparing a Concrete Pad for Pad Mounted Transformers?

When I first started working with pad mounted transformers, I underestimated the importance of the concrete pad. I quickly learned that a poorly designed pad can lead to a host of problems.

Key considerations for concrete pad design include load-bearing capacity, dimensions, drainage, conduit placement, and soil conditions. The pad must support the transformer’s weight, allow for proper cable entry, and ensure adequate drainage to prevent water accumulation.

Let’s dive deeper into these key considerations:

Load-Bearing Capacity

The pad’s load-bearing capacity is crucial:

- Transformer Weight: Pads must support the full weight of the transformer.

- Oil Weight: For oil-filled transformers, factor in the oil weight.

- Safety Factor: Include a safety margin for additional loads.

I once worked on a project where an undersized pad cracked under the transformer’s weight. We had to replace both the pad and the transformer, a costly mistake that could have been avoided with proper design.

Dimensions and Thickness

Pad dimensions are critical:

| Aspect | Consideration |

|---|---|

| Length and Width | Must extend beyond transformer footprint |

| Thickness | Depends on soil conditions and transformer weight |

| Reinforcement | Steel rebar for added strength |

In a recent project, we designed a pad with extended dimensions to accommodate future transformer upgrades. This foresight saved the utility company significant costs down the line.

Drainage and Slope

Proper drainage is essential:

- Slope: Typically 1% away from the transformer.

- Surrounding Area: Grade the area to direct water away.

- Drainage Channels: Consider adding channels in flood-prone areas.

I remember a site where poor drainage led to water pooling around the transformer. We had to retrofit a drainage system, which was much more expensive than if it had been included in the initial design.

Conduit Placement

Conduit placement requires careful planning:

- Primary Conduits: For incoming high-voltage cables.

- Secondary Conduits: For outgoing low-voltage cables.

- Future Expansion: Include spare conduits for potential upgrades.

In one project, we used a template to ensure precise conduit placement. This made cable installation much easier and reduced the risk of damage to the cables during installation.

Soil Conditions

Soil conditions significantly impact pad design:

- Soil Testing: Conduct geotechnical surveys.

- Compaction: Ensure proper soil compaction before pouring concrete.

- Frost Heave: In cold climates, consider frost heave protection.

I once worked on a site with expansive clay soil. We had to design a special pad with a deeper foundation to prevent movement and cracking.

How Does Proper Concrete Pad Installation Affect the Performance and Longevity of Pad Mounted Transformers?

Early in my career, I saw a transformer fail due to a poorly installed pad. It was a wake-up call that showed me how crucial proper installation is.

Proper concrete pad installation significantly impacts transformer performance and longevity. It ensures stability, prevents water ingress, facilitates heat dissipation, and enables easy maintenance access. A well-installed pad can extend a transformer’s lifespan and reduce the risk of failures.

Let’s explore how proper installation affects transformers:

Stability and Vibration Reduction

A properly installed pad provides stability:

- Level Surface: Prevents transformer tilting.

- Vibration Absorption: Reduces operational vibrations.

- Seismic Protection: In earthquake-prone areas, proper installation is crucial.

I once worked on a project in a seismic zone. We designed a pad with special anchoring systems that significantly improved the transformer’s ability to withstand earthquakes.

Water Protection

Water is a transformer’s enemy. Good pad installation helps:

| Aspect | Benefit |

|---|---|

| Elevation | Keeps transformer above flood levels |

| Slope | Directs water away from the transformer |

| Sealant | Prevents water ingress through conduit entries |

In a coastal project, we used a raised pad design with special sealants. It successfully protected the transformer from saltwater corrosion and flooding.

Heat Dissipation

Proper pad installation aids in heat dissipation:

- Air Circulation: Adequate clearance allows airflow.

- Thermal Mass: Concrete acts as a heat sink.

- Surface Treatment: Reflective coatings can reduce heat absorption.

I remember a case where poor air circulation led to transformer overheating. By redesigning the pad with better clearance, we solved the issue and extended the transformer’s life.

Maintenance Access

A well-designed pad facilitates maintenance:

- Working Space: Ensures enough room for technicians.

- Equipment Access: Allows for easy replacement of components.

- Oil Containment: Proper design can include oil containment features.

In one project, we incorporated a built-in oil containment system into the pad design. It not only met environmental regulations but also made oil changes and spill cleanups much easier.

Long-Term Cost Savings

Proper installation leads to cost savings:

- Reduced Failures: Fewer transformer failures mean less downtime.

- Extended Lifespan: Well-supported transformers last longer.

- Lower Maintenance Costs: Easier access reduces maintenance time and costs.

I’ve seen utilities save millions in the long run by investing in proper pad installation upfront. It’s a classic case of "pay now or pay more later."

What Safety Measures and Regulations Should Utility Companies Follow During Concrete Pad Installation?

Safety is paramount in utility work. I’ve seen the consequences of neglecting safety measures, and it’s not pretty.

Utility companies must follow strict safety measures and regulations during concrete pad installation. These include adherence to OSHA standards, proper equipment usage, electrical safety protocols, and environmental protection measures. Compliance ensures worker safety and prevents accidents.

Let’s delve into the key safety measures and regulations:

OSHA Compliance

OSHA standards are crucial:

- Personal Protective Equipment (PPE): Hard hats, safety boots, gloves.

- Fall Protection: When working at heights.

- Trench Safety: For excavation work.

I once consulted on a project where strict adherence to OSHA standards prevented a potentially serious accident during excavation. It reinforced the importance of these regulations.

Equipment Safety

Proper equipment usage is essential:

| Equipment | Safety Measure |

|---|---|

| Concrete Mixers | Regular maintenance, proper operation training |

| Excavators | Certified operators, clear communication protocols |

| Power Tools | Proper grounding, GFCI protection |

In a recent project, we implemented a comprehensive equipment safety program. It reduced accidents and improved overall efficiency.

Electrical Safety

Electrical safety is paramount:

- De-energization: Ensure all nearby power sources are off.

- Lockout/Tagout: Use proper procedures to prevent accidental energization.

- Grounding: Properly ground all equipment.

I remember a close call where a worker almost contacted a live wire. Our strict electrical safety protocols prevented what could have been a fatal accident.

Environmental Protection

Environmental considerations are important:

- Spill Prevention: Have containment measures for concrete and chemicals.

- Dust Control: Use water sprays to minimize dust.

- Noise Reduction: Schedule noisy work during appropriate hours.

In an urban project, we used innovative low-noise equipment and dust control measures. It helped maintain good relations with the surrounding community.

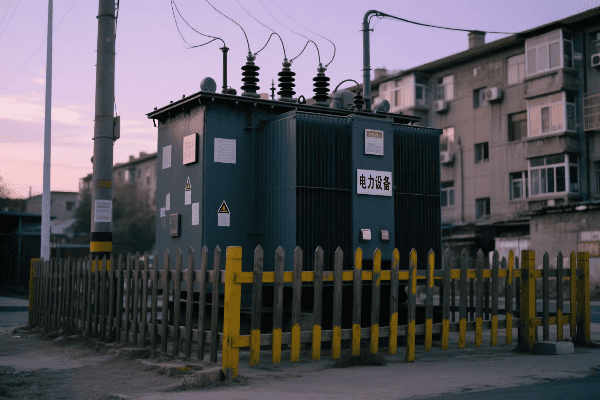

Site Security

Securing the site is crucial:

- Fencing: Erect temporary fencing around the work area.

- Signage: Clear warning signs about the construction.

- Access Control: Limit site access to authorized personnel only.

I’ve seen how proper site security can prevent vandalism and theft. In one project, our security measures deterred copper thieves, saving the utility company significant costs.

How Can Utility Companies Optimize the Concrete Pad Layout for Efficient Transformer Maintenance and Access?

Efficient maintenance is key to transformer longevity. I’ve seen how a well-designed pad layout can make a huge difference in maintenance operations.

Utility companies can optimize concrete pad layout by ensuring adequate working space, strategic placement of access points, incorporation of oil containment features, and consideration of future expansion. An optimized layout facilitates easier maintenance, reduces downtime, and improves overall efficiency.

Let’s explore ways to optimize pad layout:

Working Space

Adequate working space is crucial:

- Clearance: Allow enough room around all sides of the transformer.

- Access Paths: Clear paths for maintenance vehicles and equipment.

- Staging Areas: Designate areas for tools and replacement parts.

In a recent project, we designed a pad with extra clearance on one side. This "maintenance alley" greatly improved the efficiency of routine checks and repairs.

Strategic Access Points

Placement of access points is key:

| Access Point | Consideration |

|---|---|

| Cable Entry | Easy access for cable replacement |

| Oil Drain | Accessible for oil changes |

| Control Cabinet | Clear view and easy reach |

I once redesigned a pad layout to relocate the control cabinet. This simple change reduced maintenance time by 30% by improving accessibility.

Oil Containment

Incorporating oil containment features is important:

- Containment Basin: Built into the pad design.

- Drainage System: For safe oil removal.

- Capacity: Sized to contain the full volume of transformer oil.

In an environmentally sensitive area, we designed a pad with an integrated oil containment system. It not only met regulations but also simplified maintenance procedures.

Future Expansion

Planning for the future is wise:

- Oversized Pad: Allow room for larger transformers.

- Extra Conduits: Install spare conduits for future needs.

- Modular Design: Enable easy expansion of the pad.

I worked on a substation where we implemented a modular pad design. When the utility needed to upgrade the transformer years later, the expansion was straightforward and cost-effective.

Ergonomic Considerations

Ergonomics can improve maintenance efficiency:

- Height: Design the pad height for comfortable working postures.

- Surface Texture: Non-slip surfaces for safety.

- Lighting: Consider built-in lighting for nighttime maintenance.

In one project, we incorporated ergonomic features like adjustable work platforms. It significantly reduced strain on maintenance workers and improved their efficiency.

What Are the Environmental and Aesthetic Considerations in Concrete Pad Design for Urban and Suburban Areas?

In urban and suburban areas, transformers can’t just be functional – they need to blend in. I’ve worked on projects where environmental and aesthetic considerations were just as important as technical specs.

Environmental and aesthetic considerations in concrete pad design include using eco-friendly materials, implementing green spaces, noise reduction measures, and visual camouflage techniques. These factors help utilities meet regulations, improve community relations, and enhance the overall urban landscape.

Let’s explore these considerations:

Eco-Friendly Materials

Using sustainable materials is increasingly important:

- Recycled Concrete: Reduces environmental impact.

- Permeable Surfaces: Allows water to seep through, reducing runoff.

- Low-Carbon Cement: Reduces the carbon footprint of the installation.

In a recent urban project, we used recycled concrete for the pad. It not only met performance standards but also helped the utility meet its sustainability goals.

Green Space Integration

Incorporating green spaces can improve aesthetics:

| Feature | Benefit |

|---|---|

| Planting Areas | Softens the visual impact |

| Green Walls | Vertical gardens on screening walls |

| Bioswales | Natural drainage and filtration |

I once designed a pad that included a small rain garden. It not only looked great but also helped manage stormwater runoff.

Noise Reduction

Minimizing noise is crucial in residential areas:

- Sound-Absorbing Materials: Use in pad and enclosure design.

- Vibration Dampening: Install vibration isolators.

- Strategic Placement: Position transformers away from sensitive areas.

In a suburban project, we used special vibration-dampening mounts on the pad. It significantly reduced noise complaints from nearby residents.

Visual Camouflage

Blending the transformer into its surroundings is an art:

- Color Matching: Use colors that complement the environment.

- Artistic Enclosures: Collaborate with local artists for creative designs.

- Landscaping: Use plants to screen the transformer.

I worked on a project in a historic district where we designed a pad and enclosure that mimicked a traditional garden shed. It preserved the area’s character while housing modern equipment.

Community Engagement

Involving the community can lead to better outcomes:

- Public Consultations: Gather input on design preferences.

- Educational Signage: Inform the public about the transformer’s role.

- Local Partnerships: Work with local organizations for maintenance of surrounding areas.

In one project, we partnered with a local school to create an educational garden around the transformer pad. It turned a potential eyesore into a community asset.

Conclusion

Proper concrete pad installation is crucial for pad mounted transformers. It ensures stability, safety, and longevity while addressing environmental and aesthetic concerns. Utility companies must consider all aspects for optimal performance and community acceptance.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group