Pad Mounted Transformer Dimensions: A Comprehensive Guide to Optimal Sizing and Installation?

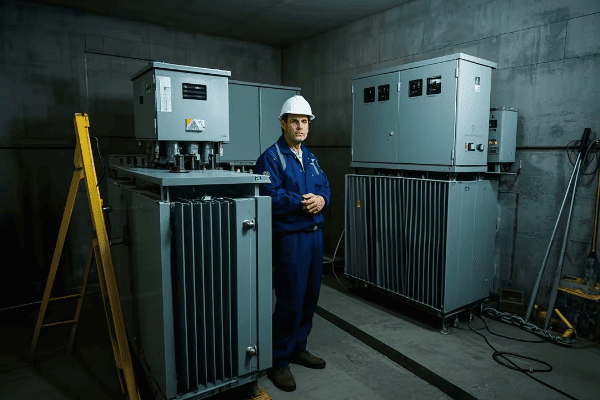

Are you struggling to determine the right dimensions for your pad mounted transformer? You’re not alone. Many engineers find this task challenging and crucial for project success.

This guide provides comprehensive insights into pad mounted transformer dimensions, covering standard sizes, installation considerations, and factors affecting optimal sizing. It aims to help engineers and project managers make informed decisions for efficient and compliant transformer installations.

As an experienced electrical engineer, I’ve worked on numerous projects involving pad mounted transformers. I understand the complexities of sizing and installation. In this guide, I’ll share my knowledge to help you navigate these challenges effectively.

Understanding Pad Mounted Transformer Dimensions: Standard Sizes and Specifications?

Have you ever wondered why pad mounted transformers come in such a wide range of sizes? The answer lies in the diverse power needs of different applications.

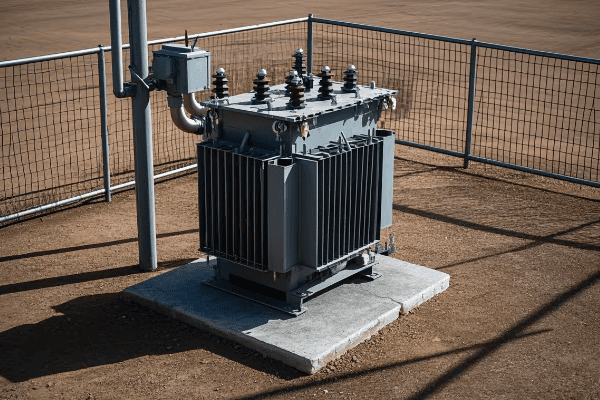

Pad mounted transformer dimensions typically range from 3x3x3 feet for smaller units to 8x8x8 feet for larger ones. These sizes are standardized based on power ratings, voltage classes, and specific application requirements.

Let’s dive deeper into the standard sizes and specifications of pad mounted transformers:

Size Categories

Pad mounted transformers are generally categorized into three size groups.

Small Transformers:

- Dimensions: 3x3x3 to 4x4x5 feet

- Typical power ratings: 75 to 500 kVA

I once worked on a residential project where we used a compact 3x3x3 transformer. Its small size was perfect for the limited space available in the suburban setting.

Medium Transformers:

- Dimensions: 5x5x6 to 6x6x7 feet

- Typical power ratings: 750 to 2000 kVA

Large Transformers:

- Dimensions: 7x7x7 to 8x8x8 feet or larger

- Typical power ratings: Above 2000 kVA

Voltage Class Impact

The voltage class significantly influences transformer dimensions.

Low Voltage Class (Up to 35 kV):

- Smaller overall dimensions

- Less insulation space required

- Compact design possible

Medium Voltage Class (35 kV to 69 kV):

- Increased dimensions for proper insulation

- Larger clearances needed

- More substantial bushings and terminals

Dimensional Specifications

Key dimensional aspects to consider include:

Height:

- Affects clearance requirements

- Impacts accessibility for maintenance

Width and Depth:

- Determine the pad size needed

- Influence cable entry and exit points

Weight:

- Affects foundation requirements

- Impacts transportation and installation methods

| Size Category | Typical Dimensions (LxWxH) | Power Rating Range | Common Applications |

|---|---|---|---|

| Small | 3x3x3 to 4x4x5 feet | 75 – 500 kVA | Residential, small commercial |

| Medium | 5x5x6 to 6x6x7 feet | 750 – 2000 kVA | Large commercial, small industrial |

| Large | 7x7x7 to 8x8x8 feet or larger | 2000+ kVA | Industrial, utility substations |

In my experience, understanding these standard sizes is crucial for project planning. I remember a case where a client initially specified a transformer that was too large for their available space. By understanding the standard size options, we were able to recommend a more compact model that still met their power needs.

It’s important to note that while these are standard sizes, custom dimensions are sometimes necessary for specific applications. I’ve worked on projects where we had to design custom enclosures to fit unique space constraints while still meeting all safety and performance requirements.

Another key consideration is the relationship between dimensions and cooling efficiency. Larger transformers often require more sophisticated cooling systems, which can impact their overall dimensions. In one industrial project, we had to carefully balance the size of the transformer with its cooling needs to ensure optimal performance in a high-temperature environment.

Don’t forget about future expansion needs when considering transformer dimensions. I always advise clients to think about potential power requirement increases in the coming years. Sometimes, it’s worth opting for a slightly larger transformer now to avoid costly upgrades later.

Lastly, remember that dimensions affect more than just physical fit. They also impact maintenance accessibility, safety clearances, and even aesthetic considerations in some settings. Always consider the full context of your installation when evaluating transformer dimensions.

Understanding pad mounted transformer dimensions is more than just knowing numbers. It’s about comprehending how these sizes relate to performance, installation requirements, and long-term suitability for your specific application.

Installation Considerations: How Transformer Dimensions Influence Setup Requirements?

Are you aware of how crucial transformer dimensions are in determining installation requirements? Many engineers overlook this aspect, leading to costly mistakes.

Transformer dimensions directly impact pad size, clearance requirements, cable entry points, and accessibility for maintenance. Proper consideration of these factors ensures safe, efficient, and compliant installations.

Let’s explore how transformer dimensions influence various installation aspects:

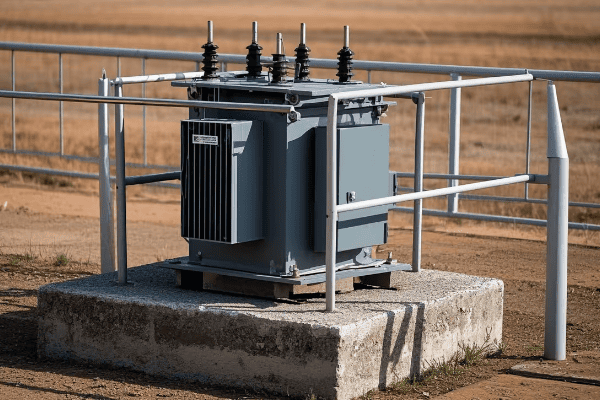

Pad Design and Construction

The transformer’s footprint is critical for pad design.

Key Considerations:

- Pad dimensions should exceed transformer base by at least 6 inches on all sides

- Thickness must support the transformer’s weight

- Proper reinforcement for larger units

I once worked on a project where an undersized pad led to settling issues. We had to reinforce the pad, causing delays and additional costs.

Clearance Requirements

Adequate clearance is essential for safety and maintenance.

Clearance Factors:

- Front clearance for operation and maintenance (typically 3-4 feet)

- Side and rear clearances for ventilation and safety

- Overhead clearance for installation and removal

Cable Entry and Routing

Dimensions affect cable management significantly.

Cable Considerations:

- Location of primary and secondary cable entry points

- Space for proper bending radius of cables

- Accessibility for future cable replacement or upgrades

Accessibility for Maintenance

Proper dimensions ensure easy access for maintenance tasks.

Accessibility Aspects:

- Door swing clearance

- Space for oil sampling and testing

- Room for cooling system maintenance

Environmental Protection

Dimensions impact the transformer’s protection from environmental factors.

Protection Considerations:

- Space for flood protection measures

- Clearance for snow accumulation in cold climates

- Room for additional protective enclosures if needed

| Dimensional Aspect | Installation Requirement | Impact on Setup |

|---|---|---|

| Footprint | Pad size and strength | Determines foundation needs |

| Height | Overhead clearance | Affects installation method |

| Width | Side clearances | Influences spacing between units |

| Depth | Front and rear access | Determines maintenance space |

| Weight | Pad thickness and reinforcement | Affects foundation design |

In my experience, one of the most overlooked aspects of transformer installation is the impact of dimensions on future maintenance and upgrades. I remember a case where a transformer was installed with minimal side clearance. When it came time to replace the cooling fans, the tight space made the job extremely difficult and time-consuming.

It’s also crucial to consider the dimensions in relation to the surrounding environment. In one coastal project, we had to account for potential flooding. The transformer’s dimensions influenced our decision to elevate the pad, which in turn affected the overall installation height and cable routing.

Don’t underestimate the importance of proper clearances for safety reasons. I’ve seen installations where insufficient clearance led to arc flash hazards during maintenance. Always err on the side of caution when it comes to safety clearances.

Another important consideration is the impact of dimensions on ventilation and cooling. In a recent project in a hot climate, we had to carefully plan the transformer layout to ensure adequate airflow around each unit. The dimensions of the transformers directly influenced the spacing and orientation of the installation.

Lastly, consider how the transformer dimensions might affect future expansions or upgrades. I always advise clients to think long-term. Sometimes, it’s worth allocating extra space now to accommodate potential larger units in the future, even if it means a slightly more complex initial installation.

Understanding how transformer dimensions influence installation requirements is crucial for successful projects. It’s not just about fitting the transformer in place; it’s about creating a safe, efficient, and future-proof installation that will serve its purpose for years to come.

Factors Affecting Optimal Sizing: Key Considerations in Dimension Selection?

Are you struggling to determine the optimal dimensions for your pad mounted transformer? This decision is crucial and involves multiple factors that many engineers overlook.

Optimal sizing of pad mounted transformers depends on factors like power requirements, voltage class, environmental conditions, and future expansion needs. Careful consideration of these elements ensures efficient operation and prevents costly oversizing or undersizing.

Let’s explore the key factors that influence the optimal sizing of pad mounted transformers:

Power Requirements

The primary factor in determining transformer size.

Considerations:

- Current load demands

- Anticipated future load growth

- Peak load handling capabilities

I once worked on a project where underestimating future load growth led to premature transformer replacement. Always factor in potential expansion when sizing your transformer.

Voltage Class

Voltage ratings significantly impact transformer dimensions.

Voltage Considerations:

- Primary voltage of the distribution system

- Required secondary voltage for end-use equipment

- Insulation requirements for different voltage classes

Environmental Conditions

The installation environment plays a crucial role in sizing.

Environmental Factors:

- Ambient temperature ranges

- Humidity and moisture levels

- Altitude considerations

- Exposure to corrosive elements

Cooling Requirements

Proper cooling is essential for transformer longevity and efficiency.

Cooling Considerations:

- ONAN (Oil Natural Air Natural) vs. ONAF (Oil Natural Air Forced) cooling

- Space for radiators or fans

- Airflow requirements

Physical Space Constraints

Available installation space can limit transformer size options.

Space Factors:

- Site dimensions and layout

- Clearance requirements for safety and maintenance

- Accessibility for installation and future replacement

Regulatory Compliance

Local regulations and standards influence sizing decisions.

Compliance Aspects:

- Minimum efficiency standards

- Safety clearance requirements

- Environmental protection regulations

| Factor | Impact on Sizing | Consideration Example |

|---|---|---|

| Power Requirements | Determines kVA rating | Future load growth projections |

| Voltage Class | Affects insulation needs | Higher voltage = larger size |

| Environmental Conditions | Influences cooling design | High temperatures may require larger unit |

| Cooling Requirements | Impacts overall dimensions | ONAF may need more space than ONAN |

| Space Constraints | Limits maximum size | Urban settings may require compact designs |

| Regulatory Compliance | Sets minimum standards | Efficiency regulations may affect size |

In my experience, balancing these factors is often challenging but crucial. I remember a project where we initially selected a transformer based solely on current power requirements. However, after considering the client’s five-year growth plan, we opted for a slightly larger unit. This foresight saved the client from a costly upgrade just three years later.

It’s important to note that oversizing can be as problematic as undersizing. I’ve seen cases where oversized transformers led to unnecessary energy losses and higher initial costs. The key is to find the sweet spot that meets current needs while allowing for reasonable future growth.

Don’t underestimate the impact of environmental conditions on sizing. In a recent project in a high-altitude location, we had to account for reduced air density in our cooling calculations. This led us to select a larger transformer than would typically be needed for the same load at sea level.

Another crucial consideration is the trade-off between size and efficiency. Sometimes, a slightly larger transformer can offer significantly better efficiency. I always advise clients to consider the long-term energy savings when making sizing decisions.

Lastly, remember that transformer sizing isn’t just about the transformer itself. It also affects related infrastructure like pads, cable sizing, and protection systems. Always consider the broader system implications when selecting transformer dimensions.

Optimal sizing of pad mounted transformers requires a holistic approach that considers multiple factors. By carefully evaluating power needs, environmental conditions, space constraints, and regulatory requirements, you can select a transformer that provides efficient, reliable service for years to come.

Dimension-Performance Relationship: Impact on Transformer Efficiency and Output?

Have you ever wondered how the size of a transformer affects its performance? The relationship between dimensions and efficiency is more complex than many engineers realize.

Transformer dimensions directly influence its efficiency and output capacity. Larger transformers generally offer higher efficiency and better cooling, but the relationship isn’t always linear. Optimal sizing balances efficiency, cost, and practical considerations.

Let’s explore how dimensions impact various aspects of transformer performance:

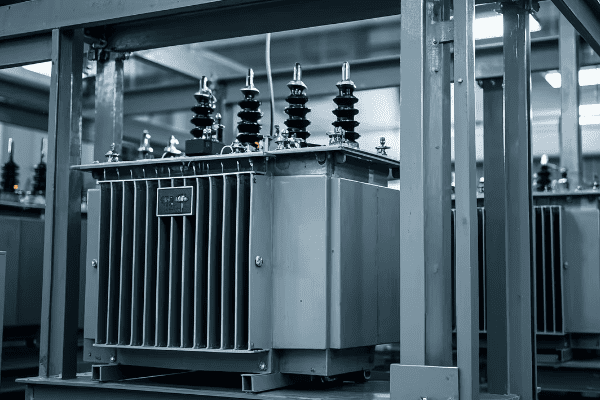

Core Size and Efficiency

The core’s dimensions significantly affect transformer efficiency.

Core Considerations:

- Larger cores generally have lower core losses

- Increased core size allows for better flux distribution

- Optimal core sizing can reduce no-load losses

I once worked on a project where increasing the core size by 10% resulted in a 15% reduction in core losses. The efficiency gain justified the slight increase in overall dimensions.

Winding Design and Losses

Winding dimensions play a crucial role in load losses.

Winding Factors:

- Larger conductor cross-sections reduce resistance losses

- Increased winding height can improve cooling

- Optimal winding design balances copper losses and size

Cooling System Effectiveness

Dimensions directly impact cooling system design and effectiveness.

Cooling Considerations:

- Larger surface area allows for better heat dissipation

- Increased oil volume provides better thermal inertia

- Dimensions affect the placement and efficiency of cooling fins or radiators

Insulation and Voltage Stress

Proper dimensioning is crucial for managing voltage stress.

Insulation Aspects:

- Larger dimensions allow for better insulation between windings

- Increased oil gaps reduce electric field stress

- Proper sizing ensures adequate creepage and clearance distances

Output Capacity and Overload Capability

Dimensions affect a transformer’s ability to handle peak loads and overloads.

Capacity Factors:

- Larger transformers generally have better overload capacity

- Increased size allows for better heat management during peak loads

- Dimensions influence short-term and long-term overload capabilities

| Dimensional Aspect | Performance Impact | Efficiency Consideration |

|---|---|---|

| Core Size | Affects core losses | Larger core = lower no-load losses |

| Winding Dimensions | Influences copper losses | Optimal sizing reduces load losses |

| Cooling System Size | Impacts heat dissipation | Better cooling = higher efficiency |

| Insulation Space | Affects voltage withstand | Proper sizing ensures reliability |

| Overall Size | Determines output capacity | Larger size often allows higher output |

In my experience, the relationship between dimensions and performance is not always straightforward. I remember a case where we were tasked with improving the efficiency of an existing transformer design. Initially, we thought simply increasing the overall size would solve the problem. However, through careful analysis and design optimization, we managed to achieve a 2% efficiency gain with only a minimal increase in dimensions.

It’s crucial to understand that bigger isn’t always better. I’ve seen instances where oversized transformers actually led to decreased efficiency due to higher core losses relative to the typical load. The key is to optimize the design for the specific load profile and operating conditions.

Don’t overlook the impact of dimensions on transformer lifespan. Proper sizing, especially in terms of cooling capacity, can significantly extend a transformer’s operational life. In one industrial project, we opted for a slightly larger transformer with enhanced cooling. This decision not only improved efficiency but also extended the expected lifespan by several years.

Another important consideration is the trade-off between efficiency and cost. While larger, more efficient transformers may have higher upfront costs, they often provide significant savings over their lifetime through reduced energy losses. I always advise clients to consider the total cost of ownership, including lifetime energy costs, when evaluating transformer options.

Lastly, remember that the dimension-performance relationship can vary based on the transformer type and application. For example, the optimal sizing for a distribution transformer in an urban setting may differ significantly from that of a large power transformer in an industrial facility.

Understanding the complex relationship between transformer dimensions and performance is crucial for making informed decisions. By carefully considering how size impacts efficiency, output, and long-term reliability, you can select a transformer that provides optimal performance for your specific needs.

Space Management: Accommodating Various Pad Mounted Transformer Dimensions?

Are you struggling to fit a pad mounted transformer into a tight space? Space management is a common challenge that many engineers face when dealing with transformer installations.

Effective space management for pad mounted transformers involves strategic placement, creative design solutions, and careful consideration of clearance requirements. Proper planning can accommodate various transformer dimensions even in limited spaces.

Let’s explore strategies for managing space with different transformer dimensions:

Strategic Placement

Careful positioning can maximize available space.

Placement Strategies:

- Corner installations to utilize dead space

- Aligning transformers with building lines

- Utilizing setback areas effectively

I once worked on a project where we placed a transformer in an unused corner of a parking lot. This creative placement saved valuable space without compromising accessibility.

Compact Designs

Opting for compact transformer designs can help in tight spaces.

Compact Solutions:

- Low-profile transformers for height-restricted areas

- Slim-line designs for narrow spaces

- Integrated switchgear for all-in-one solutions

Underground Solutions

In extremely tight spaces, underground installations can be a viable option.

Underground Considerations:

- Vault designs for below-grade installations

- Waterproofing and drainage requirements

- Access considerations for maintenance

Multi-level Installations

Utilizing vertical space can be an effective solution in urban environments.

Multi-level Options:

- Rooftop installations for high-rise buildings

- Elevated platforms in industrial settings

- Basement installations in commercial buildings

Clearance Optimization

Carefully planning clearances can maximize usable space.

Clearance Strategies:

- Using minimum allowable clearances in tight spaces

- Incorporating clearances into landscaping or architectural features

- Designing custom barriers to reduce required clearances

| Space Management Strategy | Application | Benefit |

|---|---|---|

| Strategic Placement | Corner installations | Utilizes often unused spaces |

| Compact Designs | Slim-line transformers | Fits in narrow areas |

| Underground Solutions | Vault installations | Preserves above-ground space |

| Multi-level Installations | Rooftop placements | Utilizes vertical space |

| Clearance Optimization | Integrated barriers | Reduces overall footprint |

In my experience, creative space management often requires thinking outside the box. I remember a challenging project in a dense urban area where space was at a premium. We ended up designing a custom enclosure that doubled as a decorative wall, effectively hiding the transformer while meeting all clearance requirements.

It’s important to note that space management isn’t just about fitting the transformer in place. It’s also about ensuring long-term accessibility for maintenance and potential replacement. I’ve seen cases where tight installations made routine maintenance extremely difficult, leading to increased costs and downtime over the transformer’s lifespan.

Don’t overlook the importance of future expansion when managing space. In one project, we deliberately left extra space around the transformer, anticipating potential upgrades. This foresight proved invaluable when the client needed to increase capacity just a few years later.

Another crucial aspect of space management is considering the impact on surrounding infrastructure. In a recent installation, we had to carefully coordinate the transformer placement with underground utilities, HVAC systems, and fire safety equipment. Comprehensive site planning is essential for successful space management.

Lastly, remember that local regulations can significantly impact space management strategies. I always advise checking with local authorities early in the planning process. In one case, local fire codes required specific clearances that initially seemed impossible to meet. By working closely with the fire marshal, we developed an innovative solution that satisfied safety requirements while still fitting within the available space.

Effective space management for pad mounted transformers is as much an art as it is a science. By combining creative thinking with technical knowledge and regulatory compliance, you can find solutions to even the most challenging space constraints.

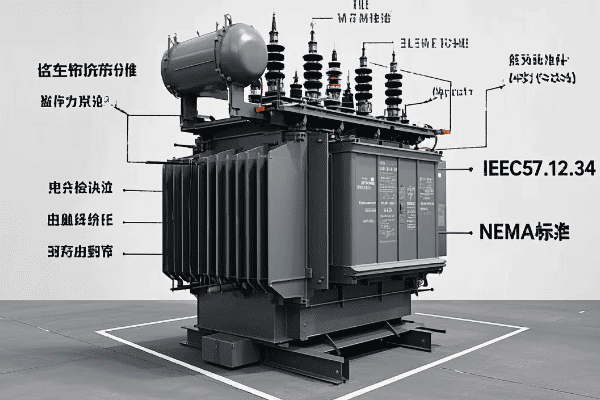

Regulatory Compliance: Dimensional Standards for Pad Mounted Transformers?

Are you confused about the myriad of regulations governing pad mounted transformer dimensions? Navigating these standards can be daunting, but it’s crucial for ensuring safe and compliant installations.

Pad mounted transformer dimensions are subject to various regulatory standards, including IEEE C57.12.34, NEMA standards, and local utility requirements. These regulations specify minimum clearances, access requirements, and safety features that directly impact transformer sizing.

Let’s break down the key regulatory standards affecting pad mounted transformer dimensions:

IEEE C57.12.34 Standard

This is the primary standard for pad mounted transformers in North America.

Key Dimensional Requirements:

- Minimum cabinet depths based on kVA rating

- Specified clearances for live parts

- Door swing and locking mechanism standards

I once worked on a project where overlooking a specific IEEE clearance requirement led to a costly redesign. Always double-check these standards during the planning phase.

NEMA Standards

NEMA provides additional guidelines for electrical equipment.

NEMA Considerations:

- Enclosure ratings for environmental protection

- Ventilation requirements affecting overall dimensions

- Accessibility standards for controls and indicators

Local Utility Requirements

Many utilities have their own specific dimensional standards.

Utility-Specific Factors:

- Preferred transformer sizes and configurations

- Additional clearance requirements

- Specific foundation and pad dimensions

Safety Clearance Regulations

Safety clearances often dictate minimum dimensions.

Safety Clearance Aspects:

- Working clearances for maintenance personnel

- Fire safety clearances from buildings

- Minimum distances from public access areas

Environmental Regulations

Environmental considerations can impact transformer dimensions.

Environmental Factors:

- Oil containment requirements affecting base dimensions

- Noise reduction needs influencing overall size

- Seismic design considerations in earthquake-prone areas

| Regulatory Body | Standard/Requirement | Dimensional Impact |

|---|---|---|

| IEEE | C57.12.34 | Specifies minimum cabinet sizes |

| NEMA | TR 1 | Defines enclosure ratings and sizes |

| Local Utilities | Varies | May require specific clearances |

| OSHA | 1910.303 | Dictates working space requirements |

| EPA | SPCC regulations | Influences oil containment design |

In my experience, compliance with these regulations requires a thorough understanding of both the letter and the spirit of the standards. I recall a project where we initially met all the dimensional requirements on paper, but during a pre-installation inspection, we realized that the placement didn’t allow for proper maintenance access. We had to quickly adjust our design to ensure practical compliance.

It’s crucial to note that regulations can vary significantly between jurisdictions. I always advise checking with local authorities early in the design process. In one memorable case, a transformer that was compliant in one state required substantial modifications to meet the standards of a neighboring state.

Don’t underestimate the importance of future-proofing your designs against potential regulatory changes. I’ve seen cases where transformers became non-compliant due to updated standards. When possible, I recommend designing with some margin beyond current requirements to accommodate potential future changes.

Another important aspect is the interaction between different regulatory requirements. For instance, meeting environmental regulations for oil containment might impact the dimensions needed to comply with electrical clearance standards. Balancing these sometimes competing requirements requires careful planning and often some creative problem-solving.

Lastly, remember that regulatory compliance isn’t just about meeting minimum standards. It’s about ensuring the safety and reliability of your installation. I always encourage going beyond mere compliance to implement best practices that enhance safety and performance.

Navigating the regulatory landscape for pad mounted transformer dimensions can be complex, but it’s essential for successful and safe installations. By staying informed about current standards and anticipating future changes, you can ensure your transformer designs are both compliant and effective.

Measurement and Specification Guide: Ensuring Accurate Transformer Dimensions?

Are you struggling to accurately measure and specify pad mounted transformer dimensions? Precise measurements are crucial for proper installation and operation, yet many engineers find this task challenging.

Accurate measurement and specification of pad mounted transformer dimensions involve considering overall size, clearances, and specific component measurements. Proper techniques and tools ensure precise specifications, critical for installation planning and regulatory compliance.

Let’s explore the key aspects of measuring and specifying transformer dimensions:

Overall Dimensions

These are the primary measurements that define the transformer’s footprint.

Key Measurements:

- Height (from base to top of unit)

- Width (side to side at widest point)

- Depth (front to back at deepest point)

I once encountered a situation where a minor error in overall dimension measurement led to significant installation delays. Always double-check these crucial measurements.

Clearance Measurements

Proper clearances are essential for safety and maintenance.

Clearance Considerations:

- Front clearance for operation and maintenance access

- Side and rear clearances for ventilation

- Top clearance for removal and replacement

Component-Specific Measurements

Certain components require specific dimensional considerations.

Critical Components:

- High and low voltage bushing locations

- Access panel and door dimensions

- Cooling fin or radiator projections

Base and Mounting Dimensions

Accurate base measurements are crucial for proper installation.

Base Measurement Aspects:

- Mounting hole patterns and sizes

- Cable entry locations and dimensions

- Overall base footprint

Weight Specifications

While not a dimension, weight is a critical specification.

Weight Considerations:

- Total assembled weight

- Oil weight (for oil-filled units)

- Weight distribution for foundation design

| Measurement Type | Importance | Common Pitfalls |

|---|---|---|

| Overall Dimensions | Critical for space planning | Overlooking protrusions |

| Clearances | Essential for safety and maintenance | Underestimating required space |

| Component Measurements | Important for connections and access | Neglecting small but crucial details |

| Base Dimensions | Crucial for proper mounting | Misaligning mounting holes |

| Weight Specifications | Vital for foundation design | Forgetting to include oil weight |

In my experience, accurate measurement and specification require more than just a tape measure. I remember a project where we used 3D laser scanning to create a precise digital model of an existing transformer. This technology allowed us to capture even the smallest details, ensuring a perfect fit for the replacement unit.

It’s important to note that measurements should account for all protrusions and attachments. I’ve seen cases where engineers forgot to include the dimensions of radiators or lightning arresters, leading to clearance issues during installation.

Don’t overlook the importance of temperature in measurements. Transformers can expand slightly when heated, so it’s wise to specify dimensions at both ambient and operating temperatures. In one hot climate installation, we had to adjust our clearances to account for thermal expansion.

Another crucial aspect is understanding the tolerance levels in your measurements. Manufacturing processes have inherent tolerances, and your specifications should reflect these. I always recommend discussing tolerance requirements with the manufacturer to ensure the final product meets your needs.

Lastly, remember that proper documentation of measurements is as important as the measurements themselves. I’ve developed a habit of creating detailed dimensional drawings that include not just numbers, but also clear indications of measurement points and any special considerations. This practice has saved countless hours of confusion and rework over the years.

Accurate measurement and specification of pad mounted transformer dimensions is a skill that combines technical knowledge with attention to detail. By following these guidelines and learning from experience, you can ensure your transformer specifications are precise, comprehensive, and reliable.

Dimensional Variations Across Power Ratings: A Comparative Analysis?

Have you ever wondered how transformer dimensions change as power ratings increase? Understanding these variations is crucial for proper planning and installation.

Pad mounted transformer dimensions generally increase with higher power ratings, but not always linearly. Factors like voltage class, cooling method, and design efficiency influence how dimensions scale with power ratings.

Let’s explore the dimensional variations across different power ratings:

Low Power Ratings (Up to 500 kVA)

These are typically compact units suitable for residential and small commercial applications.

Typical Dimensions:

- Height: 3-5 feet

- Width: 3-4 feet

- Depth: 3-4 feet

I once worked on a residential development where we used 100 kVA transformers. Their compact size allowed for discreet placement in landscaped areas.

Medium Power Ratings (500 kVA to 2000 kVA)

These units are common in larger commercial and small industrial settings.

Dimensional Trends:

- Height increases to 5-7 feet

- Width expands to 5-6 feet

- Depth grows to 5-6 feet

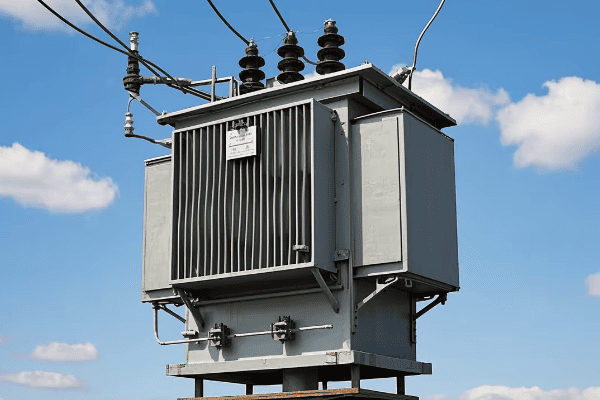

High Power Ratings (Above 2000 kVA)

These large units are typically used in industrial and utility applications.

Size Characteristics:

- Height can exceed 8 feet

- Width often reaches 7-8 feet or more

- Depth increases to 7-8 feet or greater

Cooling System Impact

The cooling method significantly affects dimensions across power ratings.

Cooling Considerations:

- ONAN (Oil Natural Air Natural) units are generally more compact

- ONAF (Oil Natural Air Forced) units require space for fans

- OFAF (Oil Forced Air Forced) systems need additional space for pumps

Voltage Class Influence

Higher voltage classes often require larger dimensions for insulation.

Voltage-Related Size Increases:

- Larger clearances between windings

- Bigger bushings for higher voltages

- More substantial insulation systems

| Power Rating | Typical Dimensions (HxWxD) | Common Applications | Cooling Method |

|---|---|---|---|

| 100 kVA | 3x3x3 feet | Residential | ONAN |

| 1000 kVA | 6x5x5 feet | Commercial | ONAN/ONAF |

| 3000 kVA | 8x7x7 feet | Industrial | ONAF/OFAF |

In my experience, the relationship between power rating and dimensions isn’t always straightforward. I remember a project where we needed to upgrade from a 1500 kVA to a 2000 kVA transformer. We expected a significant size increase, but thanks to advancements in design efficiency, the new unit was only marginally larger.

It’s important to note that dimensional increases often come with challenges in transportation and installation. I once worked on an industrial project requiring a 5000 kVA transformer. The size necessitated special transportation permits and a crane for installation, factors we had to consider early in the planning phase.

Don’t overlook the impact of efficiency standards on dimensions. In recent years, I’ve noticed that higher efficiency requirements have sometimes led to larger transformers for the same power rating. This is due to the need for more core material to reduce losses.

Another crucial aspect is the trade-off between size and features. In some cases, adding features like advanced monitoring systems or more robust protection can increase dimensions. I always advise clients to carefully consider which features are essential and how they might impact the overall size.

Lastly, remember that site constraints often dictate the maximum allowable dimensions regardless of power rating. I’ve been involved in projects where we had to use multiple smaller units instead of one large transformer due to space limitations. This approach can offer benefits in terms of redundancy and flexibility, though it may increase overall costs.

Understanding dimensional variations across power ratings is essential for effective planning and design. By considering factors like cooling methods, voltage class, and efficiency requirements, you can better anticipate and accommodate the size needs of different transformer ratings in your projects.

Installation Challenges and Solutions for Different Transformer Dimensions?

Are you facing difficulties installing pad mounted transformers of various sizes? Installation challenges can vary significantly based on transformer dimensions, but solutions are available for each scenario.

Installation challenges for pad mounted transformers include space constraints, weight management, access issues, and cooling considerations. Solutions involve careful planning, specialized equipment, and sometimes custom installation techniques.

Let’s explore common installation challenges and their solutions for different transformer dimensions:

Compact Transformers (Small Dimensions)

These units often present challenges in tight urban spaces.

Challenges and Solutions:

- Limited working space: Use compact installation equipment

- Difficult access: Consider prefabrication and modular designs

- Ventilation in confined areas: Implement forced air cooling systems

I once installed a compact transformer in a crowded urban alley. We used a mini crane and prefabricated the pad off-site to overcome the space limitations.

Medium-Sized Transformers

These common units can still present significant installation challenges.

Installation Considerations:

- Weight management: Use appropriate lifting equipment

- Cable routing in limited spaces: Plan detailed cable pathways

- Balancing size with required clearances: Optimize layout design

Large Transformers

Installing large transformers often requires specialized approaches.

Large Unit Challenges:

- Transportation to site: Plan routes carefully, obtain necessary permits

- Heavy lifting requirements: Use high-capacity cranes or specialized transporters

- Extensive foundation needs: Conduct thorough soil analysis and foundation design

Unique Dimensional Challenges

Some installations present unique dimensional challenges.

Unusual Scenarios:

- Height restrictions: Consider low-profile or underground designs

- Width constraints: Explore slim-line transformer options

- Depth limitations: Investigate front-access-only models

Environmental Adaptations

Different environments require specific installation adaptations.

Environmental Solutions:

- Flood-prone areas: Elevate transformers on platforms

- High-temperature regions: Enhance cooling systems

- Seismic zones: Implement vibration isolation and anchoring

| Transformer Size | Common Challenges | Potential Solutions |

|---|---|---|

| Compact | Limited space, access | Modular design, specialized equipment |

| Medium | Weight, clearances | Proper lifting gear, optimized layout |

| Large | Transportation, foundation | Route planning, enhanced foundations |

| Unique Dimensions | Specific site constraints | Custom designs, alternative placements |

In my experience, successful installation often comes down to thorough planning and creative problem-solving. I recall a particularly challenging installation where we needed to placea large transformer in a historic building with very limited access. We ended up disassembling the transformer, moving it in pieces, and reassembling it on site. This approach required meticulous planning but allowed us to overcome what initially seemed like an impossible situation.

It’s important to note that installation challenges aren’t just about physical placement. I’ve encountered situations where electromagnetic interference was a concern due to nearby sensitive equipment. In one case, we had to design a custom shielding solution to protect adjacent medical imaging devices from the transformer’s electromagnetic field.

Don’t underestimate the importance of timing in installations, especially for larger units. I once managed a project where we had to coordinate the transformer delivery with a brief window of reduced traffic in a busy urban area. Precise scheduling and coordination with local authorities were crucial for success.

Another critical aspect is adapting to unexpected site conditions. In a recent installation, we discovered unmapped underground utilities that conflicted with our planned transformer location. We quickly had to redesign the pad and adjust the transformer placement, highlighting the need for flexibility and quick problem-solving in the field.

Lastly, consider the long-term implications of your installation choices. I always advise clients to think about future maintenance and potential replacement. In one foresighted project, we designed a removable wall section in a building to allow for easier transformer replacement in the future, saving significant costs and disruption down the line.

Overcoming installation challenges for different transformer dimensions requires a combination of technical knowledge, creative thinking, and practical experience. By anticipating potential issues and preparing flexible solutions, you can ensure successful installations across a wide range of transformer sizes and site conditions.

Environmental Adaptations: Selecting Appropriate Dimensions for Various Settings?

Are you struggling to choose the right transformer dimensions for challenging environmental conditions? Environmental factors can significantly impact the suitability and performance of pad mounted transformers.

Selecting appropriate transformer dimensions for various environments involves considering factors like temperature extremes, humidity, altitude, flood risks, and seismic activity. Proper sizing and design adaptations ensure optimal performance and longevity in diverse settings.

Let’s explore how to adapt transformer dimensions for different environmental settings:

Hot Climate Adaptations

High temperatures require special considerations in transformer sizing.

Hot Climate Solutions:

- Increased cooling surface area

- Larger oil volume for better heat dissipation

- Enhanced ventilation systems

I once designed a transformer for a desert installation where we increased the radiator size by 30% to handle the extreme heat, significantly altering the overall dimensions.

Cold Climate Considerations

Extreme cold presents unique challenges for transformer operation.

Cold Weather Adaptations:

- Insulated and sealed cabinets to prevent freezing

- Space for heating elements in critical areas

- Consideration for thermal expansion and contraction

Coastal and High Humidity Environments

Corrosive salt air and high humidity require specific dimensional considerations.

Coastal Area Solutions:

- Larger clearances to accommodate enhanced insulation

- Space for corrosion-resistant coatings and materials

- Sealed designs to prevent moisture ingress

High Altitude Installations

Reduced air density at high altitudes affects transformer cooling and insulation.

Altitude Adaptations:

- Increased overall size for better cooling efficiency

- Larger clearances for reduced air insulation strength

- Enhanced insulation systems requiring more space

Flood-Prone Areas

Flood risks necessitate specific dimensional adaptations.

Flood Protection Measures:

- Elevated designs with increased height

- Sealed and waterproof enclosures

- Space for integrated flood barriers

Seismic Zones

Earthquake-prone areas require robust and stable transformer designs.

Seismic Considerations:

- Lower center of gravity designs

- Increased base dimensions for stability

- Space for vibration dampening systems

| Environment | Dimensional Adaptation | Performance Impact |

|---|---|---|

| Hot Climate | Larger cooling systems | Improved heat dissipation |

| Cold Climate | Insulated enclosures | Prevention of freezing |

| Coastal Areas | Enhanced sealing | Corrosion resistance |

| High Altitude | Increased overall size | Compensates for reduced air density |

| Flood-Prone | Elevated design | Flood protection |

| Seismic Zones | Wider base | Enhanced stability |

In my experience, adapting transformer dimensions to environmental conditions often requires innovative thinking. I remember a project in a tropical region with both high temperatures and frequent flooding. We designed a custom elevated platform with integrated cooling channels, effectively addressing both issues while minimizing the overall footprint.

It’s crucial to consider the interaction between different environmental factors. In a coastal project, we had to balance corrosion protection with efficient cooling. The solution involved a slightly larger enclosure to accommodate specialized cooling fins with corrosion-resistant coatings, demonstrating how multiple environmental factors can compound dimensional requirements.

Don’t overlook the impact of environmental adaptations on maintenance access. In a high-altitude installation, the increased size for better cooling initially created challenges for routine maintenance. We solved this by incorporating strategically placed access panels, highlighting the need to consider long-term serviceability in dimensional planning.

Another important aspect is future-proofing against changing environmental conditions. In light of climate change, I now often recommend designing with some margin for potentially more extreme conditions. For instance, in a recent coastal project, we sized the transformer to withstand higher flood levels than currently expected, anticipating potential sea-level rise.

Lastly, remember that environmental adaptations can sometimes conflict with local regulations or aesthetic requirements. I once worked on a project where the ideal dimensions for flood protection exceeded local height restrictions. We had to engage in detailed negotiations with local authorities and develop a creative, compliant solution that still provided adequate protection.

Selecting appropriate transformer dimensions for various environmental settings is a complex task that requires balancing technical requirements, regulatory compliance, and practical considerations. By carefully analyzing environmental factors and applying creative solutions, you can ensure your transformers are well-suited to their specific operating conditions, enhancing performance, reliability, and longevity.

Conclusion

Pad mounted transformer dimensions play a crucial role in efficient power distribution. Understanding standard sizes, installation considerations, and environmental adaptations is essential for optimal transformer selection and placement. By carefully considering these factors, engineers can ensure reliable, efficient, and compliant transformer installations across various settings.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group