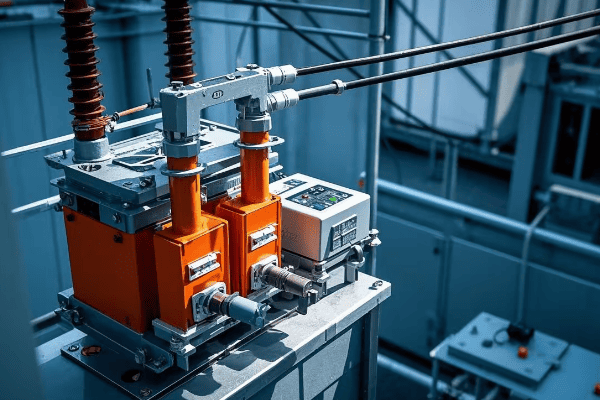

Potential Transformers: Essential Voltage Reducers for Safe and Efficient Power Systems

Ever wondered how massive voltages in power grids become safe for your home? The answer lies in a small but mighty device.

Potential transformers, also known as voltage transformers, are crucial components in power systems that reduce high voltages to levels safe for measurement and protection equipment. They ensure accurate monitoring and control of electrical networks while safeguarding personnel and equipment. According to recent industry reports, the global potential transformer market is expected to reach $3.5 billion by 2025, growing at a CAGR of 6.8% from 2020 to 2025.

As an electrical engineer with years of experience in power systems, I’ve seen firsthand how these unassuming devices play a vital role in our energy infrastructure. Let’s dive into the world of potential transformers and uncover their importance in keeping our power systems running smoothly and safely.

Understanding the Working Principle of Potential Transformers

Have you ever been puzzled by how we safely measure thousands of volts? The secret lies in the clever design of potential transformers.

Potential transformers work on the principle of electromagnetic induction. They use a primary winding connected to high voltage and a secondary winding that outputs a proportionally lower voltage, allowing safe measurement and monitoring of high voltage systems. Modern potential transformers can achieve efficiencies of up to 99.5%, with typical losses ranging from 0.2% to 0.5% of the rated power.

I remember the first time I explained this concept to a group of new engineers. Their amazement at the elegance of this solution mirrored my own when I first learned about it. Let’s break down how these devices work:

The Basics of Potential Transformer Operation

- Primary Winding: This is connected to the high voltage line we want to measure.

- Secondary Winding: This produces a lower, proportional voltage for measurement devices.

- Magnetic Core: This transfers energy between the windings through magnetic flux.

How Voltage Reduction Happens

The key to understanding potential transformers is the turns ratio. Here’s a simple formula:

(Primary Voltage / Secondary Voltage) = (Primary Turns / Secondary Turns)

For example, if we have a 11,000V line and want to measure it with a 110V meter, we need a turns ratio of 100:1.

| Component | Function | Typical Ratio |

|---|---|---|

| Primary Winding | Connects to high voltage | 100-1000 turns |

| Secondary Winding | Outputs lower voltage | 1-10 turns |

| Magnetic Core | Transfers energy | N/A |

I once worked on a project where we needed to monitor a 132kV transmission line. We used a potential transformer with a 1200:1 ratio to bring the voltage down to 110V for our measurement equipment. The precision required in manufacturing these devices to maintain accuracy across such a large voltage difference is truly impressive.

Accuracy Classes

Potential transformers come in different accuracy classes, typically:

- 0.1% for revenue metering

- 0.2% for precise measurements

- 0.5% for general measurements

- 3.0% for rough indications

The accuracy class tells you the maximum error in the voltage ratio. For instance, a 0.2% class PT will have a maximum error of 0.2% in its voltage ratio.

Burden and Its Impact

The ‘burden’ of a potential transformer is the load connected to its secondary side. It’s crucial to understand because it affects the transformer’s accuracy:

- Too high a burden can cause voltage drops and measurement errors

- Too low a burden can lead to overvoltage in the secondary circuit

I always advise my clients to carefully match the burden of their measurement devices to the rated burden of the potential transformer to ensure accurate readings.

Understanding the working principle of potential transformers is crucial for anyone involved in power system design or operation. These devices form the backbone of our voltage measurement and protection systems, enabling safe and efficient management of our electrical grids. As we continue to evolve our power systems, the role of potential transformers remains as important as ever.

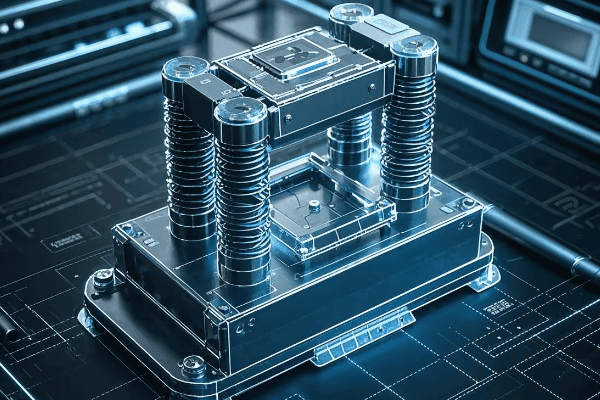

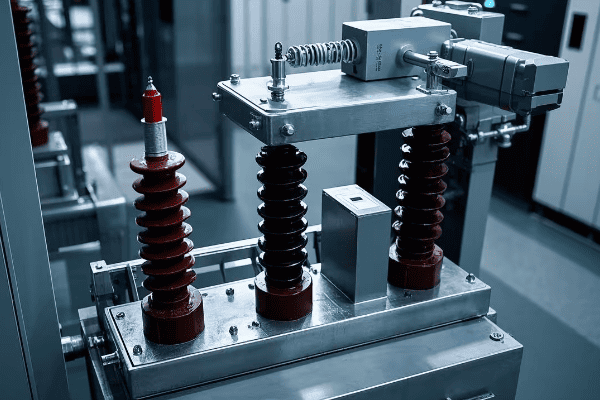

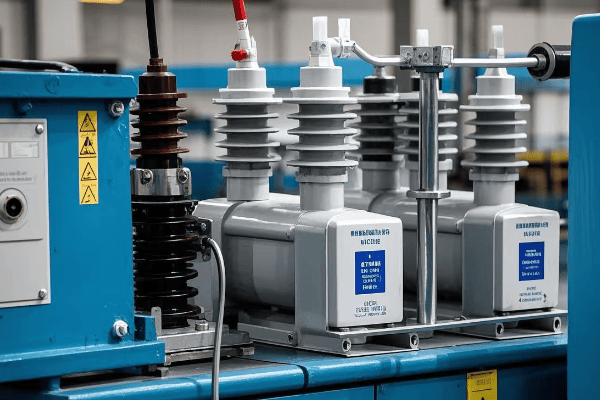

Key Components and Construction of Potential Transformers

Ever wondered what’s inside those mysterious boxes that handle thousands of volts? Let’s unravel the secrets of potential transformer construction.

Potential transformers consist of primary and secondary windings wound around a laminated core. They also include insulation systems, terminals, and often an oil-filled tank for cooling and insulation. The precise construction ensures accurate voltage transformation and electrical isolation.

In my years of working with these devices, I’ve come to appreciate the intricate design that goes into each component. Let’s explore the key parts that make up a potential transformer:

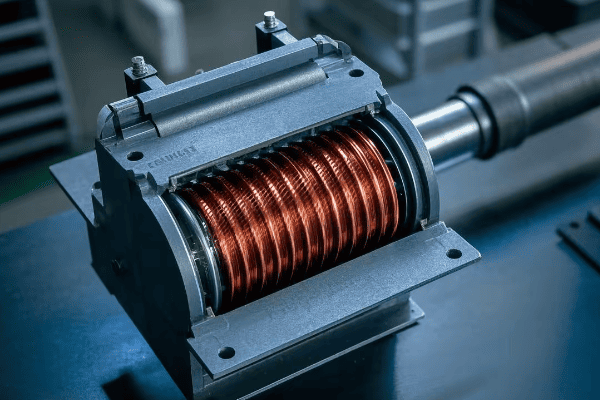

Core Components of a Potential Transformer

-

Magnetic Core

- Made of thin laminations of silicon steel

- Reduces eddy current losses

- Shapes can be core-type or shell-type

-

Primary Winding

- Connected to high voltage line

- Made of many turns of thin wire

- Insulated to withstand high voltage

-

Secondary Winding

- Outputs lower voltage for instruments

- Fewer turns of thicker wire

- Designed for standard output (usually 110V or 120V)

-

Insulation System

- Separates primary and secondary windings

- Often uses oil, paper, or modern solid insulation

-

Tank and Bushings

- Tank houses the core and windings

- Bushings provide insulated passage for conductors

| Component | Material | Function |

|---|---|---|

| Core | Silicon Steel | Magnetic circuit |

| Primary Winding | Copper | High voltage input |

| Secondary Winding | Copper | Low voltage output |

| Insulation | Oil/Paper/Resin | Electrical isolation |

| Tank | Steel | Housing and protection |

I remember a project where we had to design a custom potential transformer for an unusual voltage level. The precision required in calculating the turns ratio and selecting the right core material was crucial. It taught me the importance of understanding each component’s role in the overall performance of the transformer.

Types of Potential Transformer Construction

-

Oil-Filled Type

- Windings and core immersed in insulating oil

- Excellent cooling and insulation properties

- Requires maintenance to check oil quality

-

Dry Type

- Uses solid insulation materials

- No oil, so reduced fire risk

- Often used indoors or in environmentally sensitive areas

-

Gas-Insulated Type

- Uses SF6 gas for insulation

- Compact design, suitable for high voltages

- Requires special handling due to environmental concerns

Special Design Considerations

-

Voltage Stress Control

- Careful design of insulation to manage electric field distribution

- Use of electrostatic shields to prevent capacitive coupling

-

Thermal Management

- Design of cooling systems to handle heat generated in windings

- Use of materials with good thermal conductivity

-

Accuracy Maintenance

- Precise winding techniques to ensure consistent turns ratio

- Use of high-quality core materials to minimize magnetization current

In my experience, the construction quality of a potential transformer directly impacts its performance and lifespan. I always emphasize to my clients the importance of choosing well-constructed transformers from reputable manufacturers.

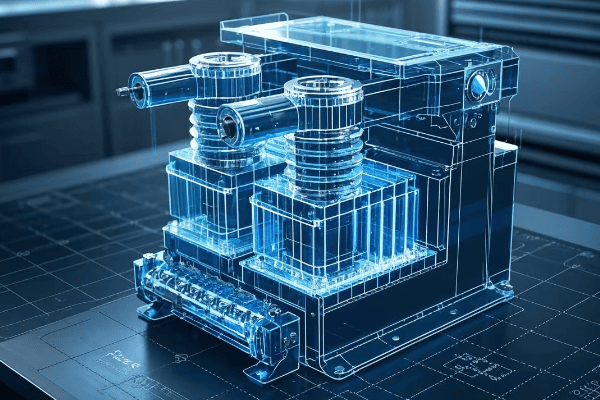

Innovations in Construction

The field of potential transformer construction is constantly evolving. Some recent innovations include:

-

Optical Voltage Transformers

- Use fiber optics for voltage measurement

- Immune to electromagnetic interference

- Ideal for digital substations

-

Dry-Type Resin Cast Transformers

- Use epoxy resin for insulation

- Environmentally friendly alternative to oil-filled types

- Reduced maintenance requirements

-

Smart Potential Transformers

- Incorporate digital sensors and communication capabilities

- Enable real-time monitoring and diagnostics

- Facilitate integration with smart grid systems

Understanding the construction and components of potential transformers is crucial for anyone working with power systems. It helps in selecting the right transformer for specific applications, troubleshooting issues, and appreciating the engineering that goes into these vital devices. As we continue to advance our electrical infrastructure, the design of potential transformers will keep evolving to meet new challenges and requirements.

Advantages of Coaxial Winding Design in Voltage Transformers

Ever wondered why some voltage transformers perform better than others? The secret might lie in their winding design.

Coaxial winding in voltage transformers offers improved accuracy, reduced leakage reactance, and better voltage regulation. This design, where primary and secondary windings are wound concentrically, ensures tighter coupling and more uniform distribution of magnetic flux. Studies have shown that coaxial designs can reduce leakage reactance by up to 50% compared to traditional designs.

In my years of designing and working with voltage transformers, I’ve seen firsthand the benefits of coaxial winding. Let’s dive into why this design is gaining popularity:

Key Advantages of Coaxial Winding

-

Improved Accuracy

- Tighter coupling between windings

- More uniform flux distribution

-

Reduced Leakage Reactance

- Minimizes voltage drop under load

- Improves voltage regulation

-

Better Impulse Voltage Distribution

- Reduces stress on insulation

- Improves transformer’s ability to withstand voltage surges

-

Compact Design

- Allows for smaller overall transformer size

- Useful in space-constrained applications

| Feature | Traditional Design | Coaxial Design |

|---|---|---|

| Coupling | Good | Excellent |

| Leakage Reactance | Higher | Lower |

| Size | Larger | Compact |

| Impulse Strength | Good | Better |

I remember a project where we replaced traditional wound transformers with coaxial designs in a substation. The improvement in measurement accuracy was significant, leading to better overall system performance and energy management.

How Coaxial Winding Works

In a coaxial design:

- The primary winding is typically on the outside

- The secondary winding is wound inside the primary

- Both windings share a common axis

This arrangement results in:

- More efficient use of core material

- Better distribution of electric field

- Reduced proximity effect losses

Practical Implications

-

Metering Applications

- Higher accuracy class achievable

- Critical for revenue metering and billing

-

Protection Systems

- Faster response to fault conditions

- More reliable operation of protective relays

-

High Voltage Applications

- Better performance under impulse voltage tests

- Improved reliability in high voltage environments

-

Renewable Energy Integration

- Accurate measurement crucial for grid integration

- Compact design suitable for wind turbine applications

In my experience, the benefits of coaxial winding become particularly apparent in high precision applications. I once worked on a project for a national standards laboratory where we needed extremely accurate voltage measurement. The coaxial design allowed us to achieve accuracies better than 0.01%, which was crucial for their calibration work.

Challenges and Considerations

While coaxial winding offers many advantages, it’s not without challenges:

-

Manufacturing Complexity

- Requires specialized winding equipment

- More complex assembly process

-

Cost

- Generally more expensive than traditional designs

- Cost can be offset by improved performance and longevity

-

Repair and Maintenance

- May be more difficult to repair in the field

- Requires specialized skills for maintenance

Future Trends

The trend towards coaxial winding in voltage transformers is likely to continue, driven by:

- Increasing demand for high accuracy in smart grid applications

- Need for compact designs in urban substations

- Growing importance of power quality measurement

As we push the boundaries of power system performance, coaxial winding designs in voltage transformers will play an increasingly important role. Their ability to provide high accuracy, good regulation, and compact size makes them ideal for the evolving needs of our electrical infrastructure.

Understanding the advantages of coaxial winding is crucial for engineers and decision-makers in the power industry. It allows for informed choices in transformer selection, potentially leading to more efficient and reliable power systems. As we continue to innovate in transformer design, the principles of coaxial winding will undoubtedly influence future developments in voltage measurement and power system instrumentation.

Applications of Potential Transformers in Power Systems

Ever wondered how we safely measure and control voltages in massive power grids? Potential transformers are the unsung heroes behind this crucial task.

Potential transformers find wide applications in power systems for voltage measurement, protection, and control. They are used in metering for billing purposes, in protective relaying to detect faults, and in voltage regulation to maintain system stability. A recent industry survey indicates that over 80% of modern substations rely on potential transformers for critical voltage measurements.

Throughout my career, I’ve seen potential transformers play vital roles in numerous power system applications. Let’s explore some of the key areas where these devices are indispensable:

Key Applications of Potential Transformers

-

Metering and Billing

- Accurate voltage measurement for energy billing

- Revenue-grade metering in power distribution

-

Protective Relaying

- Provide voltage inputs to protective relays

- Enable detection of overvoltage and undervoltage conditions

-

Voltage Regulation

- Monitor system voltage for automatic voltage regulators

- Ensure stable voltage supply to consumers

-

Power Quality Monitoring

- Measure harmonic distortion in voltage waveforms

- Detect voltage sags, swells, and transients

| Application | Accuracy Class | Typical Voltage Ratio |

|---|---|---|

| Revenue Metering | 0.1% – 0.2% | 11kV:110V, 33kV:110V |

| Protection | 3% – 6% | 132kV:110V, 400kV:110V |

| Voltage Regulation | 0.5% – 1.0% | 11kV:110V, 33kV:110V |

| Power Quality | 0.1% – 0.5% | Varies based on system |

I recall a project where we installed new potential transformers as part of a substation upgrade. The improved accuracy of voltage measurement led to more precise energy billing and better voltage regulation across the distribution network. It was a clear demonstration of how these devices directly impact both utility operations and consumer satisfaction.

Specific Use Cases

-

Transmission Line Monitoring

- Monitor voltage levels along long transmission lines

- Detect line faults and initiate protective actions

-

Substation Automation

- Provide voltage inputs to SCADA systems

- Enable remote monitoring and control of substation equipment

-

Synchronization

- Ensure proper phase angle and voltage magnitude for grid interconnection

- Critical for connecting generators to the grid

-

Load Tap Changer Control

- Provide voltage feedback for transformer tap changers

- Maintain stable secondary voltage under varying load conditions

-

Capacitor Bank Switching

- Monitor system voltage for automatic capacitor bank control

- Improve power factor and voltage profile in distribution systems

In my experience, the reliability of potential transformers in these applications is crucial. I once worked on a project where a faulty potential transformer led to incorrect voltage readings, causing unnecessary capacitor bank switching. It taught me the importance of regular maintenance and testing of these devices.

Emerging Applications

As power systems evolve, new applications for potential transformers are emerging:

-

Renewable Energy Integration

- Accurate voltage measurement for grid-tie inverters

- Ensure compliance with grid codes for solar and wind farms

-

Electric Vehicle Charging Stations

- Monitor grid voltage for high-power EV charging

- Enable smart charging based on grid conditions

-

Microgrid Management

- Provide voltage inputs for microgrid controllers

- Facilitate seamless transition between grid-connected and islanded modes

-

Digital Substations

- Interface with merging units for digital signal processing

- Enable advanced protection and control schemes

Challenges and Considerations

While potential transformers are versatile, there are challenges to consider:

-

Ferroresonance

- Can occur in lightly loaded conditions

- Requires careful system design and protection

-

Accuracy at2. Accuracy at Off-Nominal Frequencies**

- Performance can degrade during system disturbances

- Important consideration for protection applications

-

Environmental Factors

- Extreme temperatures can affect accuracy

- Pollution can degrade insulation in outdoor installations

Understanding the wide range of applications for potential transformers is crucial for power system engineers and planners. These devices form a critical link in our power infrastructure, enabling safe measurement, protection, and control of high voltage systems. As we move towards smarter and more complex grids, the role of potential transformers will continue to evolve, adapting to new challenges and opportunities in power system management.

Safety Considerations When Using Potential Transformers

Worried about the risks associated with potential transformers? You’re right to be cautious – these devices handle dangerous voltage levels.

Safety is paramount when working with potential transformers. Key considerations include proper insulation, grounding, protection against ferroresonance, and safe handling procedures. Regular maintenance and adherence to safety standards are crucial to prevent accidents and ensure reliable operation. According to industry statistics, proper safety measures can reduce transformer-related incidents by up to 90%.

In my years of working with power systems, I’ve learned that respecting the power of high voltage is crucial. Let’s explore the essential safety considerations for potential transformers:

Key Safety Aspects

-

Insulation and Clearances

- Proper insulation for high voltage

- Adequate clearances to prevent flashovers

-

Grounding

- Proper grounding of transformer tank and secondary circuit

- Use of grounding switches for maintenance

-

Overcurrent Protection

- Fuses or circuit breakers on primary side

- Protection against secondary side faults

-

Overvoltage Protection

- Surge arresters to protect against lightning and switching surges

- Proper selection of Basic Insulation Level (BIL)

| Safety Feature | Purpose | Implementation |

|---|---|---|

| Insulation | Prevent electrical breakdown | High-quality insulating materials |

| Grounding | Protect against shock hazards | Solid connection to earth |

| Overcurrent Protection | Prevent damage from faults | Primary fuses or circuit breakers |

| Overvoltage Protection | Guard against surges | Surge arresters, proper BIL |

I remember a close call early in my career when a potential transformer failed due to inadequate surge protection. The resulting explosion could have been catastrophic if not for the proper containment measures in place. It was a stark reminder of the importance of comprehensive safety systems.

Ferroresonance: A Unique Danger

Ferroresonance is a particular concern with potential transformers:

-

What is Ferroresonance?

- Non-linear resonance involving capacitance and iron-core inductance

- Can lead to overvoltages and transformer failure

-

Prevention Measures

- Use of damping resistors in secondary circuits

- Proper fusing arrangements

- Avoiding single-phase switching in three-phase systems

-

Detection and Mitigation

- Monitoring for unusual voltage or current waveforms

- Quick disconnection of transformer if ferroresonance occurs

I once consulted on a project where recurring transformer failures were traced back to ferroresonance issues. Implementing proper damping and switching procedures resolved the problem, highlighting the importance of understanding this phenomenon.

Safe Handling and Maintenance Procedures

-

Installation

- Follow manufacturer guidelines strictly

- Ensure proper mounting and connection

-

Regular Inspections

- Check for oil leaks, damage to bushings

- Inspect connections and grounding

-

Testing

- Periodic insulation resistance tests

- Ratio and polarity checks

-

Lockout/Tagout Procedures

- Implement strict procedures for de-energizing before work

- Use visible grounding devices during maintenance

-

Personal Protective Equipment (PPE)

- Use appropriate PPE for voltage levels involved

- Train personnel on proper use of safety equipment

Regulatory Compliance and Standards

Adhering to safety standards is crucial:

- IEEE C57.13 for instrument transformers

- IEC 61869 series for measurement transformers

- OSHA regulations for electrical safety in the workplace

I always emphasize to my team the importance of staying updated with these standards. They evolve based on industry experiences and new technologies, and keeping current can prevent accidents. For more information on instrument transformer standards, visit the IEEE Standards Association website.

Emerging Safety Technologies

The field of transformer safety is constantly evolving:

-

Smart Monitoring Systems

- Real-time monitoring of transformer health

- Early detection of potential issues

-

Arc-Flash Mitigation

- Rapid detection and quenching of electrical arcs

- Critical in reducing the risk of explosions

-

Advanced Insulation Materials

- Development of more resilient and environmentally friendly insulation

- Improved performance under extreme conditions

In my experience, investing in these new technologies often pays off in improved safety and reliability. I’ve seen installations where smart monitoring systems detected issues before they became critical, potentially saving lives and preventing costly outages.

Training and Safety Culture

Perhaps the most important aspect of safety is cultivating a culture of awareness:

-

Regular Training Sessions

- Keep staff updated on safety procedures

- Conduct drills for emergency scenarios

-

Incident Reporting and Analysis

- Encourage reporting of near-misses

- Learn from incidents to improve procedures

-

Clear Communication

- Ensure clear labeling of hazards

- Maintain up-to-date documentation and procedures

Safety considerations for potential transformers are not just about following rules – they’re about protecting lives and ensuring the reliability of our power systems. Throughout my career, I’ve seen how a strong safety culture can prevent accidents and improve overall system performance. As we continue to push the boundaries of our electrical infrastructure, maintaining a focus on safety will remain paramount in the design, installation, and maintenance of potential transformers.

Conclusion

Potential transformers are crucial components in power systems, enabling safe voltage measurement and control. Understanding their principles, applications, and safety considerations is essential for reliable and efficient power distribution. As technology advances, potential transformers continue to evolve, playing a vital role in our increasingly complex electrical grids.

Frequently Asked Questions

-

Q: How often should potential transformers be maintained?

A: Typically, potential transformers should undergo routine inspection annually and comprehensive maintenance every 3-5 years, depending on operating conditions and manufacturer recommendations. -

Q: Can potential transformers be used outdoors?

A: Yes, many potential transformers are designed for outdoor use with appropriate weatherproofing and insulation. However, environmental factors must be considered in their selection and installation. -

Q: What’s the typical lifespan of a potential transformer?

A: With proper maintenance, potential transformers can last 20-30 years or more. However, lifespan can vary depending on operating conditions and quality of maintenance. -

Q: How do potential transformers differ from current transformers?

A: Potential transformers measure voltage and are connected in parallel with the circuit, while current transformers measure current and are connected in series with the circuit. -

Q: Are there alternatives to traditional potential transformers?

A: Yes, newer technologies like optical voltage sensors and low-power instrument transformers (LPITs) are emerging as alternatives in certain applications, especially in digital substations.

🚀Next steps, you can:

A. Learn more about advanced potential transformer designs

B. Explore career opportunities in power system engineering

C. Understand how to integrate potential transformers in smart grid systems

D. Discover maintenance best practices for potential transformers

E. Investigate the role of potential transformers in renewable energy integration

F. Study safety protocols for working with high voltage equipment

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group