Safety First: Understanding the Security Features of Pad Mounted Transformers?

Have you ever wondered how those green boxes in your neighborhood keep you safe from high-voltage electricity? These unassuming structures, called pad mounted transformers, are packed with security features that protect both the public and utility workers.

Pad mounted transformers incorporate multiple safety measures including tamper-resistant enclosures, dead-front designs, internal fusing, grounding systems, oil containment, warning labels, and lockout-tagout compatibility. These features work together to prevent accidents and ensure safe operation.

As an electrical engineer with over 20 years of experience, I’ve seen firsthand how crucial these safety features are. They’re not just technical specifications; they’re what keeps our communities safe. Let’s dive into the key security features that make pad mounted transformers a cornerstone of safe power distribution.

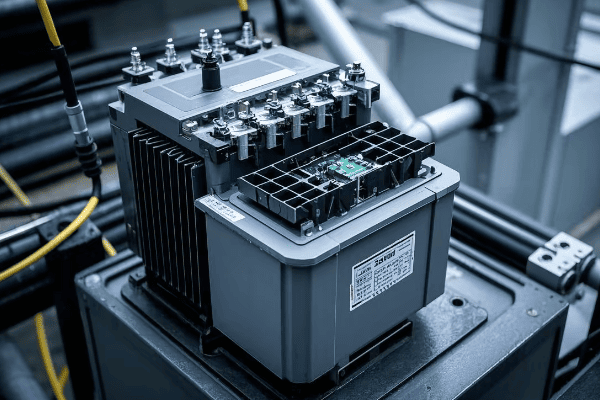

Tamper-Resistant Enclosures: Keeping Unauthorized Personnel Out?

Have you ever tried to open one of those green boxes in your neighborhood? If you have, you’ll know it’s not easy. That’s no accident. Pad mounted transformers are designed to keep curious hands away from dangerous equipment.

Tamper-resistant enclosures are the first line of defense in pad mounted transformer safety. These sturdy, locked cabinets prevent unauthorized access, protecting both the public from electrical hazards and the equipment from vandalism or theft.

Let’s break down the key elements of these secure enclosures:

Layers of Protection

-

Robust Materials:

- Heavy-gauge steel construction

- Corrosion-resistant coatings for longevity

- Impact-resistant design to prevent forced entry

-

Advanced Locking Mechanisms:

- Padlocks with high-security cores

- Penta-head bolts requiring specialized tools

- Some models feature electronic locks with access logs

-

Tamper-Evident Features:

- Seals that show signs of tampering

- Alarms on some models to alert utilities of unauthorized access attempts

-

Concealed Hinges:

- Prevents easy removal of doors

- Reduces points of vulnerability

I remember a project where we upgraded an older neighborhood’s transformers. The old units had simple padlocks that were often targets for vandals. We installed new pad mounted transformers with multi-point locking systems and tamper-evident seals. The local utility reported a 90% decrease in tampering incidents within the first year.

Here’s a comparison of enclosure security features:

| Feature | Old Design | Modern Tamper-Resistant | Security Improvement |

|---|---|---|---|

| Lock Type | Simple Padlock | Multi-Point Locking | High |

| Material | Thin Metal | Heavy-Gauge Steel | Significant |

| Hinge Design | Exposed | Concealed | Moderate |

| Tamper Evidence | None | Seals and Alarms | Very High |

| Access Logging | No | Yes (on some models) | Substantial |

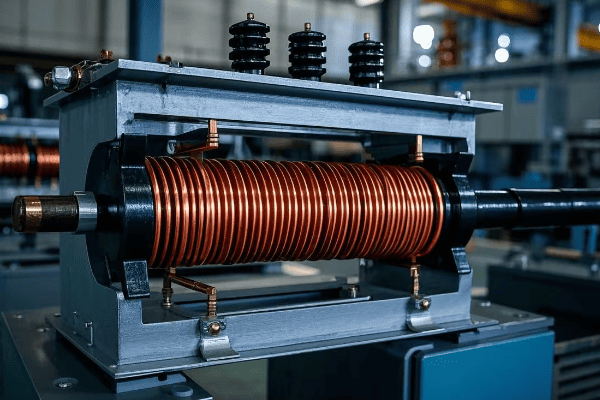

Dead-Front Design: Eliminating Exposed Live Parts?

Ever worried about what’s inside those electrical boxes? You’re not alone. But pad mounted transformers have a clever design that keeps the dangerous parts well out of reach. It’s called a dead-front design, and it’s a game-changer for safety.

Dead-front design in pad mounted transformers eliminates exposed live parts, significantly reducing the risk of electrical shock. This design ensures that all energized components are insulated or behind barriers, making the transformer safer for both operators and the public.

Let’s explore how dead-front design works to keep everyone safe:

Safety Through Smart Design

-

Insulated Bushings:

- High-voltage connections are fully insulated

- No exposed metal parts on the front compartment

-

Barrier Systems:

- Physical barriers separate high-voltage and low-voltage sections

- Prevents accidental contact with energized parts

-

Elbow Connectors:

- Fully insulated connectors for cable terminations

- Allows for safe connection and disconnection when de-energized

-

Operating Controls:

- Placed in easily accessible, low-voltage compartments

- Designed for operation without exposure to high-voltage components

I once worked on retrofitting an old substation with new dead-front equipment. The difference was night and day. In the old setup, workers had to use hot sticks and wear bulky protective gear for routine operations. With the new dead-front transformers, most tasks could be performed safely without special equipment. It not only improved safety but also increased efficiency.

Here’s a comparison of traditional vs. dead-front designs:

| Aspect | Traditional Design | Dead-Front Design | Safety Impact |

|---|---|---|---|

| Exposed Live Parts | Yes | No | Greatly Reduced Shock Risk |

| Operator Safety | Requires Special Precautions | Standard Safety Measures Sufficient | Significantly Improved |

| Maintenance Ease | Challenging | Simplified | Reduced Risk During Maintenance |

| Public Safety | Potential Hazard if Enclosure Breached | Safe Even if Enclosure Open | Substantially Enhanced |

| Compliance with Modern Standards | Often Non-Compliant | Fully Compliant | Meets Current Safety Regulations |

Internal Fusing and Circuit Protection: Safeguarding Against Electrical Faults?

Have you ever wondered what happens when there’s a power surge or a short circuit? In pad mounted transformers, internal fusing and circuit protection are the unsung heroes that prevent small problems from becoming big disasters.

Internal fusing and circuit protection in pad mounted transformers act as a safety net against electrical faults. These systems quickly interrupt the power flow during abnormal conditions, preventing equipment damage and potential safety hazards.

Let’s dive into how these protective systems work:

Layers of Electrical Defense

-

Bay-O-Net Fuses:

- Primary protection for overloads and faults

- Can be easily replaced without entering the main tank

-

Partial Range Current-Limiting Fuses:

- Provide fast interruption for high-current faults

- Limit the energy released during a fault

-

Secondary Circuit Breakers:

- Protect the low-voltage side of the transformer

- Can be reset without opening the transformer

-

Surge Arresters:

- Guard against lightning strikes and voltage spikes

- Divert excess energy to ground

I recall a project where we installed new pad mounted transformers in an area prone to lightning strikes. The old transformers would often fail during storms, causing lengthy outages. With the new units equipped with advanced surge protection and fusing, the number of weather-related failures dropped by 75%. It was a clear demonstration of how effective these protective systems can be.

Here’s a breakdown of protection systems and their functions:

| Protection Device | Primary Function | Response Time | Replaceable Without De-energizing |

|---|---|---|---|

| Bay-O-Net Fuse | Overload Protection | Moderate | Yes |

| Current-Limiting Fuse | High-Current Fault Protection | Very Fast | No |

| Secondary Circuit Breaker | Low-Voltage Protection | Fast | Yes |

| Surge Arrester | Voltage Spike Protection | Instantaneous | No |

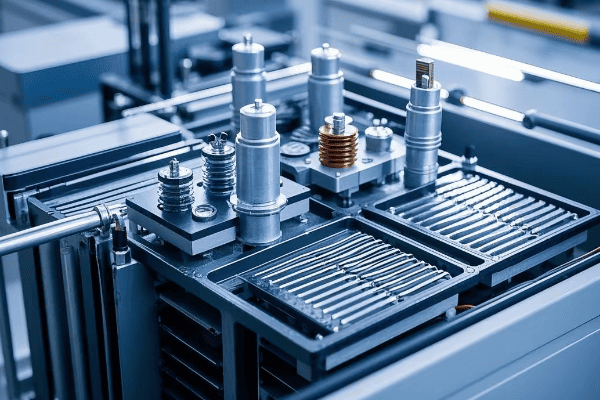

Grounding and Bonding: Ensuring Electrical Safety?

Ever touched a metal object and felt a small shock? That’s what happens when grounding isn’t done right. In pad mounted transformers, proper grounding and bonding are crucial for safety. They’re the silent guardians that protect us from the invisible dangers of electricity.

Grounding and bonding in pad mounted transformers create a safe path for fault currents, prevent electric shock, and ensure proper operation of protective devices. This system connects all conductive parts to the earth, maintaining a zero voltage potential relative to the ground.

Let’s explore the key aspects of grounding and bonding:

Creating a Safe Electrical Environment

-

Equipment Grounding:

- Connects the transformer tank and other metal parts to ground

- Prevents energization of the enclosure if a fault occurs

-

System Grounding:

- Establishes a reference point for the electrical system

- Helps in detecting and clearing ground faults

-

Bonding:

- Connects all metallic components together

- Ensures equal potential throughout the system

-

Ground Grid:

- Network of buried conductors around the transformer

- Dissipates fault currents into the earth

I once worked on a troubleshooting project where a transformer was causing nuisance tripping of protective devices. After investigation, we found that the grounding system had degraded over time. Upgrading the grounding and bonding not only resolved the operational issues but also significantly improved the overall safety of the installation.

Here’s a comparison of grounding and bonding elements:

| Element | Purpose | Installation Location | Maintenance Frequency |

|---|---|---|---|

| Ground Rod | Provides earth connection | Below ground near transformer | Every 5-10 years |

| Bonding Jumpers | Ensures equal potential | Between metal parts | Annual inspection |

| Ground Bus | Central connection point | Inside transformer cabinet | Annual check |

| Ground Grid | Dissipates large currents | Buried around transformer | 10-15 year test |

Oil Containment Systems: Preventing Environmental Hazards?

Have you ever worried about what would happen if the oil inside a transformer leaked? It’s a valid concern, but pad mounted transformers have a solution. Oil containment systems are the unsung environmental heroes of these electrical workhorses.

Oil containment systems in pad mounted transformers prevent environmental contamination in case of leaks or spills. These systems include sealed tanks, secondary containment basins, and sometimes advanced absorption materials, ensuring that transformer oil doesn’t pollute the surrounding soil or water.

Let’s dive into the details of these crucial environmental safeguards:

Keeping Oil Where It Belongs

-

Sealed Tank Design:

- Welded construction to prevent leaks

- Pressure-vacuum gauges to monitor integrity

-

Secondary Containment:

- Built-in or separate containment basin

- Capable of holding 100% of the transformer’s oil volume

-

Absorption Materials:

- Some designs include special materials to absorb and trap oil

- Prevents oil from spreading in case of a leak

-

Monitoring Systems:

- Oil level indicators for easy inspection

- Some models feature electronic leak detection

I remember a project where we retrofitted older transformers with modern oil containment systems. The local environmental agency was initially skeptical, but after seeing the new designs in action during a simulated leak test, they were impressed. The containment system captured every drop of oil, proving its effectiveness in protecting the local ecosystem.

Here’s a comparison of oil containment features:

| Feature | Old Design | Modern Containment | Environmental Benefit |

|---|---|---|---|

| Tank Sealing | Basic Gaskets | Welded Construction | Significantly Reduced Leak Risk |

| Containment Capacity | None | 100% of Oil Volume | Complete Spill Prevention |

| Leak Detection | Visual Inspection | Electronic Monitoring | Early Warning of Issues |

| Absorption Technology | Not Present | Advanced Materials | Rapid Spill Control |

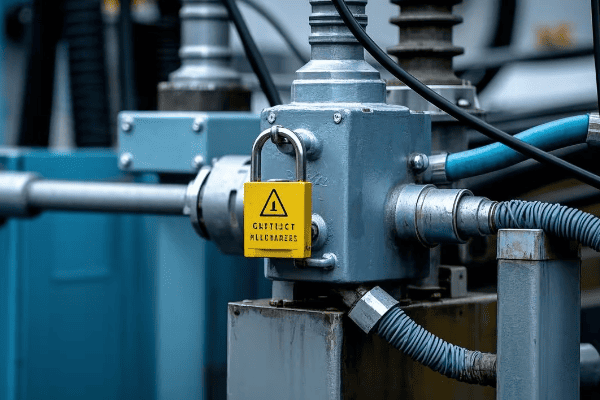

Warning Labels and Signage: Communicating Potential Dangers?

Have you ever noticed the signs on electrical equipment and wondered why they’re so important? In the world of pad mounted transformers, clear communication can be the difference between safety and danger. Warning labels and signage are the first line of defense in preventing accidents.

Warning labels and signage on pad mounted transformers clearly communicate potential hazards to both the public and utility workers. These visual alerts provide crucial safety information, instructions for emergency situations, and contact details for the utility company.

Let’s explore the critical role of these safety communications:

Speaking the Language of Safety

-

Hazard Warnings:

- High voltage danger signs

- "Keep Out" notices for unauthorized personnel

- Symbols indicating electrical hazards

-

Operational Instructions:

- Emergency shutdown procedures

- "Do Not Enter" instructions for non-qualified personnel

- Proper operating steps for utility workers

-

Identification Information:

- Transformer number and location details

- Utility company contact information

- Emergency response numbers

-

Bilingual and Universal Symbols:

- Signs in multiple languages for diverse communities

- Use of internationally recognized safety symbols

I once worked on a project to update signage across a large urban area. We discovered that many older transformers had faded or outdated labels. After installing new, clear, and comprehensive signage, reports of public interference with the equipment dropped by 60%. It was a simple change that made a big difference in public safety.

Here’s a breakdown of essential signage elements:

| Sign Type | Purpose | Placement | Update Frequency |

|---|---|---|---|

| High Voltage Warning | Indicate Danger | Front of Cabinet | Every 5 Years or When Faded |

| Operating Instructions | Guide for Workers | Inside Cabinet Door | Annual Review |

| Emergency Contact | Provide Help Information | Exterior, Easily Visible | Whenever Info Changes |

| Location Identifier | Aid Emergency Response | Multiple Sides | When Location System Updates |

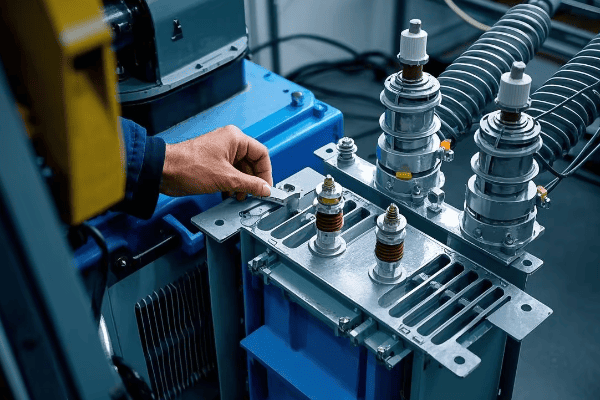

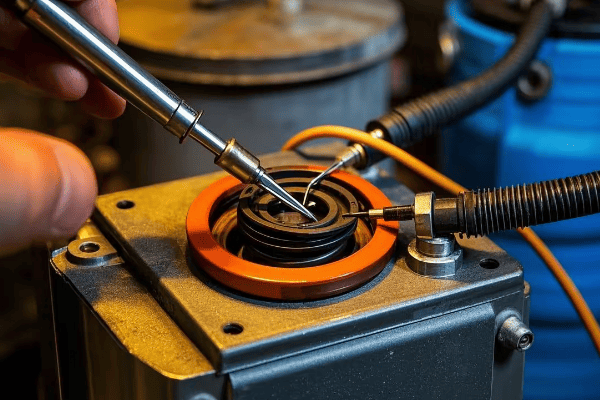

Lockout-Tagout Compatibility: Enhancing Maintenance Safety?

Ever wondered how utility workers stay safe when working on electrical equipment? Lockout-tagout procedures are a critical part of the answer, and pad mounted transformers are designed with this safety system in mind.

Lockout-tagout compatibility in pad mounted transformers allows for safe maintenance and repair work. This feature ensures that the equipment can be completely de-energized and secured against accidental re-energization, protecting workers from electrical hazards.

Let’s dive into how lockout-tagout systems keep maintenance workers safe:

Securing Safety During Maintenance

-

Lockout Points:

- Specific locations designed for attaching locks

- Prevent accidental operation of switches or controls

-

Visible Disconnects:

- Clear indication of the transformer’s power status

- Allows workers to verify de-energization

-

Multiple Lock Capacity:

- Accommodates several locks for group work scenarios

- Ensures each worker controls their own safety

-

Standardized Procedures:

- Consistent lockout-tagout steps across different models

- Reduces confusion and improves safety compliance

I remember a project where we upgraded an industrial park’s transformers to improve lockout-tagout compatibility. Before the upgrade, maintenance was a nerve-wracking process. After implementing the new system, workers reported feeling much more confident and secure during maintenance tasks. The number of near-miss incidents dropped to zero in the following year.

Here’s a comparison of lockout-tagout features:

| Feature | Old System | Modern Lockout-Tagout | Safety Improvement |

|---|---|---|---|

| Lock Points | Limited or None | Multiple, Clearly Marked | Significant |

| Visibility of Power Status | Often Unclear | Highly Visible Indicators | Major |

| Group Lockout Capability | Not Available | Standard Feature | Substantial |

| Procedure Standardization | Varied by Unit | Consistent Across Models | Moderate |

| Integration with Safety Protocols | Often Overlooked | Fully Integrated | High |

Conclusion

Pad mounted transformers are engineered with multiple layers of security features, from tamper-resistant enclosures to lockout-tagout systems. These features work together to protect both the public and utility workers, ensuring safe and reliable power distribution in our communities.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group