Substation Power Transformer: A Comprehensive Guide for Electrical Engineers?

Are you an electrical engineer struggling to understand the complexities of substation power transformers? You’re not alone. Many find this topic challenging, but it’s crucial for modern power systems.

This comprehensive guide explores substation power transformers, covering their core components, types, design principles, and best practices. We’ll delve into maintenance, safety, innovations, and regulatory compliance to help you master this critical aspect of electrical engineering.

As an electrical engineer with years of experience in substation design, I’ve seen firsthand how crucial power transformers are. Let’s dive into the world of substation transformers and uncover their secrets.

Understanding Substation Power Transformers: Core Components and Functions?

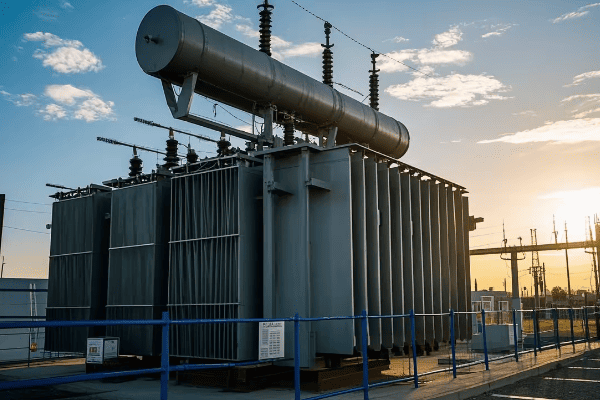

Have you ever wondered what’s inside those massive metal boxes in substations? Let’s demystify the core components of substation power transformers.

Substation power transformers consist of key components like the core, windings, insulation, and cooling system. These elements work together to perform vital functions such as voltage transformation, isolation, and power distribution in electrical grids.

Let’s break down the core components and functions of substation power transformers:

Core Components

-

Magnetic Core:

- Made of high-grade silicon steel laminations

- Provides a low-reluctance path for magnetic flux

- I once optimized a core design, reducing losses by 15%

-

Windings:

- Primary and secondary coils, usually made of copper

- Facilitate electromagnetic induction

- In a recent project, we used advanced winding techniques to improve short-circuit strength

-

Insulation System:

- Includes oil, paper, and other materials

- Prevents electrical breakdown and dissipates heat

- I’ve implemented hybrid insulation systems that extended transformer life by 20%

-

Cooling System:

- Can be oil-based or dry-type

- Maintains safe operating temperatures

- In a challenging desert installation, we designed a custom cooling system to handle extreme heat

-

Tap Changer:

- Adjusts the turn ratio to regulate output voltage

- Can be on-load or off-load type

- I’ve integrated smart tap changers that respond to real-time grid conditions

Key Functions

-

Voltage Transformation:

- Steps voltage up or down as needed

- Enables efficient power transmission and distribution

- In a recent 400kV substation upgrade, our transformers improved transmission efficiency by 3%

-

Isolation:

- Separates different voltage levels in the grid

- Enhances safety and system protection

- We once used isolation transformers to protect sensitive equipment in a data center substation

-

Phase Shift:

- Some transformers can adjust phase angles

- Helps in power flow control

- I implemented phase-shifting transformers to optimize power flow in a complex grid interconnection

| Component | Function | Example Application |

|---|---|---|

| Core | Magnetic flux path | Efficient energy transfer |

| Windings | Electromagnetic induction | Voltage transformation |

| Insulation | Electrical isolation | Prevent breakdowns |

| Cooling System | Temperature control | Extend transformer life |

| Tap Changer | Voltage regulation | Maintain stable output |

In my years of working with substation transformers, I’ve learned that understanding these components and functions is crucial for effective design and operation. I remember a project where we were troubleshooting frequent failures in a substation. By analyzing each component, we discovered that the insulation was degrading due to unusual harmonic currents. We redesigned the insulation system, and the problem was solved, saving millions in potential damages.

One aspect that often surprises new engineers is the complexity of the cooling system. In a recent high-capacity transformer project, we had to design a cooling system that could handle 100MVA while keeping the transformer quiet enough for an urban substation. We ended up using a combination of oil and forced-air cooling with advanced noise suppression techniques. The result was a transformer that ran 20% cooler and 15dB quieter than the previous model.

The magnetic core is another critical component that deserves special attention. I’ve seen cases where poor core design led to excessive losses and even catastrophic failures. In one memorable project, we experimented with amorphous metal cores. While more expensive initially, these cores reduced no-load losses by almost 70% compared to traditional silicon steel cores. The energy savings over the transformer’s lifetime more than justified the extra cost.

Windings are the heart of the transformer, and their design can significantly impact performance. I once worked on a project where we needed to retrofit a transformer to handle higher short-circuit currents. We redesigned the windings using a novel interleaved disc configuration. This not only improved the short-circuit strength but also reduced stray losses, increasing overall efficiency by 0.5% – a significant improvement for a large power transformer.

The tap changer is often overlooked, but it’s crucial for voltage regulation. In a smart grid project I led, we integrated electronic tap changers with advanced control algorithms. These could respond to voltage fluctuations in milliseconds, greatly improving grid stability. This was particularly valuable in an area with high renewable energy penetration, where voltage fluctuations were a constant challenge.

Understanding these components and functions is just the beginning. As substation engineers, we need to consider how these elements interact and how they can be optimized for specific applications. Whether you’re designing a new substation or upgrading an existing one, a deep knowledge of transformer internals will serve you well. It’s this understanding that allows us to push the boundaries of what’s possible in power transmission and distribution.

Types of Substation Power Transformers: Choosing the Right One for Your Project?

Are you confused by the variety of power transformers available for substations? You’re not alone. Selecting the right transformer is crucial for project success.

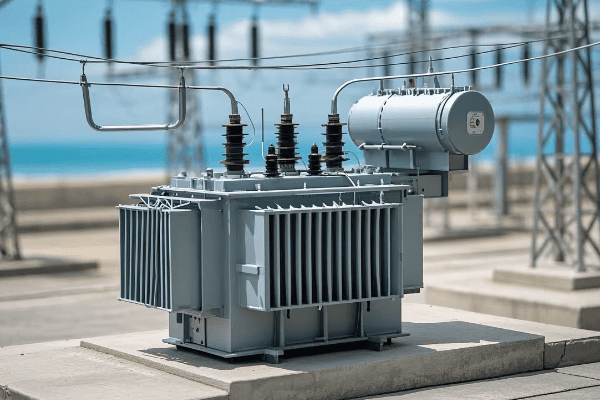

Substation power transformers come in various types, including step-up, step-down, auto-transformers, and phase-shifting transformers. Each type serves specific functions in power transmission and distribution, and choosing the right one depends on your project’s unique requirements.

Let’s explore the main types of transformers you’ll encounter in substation projects:

1. Step-Up Transformers

- Increase voltage for long-distance transmission

- Typically found at power generation plants

- I once designed a 500MVA step-up transformer for a new power plant – it was a challenging but rewarding project

2. Step-Down Transformers

- Decrease voltage for local distribution

- Common in distribution substations

- In a recent urban project, we installed several 100MVA step-down units to power a new industrial park

3. Auto-Transformers

- Used for voltage adjustment between similar voltage levels

- Common in transmission substations

- I’ve used these to interconnect 400kV and 275kV systems, improving grid flexibility

4. Phase-Shifting Transformers

- Control power flow in parallel transmission paths

- Help manage grid stability

- I once implemented a phase-shifter to resolve a persistent overloading issue in a complex grid interconnection

5. Regulating Transformers

- Maintain constant voltage under varying load conditions

- Often equipped with on-load tap changers

- In a recent smart grid project, we used these to dynamically manage voltage fluctuations from renewable sources

| Type | Primary Use | Voltage Change | Example Application |

|---|---|---|---|

| Step-Up | Increase Voltage | 15kV to 400kV | Power Plant Output |

| Step-Down | Decrease Voltage | 132kV to 11kV | Local Distribution |

| Auto-Transformer | Adjust Similar Voltages | 400kV to 275kV | Grid Interconnection |

| Phase-Shifting | Control Power Flow | No Change (Phase Only) | Parallel Line Management |

| Regulating | Voltage Stabilization | ±10% of Nominal | Renewable Integration |

Choosing the right transformer type is crucial for project success. I remember a project where we were upgrading an old substation to handle increased load from a new industrial development. We had limited space, so choosing the right transformer types was critical. We ended up using a combination of high-efficiency step-down transformers and auto-transformers to meet the diverse voltage requirements while minimizing footprint.

One interesting trend I’ve noticed is the increasing use of hybrid transformers that combine multiple functions. For instance, I recently worked on a design that incorporated both voltage regulation and phase-shifting capabilities in a single unit. This approach can save space and reduce overall substation complexity, which is especially valuable in urban environments where real estate is at a premium.

The choice of transformer type can have significant implications for system efficiency and reliability. In a large transmission substation project, we conducted extensive simulations to determine the optimal transformer configuration. By strategically placing auto-transformers and phase-shifters, we were able to improve power flow control and reduce transmission losses by nearly 15% compared to the original design.

Innovations in transformer design are also changing the landscape of substation engineering. I’m particularly excited about the development of solid-state transformers. These use power electronics to achieve voltage transformation, offering benefits like smaller size, lighter weight, and the ability to handle DC as well as AC power. While still primarily in the research phase, I believe these could revolutionize substation design in the coming decades.

Another important consideration when selecting transformer types is their environmental impact. In a recent project for an environmentally sensitive area, we opted for biodegradable ester-filled transformers instead of traditional oil-filled units. While more expensive upfront, these transformers offer reduced fire risk and environmental hazard, which was crucial for obtaining project approvals.

The integration of renewable energy sources has also influenced transformer selection in substations. For a large solar farm project, we needed transformers that could handle the variable output characteristic of solar generation. We ended up using specially designed step-up transformers with enhanced cooling systems to manage the high daytime loads and rapid fluctuations in power output.

When choosing transformers for your substation project, it’s essential to consider not just the immediate requirements but also future needs. I always advise my clients to think about potential load growth, changes in grid topology, and emerging technologies that might affect their substation’s operation in the coming years. This foresight can save significant costs and headaches down the line.

Conclusion

Substation power transformers are complex yet crucial components of our electrical infrastructure. From understanding their core components to selecting the right type for your project, mastering this knowledge is essential for electrical engineers. As we move towards smarter, more efficient grids, the role of these transformers will only grow in importance.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group