The Evolution of Dry Type Transformer Types: Past, Present, and Future?

Have you ever wondered how the transformers powering our world have changed over time? The story of dry type transformers is a fascinating journey through technological innovation. It’s a tale that continues to unfold, shaping our energy future.

Dry type transformers have evolved from simple air-cooled designs to sophisticated, efficient, and environmentally friendly technologies. This evolution spans from early 20th century models to modern cast resin and vacuum pressure impregnated (VPI) types. The future promises smart, sustainable transformers integrated with digital technologies for enhanced performance and grid stability.

In my years working with power systems, I’ve witnessed firsthand the remarkable progress in dry type transformer technology. From bulky, inefficient models to sleek, high-performance units, the transformation has been incredible. Let’s explore this evolution and peek into the future of these essential devices.

The Origins of Dry Type Transformers: Tracing the Roots of Modern Power Distribution?

Did you know that the first transformers were actually "dry" by default? It’s true! The story of dry type transformers begins with the very invention of the transformer itself. But how did we get from those early models to the advanced units we use today?

The origins of dry type transformers can be traced back to the late 19th century. Early transformers were naturally air-cooled and considered "dry." As power demands grew, oil-filled transformers became prevalent. However, safety concerns and technological advancements in the mid-20th century led to the resurgence and development of modern dry type transformers.

I’ve always been fascinated by the history of electrical engineering. Let’s dive deeper into the origins of dry type transformers:

The Early Days

From humble beginnings:

- 1885: First commercial transformer by William Stanley, naturally air-cooled.

- Early 1900s: Growth of electrical grids increased demand for larger transformers.

- 1920s-1940s: Oil-filled transformers dominate due to better cooling capabilities.

I once had the chance to see a restored Stanley transformer from the 1890s. It was a simple, yet ingenious design that laid the foundation for all modern transformers.

The Resurgence of Dry Types

Safety drives innovation:

| Decade | Development | Impact |

|---|---|---|

| 1950s | Introduction of modern dry type designs | Improved safety in indoor applications |

| 1960s | Advancements in insulation materials | Enhanced performance and reliability |

| 1970s | Development of cast resin technology | Increased use in harsh environments |

During my early career, I worked on replacing old oil-filled transformers in a city building with modern dry types. The improvement in safety and peace of mind for the building managers was remarkable.

The Push for Efficiency

Meeting growing energy demands:

- 1980s: Focus on energy efficiency leads to improved core materials.

- 1990s: Introduction of amorphous metal cores for lower losses.

- 2000s: Refinement of vacuum pressure impregnation (VPI) techniques.

I remember the excitement when we first installed an amorphous core transformer in a data center. The reduction in energy losses compared to traditional silicon steel cores was impressive, marking a new era in transformer efficiency.

Technological Milestones: Key Innovations in Dry Type Transformer Design?

Ever wondered how dry type transformers went from basic air-cooled units to the high-tech marvels we see today? The journey is marked by several groundbreaking innovations. But what were these key technological leaps?

Key innovations in dry type transformer design include the development of cast resin technology, vacuum pressure impregnation (VPI) processes, advanced insulation materials, and more efficient core designs. These milestones have significantly improved performance, reliability, and safety, enabling dry type transformers to meet increasingly demanding power distribution needs.

Throughout my career, I’ve seen these innovations transform the industry. Let’s explore the most significant technological milestones:

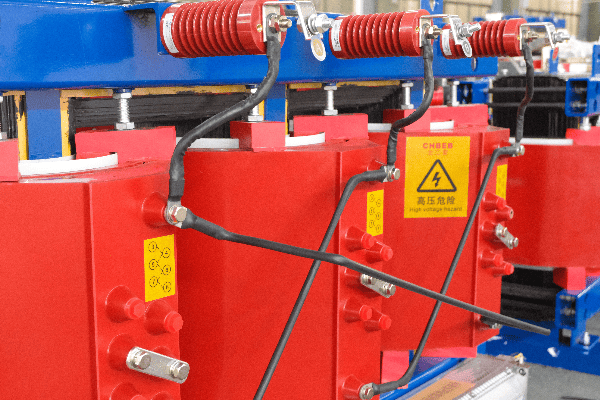

Cast Resin Technology

A game-changer in harsh environments:

- 1970s: Introduction of epoxy resin encapsulation.

- 1980s: Refinement of casting techniques for larger transformers.

- 1990s: Development of fire-resistant and low-smoke resin formulations.

I once worked on a project replacing old transformers in a coastal chemical plant. The cast resin units we installed were able to withstand the corrosive atmosphere far better than any previous technology.

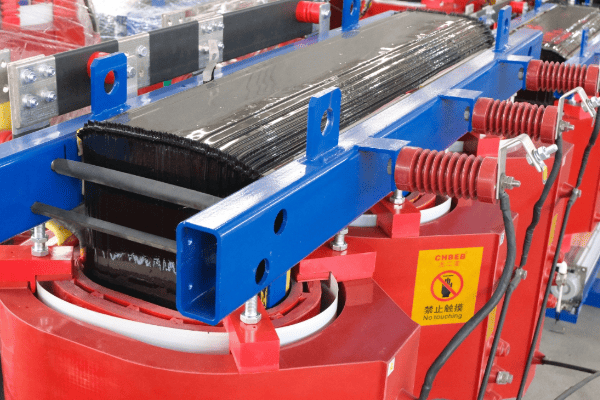

Vacuum Pressure Impregnation (VPI)

Enhancing insulation and cooling:

| Aspect | Improvement | Benefit |

|---|---|---|

| Insulation | Better penetration of resin | Increased lifespan and reliability |

| Cooling | Improved heat dissipation | Higher efficiency and overload capacity |

| Customization | Flexible design options | Adaptable to various applications |

In a recent data center project, we used VPI transformers to meet the strict efficiency and reliability requirements. The ability to customize the design for optimal cooling was crucial in this high-heat environment.

Advanced Core Materials

Pushing the boundaries of efficiency:

- 1980s: Introduction of grain-oriented silicon steel.

- 1990s: Development of amorphous metal cores.

- 2000s: Nanocrystaline materials for ultra-low losses.

I remember the first time I specified an amorphous core transformer for a renewable energy project. The reduction in core losses was so significant that it noticeably improved the overall system efficiency.

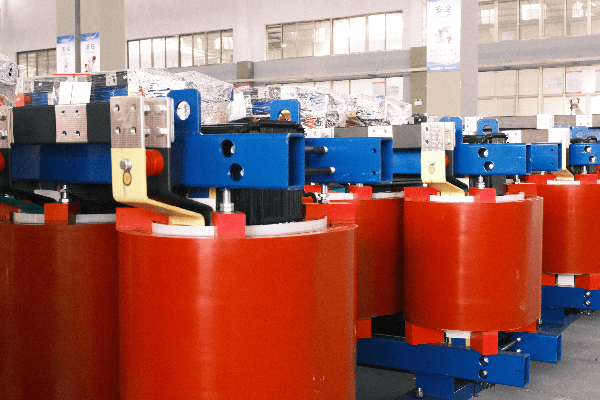

Current State of the Art: Analyzing Modern Dry Type Transformer Technologies?

Curious about what makes today’s dry type transformers so special? The current state of the art in transformer technology is a blend of advanced materials, precision engineering, and smart design. But what exactly sets modern transformers apart?

Modern dry type transformers incorporate cutting-edge technologies like advanced thermal management systems, high-efficiency core materials, and smart monitoring capabilities. They offer improved energy efficiency, reduced environmental impact, and enhanced reliability. Current designs focus on compact sizes, higher power densities, and integration with smart grid technologies.

In my recent projects, I’ve had the opportunity to work with some of the most advanced dry type transformers available. Here’s an in-depth look at the current state of the art:

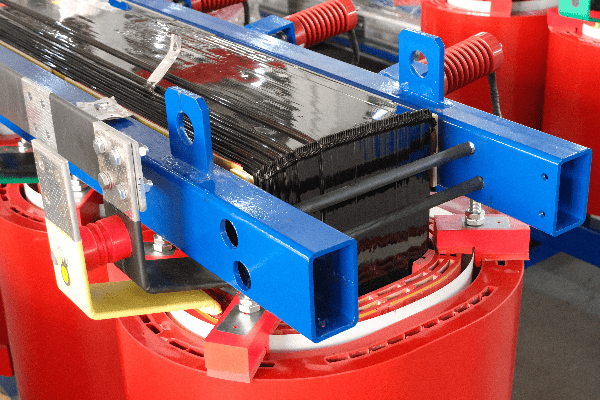

Advanced Thermal Management

Keeping cool under pressure:

- Computational Fluid Dynamics (CFD) for optimized cooling designs.

- Use of thermally conductive materials in winding and core construction.

- Integration of advanced sensors for real-time temperature monitoring.

I recently oversaw the installation of a large dry type transformer with an advanced cooling system in a data center. The unit’s ability to maintain optimal temperatures even under heavy loads was impressive, ensuring reliable operation in this critical environment.

High-Efficiency Core Materials

Pushing the limits of efficiency:

| Material | Advantage | Application |

|---|---|---|

| Amorphous Metal | Ultra-low core losses | Distribution transformers |

| Nanocrystaline | Excellent high-frequency performance | Medium voltage transformers |

| Advanced Silicon Steel | Balance of performance and cost | Various applications |

In a recent industrial project, we used transformers with nanocrystaline cores. The improvement in efficiency, especially under partial load conditions which were common in this facility, led to significant energy savings.

Smart Monitoring and Diagnostics

Predictive maintenance becomes reality:

- Integration of IoT sensors for real-time data collection.

- Use of AI algorithms for predictive maintenance.

- Remote monitoring and control capabilities.

I helped implement a smart monitoring system for a fleet of transformers in a large utility company. The system’s ability to predict potential issues before they became problems significantly reduced downtime and maintenance costs.

Future Horizons: Emerging Trends and Predictions in Dry Type Transformer Development?

What will the transformers of tomorrow look like? As we stand on the brink of a new era in power distribution, the future of dry type transformers is both exciting and challenging. But what trends are shaping this future?

Future dry type transformers are likely to be smarter, more efficient, and more sustainable. Emerging trends include the use of superconducting materials, integration with renewable energy systems, and advanced AI-driven optimization. We can expect transformers that are not just passive power distribution components, but active, intelligent parts of a smart grid ecosystem.

As someone who’s been in this industry for years, I’m thrilled by the possibilities on the horizon. Let’s explore some of the most promising trends:

Superconducting Transformers

The next leap in efficiency:

- Near-zero resistance materials for minimal losses.

- Compact designs with higher power densities.

- Potential for room-temperature superconductors in the future.

I recently attended a conference where prototype superconducting transformers were showcased. While still in the experimental stage, the potential for drastically reduced losses and smaller sizes is incredibly promising.

Integration with Renewable Energy

Adapting to a changing grid:

| Aspect | Challenge | Solution |

|---|---|---|

| Variable Input | Fluctuating renewable sources | Adaptive voltage regulation |

| Bidirectional Power Flow | Grid feed-in from renewables | Smart power management |

| Energy Storage Integration | Balancing supply and demand | Hybrid transformer-storage systems |

In a recent project, I worked on integrating dry type transformers with a large solar farm. The ability of these new transformers to handle variable inputs and bidirectional power flow was crucial for the system’s efficiency.

AI-Driven Optimization

Transformers get smart:

- Real-time load management and efficiency optimization.

- Predictive maintenance using machine learning algorithms.

- Self-diagnosing and self-healing capabilities.

I’m currently involved in a pilot project testing AI-optimized transformers in a smart city initiative. The early results show promising improvements in grid stability and energy efficiency.

Sustainability and Smart Technology: Shaping the Next Generation of Dry Type Transformers?

How can we make transformers not just powerful, but also planet-friendly and intelligent? This question is driving the next wave of innovation in dry type transformer technology. But what exactly does a sustainable and smart transformer look like?

The next generation of dry type transformers will focus on sustainability and smart technology integration. This includes the use of eco-friendly materials, designs optimized for recyclability, and incorporation of digital technologies for enhanced monitoring and control. These transformers will be key components in creating more efficient, reliable, and environmentally friendly power distribution systems.

In my recent work, I’ve been increasingly involved in projects that prioritize sustainability and smart technology. Here’s what I see shaping the future:

Eco-Friendly Materials and Design

Building a greener grid:

- Biodegradable insulation materials.

- Designs optimized for easy recycling at end-of-life.

- Use of recycled materials in transformer construction.

I recently consulted on a project where we specified transformers with biodegradable insulation. The client was impressed not just by the performance, but by the reduced environmental impact over the transformer’s lifecycle.

Energy Efficiency and Loss Reduction

Pushing the limits of efficiency:

| Technology | Benefit | Impact |

|---|---|---|

| Advanced Core Materials | Ultra-low core losses | Reduced energy waste |

| Optimized Winding Designs | Lower copper losses | Improved overall efficiency |

| Smart Load Management | Efficiency at all load levels | Adaptive performance |

In a recent industrial installation, we used transformers with advanced core materials and optimized windings. The reduction in losses was so significant that it noticeably reduced the facility’s overall energy consumption.

Digital Integration and Smart Grid Compatibility

Transformers join the IoT revolution:

- Real-time monitoring and data analytics.

- Integration with smart grid systems for dynamic load balancing.

- Cybersecurity features to protect critical infrastructure.

I’m currently working on a project to upgrade a city’s power distribution network with smart transformers. The ability of these units to communicate with the grid management system is revolutionizing how we approach power distribution and maintenance.

Conclusion

The evolution of dry type transformers reflects a journey of continuous innovation, from basic air-cooled designs to advanced, smart, and sustainable technologies. Future developments promise even more efficient, environmentally friendly, and intelligent transformer solutions, shaping the future of power distribution.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group