The Ultimate Guide to Creating a Three-Phase Transformer from Single-Phase Units?

Are you facing a power dilemma? Maybe you need three-phase power but only have single-phase transformers on hand. Don’t worry, you’re not alone in this challenge.

Creating a three-phase transformer from single-phase units is not only possible but can be a cost-effective solution. This guide will walk you through the process, from basic concepts to practical steps, helping you make an informed decision for your power needs.

As an electrical engineer with years of experience, I’ve helped many clients tackle this exact problem. In this guide, I’ll share practical insights to help you understand and implement this conversion safely and efficiently. Whether you’re a seasoned pro or new to electrical systems, you’ll find valuable information here.

Understanding the Basics: Single-Phase vs Three-Phase Power Systems?

Ever wondered why your home uses a different electrical system than a factory? The answer lies in the difference between single-phase and three-phase power. But what exactly sets these two apart?

Single-phase power uses one alternating current, while three-phase uses three currents offset by 120 degrees. Three-phase is more efficient for large loads, delivering more power with the same current and providing smoother operation for motors.

Let’s break this down further:

Single-Phase vs Three-Phase: A Simple Comparison

-

Single-Phase Power:

- Used in: Homes, small offices

- Wiring: Two wires (one power, one neutral)

- Power delivery: Pulsating

- Best for: Light loads, appliances

-

Three-Phase Power:

- Used in: Factories, large buildings

- Wiring: Three or four wires

- Power delivery: Constant

- Best for: Heavy machinery, industrial equipment

I once helped a small business owner who was expanding his workshop. He was surprised to learn that switching to three-phase could reduce his energy bills by 15% and make his machines run more smoothly. It’s a common "aha" moment for many.

Here’s a quick comparison table:

| Feature | Single-Phase | Three-Phase |

|---|---|---|

| Wires | 2 | 3 or 4 |

| Power Consistency | Pulsating | Constant |

| Efficiency for Large Loads | Lower | Higher |

| Typical Applications | Residential | Industrial |

| Motor Starting | Less Efficient | More Efficient |

The Basics of Delta and Wye Connections in Three-Phase Transformers?

When setting up a three-phase system, you’ll often hear about Delta and Wye connections. But what are they, and why do they matter?

Delta and Wye are two ways to connect three-phase transformers. Delta forms a triangle, while Wye forms a star with a neutral point. The choice affects voltage relationships, current flow, and system grounding.

Let’s explore these connections:

Delta vs Wye: What’s the Difference?

-

Delta Connection:

- Shape: Triangle

- Use: Often on high-voltage side

- Advantage: Good for balancing loads

-

Wye (Star) Connection:

- Shape: Star with neutral point

- Use: Common on low-voltage side

- Advantage: Provides a neutral for single-phase loads

In a recent project for a manufacturing plant, we used a Delta-Wye configuration. The Delta on the high-voltage side helped with load balancing, while the Wye on the low-voltage side provided the neutral needed for office equipment. It’s all about finding the right balance for your specific needs.

Here’s a simple comparison:

| Aspect | Delta | Wye |

|---|---|---|

| Shape | Triangle | Star |

| Neutral Point | No | Yes |

| Voltage Relationship | VLine = VPhase | VLine = √3 × VPhase |

| Typical Use | High-voltage side | Low-voltage side |

| Load Balancing | Excellent | Good |

How to Convert Single-Phase Transformers to a Three-Phase System: A Step-by-Step Guide?

Ready to convert your single-phase transformers into a three-phase system? Here’s a straightforward guide to help you through the process.

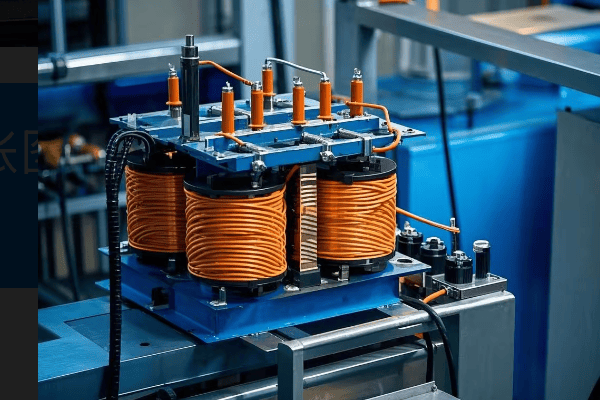

Converting single-phase transformers to three-phase involves connecting three identical transformers in a specific configuration. The primary windings are typically connected in Delta, and the secondary in Wye. Proper connection and testing are crucial for safety and efficiency.

Follow these steps:

Converting to Three-Phase: A Simple Process

-

Gather Materials:

- Three identical single-phase transformers

- Wiring and connectors

- Testing equipment (multimeter, phase rotation meter)

-

Connect Primary Windings (Delta):

- Link end of first to start of second

- Link end of second to start of third

- Link end of third to start of first

-

Connect Secondary Windings (Wye):

- Join one end of each transformer to form neutral

- Other ends become your three phases

-

Test and Verify:

- Check all connections

- Measure voltages

- Verify phase rotation

-

Connect Load:

- Attach your three-phase load to the output

I remember a project where we converted single-phase transformers for a small factory. The owner was amazed at how smooth his machines ran afterward. It’s a bit like turning three soloists into a harmonious trio.

Here’s a checklist to keep handy:

| Step | Action | Key Point |

|---|---|---|

| 1 | Select Transformers | Must be identical |

| 2 | Connect Primary (Delta) | Form a triangle |

| 3 | Connect Secondary (Wye) | Create a neutral point |

| 4 | Test Connections | Use proper safety gear |

| 5 | Verify Voltages | Should be balanced |

| 6 | Check Phase Rotation | Use rotation meter |

| 7 | Connect Load | Ensure balanced loading |

Remember, safety first! If you’re not comfortable with electrical work, always consult a professional.

Safety First: Key Precautions for Transformer Conversion Projects?

When working with electrical systems, especially high-voltage ones, safety isn’t just important—it’s critical. What are the key safety measures you need to take?

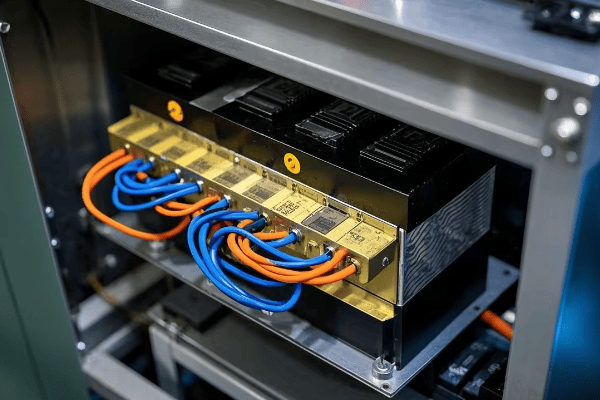

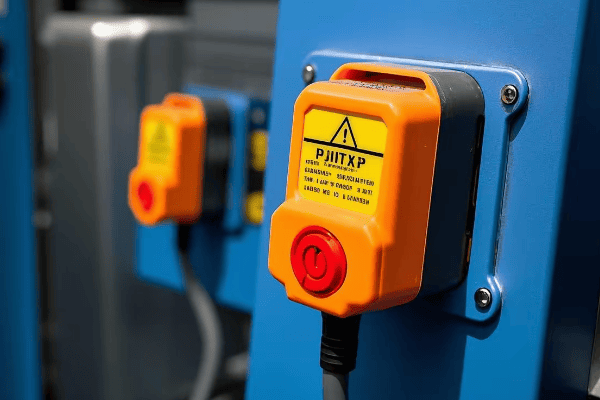

Transformer conversion projects involve high voltages and currents. Essential safety measures include proper protective equipment, lockout/tagout procedures, grounding, and following all relevant electrical codes. These precautions can prevent accidents and save lives.

Let’s go through the crucial safety steps:

Staying Safe: Your Transformer Conversion Safety Checklist

-

Personal Protective Equipment (PPE):

- Insulated gloves

- Safety glasses

- Arc-flash rated clothing

-

Lockout/Tagout:

- Identify all power sources

- Disconnect and lock out power

- Use "Do Not Operate" tags

-

Grounding:

- Ground all equipment properly

- Use temporary grounding cables during work

-

Testing:

- Always test before touching

- Use properly calibrated equipment

-

Workspace Safety:

- Keep area clean and dry

- Ensure good lighting

- Have a fire extinguisher nearby

I once witnessed a close call where a technician forgot to verify a circuit was de-energized. Luckily, a colleague caught the mistake in time. It was a powerful reminder that you can never be too careful with electricity.

Here’s a quick safety reference:

| Safety Aspect | Key Action | Why It’s Important |

|---|---|---|

| PPE | Wear proper gear | Protects against shock and arc flash |

| Lockout/Tagout | Secure power sources | Prevents accidental energization |

| Grounding | Ground all equipment | Protects against stray voltages |

| Testing | Verify de-energized state | Ensures safe working conditions |

| Workspace | Keep area clean and organized | Reduces accident risks |

Always remember: When in doubt, don’t touch. It’s better to ask for help than to take unnecessary risks.

Choosing the Right Transformers: What to Look For?

Selecting the right transformers for your three-phase conversion is crucial. But what factors should you consider to ensure optimal performance?

When choosing transformers, match voltage ratings, power capacity, and impedance. All three units must be identical for balanced operation. Consider factors like efficiency, cooling method, and future load growth to make the best long-term choice.

Here’s what to keep in mind:

Transformer Selection: Key Factors to Consider

-

Voltage Ratings:

- Primary: Must match your input voltage

- Secondary: Determine based on your load needs

-

Power Capacity (kVA):

- Calculate your total load

- Allow for future growth (typically 20-30% extra)

-

Impedance:

- Must be identical for all three units

- Typical range: 2-5% for distribution transformers

-

Efficiency:

- Look for high-efficiency models

- Consider long-term energy savings

-

Cooling Method:

- Oil-filled vs. Dry-type

- Choose based on location and environment

In a recent project, we helped a client select transformers for a new workshop. By choosing high-efficiency models, they’re saving about $2,000 annually on energy costs. Sometimes, spending a bit more upfront can lead to significant long-term savings.

Here’s a handy selection guide:

| Specification | What to Look For | Why It Matters |

|---|---|---|

| Voltage Rating | Exact match to system | Ensures compatibility |

| kVA Rating | Exceeds total load | Allows for growth |

| Impedance | Identical for all three | Ensures balanced operation |

| Efficiency | High efficiency (>98%) | Reduces operating costs |

| Cooling | Suitable for environment | Affects lifespan and maintenance |

Remember, the cheapest option isn’t always the most cost-effective in the long run. Consider the total cost of ownership, including energy costs and maintenance.

DIY vs Professional: Which Option is Right for You?

Wondering whether to tackle the three-phase conversion yourself or hire a professional? It’s a common dilemma, but how do you decide?

DIY conversion can be cost-effective for smaller, simpler setups but carries risks. Professional installation ensures compliance, optimal efficiency, and often comes with warranties. Your choice depends on your technical skills, project complexity, and risk tolerance.

Let’s weigh the pros and cons:

DIY vs Professional: Making the Right Choice

-

DIY Approach:

- Pros: Lower initial cost, learning experience

- Cons: Higher risk, potential for errors

-

Professional Installation:

- Pros: Expertise, warranty, code compliance

- Cons: Higher upfront cost

I once consulted for a small business owner who attempted a DIY conversion. While he saved money initially, he ended up calling us to fix issues that arose. In the end, it cost more than if he’d hired professionals from the start.

Here’s a comparison to help you decide:

| Factor | DIY | Professional |

|---|---|---|

| Initial Cost | Lower | Higher |

| Expertise Required | High | Provided |

| Time Investment | Significant | Minimal for you |

| Risk | Higher | Lower |

| Warranty | Limited/None | Typically Included |

| Code Compliance | Your Responsibility | Ensured by Pros |

| Long-term Reliability | Varies | Generally Higher |

Consider your skills, time, and the criticality of the system. For critical operations or complex setups, professional installation is often the safer, more cost-effective choice in the long run.

Conclusion

Creating a three-phase transformer from single-phase units can be a cost-effective solution when done correctly. By understanding the basics, prioritizing safety, choosing the right equipment, and deciding between DIY and professional help, you can successfully navigate this complex process. Remember, when in doubt, consult with a professional to ensure safety and optimal performance.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group