Three Phase Power Transformer: Understanding the Basics and Applications?

Power outages can be frustrating. I’ve experienced them firsthand, and they always make me wonder about our electrical systems.

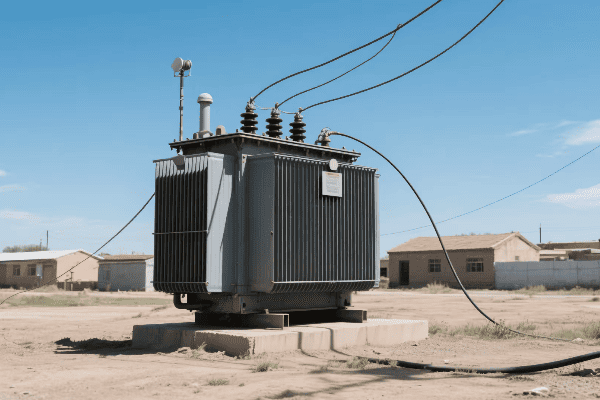

Three-phase power transformers are key components in electrical grids. They convert high-voltage electricity from power plants to lower voltages for homes and businesses. These transformers ensure efficient and reliable power distribution across long distances.

Let’s dive deeper into the world of three-phase power transformers. I’ll share my insights from years of working in the power industry.

What Are the Fundamental Principles Behind Three Phase Power Transformer Operation?

Have you ever wondered how electricity travels from power plants to your home? It’s a fascinating process that I’ve studied for years.

Three-phase power transformers work on the principle of electromagnetic induction. They use three sets of primary and secondary windings to transfer electrical energy between two circuits with different voltage levels.

Let me break down the fundamental principles of three-phase power transformer operation:

Electromagnetic Induction

Electromagnetic induction is the heart of transformer operation. I remember learning about this in my early days as an electrical engineer. It’s amazing how a simple principle can have such a huge impact on our daily lives.

- Primary Windings: These are connected to the power source.

- Secondary Windings: These deliver power to the load.

- Magnetic Core: This links the primary and secondary windings.

When alternating current flows through the primary windings, it creates a changing magnetic field. This field induces a voltage in the secondary windings. The ratio of primary to secondary turns determines the voltage transformation.

Three-Phase System

A three-phase system uses three alternating currents, each offset by 120 degrees. This system is more efficient than single-phase for power transmission. Here’s why:

| Advantage | Explanation |

|---|---|

| Constant Power Delivery | Three phases provide a steady power flow |

| Higher Power Capacity | Can transmit more power with less material |

| Balanced Load | Reduces vibration in generators and motors |

Voltage Transformation

The voltage transformation in a three-phase transformer follows this principle:

Vs / Vp = Ns / Np

Where:

- Vs = Secondary voltage

- Vp = Primary voltage

- Ns = Number of secondary turns

- Np = Number of primary turns

This relationship allows us to step up or step down voltage as needed. It’s crucial for efficient power transmission over long distances.

How Do Three Phase Power Transformers Differ from Single Phase Transformers in Design and Function?

I often get asked about the differences between three-phase and single-phase transformers. It’s a great question that highlights the complexity of power systems.

Three-phase transformers have three sets of windings and can handle higher power loads. Single-phase transformers have one set of windings and are used for lower power applications. Three-phase systems are more efficient for power transmission and distribution.

Let’s explore the key differences:

Core Design

The core design is one of the most visible differences between three-phase and single-phase transformers.

-

Three-Phase Core:

- Usually has a three-limb or five-limb design

- More efficient use of core material

- Better magnetic flux distribution

-

Single-Phase Core:

- Typically has a simpler two-limb design

- Less efficient in material usage

- Simpler construction

I remember working on a project where we had to choose between a bank of single-phase transformers and a three-phase unit. The three-phase option saved us significant space and material costs.

Winding Configuration

The winding configuration is another crucial difference:

| Three-Phase Transformer | Single-Phase Transformer |

|---|---|

| Three sets of primary and secondary windings | One set of primary and secondary windings |

| Can be connected in delta or star configuration | Simpler connection options |

| Allows for flexible voltage and current ratios | Limited voltage and current ratio options |

Power Handling Capacity

Three-phase transformers generally have higher power handling capacities:

-

Three-Phase:

- Can handle higher power loads

- More suitable for industrial and utility-scale applications

- More efficient for long-distance power transmission

-

Single-Phase:

- Lower power handling capacity

- Commonly used in residential and small commercial settings

- Less efficient for high-power applications

Efficiency and Size

In my experience, three-phase transformers often come out on top in terms of efficiency and size:

-

Efficiency:

- Three-phase transformers are generally more efficient

- They have lower core losses per unit of power transferred

- Better utilization of core material

-

Size:

- For the same power rating, a three-phase transformer is usually smaller

- This leads to lower material costs and space requirements

- Important for substation design and urban installations

What Are the Key Components and Their Roles in a Three Phase Power Transformer?

Understanding the components of a three-phase transformer is crucial. I’ve spent countless hours working with these machines, and each part plays a vital role.

The key components of a three-phase power transformer include the core, windings, insulation, cooling system, and tap changers. Each component contributes to the transformer’s ability to efficiently and safely transform voltage levels in a three-phase power system.

Let’s break down these components and their roles:

Core

The core is the heart of the transformer. It’s typically made of high-grade silicon steel laminations.

-

Function:

- Provides a low reluctance path for magnetic flux

- Minimizes eddy current losses

-

Types:

- Three-limb core: Most common for three-phase transformers

- Five-limb core: Used for larger units or special applications

I once worked on a project where we had to choose between a three-limb and a five-limb core. The five-limb design was more expensive but offered better performance under unbalanced load conditions.

Windings

Windings are crucial for voltage transformation. They’re usually made of copper or aluminum.

| Primary Windings | Secondary Windings |

|---|---|

| Connected to the power source | Connected to the load |

| Typically have more turns for step-down transformers | Fewer turns for step-down transformers |

| Made of insulated wire | Also made of insulated wire |

The winding design affects the transformer’s efficiency and short-circuit strength. I’ve seen how different winding configurations can significantly impact a transformer’s performance.

Insulation

Insulation is critical for safety and proper operation. It prevents short circuits and allows for higher voltage operation.

-

Types of Insulation:

- Oil immersion: Common for large power transformers

- Dry type: Used in indoor installations

-

Insulation Components:

- Paper insulation on windings

- Oil in oil-immersed transformers

- Air or epoxy resin in dry-type transformers

Proper insulation maintenance is crucial. I’ve seen transformers fail due to insulation breakdown, which can be catastrophic.

Cooling System

The cooling system prevents overheating, which can damage the transformer.

-

Oil-Immersed Transformers:

- ONAN (Oil Natural Air Natural)

- ONAF (Oil Natural Air Forced)

- OFAF (Oil Forced Air Forced)

-

Dry-Type Transformers:

- AN (Air Natural)

- AF (Air Forced)

Choosing the right cooling system depends on the transformer’s size, location, and load profile. I’ve worked on projects where the cooling system design was crucial for ensuring reliable operation in harsh environments.

Tap Changers

Tap changers allow for voltage adjustment to maintain proper output voltage.

-

Types:

- On-Load Tap Changers (OLTC): Can change taps while the transformer is energized

- Off-Load Tap Changers: Require the transformer to be de-energized for tap changes

-

Function:

- Compensate for voltage variations in the power system

- Maintain stable output voltage

Tap changers are complex mechanisms that require regular maintenance. I’ve seen how proper tap changer operation can significantly improve power quality and transformer lifespan.

Where Are Three Phase Power Transformers Commonly Used in Industrial and Utility Applications?

Throughout my career, I’ve seen three-phase power transformers used in various settings. Their versatility never ceases to amaze me.

Three-phase power transformers are widely used in power generation plants, transmission substations, distribution networks, and large industrial facilities. They’re essential for voltage transformation in the power grid and for powering heavy machinery in factories.

Let’s explore the common applications of three-phase power transformers:

Power Generation Plants

In power plants, three-phase transformers play a crucial role:

-

Step-Up Transformers:

- Increase generator voltage for long-distance transmission

- Typically raise voltage from 15-25 kV to 115-765 kV

-

Auxiliary Transformers:

- Supply power to plant equipment

- Step down high voltage to usable levels for motors and controls

I once worked on a project to upgrade a power plant’s main step-up transformer. The new unit’s improved efficiency resulted in significant energy savings for the plant.

Transmission Substations

Transmission substations use large three-phase transformers to manage power flow:

| Function | Voltage Levels |

|---|---|

| Step-Up | Increase voltage for long-distance transmission |

| Step-Down | Reduce voltage for regional distribution |

| Interconnection | Match voltages between different transmission lines |

These transformers are often massive. I remember being in awe the first time I saw a 500 MVA transformer being installed at a substation.

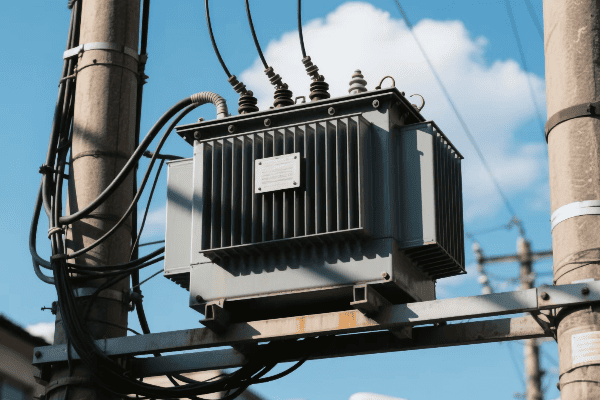

Distribution Networks

In distribution networks, three-phase transformers are used to:

- Step down voltage from sub-transmission levels to distribution levels

- Supply power to commercial and industrial customers

- Feed single-phase transformers for residential areas

The design of distribution transformers often involves balancing cost, efficiency, and reliability. I’ve worked on projects where we had to carefully consider load growth projections to size these transformers correctly.

Industrial Facilities

Large industrial facilities rely heavily on three-phase power:

-

Main Incoming Transformers:

- Step down utility voltage to plant distribution voltage

- Often include features like on-load tap changers for voltage regulation

-

Process Power Transformers:

- Supply power to specific production lines or equipment

- May have special designs for harsh environments or variable loads

-

Arc Furnace Transformers:

- Specialized units for steel production

- Handle extreme load variations and high currents

I once consulted on a project for a large aluminum smelter. The transformers there were some of the most robust I’ve ever seen, designed to handle the enormous power demands of the electrolysis process.

Renewable Energy Integration

With the growth of renewable energy, three-phase transformers are increasingly used in:

-

Wind Farms:

- Step up voltage from individual turbines

- Combine power for transmission to the grid

-

Solar Power Plants:

- Convert DC output from inverters to AC

- Step up voltage for grid connection

-

Energy Storage Systems:

- Interface large battery systems with the grid

- Manage bidirectional power flow

The integration of renewables has brought new challenges in transformer design. I’ve been involved in projects where we had to design transformers to handle the variable output of wind and solar farms.

How Do Three Phase Power Transformers Contribute to Efficient Power Distribution and Transmission?

Efficiency in power systems has always been a passion of mine. Three-phase transformers play a crucial role in this area.

Three-phase power transformers enhance efficiency in power distribution and transmission by reducing losses, enabling high-voltage transmission, and providing a balanced power supply. They allow for more economical power transfer over long distances and better utilization of electrical infrastructure.

Let’s delve into how three-phase transformers contribute to efficiency:

Reduced Transmission Losses

Three-phase systems, enabled by three-phase transformers, significantly reduce transmission losses:

-

Lower Current for Same Power:

- Three-phase systems carry more power at lower currents

- Lower currents mean lower I²R losses in transmission lines

-

Balanced Load Distribution:

- Even distribution of load across three phases

- Reduces overall system stress and losses

I once worked on a project to upgrade a long-distance transmission line. By switching from single-phase to three-phase, we reduced line losses by almost 30%.

High Voltage Transmission

Three-phase transformers enable high voltage transmission, which is key to efficiency:

| Voltage Level | Advantage |

|---|---|

| Higher Voltage | Lower current for same power |

| Lower Current | Reduced line losses |

| Increased Capacity | More power transmitted on existing lines |

High voltage transmission is crucial for long-distance power transfer. I’ve seen how upgrading to higher voltage levels can dramatically improve system efficiency and capacity.

Power Quality Improvement

Three-phase transformers contribute to better power quality:

-

Voltage Regulation:

- On-load tap changers maintain stable voltage

- Improved voltage profile across the network

-

Harmonic Mitigation:

- Special designs can help reduce harmonic distortion

- Improves overall system efficiency and equipment lifespan

-

Phase Balancing:

- Helps maintain balanced voltages across the three phases

- Reduces losses and improves equipment performance

I’ve worked on projects where installing advanced three-phase transformers with on-load tap changers significantly improved voltage stability in a large industrial park.

Efficient Substation Design

Three-phase transformers allow for more efficient substation designs:

-

Compact Footprint:

- Single three-phase unit vs. three single-phase units

- Reduces land requirements and construction costs

-

Simplified Connections:

- Fewer connections mean lower installation and maintenance costs

- Reduced potential points of failure

-

Integrated Cooling Systems:

- More efficient cooling for three-phase units

- Better overall system reliability

In my experience, using three-phase transformers in substations often leads to significant space savings and simpler maintenance procedures.

Renewable Energy Integration

Three-phase transformers are crucial for efficiently integrating renewable energy sources:

-

Wind Farms:

- Step-up transformers at each turbine

- Larger substation transformers for grid connection

-

Solar Plants:

- Inverter transformers for DC to AC conversion

- Step-up transformers for grid connection

-

Energy Storage:

- Bidirectional power flow management

- Grid stabilization during peak demand

I’ve been involved in several renewable energy projects where the choice of transformer was critical for maximizing energy capture and minimizing losses.

Conclusion

Three-phase power transformers are vital for efficient power distribution. They enable high-voltage transmission, reduce losses, and support renewable energy integration. Understanding their principles and applications is crucial for modern power systems.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group