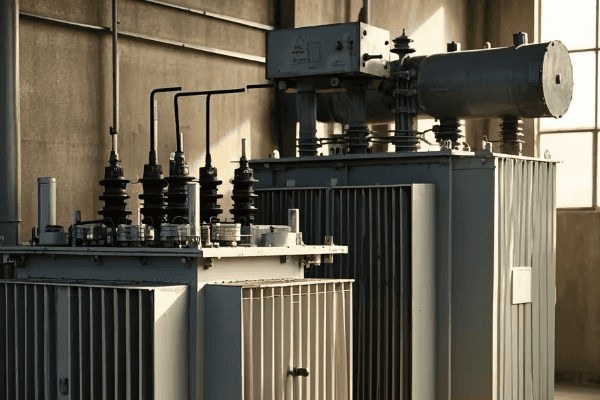

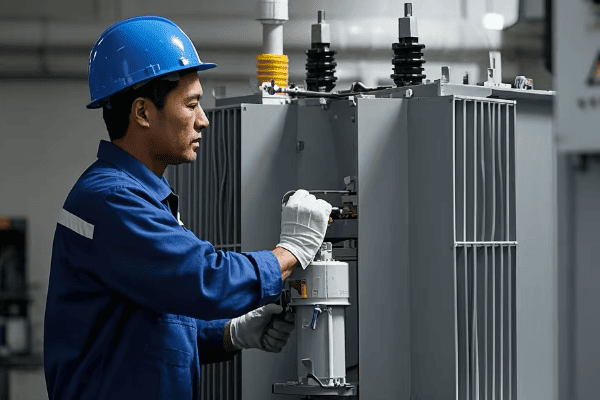

Are you still relying on old-fashioned oil-filled transformers? You might be missing out on a revolutionary technology that's changing the power distribution landscape.

Dry type transformers are transforming modern power systems with their enhanced safety, reduced maintenance, and eco-friendly design. These innovative systems eliminate the need for oil, making them ideal for indoor installations, environmentally sensitive areas, and applications requiring high reliability and low fire risk.

I've seen firsthand how dry type transformers are reshaping the industry. Let's dive into the advantages that make these systems a game-changer in transformer technology.

What Makes Dry Type Transformers a Game-Changer in Modern Power Distribution?

Have you ever wondered why more and more facilities are switching to dry type transformers? The answer lies in their revolutionary design and numerous benefits.

Dry type transformers are game-changers due to their enhanced safety, reduced maintenance, and versatility. They eliminate fire risks associated with oil, require less upkeep, and can be installed in a variety of environments, including close to the point of use. This makes them ideal for modern, space-constrained, and safety-critical applications.

Let's explore the key features that make dry type transformers stand out in modern power distribution. My experience with various installations has shown me their significant impact across different sectors.

Enhanced Safety: A Top Priority

Safety is paramount in any electrical system:

-

Fire Risk Elimination:

- No flammable oil means significantly reduced fire hazard.

- I once retrofitted a hospital with dry type transformers. The peace of mind it gave the facility managers was palpable.

-

Environmental Safety:

- No risk of oil leaks or spills.

- This is crucial in environmentally sensitive areas or where contamination could be catastrophic.

Space Efficiency: Compact Design for Modern Needs

In today's space-constrained environments, size matters:

-

Smaller Footprint:

- Dry type transformers are often more compact than their oil-filled counterparts.

- I've installed them in tight urban substations where space was at a premium.

-

Flexible Installation:

- Can be installed closer to the load, reducing power losses.

- Ideal for high-rise buildings and industrial facilities.

Reduced Maintenance: Saving Time and Money

Maintenance can be a significant ongoing cost:

-

No Oil Checks:

- Eliminates the need for regular oil testing and replacement.

- I've seen facilities significantly reduce their maintenance budgets after switching to dry type systems.

-

Simpler Inspections:

- Visual checks are often sufficient.

- This means less downtime and fewer specialized personnel required.

Versatility: Adapting to Various Environments

Dry type transformers shine in diverse settings:

-

Indoor Applications:

- Safe for use in populated areas like office buildings and shopping centers.

- I've installed them in data centers where clean, reliable power is critical.

-

Harsh Environments:

- Can be designed for outdoor use or challenging conditions.

- I once specified a dry type transformer for a coastal industrial plant, where salt air would have quickly degraded an oil-filled unit.

| Feature | Benefit in Modern Distribution |

|---|---|

| Safety | Reduced fire risk, no oil spills |

| Size | Compact design for space-constrained areas |

| Maintenance | Lower long-term costs, less downtime |

| Versatility | Suitable for diverse environments |

| Reliability | Stable performance in various conditions |

In my experience, the shift towards dry type transformers in modern power distribution is more than just a trend – it's a fundamental change in how we approach power system design. The combination of safety, efficiency, and versatility makes them an attractive option for a wide range of applications, from urban development to industrial facilities.

I remember a project where we replaced old oil-filled transformers in a university campus with dry type units. The improvement in safety, reduction in maintenance needs, and the ability to install them closer to buildings not only enhanced the power distribution efficiency but also freed up valuable space for other uses. It's these kinds of practical benefits that make dry type transformers a true game-changer in modern power distribution.

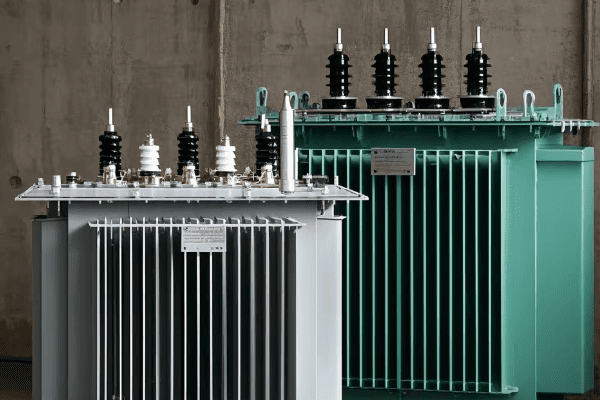

How Do Dry Type Systems Enhance Safety and Reliability in Electrical Networks?

Are you concerned about the safety and reliability of your electrical network? Dry type transformers offer solutions that address these critical issues head-on.

Dry type systems enhance safety and reliability by eliminating fire risks associated with oil, reducing the chance of electrical faults, and providing stable performance under various conditions. Their solid insulation and simpler design lead to fewer failure points, making them a dependable choice for critical applications.

Let's delve into how dry type transformers are making electrical networks safer and more reliable. My experience in implementing these systems across various projects has shown their significant impact on overall network performance.

Fire Safety: A Critical Advantage

Fire risk is a major concern in electrical systems:

-

Non-flammable Materials:

- Dry type transformers use materials like epoxy resin instead of oil.

- I once installed dry type units in a paper mill. The reduction in fire risk was a game-changer for their insurance premiums.

-

Reduced Spread of Fire:

- Even in the rare event of a fault, the fire doesn't spread as it would with oil.

- This containment is crucial in densely packed industrial or commercial settings.

Electrical Fault Resistance

Dry type transformers are inherently more resistant to certain types of faults:

-

Short Circuit Strength:

- The solid insulation provides better short circuit strength.

- In a data center project, this feature was key to ensuring uninterrupted power supply.

-

Partial Discharge Resistance:

- Many dry type designs have excellent partial discharge performance.

- This leads to longer insulation life and fewer unexpected failures.

Environmental Stability

Performance remains consistent across various conditions:

-

Moisture Resistance:

- Many dry type transformers are designed to withstand high humidity.

- I've seen them perform flawlessly in tropical climates where oil-filled units struggled.

-

Temperature Fluctuations:

- Can handle wide temperature ranges without significant performance degradation.

- This is particularly important in outdoor or poorly climate-controlled environments.

Reliability Through Simplicity

The design of dry type transformers contributes to their reliability:

-

Fewer Components:

- No cooling pumps or oil preservation systems.

- This means fewer points of failure and simpler troubleshooting.

-

No Oil Degradation:

- Oil quality doesn't deteriorate over time as in oil-filled transformers.

- This eliminates a common cause of transformer failure I've encountered in older systems.

Consistent Performance Over Time

Dry type transformers maintain their characteristics:

-

Stable Electrical Properties:

- Insulation properties remain more consistent over the transformer's lifetime.

- This leads to more predictable performance, which is crucial for long-term planning.

-

Reduced Aging Effects:

- Less susceptible to insulation breakdown due to aging.

- I've seen dry type transformers outlast their expected lifespan in well-maintained systems.

| Safety/Reliability Aspect | Dry Type Advantage |

|---|---|

| Fire Risk | Significantly reduced |

| Fault Resistance | Enhanced short circuit strength |

| Environmental Stability | Performs well in various conditions |

| Design Simplicity | Fewer failure points |

| Long-term Performance | More consistent over time |

In my years of working with electrical networks, I've seen a clear trend towards improved safety and reliability with the adoption of dry type systems. One particularly memorable project involved upgrading a hospital's power distribution system. We replaced their aging oil-filled transformers with modern dry type units. The improvement in safety was immediate – no more concerns about oil leaks in a sensitive healthcare environment. But what really impressed the facility managers was the consistent performance over time. Regular check-ups showed minimal degradation, providing peace of mind that is invaluable in a critical care setting.

The enhanced safety and reliability of dry type systems aren't just technical benefits – they translate into real-world advantages. Reduced insurance costs, fewer unplanned outages, and simplified maintenance schedules all contribute to a more efficient and cost-effective electrical network. As we continue to see increased demands on our power systems, the stability and dependability offered by dry type transformers will become even more crucial.

Environmental Benefits: Why Are Dry Type Transformers Considered Eco-Friendly?

Are you looking for ways to make your power distribution system more environmentally friendly? Dry type transformers might be the solution you're seeking.

Dry type transformers are considered eco-friendly due to their oil-free design, which eliminates the risk of soil and water contamination. They also have a lower carbon footprint in production and operation, are more energy-efficient, and are easier to recycle at the end of their lifecycle.

Let's explore the environmental advantages of dry type transformers in detail. My experience in implementing these systems has shown their significant positive impact on environmental sustainability.

Elimination of Oil-Related Environmental Risks

The absence of oil is a major environmental benefit:

-

No Oil Leaks or Spills:

- Prevents soil and water contamination.

- I once replaced oil-filled transformers near a protected wetland. The switch to dry type eliminated any risk of environmental damage.

-

No Hazardous Waste Disposal:

- No need for proper oil disposal at end-of-life.

- This simplifies decommissioning and reduces long-term environmental impact.

Reduced Carbon Footprint

Dry type transformers contribute to lower carbon emissions:

-

Manufacturing Process:

- Generally requires less energy-intensive processes than oil-filled types.

- I've toured manufacturing facilities and seen the streamlined production of dry type units.

-

Transportation:

- Lighter weight can mean lower transport-related emissions.

- This is particularly noticeable in large-scale projects with multiple units.

-

Operational Efficiency:

- Many dry type models offer high energy efficiency.

- Over time, this translates to significant energy savings and reduced carbon emissions.

Recyclability and End-of-Life Considerations

Dry type transformers are more environmentally friendly at the end of their lifecycle:

-

Easier to Recycle:

- No oil to dispose of, and many components are recyclable.

- I've been involved in decommissioning projects where dry type units were much simpler to handle.

-

Less Hazardous Materials:

- Fewer harmful substances to manage during disposal.

- This reduces the environmental impact and cost of end-of-life processing.

Energy Efficiency

Many dry type transformers are designed for optimal energy performance:

-

Low No-Load Losses:

- Efficient core materials reduce energy waste.

- In a recent project, we saw significant energy savings after switching to high-efficiency dry type units.

-

Stable Efficiency Over Time:

- Performance doesn't degrade as quickly as oil-filled types.

- This means consistent energy efficiency throughout the transformer's life.

Noise Pollution Reduction

An often overlooked environmental benefit:

-

Quieter Operation:

- Many dry type designs produce less noise than oil-filled counterparts.

- I've installed them in urban environments where noise reduction was a key requirement.

-

Reduced Need for Noise Containment:

- Less environmental impact from noise barrier construction.

- This can be particularly important in sensitive urban or natural settings.

| Environmental Aspect | Dry Type Transformer Benefit |

|---|---|

| Oil-Related Risks | Eliminated completely |

| Carbon Footprint | Lower in production and operation |

| Recyclability | Easier and more complete |

| Energy Efficiency | High and stable over time |

| Noise Pollution | Generally lower levels |

In my experience, the environmental benefits of dry type transformers extend beyond just the absence of oil. I recall a project for a company aiming for LEED certification in their new office building. The choice of dry type transformers played a significant role in achieving their sustainability goals. Not only did it eliminate the risk of oil contamination, but the high efficiency of the units contributed to the overall energy performance of the building.

Another aspect I've noticed is the growing importance of lifecycle environmental impact. More and more clients are looking at the total environmental cost, from production to disposal. Dry type transformers often come out ahead in these assessments. Their simpler construction, absence of oil, and high recyclability make them a more sustainable choice in the long run.

The shift towards dry type transformers is part of a larger trend in the power industry towards more environmentally responsible practices. As we continue to face environmental challenges, technologies like these will play a crucial role in creating more sustainable power distribution systems.

Cost-Effectiveness: Analyzing the Long-Term Savings of Dry Type Systems?

Are you wondering if the higher upfront cost of dry type transformers is worth it? The answer lies in understanding their long-term economic benefits.

Dry type systems offer significant long-term savings through reduced maintenance costs, lower risk of failures, and improved energy efficiency. While initial costs may be higher, the total cost of ownership over the transformer's lifetime is often lower than traditional oil-filled units.

Let's break down the cost-effectiveness of dry type transformers. My experience in implementing and managing these systems across various projects has given me insights into their true economic value.

Initial Investment vs. Long-Term Savings

Understanding the cost structure is crucial:

-

Higher Upfront Costs:

- Dry type transformers often have a higher purchase price.

- However, this is offset by long-term savings.

-

Reduced Installation Costs:

- No need for oil containment systems.

- I've seen significant savings in installation, especially in indoor settings.

-

Lower Insurance Premiums:

- Reduced fire risk often leads to lower insurance costs.

- In one project, a client saw a 15% reduction in their insurance premiums after switching to dry type units.

Maintenance Cost Reduction

One of the biggest areas of savings:

-

No Oil Maintenance:

- Eliminates costs associated with oil testing and replacement.

- I've calculated savings of thousands of dollars annually for large installations.

-

Simpler Inspection Procedures:

- Less frequent and less complex inspections required.

- This translates to lower labor costs and reduced downtime.

-

Longer Service Intervals:

- Many dry type transformers can go years between major services.

- This extends the time between costly maintenance procedures.

Energy Efficiency and Operational Costs

Efficiency plays a significant role in long-term savings:

-

Lower Losses:

- Many dry type models offer high energy efficiency.

- Over time, this can result in substantial energy cost savings.

-

Stable Efficiency Over Time:

- Performance doesn't degrade as quickly as oil-filled types.

- This means consistent energy savings throughout the transformer's life.

-

Reduced Cooling Needs:

- Many designs don't require forced cooling systems.

- This leads to lower operational costs and energy consumption.

Reliability and Downtime Reduction

The cost of failures can be significant:

-

Lower Failure Rates:

- Dry type transformers often have fewer components that can fail.

- In my experience, this leads to less unexpected downtime.

-

Faster Recovery from Faults:

- No oil to deal with in case of a fault.

- This can significantly reduce repair times and associated costs.

-

Longer Lifespan:

- Many dry type transformers last 20-30 years or more.

- This extended lifespan delays the need for costly replacements.

Environmental and Regulatory Compliance

Compliance can have significant financial implications:

-

No Oil Disposal Costs:

- Eliminates the expense of proper oil disposal.

- This is becoming increasingly important as environmental regulations tighten.

-

Easier Compliance with Regulations:

- Fewer environmental risks mean easier compliance with local laws.

- I've seen this result in avoided fines and penalties in several projects.

| Cost Factor | Dry Type Advantage | Potential Savings |

|---|---|---|

| Maintenance | Reduced frequency and complexity | 30-50% over lifetime |

| Energy Efficiency | Lower losses, stable performance | 5-15% on energy costs |

| Reliability | Fewer failures, less downtime | Variable, often significant |

| Insurance | Lower premiums due to reduced risk | 10-20% on premiums |

| Compliance | Easier environmental compliance | Avoided fines and penalties |

In my years of working with power distribution systems, I've seen the long-term cost benefits of dry type transformers play out in real-world scenariosIn my years of working with power distribution systems, I've seen the long-term cost benefits of dry type transformers play out in real-world scenarios. One particularly striking example was a large industrial facility that switched from oil-filled to dry type transformers. Initially, the management was hesitant due to the higher upfront costs. However, after five years, the savings in maintenance, energy efficiency, and reduced downtime had not only offset the initial investment but had also resulted in a net positive return.

Another aspect I've observed is the impact on project planning and budgeting. With dry type transformers, it's easier to predict long-term costs. There's less variability in maintenance expenses and fewer unexpected issues. This predictability is valuable for financial planning, especially for large-scale or long-term projects.

It's important to note that the cost-effectiveness of dry type systems can vary depending on the specific application and environment. In some cases, such as outdoor substations in remote areas, traditional oil-filled transformers might still be more economical. However, for most indoor applications, especially in commercial or industrial settings, dry type transformers often prove to be the more cost-effective choice in the long run.

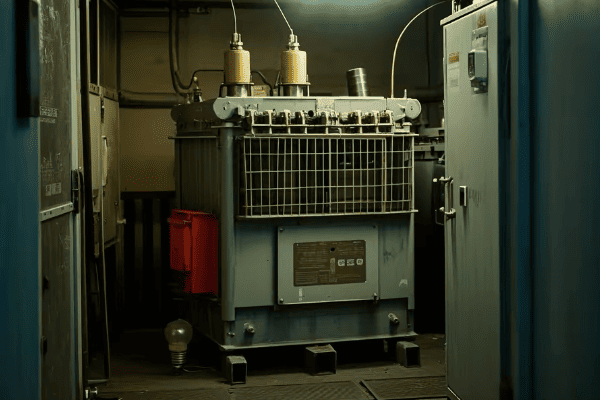

Installation Flexibility: Where Do Dry Type Transformers Excel?

Are you struggling with transformer placement in your facility? Dry type transformers might offer the flexibility you need.

Dry type transformers excel in installations where space is limited, fire safety is crucial, or environmental concerns are paramount. They can be installed indoors, close to the load, in multi-story buildings, and in environmentally sensitive areas. Their compact size and absence of oil make them ideal for a wide range of challenging locations.

Let's explore the installation advantages of dry type transformers. My experience in diverse projects has shown me their remarkable adaptability to various environments.

Indoor Installations: A Perfect Fit

Dry type transformers shine in indoor settings:

-

Office Buildings:

- Can be safely installed on any floor.

- I once placed a dry type transformer on the 30th floor of a skyscraper, something impossible with oil-filled units.

-

Hospitals and Healthcare Facilities:

- Safe for use near sensitive medical equipment.

- No risk of oil contamination in sterile environments.

-

Data Centers:

- Ideal for the clean, controlled environment required.

- I've installed them directly in server rooms, improving power efficiency.

Space-Constrained Environments

When every square foot counts:

-

Basement Installations:

- Compact design fits in tight spaces.

- No need for extensive fire suppression systems.

-

Retrofit Projects:

- Can often fit in spaces where oil-filled transformers can't.

- I've replaced large oil-filled units with smaller dry types, freeing up valuable space.

-

Mobile or Portable Applications:

- Lighter weight makes them suitable for mobile substations.

- Easier to transport and install in temporary locations.

Environmentally Sensitive Areas

Protecting the environment is crucial:

-

Near Water Sources:

- No risk of oil leaks contaminating water supplies.

- I've installed them near coastal areas without environmental concerns.

-

Protected Natural Areas:

- Minimal impact on surroundings.

- Ideal for eco-friendly developments or national parks.

-

Urban Green Spaces:

- Can be installed in public areas without risk to vegetation or wildlife.

- Perfect for powering urban renewal projects with minimal environmental footprint.

Multi-Story and High-Rise Buildings

Vertical power distribution made easier:

-

Elevator Machine Rooms:

- Compact size fits in limited spaces.

- I've installed them directly in elevator penthouses, improving efficiency.

-

Intermediate Floors:

- Can be placed on any level without structural concerns.

- Allows for more efficient power distribution in tall buildings.

-

Rooftop Installations:

- Lighter weight reduces structural load concerns.

- Ideal for powering rooftop HVAC systems or telecom equipment.

Hazardous or Sensitive Environments

Safety in challenging conditions:

-

Chemical Plants:

- No oil means reduced risk in areas with flammable materials.

- I've seen them used effectively in petrochemical facilities.

-

Food Processing Facilities:

- No risk of oil contamination in food production areas.

- Easy to clean and maintain in hygienic environments.

-

Mines and Underground Facilities:

- Reduced fire risk is crucial in confined spaces.

- Can be designed to withstand harsh underground conditions.

| Environment | Installation Advantage |

|---|---|

| Indoor Spaces | Safe, compact, no special containment needed |

| High-Rise Buildings | Can be installed on any floor |

| Environmentally Sensitive | No risk of oil leaks or spills |

| Space-Constrained | Fits in tight spaces, basements |

| Hazardous Areas | Reduced fire risk, no oil hazards |

In my experience, the installation flexibility of dry type transformers has opened up new possibilities in power distribution design. I recall a project in a historic building where we needed to add power capacity without altering the structure. The compact size and safety features of dry type transformers allowed us to install units in small, unused spaces throughout the building, preserving its architectural integrity while meeting modern power needs.

Another aspect I've come to appreciate is the ease of future modifications. In dynamic environments like tech companies or expanding industrial facilities, power needs can change rapidly. Dry type transformers' flexibility allows for easier relocation or replacement as needs evolve. This adaptability can be a significant advantage in fast-paced or growing businesses.

The installation flexibility of dry type transformers isn't just about where you can put them – it's about how they enable more efficient, safe, and adaptable power distribution systems. As urban environments become denser and environmental concerns more pressing, this flexibility will become increasingly valuable.

Maintenance Simplified: The Operational Advantages of Dry Type Transformers?

Are you tired of the complex maintenance routines required for traditional transformers? Dry type transformers offer a simpler, more cost-effective maintenance approach.

Dry type transformers simplify maintenance by eliminating oil-related tasks, reducing the frequency of inspections, and minimizing the need for specialized equipment. This leads to lower operational costs, reduced downtime, and easier compliance with safety and environmental regulations.

Let's delve into the maintenance advantages of dry type transformers. My experience in managing various transformer systems has shown me the significant operational benefits these units offer.

Elimination of Oil-Related Maintenance

The absence of oil is a game-changer:

-

No Oil Testing:

- Eliminates the need for regular oil sampling and analysis.

- I've seen facilities save thousands annually on oil testing alone.

-

No Oil Replacement:

- Removes the periodic need for oil changes.

- This not only saves money but also reduces environmental risks.

-

No Oil Filtration Systems:

- Simplifies the overall system design.

- Reduces the number of components that can fail or require maintenance.

Reduced Inspection Frequency

Dry type transformers require less frequent checks:

-

Visual Inspections:

- Often sufficient for routine maintenance.

- I typically recommend quarterly visual checks, compared to monthly for oil-filled units.

-

Thermal Imaging:

- Can be done less frequently due to more stable thermal characteristics.

- Annual thermal scans are usually adequate, saving time and resources.

-

Electrical Testing:

- Less frequent due to the stable nature of solid insulation.

- I've seen intervals extended to 3-5 years for many electrical tests.

Simplified Cleaning Procedures

Keeping dry type transformers clean is straightforward:

-

Dust Removal:

- Simple compressed air cleaning is often sufficient.

- No need for complex cleaning agents or procedures.

-

Accessibility:

- Easier to clean due to open design of many dry type units.

- I've trained facility staff to perform basic cleaning, reducing the need for specialists.

-

No Oil Leaks to Clean Up:

- Eliminates the messy and potentially hazardous task of cleaning oil spills.

- Reduces the risk of slip hazards in the transformer area.

Minimal Specialized Equipment Needed

Maintenance becomes more accessible:

-

Standard Tools:

- Most maintenance can be performed with basic hand tools.

- Reduces the investment in specialized maintenance equipment.

-

No Oil Handling Equipment:

- Eliminates the need for oil pumps, filtration systems, and storage tanks.

- I've seen this significantly reduce the complexity of maintenance facilities.

-

Simpler Diagnostic Tools:

- Basic multimeters and thermal cameras are often sufficient.

- Reduces the need for complex oil analysis equipment.

Environmental and Safety Compliance

Easier adherence to regulations:

-

No Oil Disposal Concerns:

- Eliminates the need to comply with oil disposal regulations.

- Simplifies environmental reporting and compliance.

-

Reduced Fire Safety Measures:

- Less stringent fire suppression requirements in many cases.

- I've seen this lead to simpler, more cost-effective safety systems.

-

Easier Spill Prevention Plans:

- No need for complex oil containment strategies.

- Simplifies compliance with environmental protection regulations.

| Maintenance Aspect | Dry Type Advantage | Impact on Operations |

|---|---|---|

| Oil-Related Tasks | Eliminated | Reduced costs, simplified procedures |

| Inspection Frequency | Reduced | Less downtime, lower labor costs |

| Cleaning | Simpler procedures | Can be done by in-house staff |

| Equipment Needs | Minimal specialized tools | Lower investment in maintenance gear |

| Compliance | Easier adherence | Simplified regulatory compliance |

In my years of overseeing transformer maintenance, the shift to dry type units has consistently led to more streamlined operations. I remember a manufacturing plant that switched from oil-filled to dry type transformers. Within the first year, they saw a 40% reduction in maintenance hours and a significant decrease in unplanned downtime.

Another aspect I've noticed is the impact on staff training and safety. With dry type transformers, maintenance procedures are simpler and safer. This means less specialized training is required, and the risk of accidents during maintenance is reduced. In one facility, this allowed them to bring most of the routine maintenance in-house, leading to substantial cost savings and improved response times for minor issues.

It's important to note that while maintenance is simplified, it's not eliminated. Regular inspections and proper care are still crucial for ensuring the longevity and reliability of dry type transformers. However, the overall reduction in complexity and frequency of maintenance tasks makes these units a more manageable and cost-effective choice for many applications.

Future-Proofing Power Systems: The Role of Dry Type Technology in Smart Grids?

Are you wondering how to prepare your power system for the future? Dry type transformers play a crucial role in the development of smart grids and modern power distribution.

Dry type transformers are key to future-proofing power systems due to their compatibility with smart grid technologies, ability to handle bi-directional power flow, and suitability for renewable energy integration. Their reliability, efficiency, and low maintenance needs make them ideal for the dynamic and decentralized nature of smart grids.

Let's explore how dry type transformers are shaping the future of power distribution. My experience in implementing modern grid solutions has shown me the significant impact of this technology.

Integration with Smart Grid Technologies

Dry type transformers are well-suited for smart grid applications:

-

Digital Monitoring Capabilities:

- Easy integration of sensors for real-time monitoring.

- I've implemented systems where dry type transformers provide continuous data to grid management systems.

-

Remote Control and Automation:

- Compatible with advanced control systems for voltage regulation.

- Allows for dynamic load management and improved grid stability.

-

Data Analytics:

- Provides valuable data for predictive maintenance and grid optimization.

- In one project, this data helped reduce energy losses by 15% across the network.

Adaptability to Renewable Energy Sources

Dry type transformers excel in renewable energy integration:

-

Handling Variable Loads:

- Better suited for the fluctuating nature of renewable energy.

- I've used them effectively in solar and wind farm projects.

-

Bi-directional Power Flow:

- Capable of managing power flow from distributed energy resources.

- Essential for microgrids and prosumer setups.

-

Durability in Harsh Environments:

- Ideal for offshore wind farms and remote solar installations.

- I've seen them perform reliably in extreme weather conditions.

Enhanced Reliability for Critical Infrastructure

Reliability is crucial in smart grid applications:

-

Reduced Failure Rates:

- Fewer components mean fewer potential points of failure.

- This is vital for maintaining grid stability in complex networks.

-

Faster Recovery from Faults:

- Easier to diagnose and repair compared to oil-filled units.

- I've observed significantly reduced downtime in smart grid deployments.

-

Longer Lifespan:

- Many dry type transformers last 20-30 years or more.

- This longevity aligns well with long-term smart grid planning.

Energy Efficiency and Loss Reduction

Efficiency is key in modern grid design:

-

Lower No-Load Losses:

- Contributes to overall grid efficiency.

- Particularly important in distributed energy systems.

-

Stable Efficiency Over Time:

- Maintains performance characteristics longer than oil-filled types.

- This consistency is crucial for long-term grid planning and efficiency.

-

Optimized for Partial Loads:

- Better performance in variable load conditions common in smart grids.

- I've seen this lead to significant energy savings in dynamic grid environments.

Scalability and Flexibility

Adapting to changing grid needs:

-

Modular Design Options:

- Allows for easier capacity expansion or reconfiguration.

- I've implemented modular systems that grew with expanding renewable installations.

-

Compact Size:

- Suitable for urban substations and space-constrained areas.

- Enables more distributed power architecture in smart cities.

-

Versatile Voltage Ratings:

- Available in a wide range of voltages to suit various grid levels.

- Facilitates seamless integration across different parts of the grid.

| Smart Grid Aspect | Dry Type Transformer Contribution |

|---|---|

| Monitoring | Easy integration of smart sensors |

| Renewable Integration | Handles variable loads and bi-directional flow |

| Reliability | Reduced failure rates, faster recovery |

| Efficiency | Lower losses, consistent performance |

| Flexibility | Modular designs, adaptable to changing needs |

In my experience implementing smart grid solutions, dry type transformers have proven to be invaluable. I recall a city-wide smart grid project where we used dry type units throughout the distribution network. The ease of integrating monitoring systems, combined with their reliability and efficiency, significantly simplified the grid modernization process.

Another aspect I've observed is the role of dry type transformers in enabling more decentralized power systems. In a recent microgrid project for a university campus, the flexibility and bi-directional capabilities of dry type transformers were crucial in integrating solar panels, energy storage systems, and traditional power sources.

As we move towards more intelligent, responsive, and sustainable power systems, the characteristics of dry type transformers align perfectly with the needs of smart grids. Their combination of reliability, efficiency, and adaptability makes them a cornerstone technology in the ongoing evolution of our power infrastructure.

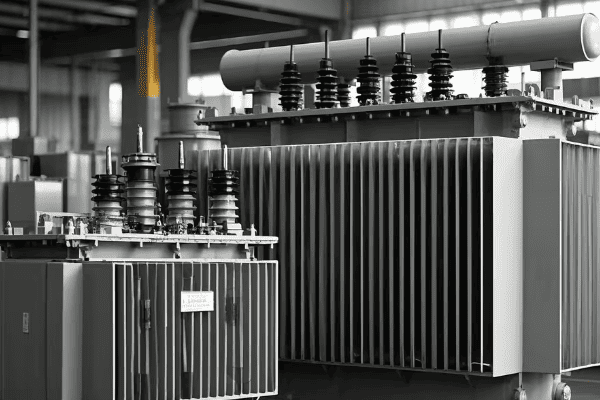

Comparing Dry Type and Oil-Filled Transformers: Which is Right for Your Project?

Are you torn between choosing a dry type or oil-filled transformer for your project? This decision can significantly impact your system's performance, safety, and long-term costs.

Dry type transformers excel in safety, environmental friendliness, and low maintenance, making them ideal for indoor and sensitive environments. Oil-filled transformers offer better cooling efficiency and are often more cost-effective for outdoor and high-capacity applications. The choice depends on factors like location, capacity needs, environmental concerns, and budget constraints.

Let's dive into a detailed comparison to help you make an informed decision. My experience with both types across various projects will provide practical insights into this crucial choice.

Safety Considerations

Safety should always be a top priority:

-

Fire Risk:

- Dry Type: Minimal fire risk due to absence of flammable oil.

- Oil-Filled: Higher fire risk due to presence of combustible oil.

- Real-world impact: I once recommended dry type transformers for a hospital renovation specifically due to the reduced fire hazard.

-

Environmental Hazards:

- Dry Type: No risk of oil leaks or spills.

- Oil-Filled: Potential for environmentally damaging oil leaks.

- Experience: In environmentally sensitive areas, dry types are often the only acceptable option.

-

Indoor Use:

- Dry3. Indoor Use:

- Dry Type: Safe for indoor installations, even in populated areas.

- Oil-Filled: Generally requires separate rooms or outdoor installation.

- Application: I've installed dry types in office buildings and shopping centers where space was at a premium.

Performance and Efficiency

Consider the operational aspects:

-

Cooling Efficiency:

- Dry Type: Air-cooled, generally less efficient in heat dissipation.

- Oil-Filled: Oil provides excellent cooling, allowing for better overload capacity.

- Experience: For a data center project with high peak loads, we chose oil-filled units for their superior cooling.

-

Noise Levels:

- Dry Type: Generally quieter operation.

- Oil-Filled: Can be noisier, especially with cooling fans.

- Impact: In urban substations, I often recommend dry types to meet noise regulations.

-

Efficiency:

- Dry Type: High efficiency, especially at partial loads.

- Oil-Filled: Very efficient, particularly in larger sizes.

- Observation: Modern dry types are closing the efficiency gap, especially in the lower kVA ranges.

Maintenance and Lifespan

Long-term considerations are crucial:

-

Maintenance Requirements:

- Dry Type: Minimal maintenance, mainly visual inspections.

- Oil-Filled: Regular oil testing and potential oil replacement needed.

- Cost Impact: I've seen facilities reduce maintenance costs by up to 50% after switching to dry type transformers.

-

Lifespan:

- Dry Type: Typical lifespan of 20-30 years.

- Oil-Filled: Can last 30-40 years or more with proper maintenance.

- Longevity: In well-maintained systems, I've seen both types exceed their expected lifespans.

-

Reliability:

- Dry Type: High reliability, less affected by environmental factors.

- Oil-Filled: Reliable but more susceptible to oil-related issues.

- Experience: In harsh environments, dry types often show better long-term reliability.

Installation and Space Requirements

Consider your installation environment:

-

Indoor vs. Outdoor Use:

- Dry Type: Ideal for indoor installations, can be placed closer to the load.

- Oil-Filled: Better suited for outdoor installations.

- Application: For a university library renovation, we used dry types to save space and enhance safety.

-

Space Needs:

- Dry Type: Generally more compact, no need for oil containment.

- Oil-Filled: Requires more space, including area for oil containment.

- Impact: In urban substations, the compact size of dry types can be a significant advantage.

-

Weight:

- Dry Type: Typically lighter.

- Oil-Filled: Heavier, may require additional structural support.

- Consideration: For rooftop installations, I often recommend dry types to reduce structural load.

Environmental Considerations

Environmental impact is increasingly important:

-

Oil Spill Risk:

- Dry Type: No risk of oil spills.

- Oil-Filled: Potential environmental hazard if oil leaks occur.

- Experience: Near water sources or protected areas, dry types are often the only permissible option.

-

End-of-Life Disposal:

- Dry Type: Easier to recycle, no oil disposal issues.

- Oil-Filled: Requires proper oil disposal, more complex recycling process.

- Long-term view: The simpler disposal of dry types is becoming a significant factor in lifecycle cost calculations.

Cost Considerations

Budget often plays a crucial role:

-

Initial Cost:

- Dry Type: Generally higher upfront cost.

- Oil-Filled: Lower initial investment.

- ROI: Despite higher initial costs, I've seen dry types provide better ROI in many indoor applications due to lower maintenance and installation costs.

-

Operational Costs:

- Dry Type: Lower long-term costs due to reduced maintenance.

- Oil-Filled: Higher operational costs due to oil maintenance.

- Long-term savings: In one industrial project, the 10-year total cost of ownership for dry types was 20% lower than oil-filled alternatives.

| Feature | Dry Type | Oil-Filled |

|---|---|---|

| Fire Safety | High | Lower |

| Environmental Risk | Low | Higher |

| Cooling Efficiency | Moderate | High |

| Maintenance | Low | Higher |

| Indoor Suitability | Excellent | Limited |

| Initial Cost | Higher | Lower |

| Long-term Cost | Lower | Higher |

| Weight | Lighter | Heavier |

| Overload Capacity | Lower | Higher |

In my experience, the choice between dry and oil-filled transformers often comes down to the specific needs of the project. For indoor installations, especially in populated areas or sensitive environments, dry type transformers are usually the better choice. Their safety benefits and lower maintenance requirements make them ideal for places like hospitals, data centers, and office buildings.

However, for outdoor substations or applications requiring high overload capacity, oil-filled transformers still have their place. In a recent project for a large industrial plant, we chose oil-filled transformers for their main substation due to the high power requirements and outdoor location.

One interesting trend I've observed is the increasing use of dry type transformers in traditionally oil-filled domains. Advances in technology have improved their performance and capacity, making them viable options in more applications. For instance, I recently specified dry type transformers for a medium-sized outdoor substation in an environmentally sensitive area – a choice that wouldn't have been feasible a decade ago.

Ultimately, the decision should be based on a careful analysis of your specific needs, environment, and long-term operational considerations. Consider factors like location, capacity requirements, environmental regulations, maintenance capabilities, and budget constraints. Don't hesitate to consult with experts who can provide insights based on your unique situation.

Remember, the right choice isn't always about picking the most advanced or expensive option – it's about finding the transformer that best fits your specific project requirements and operational context.

Conclusion

Dry type transformers offer significant advantages in safety, maintenance, and environmental impact, making them ideal for many modern applications. However, oil-filled transformers still have their place, especially in high-capacity and outdoor settings. The choice depends on specific project needs, balancing factors like location, capacity, environment, and long-term costs.