What Causes Transformer Noise? Understanding the 4 Main Sources

Have you ever stood near a power substation and heard a persistent humming sound? That’s transformer noise, and it’s more complex than you might think.

Transformer noise comes from four main sources: magnetostriction in the core, electromagnetic forces in the windings, cooling fans, and mechanical vibrations. These sources combine to create the characteristic hum we associate with transformers, which can range from 40 to 80 decibels, depending on the transformer’s size and load.

As an electrical engineer with over 15 years of experience in power systems, I’ve encountered numerous noise issues with transformers. Let’s dive into each source of noise and explore why understanding them is crucial for both engineers and the general public.

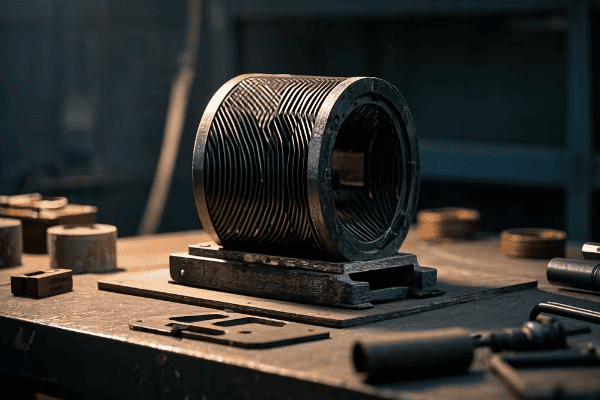

How Does Magnetostriction Contribute to Transformer Noise?

Ever wondered why a transformer’s hum seems to pulse with the electricity flowing through it? The answer lies in a phenomenon called magnetostriction.

Magnetostriction is a key source of transformer noise, caused by the transformer’s core changing shape slightly as the magnetic field fluctuates. This shape change occurs twice per cycle in the alternating current, creating a vibration that we hear as a humming sound. The noise level increases with higher current levels.

Let’s break down magnetostriction in more detail:

-

Magnetic Field Changes: As alternating current flows through the transformer, the magnetic field in the core changes direction rapidly.

-

Core Material Reaction: The core, typically made of silicon steel, responds to these magnetic changes by expanding and contracting slightly.

-

Vibration Creation: This rapid expansion and contraction creates vibrations in the core material.

-

Sound Production: These vibrations produce the characteristic humming sound we associate with transformers.

I remember working on a project where we were trying to reduce noise in a residential area near a substation. We found that replacing the older transformer cores with newer, more efficiently designed ones reduced the magnetostriction noise by almost 5 decibels. It made a noticeable difference to the local residents.

Key Takeaway: Magnetostriction is an inherent property of magnetic materials and can’t be eliminated entirely, but it can be minimized through careful core design and material selection.

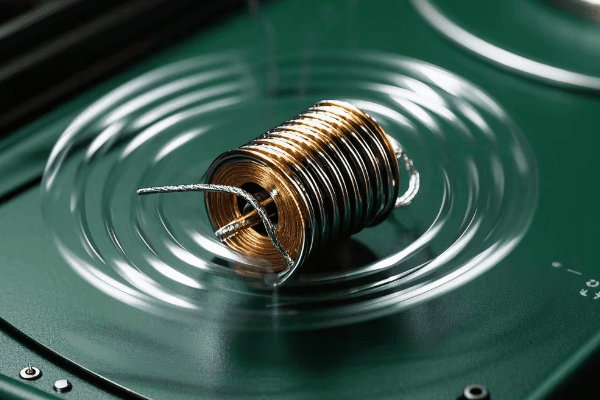

What Role Do Electromagnetic Forces Play in Transformer Noise?

Have you noticed that transformer noise sometimes changes when the power load fluctuates? This is often due to electromagnetic forces at work.

Electromagnetic forces in transformer windings are a significant source of noise. As current flows through the windings, it creates magnetic fields that cause the windings to vibrate. This vibration produces a humming noise that’s typically loudest at the start of operation and decreases as the transformer stabilizes.

Here’s a closer look at how electromagnetic forces create noise:

-

Current Flow: Electricity flowing through the windings creates a magnetic field.

-

Force Generation: This magnetic field interacts with the current, creating forces that act on the windings.

-

Winding Movement: These forces cause the windings to move slightly, expanding and contracting.

-

Vibration and Sound: The movement of the windings creates vibrations, which we hear as noise.

During a recent factory acceptance test, we observed that the noise level from electromagnetic forces was about 3 decibels higher than expected. We traced it to a slight looseness in the winding clamping system. After tightening the clamps, the noise reduced significantly.

Key Takeaway: Proper winding design and secure clamping are crucial for minimizing noise from electromagnetic forces.

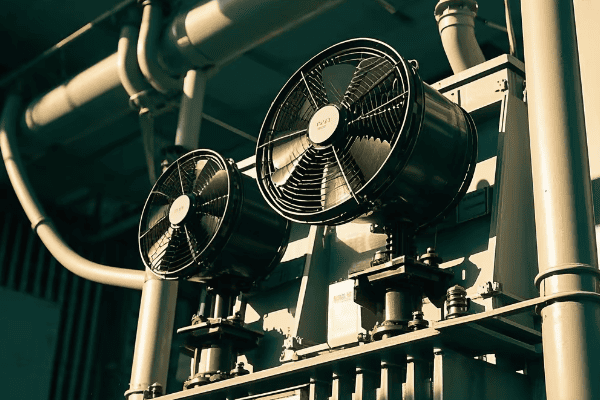

How Do Cooling Fans Contribute to Transformer Noise?

If you’ve ever been near a large transformer on a hot day, you might have noticed an increase in noise. This is often due to the cooling system kicking into high gear.

Cooling fans are a significant source of transformer noise, especially in larger units. These fans are essential for dissipating heat generated during operation, but they can create substantial noise. The sound level typically increases with fan speed, which is adjusted based on the transformer’s temperature.

Let’s examine the cooling fan noise in more detail:

-

Heat Generation: Transformers produce heat during operation due to losses in the core and windings.

-

Cooling Necessity: Fans are used to circulate air or oil to remove this heat and prevent overheating.

-

Fan Operation: As the transformer’s load and temperature increase, fans operate at higher speeds.

-

Noise Production: The fan blades moving through air create noise, which increases with fan speed.

I once worked on a project to retrofit an older transformer with a new cooling system. By using larger, slower-spinning fans, we were able to reduce the cooling noise by about 7 decibels while maintaining effective cooling.

Key Takeaway: While cooling fans are necessary for transformer operation, their noise can be minimized through careful design and speed control strategies.

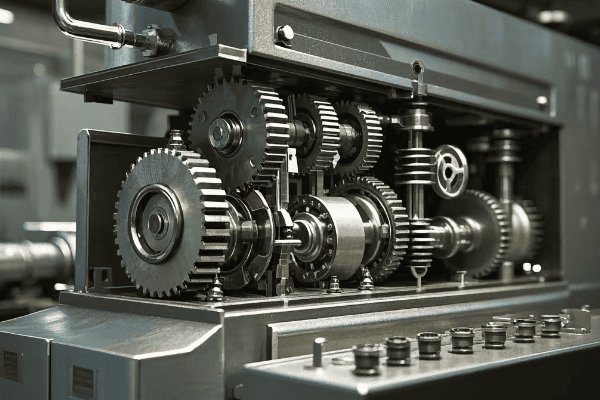

How Do Mechanical Vibrations Contribute to Transformer Noise?

Have you ever felt a slight tremor when standing near a large transformer? That’s mechanical vibration, and it’s more than just a feeling – it’s a source of noise too.

Mechanical vibrations in transformers are caused by the interaction of electromagnetic forces and the physical structure of the transformer. These vibrations can propagate through the transformer tank and supporting structures, creating noise. The intensity of this noise depends on the transformer’s design, mounting, and the surrounding environment.

Here’s how mechanical vibrations contribute to noise:

-

Force Origin: Electromagnetic forces in the core and windings create the initial vibrations.

-

Structural Transmission: These vibrations are transmitted through the transformer’s structure.

-

Resonance Effects: Sometimes, the vibration frequency can match the natural frequency of the transformer parts or supporting structures, amplifying the noise.

-

Environmental Factors: The surrounding environment, including the transformer’s mounting and nearby structures, can affect how the vibrations translate into audible noise.

In a recent project, we encountered excessive noise due to mechanical vibrations in a transformer installed on the roof of a building. By adding vibration isolators between the transformer and the building structure, we reduced the noise level inside the building by about 10 decibels.

Key Takeaway: Proper installation, including vibration isolation and structural design, is crucial for minimizing noise from mechanical vibrations.

Conclusion

Understanding the sources of transformer noise is crucial for effective noise management in electrical systems. From the microscopic movements in the core due to magnetostriction to the more obvious noise from cooling fans, each source presents unique challenges and opportunities for noise reduction. By addressing these sources through improved design, materials, and installation practices, we can significantly reduce the impact of transformer noise on both equipment performance and human comfort.

FAQs: Common Questions About Transformer Noise

- Is transformer noise harmful to human health?

While transformer noise is generally not harmful to human health at typical levels, prolonged exposure to high noise levels can cause stress and discomfort. Most transformers produce noise between 40-80 decibels, which is below the 85 decibel threshold considered harmful by occupational health standards. However, in residential areas, even lower noise levels can be disturbing, especially at night.

- How can transformer noise be reduced?

Transformer noise can be reduced through several methods:

- Using high-quality core materials to reduce magnetostriction

- Improving winding design and clamping to minimize electromagnetic vibrations

- Implementing advanced cooling systems with quieter fans

- Using sound enclosures or barriers around transformers

- Proper installation with vibration isolation mounts

In my experience, a combination of these methods can reduce transformer noise by 10-15 decibels or more.

- Do all transformers produce the same amount of noise?

No, noise levels vary significantly between transformers. Factors affecting noise levels include:

- Size and power rating of the transformer

- Design and construction quality

- Age and condition

- Operating load

- Environmental factors

Generally, larger and older transformers tend to be noisier. Modern designs often incorporate noise reduction features.

- Can transformer noise change over time?

Yes, transformer noise can change over time. Common reasons include:

- Loosening of core or winding clamps

- Degradation of insulation materials

- Changes in cooling system performance

- Increased load on the transformer

Regular maintenance and monitoring can help identify and address changes in noise levels before they become significant problems.

- Are there regulations governing transformer noise levels?

Yes, many countries and regions have regulations specifying maximum allowable noise levels for transformers, especially in residential areas. For example, in the United States, NEMA (National Electrical Manufacturers Association) provides guidelines for transformer noise levels. In Europe, the IEC (International Electrotechnical Commission) standards address transformer noise. Always check local regulations when installing or operating transformers.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group