What Does OMP and TMG Mean in Transformers: Decoding the Acronyms?

Are you confused by transformer acronyms? You’re not alone. Many engineers and technicians struggle with these technical terms, often leading to misunderstandings and potential mistakes in system design.

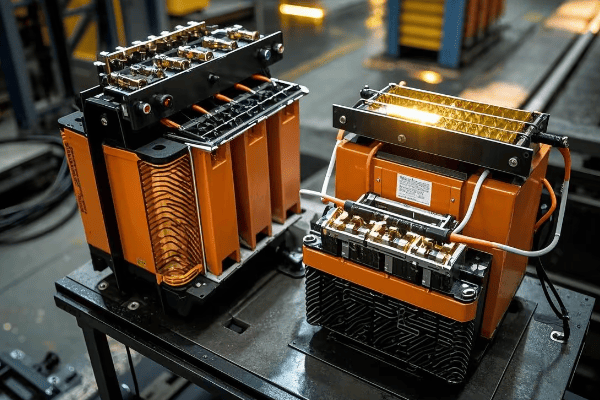

OMP stands for Oil-immersed, Mono-phase (single-phase) Power transformer, while TMG means Three-phase, oil-immersed transformer with Hermetic corrugated tank. These acronyms describe specific types of transformers designed for different applications and environments, each with unique features that make them suitable for particular power distribution needs.

As an electrical engineer with over two decades of experience in transformer design and implementation, I’ve seen firsthand how crucial it is to understand these acronyms. Let’s dive into the world of OMP and TMG transformers and uncover their unique features, applications, and the critical role they play in our power systems.

What Are the Key Features of OMP Transformers?

Have you ever wondered how power is safely stepped down in extreme temperatures, from scorching deserts to frigid arctic regions? OMP transformers might be the answer you’re looking for, but what makes them so special?

OMP transformers are single-phase, oil-immersed units designed for voltage step-down in various electrical networks. They excel in extreme temperatures, ranging from -60°C to +40°C, making them ideal for harsh environments and specialized applications like railroad systems, remote industrial sites, and critical infrastructure in challenging climates.

In my career, I’ve worked with OMP transformers in various challenging environments, from Siberian oil fields to Middle Eastern deserts. Let’s break down their key features and applications:

Design and Construction

-

Oil Immersion

- Entire core and windings submerged in insulating oil

- Provides excellent cooling and insulation

- Uses specially formulated oil for extreme temperature resistance

-

Single-Phase Configuration

- Designed for single-phase power systems

- Simpler construction compared to three-phase units

- Ideal for specialized applications and smaller power needs

-

Robust Build

- Engineered to withstand extreme temperatures

- Typically features reinforced tank construction

- Uses special alloys and materials for thermal expansion management

-

Compact Design

- Optimized for space efficiency

- Suitable for installations with limited footprint

Technical Specifications

| Feature | Specification | Benefit |

|---|---|---|

| Voltage Range | Up to 35kV primary | Suitable for medium voltage applications |

| Power Rating | 5 kVA to 250 kVA | Flexible for various load requirements |

| Frequency | 50 Hz or 60 Hz | Compatible with global power systems |

| Temperature Range | -60°C to +40°C | Operable in extreme climates |

| Insulation Class | A (105°C) | Ensures long-term reliability |

| Efficiency | Up to 98% | Minimizes energy losses |

| Cooling Method | ONAN (Oil Natural Air Natural) | Simplifies maintenance and operation |

I remember a project in Siberia where we installed OMP transformers for a remote mining operation. The units performed flawlessly even when temperatures plummeted to -50°C, showcasing their exceptional durability. The client was amazed at how these transformers continued to operate efficiently when other equipment struggled.

Applications of OMP Transformers

-

Railroad Systems

- Power supply for signaling and control systems

- Reliable operation in varying weather conditions

- Critical for maintaining safety in rail networks

-

Remote Industrial Sites

- Oil and gas facilities in extreme climates

- Mining operations in harsh environments

- Provides stable power for critical equipment

-

Alarm and Security Systems

- Stable power supply for critical safety equipment

- Suitable for both indoor and outdoor installations

- Ensures continuous operation of surveillance and alert systems

-

Specialized Power Distribution

- Step-down voltage for specific equipment or processes

- Ideal for isolated single-phase power needs

- Used in research facilities and specialized manufacturing

-

Renewable Energy Integration

- Connecting small-scale solar or wind installations to the grid

- Adapting single-phase renewable sources to local power needs

Advantages of OMP Transformers

-

Temperature Resilience

- Operates efficiently in both extremely cold and moderately hot climates

- Reduces need for additional environmental control systems

- Saves on installation and operational costs in harsh environments

-

Maintenance Efficiency

- Oil immersion reduces wear on internal components

- Longer intervals between maintenance checks

- Simplified maintenance procedures due to single-phase design

-

Versatility

- Suitable for both indoor and outdoor installations

- Can be customized for specific voltage requirements

- Adaptable to various mounting configurations (pole-mounted, pad-mounted, etc.)

-

Safety Features

- Sealed design minimizes risk of oil leaks

- Built-in thermal protection against overheating

- Reduced fire risk due to high flash point insulating oil

-

Longevity

- Designed for extended operational life, often 25-30 years

- Resistant to environmental factors that typically degrade transformers

Challenges and Considerations

-

Limited Power Capacity

- Not suitable for high-power applications

- May require multiple units for larger loads

-

Single-Phase Limitation

- Not applicable in three-phase power systems without additional configuration

-

Initial Cost

- Can be more expensive than standard transformers due to specialized design

-

Weight

- Oil-filled design makes them heavier than dry-type alternatives

- May require special handling and installation equipment

Understanding the features and applications of OMP transformers is crucial for engineers working in specialized environments or with single-phase power systems. Their unique design makes them invaluable in situations where standard transformers would fail, ensuring reliable power distribution even in the most challenging conditions.

How Do TMG Transformers Differ from OMP Models?

Wondering about the best transformer for your three-phase power needs, especially in areas where maintenance is a challenge? TMG transformers might be the solution you’re looking for, but how do they compare to their OMP counterparts?

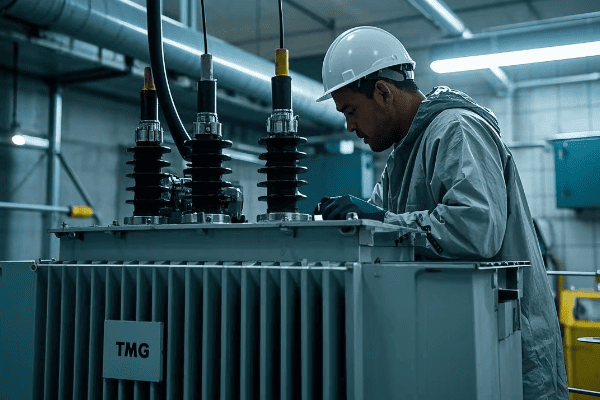

TMG transformers are three-phase, oil-immersed units with hermetically sealed corrugated tanks. They offer superior efficiency, require minimal maintenance, and are designed for long-term reliability in various industrial and commercial applications. Unlike OMP models, TMG transformers are optimized for three-phase power distribution and larger power capacities.

Throughout my career, I’ve seen TMG transformers revolutionize power distribution in numerous industries, from manufacturing plants to large commercial complexes. Let’s explore their unique features and how they compare to OMP models:

Design and Construction

-

Three-Phase Configuration

- Designed for three-phase power systems

- More efficient for large-scale power distribution

- Balanced load handling across all phases

-

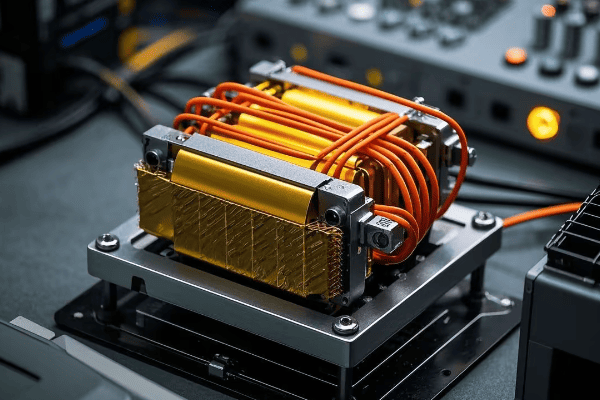

Hermetic Corrugated Tank

- Completely sealed design prevents moisture ingress

- Corrugated walls allow for thermal expansion

- Enhances cooling efficiency and structural integrity

-

Oil Immersion

- Core and windings immersed in high-grade insulating oil

- Provides excellent cooling and insulation

- Specially formulated oil for long-term stability

-

Advanced Core Design

- Uses high-grade silicon steel for the core

- Step-lap core construction for reduced losses

- Optimized magnetic circuit for improved efficiency

Technical Specifications

| Feature | TMG Specification | OMP Specification |

|---|---|---|

| Phases | Three-phase | Single-phase |

| Power Rating | 25 kVA to 2500 kVA | 5 kVA to 250 kVA |

| Voltage Range | Up to 35kV primary | Up to 35kV primary |

| Frequency | 50 Hz or 60 Hz | 50 Hz or 60 Hz |

| Temperature Range | -60°C to +40°C | -60°C to +40°C |

| Tank Design | Hermetic corrugated | Standard sealed |

| Efficiency | Up to 99% | Up to 98% |

| Cooling Method | ONAN/ONAF | ONAN |

| Maintenance Interval | 10-15 years | 5-7 years |

I once oversaw the installation of TMG transformers in a large manufacturing plant that operated 24/7. The client was impressed by the units’ compact size and the fact that they required no maintenance for the first five years of operation. This resulted in significant cost savings and improved production uptime.

Key Advantages of TMG Transformers

-

Minimal Maintenance

- Hermetic design eliminates need for regular oil checks

- No need for preventive repairs throughout operational life

- Reduces operational costs and downtime

-

Improved Efficiency

- Three-phase design reduces overall power losses

- Corrugated tank enhances heat dissipation

- Higher efficiency translates to lower operating costs

-

Long-Term Reliability

- Sealed construction prevents oil oxidation and moisture ingress

- Designed for decades of trouble-free operation

- Reduces risk of unexpected failures

-

Cost-Effective Operation

- Lower lifetime maintenance costs

- Higher energy efficiency reduces operational expenses

- Extended lifespan improves return on investment

-

Environmental Benefits

- Reduced risk of oil leaks due to hermetic sealing

- Lower energy losses contribute to reduced carbon footprint

- Longer lifespan means less frequent replacement and waste

Applications of TMG Transformers

-

Industrial Facilities

- Power distribution in factories and plants

- Suitable for continuous heavy-load operations

- Ideal for environments with limited maintenance access

-

Commercial Buildings

- Office complexes and shopping centers

- Reliable power supply for diverse load profiles

- Compact design suitable for limited space installations

-

Renewable Energy Projects

- Integration of wind and solar farms into the grid

- Efficient power transformation for large-scale projects

- Ability to handle variable loads from renewable sources

-

Urban Infrastructure

- Substations in densely populated areas

- Low maintenance needs ideal for difficult-to-access locations

- Quiet operation suitable for residential areas

-

Data Centers

- Reliable power supply for critical IT infrastructure

- Efficiency crucial for reducing operational costs

- Minimal maintenance aligns with high-uptime requirements

Comparison with OMP Transformers

-

Phase Configuration

- TMG: Three-phase, suitable for larger power systems

- OMP: Single-phase, ideal for specialized applications

- Impact: TMG more versatile for general industrial and commercial use

-

Power Capacity

- TMG: Higher power ratings, up to 2500 kVA

- OMP: Lower power ratings, typically up to 250 kVA

- Impact: TMG can handle larger loads and more complex power distribution needs

-

Maintenance Requirements

- TMG: Minimal to no maintenance over operational life

- OMP: Regular maintenance, though less frequent than traditional transformers

- Impact: TMG offers lower total cost of ownership in the long run

-

Application Flexibility

- TMG: Widely used in industrial and commercial settings

- OMP: Specialized use in railroad systems and remote locations

- Impact: TMG is more adaptable to various industrial and urban applications

-

Efficiency and Losses

- TMG: Generally higher efficiency due to three-phase design

- OMP: Good efficiency, but limited by single-phase operation

- Impact: TMG often provides better energy savings in large-scale applications

-

Installation Considerations

- TMG: Often larger and heavier, may require more installation space

- OMP: More compact, easier to install in confined spaces

- Impact: OMP may be preferable in applications with severe space constraints

In my experience, the choice between TMG and OMP transformers often comes down to the specific needs of the power system. TMG units excel in large-scale, three-phase applications where long-term reliability and low maintenance are priorities. They’re particularly valuable in settings where frequent maintenance is impractical or costly. OMP transformers, on the other hand, are the go-to choice for specialized single-phase applications, particularly in harsh environments or where space is at a premium.

I recall a project where we replaced several aging transformers in a busy urban substation with TMG units. The utility company was initially skeptical about the higher upfront cost, but after two years of operation, they reported a 15% reduction in energy losses and zero maintenance calls. This experience underscored the long-term benefits of choosing the right transformer type for the application.

Understanding the differences between TMG and OMP transformers is crucial for engineers and project managers in the power distribution field. By selecting the right type of transformer, you can ensure optimal performance, efficiency, and longevity of your electrical systems. Whether you’re powering a remote outpost or a bustling factory, there’s a transformer solution that fits your needs perfectly.

Conclusion

OMP and TMG transformers serve distinct purposes in power distribution. OMP excels in single-phase, extreme temperature applications, while TMG offers efficient, low-maintenance solutions for three-phase systems. Understanding their differences is key to selecting the right transformer for specific power needs, ensuring optimal performance, efficiency, and long-term reliability in various environments.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group