What is a Gas Insulated Substation (GIS) and How Does it Revolutionize Power Distribution?

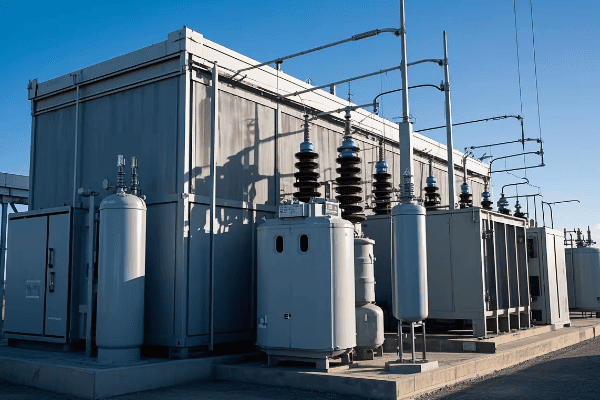

Have you ever wondered how cities manage to power skyscrapers and dense urban areas without massive electrical substations taking up valuable real estate? The answer lies in a revolutionary technology called Gas Insulated Substations (GIS).

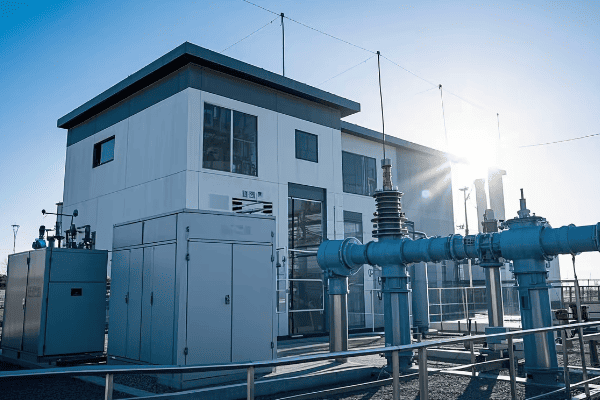

A Gas Insulated Substation (GIS) is a compact power substation that uses sulfur hexafluoride (SF6) gas as an insulating medium. It revolutionizes power distribution by dramatically reducing the substation’s size, increasing reliability, and allowing installations in space-constrained urban areas or harsh environments.

As someone who’s worked in the power industry for years, I’ve seen firsthand how GIS technology has transformed urban power distribution. Let’s dive into the details of this innovative technology and explore why it’s becoming the go-to solution for modern power systems.

How Does a Gas Insulated Substation Work? Understanding the Basics

Imagine shrinking a football field-sized substation down to the size of a small house. That’s essentially what GIS technology does, and it’s all thanks to the unique properties of SF6 gas.

A Gas Insulated Substation works by enclosing high-voltage conductors and circuit breakers in sealed metal containers filled with SF6 gas. This gas has superior insulating properties compared to air, allowing components to be placed much closer together, resulting in a compact and efficient substation design.

Let’s break down the key aspects of how a GIS operates:

The Role of SF6 Gas

SF6 gas is the hero of GIS technology. Here’s why:

- Superior Insulation: SF6 has an insulation strength 2.5 to 3 times higher than air.

- Arc Quenching: It’s excellent at extinguishing electrical arcs, enhancing safety.

- Chemical Stability: SF6 doesn’t react with other materials in the substation.

- Heat Dissipation: It efficiently conducts heat away from conductors.

Sealed Environment

The sealed metal enclosures in a GIS offer several benefits:

- Protection from Environment: Dust, moisture, and pollutants can’t affect the equipment.

- Reduced Maintenance: The clean, controlled environment means less wear and tear.

- Enhanced Safety: The risk of external interference or accidents is minimized.

Compact Design

The compact nature of GIS is its most revolutionary aspect:

- Space Saving: A GIS can be up to 90% smaller than an equivalent Air Insulated Substation (AIS).

- Flexible Installation: GIS can be installed indoors, underground, or in tight urban spaces.

- Modular Construction: Easy to expand or reconfigure as needs change.

Here’s a comparison table to illustrate the space-saving aspect:

| Voltage Level | AIS Footprint | GIS Footprint | Space Saving |

|---|---|---|---|

| 110 kV | 3000 m² | 300 m² | 90% |

| 220 kV | 8000 m² | 600 m² | 92.5% |

| 400 kV | 15000 m² | 1000 m² | 93.3% |

I remember a project where we needed to upgrade a substation in a densely populated urban area. The local authorities were concerned about the impact on the neighborhood. By choosing GIS technology, we were able to fit the entire substation in a building the size of a small warehouse. The compact design not only satisfied the authorities but also impressed the local community with its minimal visual impact.

When explaining GIS to newcomers in the industry, I often use the analogy of comparing it to the evolution of computers. Just as we’ve gone from room-sized mainframes to powerful smartphones, GIS has allowed us to shrink substations without compromising on power or functionality.

Understanding the basics of GIS operation is crucial for anyone involved in modern power distribution. As urban areas continue to grow and energy demands increase, the ability to install powerful substations in compact spaces will become even more valuable.

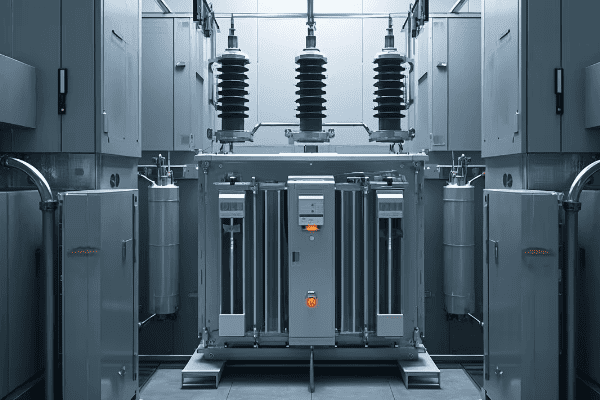

What Are the Key Components of a Gas Insulated Substation?

When I first encountered a Gas Insulated Substation, I was amazed by its compact design. But what’s inside this marvel of electrical engineering? Let’s unpack the key components that make GIS technology so effective.

A Gas Insulated Substation consists of several key components, all enclosed in SF6-filled compartments. These include circuit breakers, disconnectors, earthing switches, current and voltage transformers, and busbars. Each component is designed to operate efficiently in the SF6 environment, contributing to the overall compact and reliable nature of the GIS.

Let’s dive deeper into each of these components:

1. Circuit Breakers

Circuit breakers are the first line of defense in a GIS. They’re designed to:

- Interrupt fault currents quickly

- Operate in the SF6 environment for enhanced arc quenching

- Require minimal maintenance due to the clean, sealed environment

2. Disconnectors and Earthing Switches

These components provide isolation and grounding:

- Disconnectors isolate sections of the substation for maintenance

- Earthing switches ensure safety during maintenance operations

- Both are designed for reliable operation in the SF6 gas

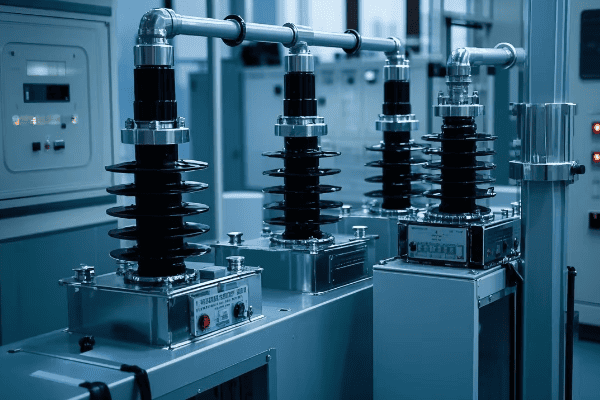

3. Current and Voltage Transformers

These are crucial for measurement and protection:

- Current transformers measure electrical current

- Voltage transformers measure voltage levels

- Both are compact and designed specifically for GIS environments

4. Busbars

Busbars are the highways of electrical distribution in a GIS:

- They connect different sections of the substation

- SF6 insulation allows for compact busbar design

- They’re typically made of aluminum or copper

5. SF6 Gas System

This system is unique to GIS and includes:

- Gas monitoring equipment

- Pressure relief devices

- Gas handling and recycling systems

Here’s a table summarizing the key components and their functions:

| Component | Function | Unique GIS Feature |

|---|---|---|

| Circuit Breakers | Interrupt fault currents | Enhanced arc quenching in SF6 |

| Disconnectors | Isolate sections | Compact design in SF6 |

| Earthing Switches | Provide grounding | Safe operation in sealed environment |

| Current/Voltage Transformers | Measurement and protection | Designed for GIS environment |

| Busbars | Connect substation sections | Compact due to SF6 insulation |

| SF6 Gas System | Maintain insulation medium | Crucial for GIS operation |

I remember a project where we were upgrading an old air-insulated substation to a GIS. The client was skeptical about fitting all these components into such a small space. We arranged a visit to a GIS manufacturer, and seeing the compact, modular design of each component in person was a game-changer. The client was amazed at how each element was engineered to work seamlessly in the SF6 environment.

One aspect that often surprises people new to GIS technology is the modularity of these components. Unlike traditional substations where components are spread out, GIS components are designed to be interconnected modules. This not only saves space but also allows for easier installation and future upgrades.

When working with GIS, it’s crucial to understand how these components interact:

- The circuit breakers and disconnectors work together to provide both protection and isolation.

- The current and voltage transformers feed critical data to the protection and control systems.

- The SF6 gas system continuously monitors and maintains the insulating medium, ensuring the reliability of all other components.

This integrated design is what makes GIS so powerful. Each component is not just miniaturized but optimized for operation in the SF6 environment. The result is a substation that’s not only compact but also more reliable and efficient than its air-insulated counterpart.

Understanding these components is essential for anyone working with or specifying GIS technology. It’s not just about space-saving; it’s about creating a more efficient, reliable, and flexible power distribution system.

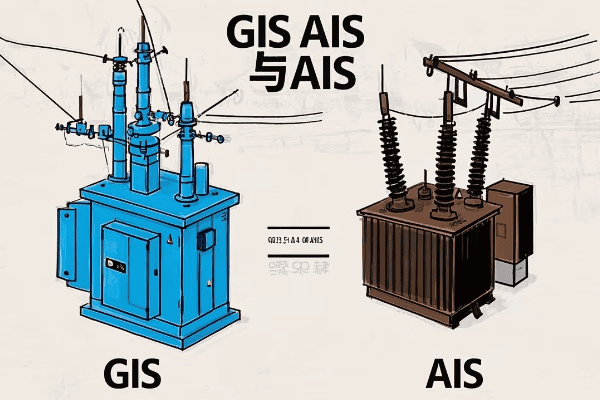

GIS vs AIS: What’s the Difference and Which One Should You Choose?

As someone who’s worked with both Gas Insulated Substations (GIS) and Air Insulated Substations (AIS), I’m often asked about their differences. It’s like comparing a smartphone to a landline – both make calls, but one offers significantly more in a smaller package.

The main difference between GIS and AIS lies in their insulating medium and size. GIS uses SF6 gas and is compact, while AIS uses air and requires more space. GIS is ideal for urban areas or where space is limited, while AIS is often more cost-effective for rural or spacious locations. The choice depends on factors like available space, environmental conditions, and budget.

Let’s dive deeper into the key differences and factors to consider when choosing between GIS and AIS:

Size and Space Requirements

-

GIS

- Typically 10-15% the size of an equivalent AIS

- Can be installed indoors, underground, or in tight spaces

- Ideal for urban areas or where land is expensive

-

AIS

- Requires large open areas

- Typically outdoor installations

- Suitable for rural areas or where land is readily available

Environmental Protection

-

GIS

- Enclosed design protects against environmental factors

- Can operate in harsh conditions (pollution, salt spray, etc.)

- Less affected by weather

-

AIS

- Exposed to environmental elements

- May require additional protection in harsh environments

- Performance can be affected by weather conditions

Maintenance Requirements

-

GIS

- Lower maintenance due to sealed environment

- Less frequent inspections needed

- Specialized skills required for SF6 handling

-

AIS

- Regular cleaning and inspection required

- More susceptible to environmental wear and tear

- Maintenance is generally simpler and doesn’t require specialized gas handling skills

Initial Cost vs. Long-term Cost

-

GIS

- Higher initial investment

- Lower long-term maintenance costs

- Potential savings in land costs in urban areas

-

AIS

- Lower initial cost

- Higher long-term maintenance costs

- May require significant land investment in urban areas

Here’s a comparison table to help visualize the differences:

| Factor | GIS | AIS |

|---|---|---|

| Space Requirement | Low | High |

| Environmental Protection | High | Low |

| Maintenance Frequency | Low | High |

| Initial Cost | High | Low |

| Long-term Cost | Lower | Higher |

| Flexibility in Location | High | Limited |

| Specialized Skills for Maintenance | Required | Not Required |

I recall a project where we were debating between GIS and AIS for a new substation in a growing suburban area. Initially, the client leaned towards AIS due to lower upfront costs. However, when we factored in the rapidly increasing land values and the area’s growth projections, GIS became the clear winner. The compact GIS design allowed for future expansion without additional land purchases, proving to be more cost-effective in the long run.

When choosing between GIS and AIS, consider these factors:

- Available Space: If space is limited, GIS is often the only viable option.

- Environmental Conditions: For harsh environments, GIS offers better protection.

- Future Expansion Plans: GIS offers more flexibility for future upgrades in tight spaces.

- Budget Constraints: Consider both initial and long-term costs.

- Maintenance Capabilities: Ensure you have access to necessary maintenance skills, especially for GIS.

In my experience, the trend is moving towards GIS, especially in urban and suburban areas. However, AIS still has its place, particularly in rural areas or where land is abundant and cheap.

Remember, the choice between GIS and AIS isn’t always black and white. In some cases, a hybrid approach using both technologies in different parts of the substation can provide the best of both worlds. Always consider your specific needs and constraints when making this important decision.

What Are the Advantages and Challenges of Using Gas Insulated Substations?

In my years working with power distribution systems, I’ve seen Gas Insulated Substations (GIS) transform the way we think about electrical infrastructure. But like any technology, GIS comes with its own set of pros and cons.

Gas Insulated Substations offer significant advantages in terms of space-saving, reliability, and environmental protection. However, they also present challenges such as higher initial costs, specialized maintenance requirements, and environmental concerns related to SF6 gas. Understanding these factors is crucial for making informed decisions about substation design and implementation.

Let’s dive deeper into the advantages and challenges of GIS:

Advantages of Gas Insulated Substations

-

Compact Design

- GIS can be up to 90% smaller than equivalent AIS

- Allows for installation in urban areas or indoor locations

- Reduces land acquisition costs

-

Increased Reliability

- Sealed environment protects against environmental factors

- Less exposure to pollution, humidity, and wildlife

- Reduced maintenance needs

-

Enhanced Safety

- Enclosed design minimizes risk of electrical accidents

- Reduced electromagnetic field emissions

- Fire risks are significantly lower

-

Flexibility in Installation

- Can be installed underground, in buildings, or on rooftops

- Modular design allows for easy expansion

- Suitable for harsh environments (coastal areas, industrial zones)

-

Long Lifespan

- Protected components last longer

- Typical lifespan of 40-50 years, compared to 30-40 for AIS

Challenges of Gas Insulated Substations

-

Higher Initial Costs

- GIS equipment is more expensive than AIS

- Specialized installation procedures increase costs

-

Specialized Maintenance

- Requires technicians trained in SF6 handling

- Special equipment needed for gas handling and testing

-

Environmental Concerns

- SF6 is a potent greenhouse gas

- Strict regulations on SF6 handling and disposal

- Potential for fines if gas leaks occur

-

Limited Accessibility

- Enclosed design can make some components hard to access

- Major repairs may require extensive disassembly

-

Technology Lock-in

- Once installed, switching to a different system is costly

- Future upgrades may be limited by the initial design

Here’s a table summarizing the advantages and challenges:

| Aspect | Advantages | Challenges |

|---|---|---|

| Space | Compact design | Limited accessibility |

| Reliability | High due to sealed environment | Specialized maintenance required |

| Safety | Enhanced personnel safety | Environmental risk from SF6 |

| Flexibility | Versatile installation options | Technology lock-in |

| Cost | Lower long-term costs | Higher initial investment |

| Lifespan | Longer than AIS | Disposal of SF6 at end-of-life |

I remember a project where we installed a GIS in a coastal area prone to salt spray and high humidity. The client was initially concerned about the higher upfront cost. However, after five years of operation, the reduced maintenance needs and consistent performance in the harsh environment more than justified the initial investment. The AIS in the same region required frequent cleaning and component replacements due to corrosion.

When considering GIS, it’s crucial to weigh these factors:

- Long-term Planning: Consider future expansion needs and potential technology advancements.

- Environmental Regulations: Stay informed about SF6 regulations in your area.

- Maintenance Capabilities: Ensure you have access to skilled technicians for GIS maintenance.

- Life Cycle Costs: Look beyond initial costs to total ownership costs over the substation’s lifespan.

- Site-Specific Factors: Consider local environmental conditions, space constraints, and reliability requirements.

In my experience, the advantages of GIS often outweigh the challenges, especially in urban or environmentally challenging locations. However, it’s not a one-size-fits-all solution. Each project requires careful consideration of these factors to determine if GIS is the right choice.

As the technology evolves, we’re seeing innovations that address some of these challenges. For example, some manufacturers are developing GIS designs that use alternative gases with lower environmental impact. It’s an exciting time in the industry, and I’m looking forward to seeing how these developments shape the future of power distribution.

How Do Gas Insulated Substations Impact Urban Power Distribution?

As cities grow taller and denser, the challenge of powering them efficiently becomes more complex. This is where Gas Insulated Substations (GIS) come into play, revolutionizing urban power distribution in ways that were unimaginablejust a few decades ago.

Gas Insulated Substations have a significant impact on urban power distribution by allowing high-voltage substations to be installed in compact spaces within cities. This enables power to be distributed more efficiently, closer to load centers, reducing transmission losses and improving reliability. GIS technology facilitates urban development without compromising on electrical infrastructure.

Let’s explore the various ways GIS impacts urban power distribution:

1. Space Optimization in Dense Urban Areas

In cities where every square foot counts, GIS offers a game-changing solution:

- Compact Footprint: A GIS can be up to 90% smaller than an equivalent AIS.

- Vertical Integration: GIS can be installed in multi-story buildings or underground.

- Repurposing of Space: Areas above or around GIS can be used for other purposes.

I once worked on a project in a major city where we installed a GIS on the ground floor of a new office building. The compact design allowed the developer to use the rest of the building for commercial space, effectively hiding the substation in plain sight.

2. Improved Power Quality and Reliability

GIS technology enhances the reliability of urban power distribution:

- Reduced Outages: Protected from environmental factors, GIS experiences fewer failures.

- Faster Restoration: Modular design allows for quicker repairs when issues do occur.

- Stable Voltage Profiles: Closer proximity to load centers helps maintain consistent voltage levels.

3. Aesthetic and Environmental Considerations

GIS helps cities maintain their aesthetic appeal and environmental standards:

- Visual Impact: Can be housed in buildings that blend with urban architecture.

- Noise Reduction: Enclosed design significantly reduces operational noise.

- EMF Mitigation: Metal enclosures contain electromagnetic fields, addressing public health concerns.

4. Facilitating Smart Grid Integration

GIS plays a crucial role in modernizing urban power grids:

- Digital Integration: Easy to incorporate advanced monitoring and control systems.

- Flexibility: Can accommodate changes in power flow directions, essential for renewable energy integration.

- Future-Proofing: Modular design allows for easier upgrades as technology advances.

Here’s a table comparing urban power distribution before and after GIS implementation:

| Aspect | Before GIS | After GIS |

|---|---|---|

| Substation Location | Outskirts of cities | Within city centers |

| Power Transmission Losses | Higher due to long distances | Reduced due to proximity to load |

| Land Use in Cities | Large areas dedicated to substations | Minimal land use, integration with buildings |

| Reliability | Vulnerable to environmental factors | Enhanced due to protected equipment |

| Aesthetic Impact | Visible, often unsightly | Can be hidden or integrated into architecture |

| Smart Grid Readiness | Limited | High, with easy integration of digital technologies |

I recall a project in a historic European city where installing a traditional substation would have been impossible due to space constraints and preservation laws. By using GIS technology, we were able to fit a high-capacity substation in the basement of a centuries-old building. This not only preserved the city’s character but also significantly improved power reliability in the old town area.

The impact of GIS on urban power distribution extends beyond just technical benefits:

- Economic Growth: Reliable power infrastructure attracts businesses and supports economic development.

- Urban Planning Flexibility: Planners have more options when they’re not constrained by large substation footprints.

- Sustainability: By reducing transmission losses and facilitating renewable energy integration, GIS supports cities’ sustainability goals.

- Public Safety: Enclosed GIS designs enhance safety in densely populated areas.

As cities continue to grow and evolve, the role of GIS in urban power distribution will only become more critical. The ability to provide reliable, high-capacity power in compact spaces is essential for supporting smart cities, electric vehicle charging infrastructure, and the increasing power demands of modern urban life.

What is the Environmental Impact of SF6 Gas in GIS Technology?

As someone deeply involved in the power industry, I’ve seen the tremendous benefits of Gas Insulated Substation (GIS) technology. However, it’s crucial to address the elephant in the room – the environmental impact of sulfur hexafluoride (SF6) gas used in these systems.

SF6 gas, while excellent for electrical insulation, is a potent greenhouse gas with a global warming potential 23,500 times that of CO2. Its use in GIS technology presents environmental challenges, including potential leaks and end-of-life disposal issues. However, proper management and emerging alternatives are helping to mitigate these concerns.

Let’s delve deeper into the environmental aspects of SF6 in GIS:

1. Global Warming Potential

SF6 is the most potent greenhouse gas known:

- High GWP: Global Warming Potential of 23,500 over 100 years.

- Long Atmospheric Lifetime: SF6 can persist in the atmosphere for up to 3,200 years.

- Cumulative Effect: Even small leaks can have a significant long-term impact.

2. Leakage Concerns

While GIS systems are designed to be sealed, leaks can occur:

- Annual Leakage Rate: Typically less than 0.1% per year, but can vary.

- Monitoring: Regular checks are essential to detect and prevent leaks.

- Repair Challenges: Fixing leaks in a live GIS can be complex and costly.

3. End-of-Life Disposal

Proper disposal of SF6 at the end of a GIS’s life is crucial:

- Recycling: SF6 can be reclaimed and purified for reuse.

- Destruction: Technologies exist to destroy SF6, but they’re energy-intensive.

- Regulatory Compliance: Strict regulations govern SF6 disposal in many countries.

4. Mitigation Strategies

The industry is actively working to reduce the environmental impact of SF6:

- Improved Sealing: Advanced designs minimize leakage potential.

- Better Monitoring: New technologies allow for more accurate leak detection.

- Alternative Gases: Research into less harmful insulating gases is ongoing.

Here’s a table summarizing the environmental aspects of SF6 use in GIS:

| Aspect | Impact | Mitigation Strategies |

|---|---|---|

| Global Warming Potential | Very High (23,500 times CO2) | Use of alternative gases, improved containment |

| Atmospheric Lifetime | 3,200 years | Proper disposal and recycling |

| Annual Leakage Rate | Typically <0.1% | Enhanced sealing, regular monitoring |

| End-of-Life Management | Challenging | Recycling, destruction technologies |

| Regulatory Compliance | Strict in many countries | Training, documentation, proper handling procedures |

I remember a project where we were upgrading an old GIS installation. The client was concerned about the environmental impact of the existing SF6. We implemented a comprehensive SF6 management plan, including advanced leak detection systems and a recycling program for the old gas. This not only addressed the environmental concerns but also improved the overall efficiency of the substation.

When dealing with SF6 in GIS, consider these key points:

- Lifecycle Management: Plan for proper handling from installation to decommissioning.

- Regular Monitoring: Implement robust leak detection and monitoring systems.

- Staff Training: Ensure all personnel are trained in proper SF6 handling procedures.

- Alternative Technologies: Stay informed about emerging alternatives to SF6.

- Regulatory Compliance: Keep up-to-date with and adhere to local and international regulations.

The industry is actively working on solutions to reduce the environmental impact of SF6:

- Gas Mixtures: Some manufacturers are developing GIS that use a mixture of SF6 and other gases, reducing the overall SF6 content.

- Alternative Gases: Research is ongoing into gases like fluoronitriles and fluoroketones that have much lower global warming potential.

- Vacuum Technology: For certain applications, vacuum interrupters are being used as an SF6-free alternative.

While the environmental impact of SF6 is a significant concern, it’s important to balance this against the benefits of GIS technology. The compact nature of GIS allows for more efficient power distribution in urban areas, potentially reducing overall energy consumption and associated emissions. Additionally, the reliability of GIS can lead to fewer outages and less energy waste.

As we move towards a more sustainable future, the power industry must continue to innovate and find ways to minimize the environmental impact of essential technologies like GIS. It’s an exciting time in the field, and I’m optimistic about the progress we’re making in developing more environmentally friendly solutions.

How Are Gas Insulated Substations Maintained and What Safety Measures Are Required?

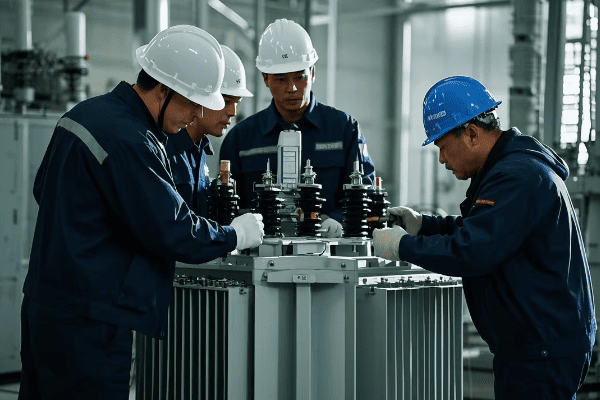

Maintaining a Gas Insulated Substation (GIS) is like performing a delicate ballet – it requires precision, expertise, and a keen awareness of safety. As someone who’s overseen numerous GIS maintenance operations, I can tell you that proper maintenance is crucial for the longevity and reliability of these systems.

Gas Insulated Substations require specialized maintenance procedures focusing on SF6 gas management, component inspection, and electrical testing. Safety measures are critical due to high voltage and the presence of SF6 gas. Key safety requirements include proper personal protective equipment (PPE), SF6 handling protocols, and strict adherence to lockout/tagout procedures.

Let’s break down the maintenance procedures and safety measures:

Maintenance Procedures

-

SF6 Gas Management

- Regular gas quality checks

- Leak detection and repair

- Gas pressure monitoring and top-up if necessary

-

Visual Inspections

- Check for signs of corrosion or damage

- Inspect seals and gaskets

- Verify proper operation of indicators and gauges

-

Electrical Testing

- Partial discharge measurements

- Contact resistance tests

- Insulation resistance tests

-

Mechanical Checks

- Verify proper operation of switches and circuit breakers

- Check alignment of components

- Lubricate moving parts as needed

-

Control and Protection Systems

- Test relay functions

- Calibrate measuring instruments

- Update software if required

Safety Measures

-

Personal Protective Equipment (PPE)

- Insulated gloves and boots

- Arc-flash protective clothing

- Respiratory protection when handling SF6

-

SF6 Handling Protocols

- Use specialized SF6 handling equipment

- Follow proper procedures for gas recovery and recycling

- Ensure adequate ventilation in work areas

-

Lockout/Tagout Procedures

- Implement strict procedures for de-energizing equipment

- Use personal locks and tags to prevent accidental energization

- Verify absence of voltage before work begins

-

Training and Certification

- Ensure all personnel are properly trained in GIS maintenance

- Require certification for SF6 handling

- Conduct regular safety refresher courses

-

Emergency Procedures

- Develop and practice emergency response plans

- Install SF6 gas detectors in GIS rooms

- Provide first aid training specific to electrical and SF6 exposure incidents

Here’s a maintenance and safety checklist table:

| Maintenance Task | Frequency | Safety Measures |

|---|---|---|

| SF6 Quality Check | Annual | PPE, Ventilation |

| Visual Inspection | Monthly | PPE, Lockout/Tagout |

| Electrical Testing | 2-3 Years | PPE, Lockout/Tagout, Training |

| Mechanical Checks | Annual | PPE, Lockout/Tagout |

| Control System Test | 6 Months | Training, Software Security |

| Leak Detection | Continuous | Gas Detectors, Ventilation |

I recall a maintenance operation where we discovered a small SF6 leak during a routine inspection. Thanks to our rigorous safety protocols and well-trained team, we were able to safely isolate the affected compartment, repair the leak, and recharge the system without any safety incidents or significant downtime. This experience reinforced the importance of regular maintenance and strict adherence to safety procedures.

Key considerations for GIS maintenance and safety:

- Predictive Maintenance: Implement condition monitoring systems to predict potential issues before they become critical.

- Documentation: Maintain detailed records of all maintenance activities and gas handling.

- Specialized Tools: Invest in proper tools and equipment designed for GIS maintenance.

- Environmental Compliance: Ensure all maintenance activities comply with environmental regulations regarding SF6 handling.

- Risk Assessment: Conduct thorough risk assessments before any maintenance activity.

Maintaining a GIS requires a different mindset compared to traditional air-insulated substations. The enclosed nature of GIS means that many components are not visible for easy inspection. This makes diagnostic tools and preventive maintenance even more critical.

One aspect that often surprises newcomers to GIS maintenance is the importance of cleanliness. Even tiny particles can compromise the insulating properties of SF6, so maintaining a clean environment during maintenance is crucial.

As technology evolves, we’re seeing new tools that make GIS maintenance safer and more efficient. For example, robotic inspection systems can now perform visual inspections in energized GIS compartments, reducing the need for shutdowns and human exposure to high-voltage environments.

Remember, while GIS technology offers many advantages in terms of reliability and compact design, it requires a specialized approach to maintenance and safety. By following proper procedures and investing in training and equipment, we can ensure that GIS continues to play a crucial role in our power distribution systems for years to come.

Conclusion

Gas Insulated Substations represent a significant advancement in power distribution technology, offering compact, reliable, and efficient solutions for modern electrical needs. While they present challenges, particularly in environmental impact and specialized maintenance, their benefits in urban settings and harsh environments are undeniable. As the technology evolves, GIS will continue to play a crucial role in shaping our electrical infrastructure.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group