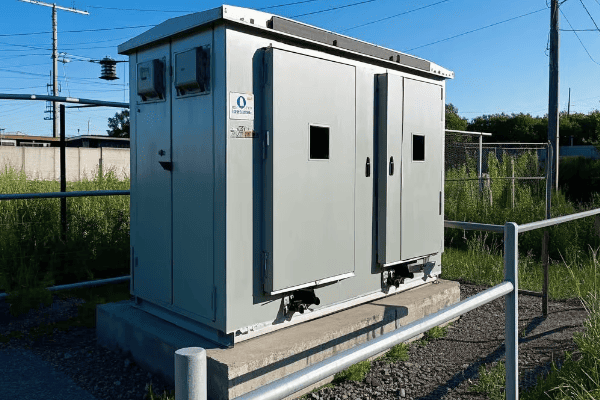

What is a Pad Mount Transformer: The Invisible Power Hub in Your Neighborhood?

Have you ever noticed those green metal boxes in your neighborhood? They’re more important than you might think!

Pad mount transformers are ground-level electrical devices that convert high voltage electricity to lower, usable voltages for homes and businesses. These unassuming boxes play a crucial role in powering our daily lives, hidden in plain sight throughout our communities.

As an electrical engineer with years of experience in power distribution, I’ve come to appreciate these silent workhorses of our electrical grid. Let’s explore the fascinating world of pad mount transformers and discover why they’re so important for our modern lifestyle.

How Do Pad Mount Transformers Work: The Magic Behind the Green Box?

Ever wondered what’s happening inside those mysterious green boxes? The answer might surprise you!

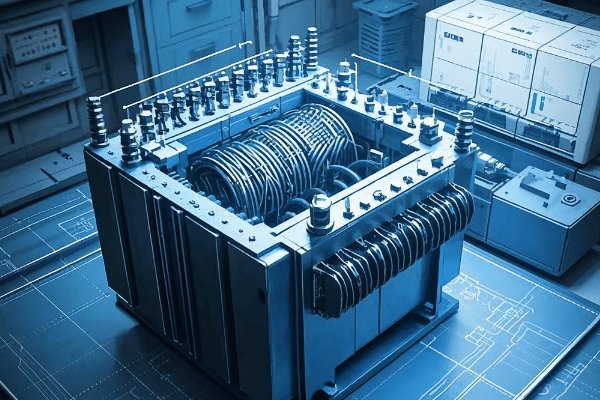

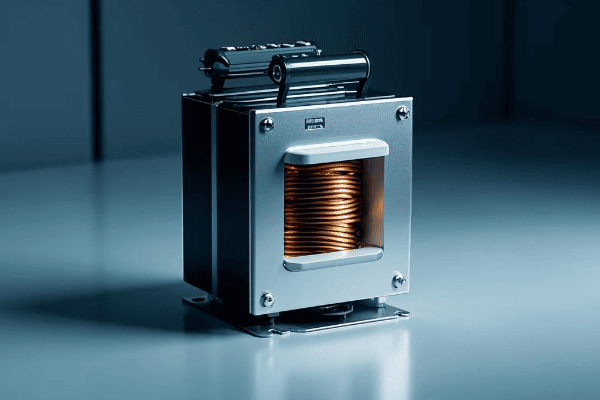

Pad mount transformers use electromagnetic induction to step down high voltage electricity to lower, safer levels for residential and commercial use. They contain coils of wire wrapped around an iron core, converting electrical energy efficiently and safely.

I remember the first time I opened a pad mount transformer. The complexity inside that simple-looking box amazed me. Let’s break down how these devices work:

The Basics of Transformer Operation

- Primary Winding: This coil receives high voltage electricity from power lines.

- Secondary Winding: This coil outputs lower voltage electricity for consumer use.

- Iron Core: This concentrates the magnetic field, improving efficiency.

The key to a transformer’s operation is the principle of electromagnetic induction. When alternating current flows through the primary winding, it creates a changing magnetic field. This field induces a voltage in the secondary winding. The ratio of turns in the primary and secondary windings determines the voltage change.

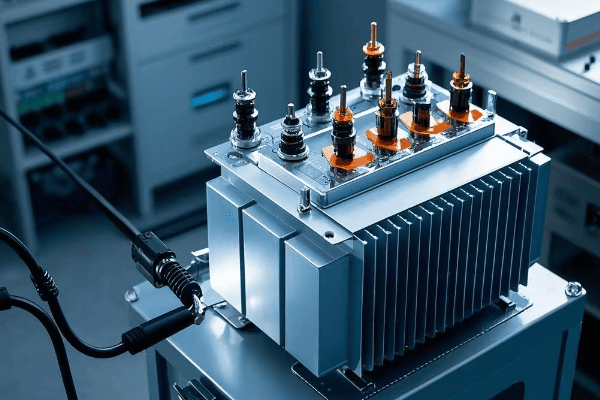

Components of a Pad Mount Transformer

| Component | Function |

|---|---|

| Tank | Houses all internal components and insulating oil |

| Bushings | Provide insulated entry/exit points for electrical connections |

| Tap Changer | Allows for minor voltage adjustments |

| Cooling Fins | Help dissipate heat |

| Pressure Relief Device | Prevents damage from internal pressure buildup |

In my experience, the efficiency of these transformers is remarkable. A well-designed pad mount transformer can operate at over 98% efficiency, meaning very little energy is lost in the conversion process.

Types of Pad Mount Transformers

- Single-Phase: Used in residential areas, typically serving 5-8 homes.

- Three-Phase: Found in commercial and industrial settings, handling higher power needs.

I once worked on a project upgrading a neighborhood from single-phase to three-phase power. The increase in available power was significant, allowing for more electric vehicle charging stations and home workshops.

Insulation and Cooling

Pad mount transformers use oil for insulation and cooling. This oil serves three crucial functions:

- It insulates the internal components from each other.

- It helps dissipate heat generated during operation.

- It prevents moisture from damaging the internal components.

The use of oil allows these transformers to be compact yet powerful. However, it also means they need regular maintenance to check oil levels and quality.

Understanding how pad mount transformers work is key to appreciating their role in our power distribution system. These devices are a testament to the ingenuity of electrical engineering, quietly performing their vital function day and night.

The Anatomy of a Pad Mount Transformer: What’s Inside That Metal Cabinet?

Curious about what’s hidden behind that green metal door? Let’s take a peek inside!

A pad mount transformer contains several key components: the core, windings, insulating oil, bushings, and protective devices. Each part plays a crucial role in converting high voltage electricity to usable levels for homes and businesses.

I’ve spent countless hours working with these transformers, and I’m always impressed by their intricate design. Let’s explore the main components:

Core Components of a Pad Mount Transformer

-

Core

- Made of thin laminations of silicon steel

- Shapes: Shell type or core type

- Function: Concentrates magnetic flux

-

Windings

- Primary (high voltage) and secondary (low voltage) coils

- Material: Usually copper or aluminum

- Insulated with paper and immersed in oil

-

Insulating Oil

- Types: Mineral oil or newer synthetic options

- Functions: Insulation, cooling, and moisture protection

-

Bushings

- High voltage and low voltage connections

- Material: Porcelain or polymer

- Function: Safely conduct electricity in and out of the transformer

-

Tank

- Houses all internal components

- Material: Steel with corrosion-resistant coating

- Features: Cooling fins or radiators for heat dissipation

| Component | Material | Function |

|---|---|---|

| Core | Silicon Steel | Magnetic flux concentration |

| Windings | Copper/Aluminum | Voltage transformation |

| Oil | Mineral/Synthetic | Insulation and cooling |

| Bushings | Porcelain/Polymer | Electrical connections |

| Tank | Steel | Housing and protection |

Protective Devices

Pad mount transformers also include several safety features:

- Pressure Relief Valve: Prevents explosion in case of excessive internal pressure

- Fuses: Protect against overcurrent

- Lightning Arresters: Guard against voltage surges

- Temperature Gauge: Monitors internal temperature

I once witnessed the importance of these safety features firsthand. During a severe thunderstorm, a nearby transformer was struck by lightning. Thanks to its lightning arrester and other protective devices, the transformer survived without any damage to the internal components.

The Importance of Proper Sealing

One crucial aspect of pad mount transformer design is its sealed construction. This serves several purposes:

- Safety: Prevents unauthorized access to high voltage components

- Environmental Protection: Keeps water and contaminants out

- Noise Reduction: Contains operational noise

- Aesthetics: Allows for a clean, unobtrusive appearance in residential areas

The sealed design is a significant improvement over older, open-air transformer designs. It’s one of the reasons pad mount transformers have become the preferred choice for many urban and suburban areas.

Understanding the anatomy of a pad mount transformer helps appreciate the engineering that goes into these devices. Each component is carefully designed and integrated to ensure safe, efficient, and reliable power distribution. As technology advances, we’re seeing innovations in materials and designs that make these transformers even more efficient and environmentally friendly.

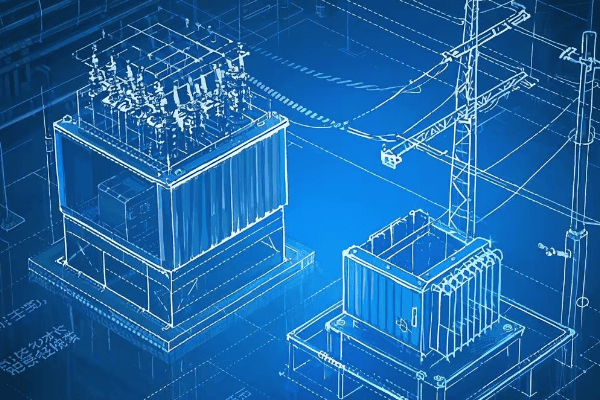

Pad Mount vs. Pole Mount Transformers: Why the Shift to Ground-Level Power?

Ever wondered why we’re seeing more green boxes on the ground instead of transformers on poles? The answer lies in both practicality and aesthetics.

Pad mount transformers offer several advantages over pole mount types, including improved safety, easier maintenance, better aesthetics, and increased reliability. This shift to ground-level power distribution reflects our changing urban landscapes and electrical needs.

In my career, I’ve worked with both types of transformers, and the transition to pad mount has been a game-changer. Let’s compare these two transformer types:

Key Differences Between Pad Mount and Pole Mount Transformers

| Feature | Pad Mount | Pole Mount |

|---|---|---|

| Location | Ground level | Elevated on utility poles |

| Accessibility | Easy access for maintenance | Requires climbing or lift equipment |

| Safety | Enclosed, tamper-resistant | More exposed to elements and potential hazards |

| Aesthetics | Less visually intrusive | More visible in skyline |

| Capacity | Generally higher | Limited by pole strength |

| Weather Resistance | Better protected | More exposed to storms and wildlife |

Advantages of Pad Mount Transformers

-

Safety:

- Enclosed design reduces risk of electrical accidents

- Less vulnerable to vehicle collisions

-

Maintenance:

- Easy ground-level access for technicians

- Can be serviced in all weather conditions

-

Reliability:

- Better protected from weather and wildlife

- Less susceptible to damage from falling trees or branches

-

Aesthetics:

- Lower profile improves neighborhood appearance

- Can be easily concealed with landscaping

-

Capacity:

- Can handle larger loads due to size flexibility

- Easier to upgrade as community needs grow

I remember a project where we replaced pole mount transformers with pad mount units in a suburban area prone to ice storms. The following winter, while neighboring areas experienced outages due to ice-laden power lines, our pad mount transformers continued to operate flawlessly.

Challenges in Transitioning to Pad Mount Transformers

While pad mount transformers offer many benefits, the transition isn’t without challenges:

-

Space Requirements:

- Need clear ground space for installation

- Can be challenging in densely built areas

-

Initial Costs:

- Installation may be more expensive than pole mounting

- Requires construction of concrete pad

-

Flooding Concerns:

- Must be elevated or specially designed in flood-prone areas

-

Public Perception:

- Some residents may be concerned about having transformers at ground level

- Education about safety features is often necessary

Despite these challenges, the benefits of pad mount transformers often outweigh the drawbacks. In my experience, once people understand the advantages, they usually prefer the pad mount option.

The Future of Power Distribution

The shift towards pad mount transformers is part of a larger trend in modernizing our power grid. As we move towards smart grids and renewable energy integration, pad mount transformers offer several advantages:

- Smart Grid Integration: Easier to equip with sensors and communication devices

- Renewable Energy: Better suited for bi-directional power flow from solar and wind sources

- Electric Vehicle Charging: Can be more easily upgraded to handle increased loads

As our electrical needs continue to evolve, pad mount transformers are well-positioned to meet these changing demands. Their flexibility, safety, and reliability make them an excellent choice for modern power distribution systems.

Safety Features of Pad Mount Transformers: Protecting Your Community

Worried about the safety of those green boxes in your neighborhood? You’ll be relieved to know they’re designed with multiple layers of protection.

Pad mount transformers incorporate several safety features, including tamper-resistant enclosures, internal fuses, and automatic shut-off mechanisms. These features work together to protect both the public and utility workers from electrical hazards.

As someone who’s worked extensively with these transformers, I can assure you that safety is a top priority in their design. Let’s explore the key safety features:

Key Safety Features of Pad Mount Transformers

-

Tamper-Resistant Enclosure

- Locked metal cabinet

- Requires special tools to open

- Deters unauthorized access

-

Dead-Front Design

- No exposed live parts when opened

- Reduces risk of accidental contact with high voltage components

-

Internal Fuses

- Protect against overcurrent

- Automatically disconnect in case of faults

-

Lightning Arresters

- Protect against voltage surges

- Divert excess energy to ground

-

Pressure Relief Device

- Prevents explosion in case of internal pressure buildup

- Safely vents excess pressure

| Safety Feature | Function | Benefit |

|---|---|---|

| Tamper-Resistant Enclosure | Prevents unauthorized access | Public safety |

| Dead-Front Design | Eliminates exposed live parts | Worker safety |

| Internal Fuses | Protect against overcurrent | Equipment protection |

| Lightning Arresters | Guard against voltage surges | Reliability |

| Pressure Relief Device | Prevents explosion | Catastrophic failure prevention |

I once witnessed these safety features in action during a severe thunderstorm. A nearby pad mount transformer was struck by lightning, but thanks to its built-in arresters and other protective devices, it continued to function normally. This incident really drove home the importance of these safety measures.

Additional Safety Measures

Beyond the built-in features, there are other safety aspects to consider:

-

Grounding

- All metal parts are grounded

- Prevents electric shock in case of insulation failure

-

Warning Labels

- Clear signage indicating high voltage danger

- Instructions for emergency situations

-

Regular Inspections

- Utility companies perform routine checks

- Ensure all safety features are functioning properly

-

Oil Containment

- Designed to prevent oil leaks

- Environmentally friendly options available

Safety Protocols for Utility Workers

While pad mount transformers are designed for safety, utility workers still follow strict protocols:

-

Personal Protective Equipment (PPE)

- Insulated gloves and boots

- Arc-flash protective clothing

-

Lock-Out/Tag-Out Procedures

- Ensure power is off before maintenance

- Prevent accidental re-energizing

-

Regular Training

- Workers are trained on latest safety procedures

- Includes emergency response drills

Public Safety Education

As part of my role, I often participate in community outreach programs to educate the public about transformer safety. Here are some key points we emphasize:

- Never touch or attempt to open a pad mount transformer

- Keep the area around transformers clear of debris and vegetation

- Report any signs of damage or tampering to your local utility company

- In case of fire or unusual noises, stay away and call emergency services

Understanding these safety features and protocols helps build public confidence in our power distribution system. Pad mount transformers are designed with multiple layers of protection to ensure the safety of both the public and utility workers. As technology advances, we continue to see improvements in safety features, making these essential components of our power grid even more secure and reliable.

Environmental Impact: Are Pad Mount Transformers Eco-Friendly?

Concerned about the environmental footprint of those green boxes in your neighborhood? You’re not alone in wondering about their eco-friendliness.

Pad mount transformers have both positive and negative environmental impacts. While they contribute to efficient power distribution and can be designed with eco-friendly materials, they also contain potentially harmful substances that require careful handling and disposal.

As an engineer who’s worked with these transformers for years, I’ve seen the industry’s efforts to make them more environmentally friendly. Let’s explore the environmental aspects of pad mount transformers:

Positive Environmental Impacts

-

Energy Efficiency

- Modern designs achieve up to 99% efficiency

- Reduces energy losses in distribution

-

Land Use

- Smaller footprint compared to substations

- Can be integrated into urban landscapes

-

Noise Pollution

- Quieter operation than older transformer types

- Typically below 60 dB at 5 feet (similar to normal conversation)

-

Longevity

- Lifespan of 20-30 years

- Reduces need for frequent replacements

Environmental Challenges

-

Oil Use

- Traditional mineral oil can be harmful if leaked

- Proper containment and disposal required

-

PCB Legacy

- Older transformers may contain PCBs

- Requires special handling and disposal

-

End-of-Life Disposal

- Contains materials that need proper recycling

- Copper and steel can be recycled, but other components may be hazardous

-

Manufacturing Impact

- Production involves resource extraction and energy use

| Aspect | Positive Impact | Negative Impact |

|---|---|---|

| Energy Use | High efficiency reduces losses | Manufacturing energy intensive |

| Materials | Long-lasting, recyclable metals | Some hazardous components |

| Land Use | Small footprint | May impact local ecosystems if not properly sited |

| Noise | Low noise levels | Still contributes some noise pollution |

I remember a project where we replaced old oil-filled transformers with newer, more eco-friendly dry-type units in a sensitive wetland area. The reduction in potential environmental risk was significant, and it gave us all a sense of pride in contributing to a more sustainable power system.

Innovations for Eco-Friendliness

The industry is constantly working on making pad mount transformers more environmentally friendly:

-

Bio-based Oils

- Vegetable-based oils as insulating fluid

- Biodegradable and less toxic

-

Dry-Type Transformers

- Eliminate need for insulating oil

-

Smart Transformers

- Optimize power flow, reducing energy waste

- Enable better integration of renewable energy sources

-

Recycling Programs

- Many utilities now have programs to recycle old transformer components

- Reduces waste and recovers valuable materials

-

SF6-Free Designs

- Eliminating use of sulfur hexafluoride, a potent greenhouse gas

- Replacing with more environmentally friendly insulating gases

In my experience, these innovations are making a real difference. I’ve seen firsthand how newer, eco-friendly transformers can significantly reduce environmental risks while maintaining or even improving performance.

Environmental Considerations in Transformer Siting

Proper placement of pad mount transformers is crucial for minimizing environmental impact:

- Flood Protection: Elevating transformers in flood-prone areas

- Wildlife Considerations: Designing enclosures to prevent animal intrusion

- Vegetation Management: Using native plants for screening without interfering with operation

- Soil Protection: Installing proper foundations and containment to prevent soil contamination

The Bigger Picture

While pad mount transformers do have some environmental impacts, they play a crucial role in our power infrastructure. Their efficiency in power distribution contributes to overall energy savings, which has a net positive environmental impact. As we move towards more renewable energy sources, efficient and reliable transformers become even more important in managing our power grid sustainably.

Understanding the environmental aspects of pad mount transformers helps us appreciate the complexities of balancing our energy needs with environmental stewardship. As technology advances, we’re continually finding ways to make these essential devices more eco-friendly.

Installation and Maintenance: Keeping Your Neighborhood’s Power Hub Running Smoothly

Ever wondered how those green boxes are installed and kept in top shape? It’s a process that requires precision and regular attention.

Installing pad mount transformers involves careful site preparation, precise placement, and proper connection to the power grid. Ongoing maintenance is crucial for ensuring reliability, safety, and longevity, including regular inspections, oil testing, and component replacements.

As someone who’s overseen numerous installations and maintenance operations, I can tell you it’s a complex but fascinating process. Let’s dive into the details:

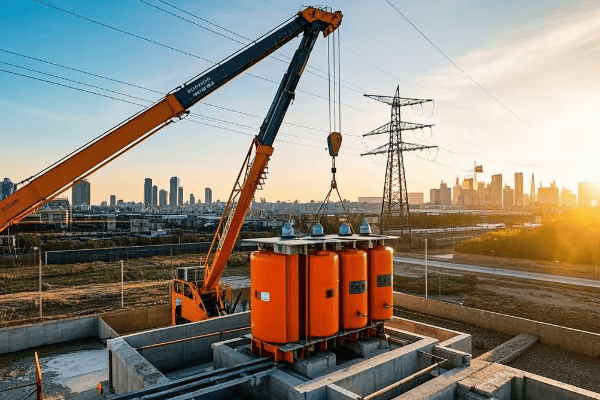

Installation Process

-

Site Preparation

- Excavation and leveling of the area

- Pouring a concrete pad (typically 6-8 inches thick)

- Installing grounding grid and conduits

-

Transformer Placement

- Using a crane to carefully position the transformer

- Ensuring proper alignment with conduits

-

Electrical Connections

- Connecting primary (high voltage) cables

- Connecting secondary (low voltage) cables

- Installing lightning arresters and grounding

-

Testing and Commissioning

- Performing insulation resistance tests

- Checking for proper voltage output

- Verifying all safety features

| Installation Step | Key Considerations | Typical Duration |

|---|---|---|

| Site Preparation | Soil conditions, drainage | 1-2 days |

| Transformer Placement | Weight, access for crane | 1 day |

| Electrical Connections | Cable sizing, proper terminations | 1-2 days |

| Testing and Commissioning | Safety protocols, accuracy of measurements | 1 day |

I remember an installation in a densely populated urban area where space was at a premium. We had to coordinate with multiple city departments and use specialized compact equipment to get the job done. It was challenging, but seeing the transformer seamlessly integrated into the neighborhood was incredibly satisfying.

Maintenance Procedures

Regular maintenance is crucial for the longevity and reliability of pad mount transformers:

-

Visual Inspections (Monthly to Quarterly)

- Check for oil leaks

- Inspect for physical damage or signs of tampering

- Ensure proper vegetation clearance

-

Oil Testing (Annually)

- Sample and analyze insulating oil

- Check for moisture content and dielectric strength

- Test for dissolved gases (indicator of internal issues)

-

Thermal Imaging (Annually)

- Use infrared cameras to detect hot spots

- Identify potential issues before they cause failures

-

Electrical Testing (Every 3-5 years)

- Perform turns ratio test

- Check insulation resistance

- Verify proper operation of protective devices

-

Component Replacement (As needed)

- Replace gaskets to prevent oil leaks

- Update bushings or other worn components

- Retrofit with newer, more efficient parts when possible

Challenges in Maintenance

Maintaining pad mount transformers comes with its own set of challenges:

- Access Issues: Sometimes transformers are installed in hard-to-reach locations

- Weather Conditions: Maintenance may be affected by extreme temperatures or storms

- Aging Infrastructure: Older transformers may require more frequent attention

- Balancing Act: Minimizing downtime while ensuring thorough maintenance

I once dealt with a transformer that was showing signs of overheating. Through careful analysis and thermal imaging, we discovered that the cooling fins were partially clogged with debris. A thorough cleaning resolved the issue, potentially preventing a costly failure.

Importance of Proactive Maintenance

Proactive maintenance is key to preventing issues before they occur:

- Predictive Maintenance: Using data and trends to anticipate potential problems

- Condition-Based Monitoring: Installing sensors for real-time health monitoring

- Asset Management Systems: Tracking maintenance history and scheduling future work

Training and Safety

Proper training for maintenance personnel is crucial:

- Safety Protocols: Rigorous training on electrical safety and PPE use

- Technical Skills: Ongoing education on new technologies and maintenance techniques

- Emergency Response: Preparation for potential failures or accidents

In my career, I’ve seen how good maintenance practices can significantly extend the life of a transformer and prevent unexpected outages. It’s not just about keeping the lights on; it’s about ensuring the safety and reliability of our entire power distribution system.

The Role of Pad Mount Transformers in Smart Grids: Powering the Future

Curious about how those green boxes fit into the future of energy? They’re more high-tech than you might think!

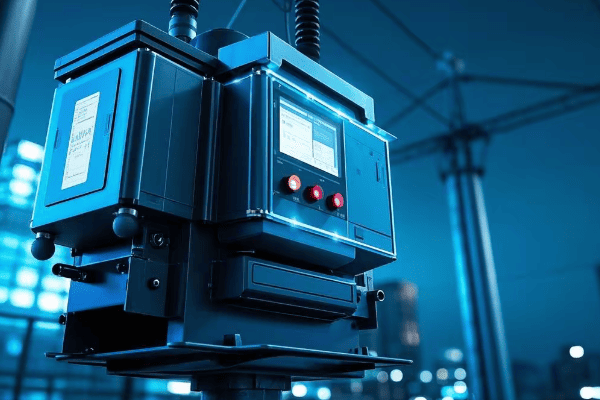

Pad mount transformers are evolving to play a crucial role in smart grids. They’re being equipped with sensors, communication devices, and advanced control systems to enable real-time monitoring, improved efficiency, and better integration of renewable energy sources.

As someone who’s been involved in smart grid projects, I’ve seen firsthand how pad mount transformers are becoming the backbone of our modern power distribution system. Let’s explore their role in smart grids:

Key Features of Smart Pad Mount Transformers

-

Real-Time Monitoring

- Sensors for load, temperature, and oil condition

- Immediate alert system for faults or abnormalities

-

Communication Capabilities

- Integration with SCADA (Supervisory Control and Data Acquisition) systems

- Two-way communication for remote control and data transmission

-

Advanced Voltage Regulation

- Automatic tap changers for voltage optimization

- Helps manage fluctuations from renewable energy sources

-

Data Analytics

- Predictive maintenance based on operational patterns

- Load forecasting for better grid management

| Feature | Traditional Transformer | Smart Transformer |

|---|---|---|

| Monitoring | Manual inspections | Real-time, continuous |

| Communication | None | Two-way with control center |

| Voltage Regulation | Fixed or manual adjustment | Automatic, dynamic |

| Maintenance | Schedule-based | Condition-based |

I remember implementing a smart transformer system in a neighborhood with high solar panel adoption. The ability to manage bi-directional power flow and voltage fluctuations made a significant difference in grid stability and efficiency.

Benefits of Smart Pad Mount Transformers in Grid Operations

-

Improved Reliability

- Quick identification and isolation of faults

- Reduced outage duration and frequency

-

Enhanced Efficiency

- Optimized power flow reduces energy losses

- Better load balancing across the grid

-

Integration of Renewable Energy

- Better management of intermittent sources like solar and wind

- Facilitates grid-scale energy storage integration

-

Demand Response Capabilities

- Enables participation in demand response programs

- Helps manage peak loads more effectively

-

Asset Management

- Extended equipment life through predictive maintenance

- More efficient use of utility resources

Challenges in Implementing Smart Transformers

While the benefits are significant, there are challenges to overcome:

- Cost: Smart features increase initial investment

- Cybersecurity: Increased connectivity raises security concerns

- Skill Gap: Requires workforce training in new technologies

- Data Management: Handling and analyzing large volumes of data

In my experience, addressing these challenges requires a collaborative approach between utilities, technology providers, and regulators. I’ve been part of projects where we’ve had to develop new protocols for data security and train teams in advanced data analytics.

Future Trends in Smart Transformer Technology

Looking ahead, I see several exciting developments on the horizon:

- AI and Machine Learning: For more sophisticated predictive maintenance and grid optimization

- Edge Computing: Processing data locally for faster response times

- Energy Storage Integration: Combining transformers with battery storage for enhanced grid stability

- Self-Healing Grids: Transformers playing a key role in automated fault detection and recovery

The Bigger Picture: Transforming Our Energy Landscape

Smart pad mount transformers are more than just an upgrade to our existing infrastructure. They’re a fundamental shift in how we manage and distribute energy. As we move towards a more decentralized, renewable-based energy system, these smart devices will be crucial in maintaining grid stability and efficiency.

In my career, I’ve seen the power industry evolve dramatically. The integration of smart pad mount transformers into our grids is one of the most exciting developments I’ve witnessed. It’s not just about keeping the lights on; it’s about creating a more resilient, efficient, and sustainable energy future for all of us.

Conclusion

Pad mount transformers are the unsung heroes of our electrical grid, quietly powering our neighborhoods while adapting to the challenges of modern energy needs. From their efficient design to their evolving role in smart grids, these devices are crucial for a reliable and sustainable power distribution system.

🚀Next steps, you can:

A. Learn more about smart grid technologies

B. Explore careers in electrical engineering and power systems

C. Investigate energy efficiency improvements for your home

D. Understand how to report transformer issues in your area

E. Discover the role of transformers in renewable energy integration

F. Find out about community initiatives for grid modernization

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group