What is a Triplex Core Transformer and Why is it Used in Building Installations?

Have you ever wondered how large buildings manage their power distribution in tight spaces? The answer might lie in a clever piece of technology called the triplex core transformer.

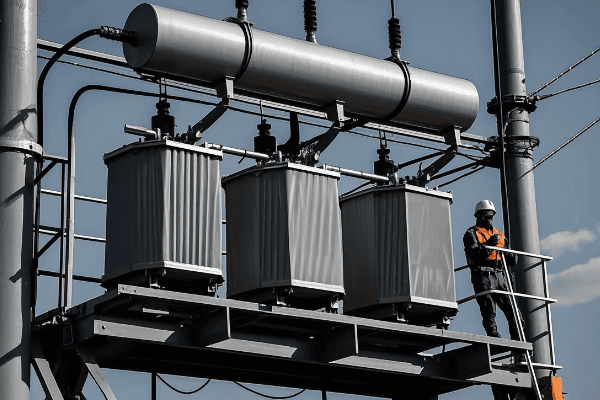

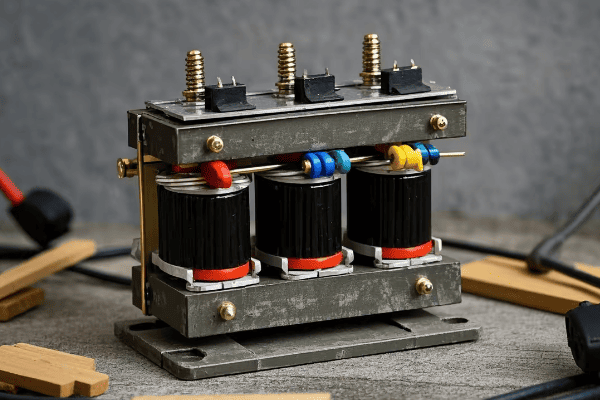

A triplex core transformer is a specialized electrical device that consists of three single-phase transformers in one unit. It’s used in building installations because it can be easily disassembled and reassembled, making it ideal for tight spaces or buildings with limited access.

As someone who’s worked in the power distribution industry for years, I’ve seen firsthand how triplex core transformers can solve complex installation challenges. Let’s dive into the details of this innovative technology and explore why it’s becoming increasingly popular in modern building designs.

How Does a Triplex Core Transformer Differ from Traditional Transformers?

Imagine trying to fit a large, bulky piece of furniture through a narrow doorway. That’s often the challenge with traditional transformers in building installations. Triplex core transformers offer a solution to this common problem.

Triplex core transformers differ from traditional transformers in their modular design. They consist of three separate single-phase units that can be easily disassembled. Traditional transformers, on the other hand, are typically one large, integrated unit. This key difference allows for much greater flexibility in installation and maintenance.

Let’s break down the key differences:

Design and Structure

-

Triplex Core Transformer

- Three separate single-phase units

- Modular design for easy disassembly

- Compact when assembled

-

Traditional Transformer

- Single integrated unit

- Fixed design

- Often bulkier overall

Installation Flexibility

Triplex core transformers offer significant advantages when it comes to installation. I remember a project where we needed to upgrade the power distribution in an old office building. The service elevator was too small for a traditional transformer, but we easily transported a triplex core transformer piece by piece and assembled it on-site.

Maintenance and Repairs

Another major difference lies in maintenance. With a triplex core transformer, you can often service or replace one phase without shutting down the entire system. This can be a huge advantage in critical applications where downtime is costly.

Here’s a comparison table to illustrate the differences:

| Feature | Triplex Core Transformer | Traditional Transformer |

|---|---|---|

| Design | Modular (3 single-phase units) | Integrated single unit |

| Installation | Easy in tight spaces | Can be challenging in confined areas |

| Maintenance | Can service individual phases | Typically requires full shutdown |

| Size | Compact when assembled | Often larger overall |

| Flexibility | High | Low |

In my experience, the choice between a triplex core and a traditional transformer often comes down to the specific requirements of the installation site. While traditional transformers are still widely used and have their advantages, triplex core transformers are becoming increasingly popular in urban environments where space is at a premium.

What Are the Key Components of a Triplex Core Transformer?

When I first encountered a triplex core transformer, I was amazed by its ingenious design. Understanding its components is crucial for anyone involved in power distribution or building management.

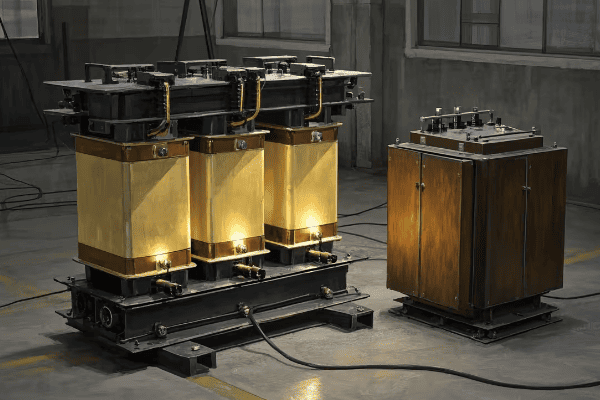

A triplex core transformer consists of three main components: the core, the windings, and the enclosure. Each of the three single-phase units has its own core and windings, all housed within a common enclosure. This design allows for modularity while maintaining the functionality of a three-phase transformer.

Let’s dive deeper into each component:

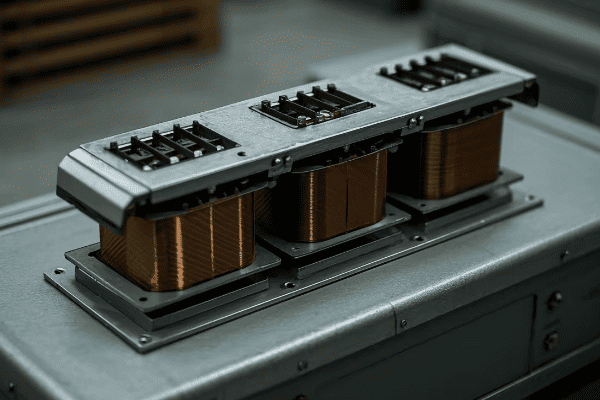

1. The Core

The core is the heart of each single-phase unit in a triplex core transformer. Here’s what you need to know:

- Material: Typically made of high-grade silicon steel

- Design: Usually a shell-type or core-type design

- Function: Provides a path for magnetic flux, crucial for the transformation process

2. The Windings

Each single-phase unit has its own set of windings. These are key to the transformer’s operation:

- Primary Winding: Connects to the input voltage

- Secondary Winding: Delivers the output voltage

- Material: Usually copper or aluminum

- Insulation: High-quality materials to prevent short circuits

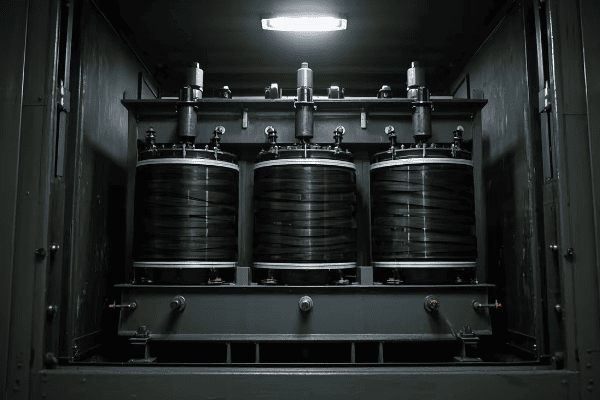

3. The Enclosure

The enclosure is what sets triplex core transformers apart. It houses all three single-phase units:

- Design: Modular for easy disassembly

- Material: Usually steel, with proper ventilation

- Features: Often includes cooling systems and monitoring equipment

Here’s a table summarizing the components:

| Component | Function | Key Features |

|---|---|---|

| Core | Magnetic flux path | High-grade silicon steel, efficient design |

| Windings | Voltage transformation | Copper/aluminum, well-insulated |

| Enclosure | Houses components | Modular, steel construction, cooling system |

In my years of working with transformers, I’ve found that the modular nature of triplex core transformers offers unique advantages. For instance, I once worked on a project where we needed to replace a faulty winding. With a traditional transformer, this would have meant replacing the entire unit. But with the triplex core design, we were able to replace just the affected single-phase unit, saving time and money.

Understanding these components is crucial for anyone working with or specifying triplex core transformers. The modular design not only aids in installation but also in maintenance and repairs, making these transformers a versatile choice for many building installations.

Why Are Triplex Core Transformers Ideal for Tight Installation Spaces?

Have you ever tried to squeeze a large appliance through a narrow doorway? That’s often the challenge with installing traditional transformers in existing buildings. This is where triplex core transformers shine.

Triplex core transformers are ideal for tight installation spaces because of their modular design. They can be disassembled into smaller, more manageable parts, making it easier to transport through narrow corridors, small elevators, or tight spaces. Once at the installation site, they can be reassembled quickly.

Let’s explore why this design is so advantageous in confined spaces:

1. Easy Transportation

The modular nature of triplex core transformers makes them much easier to transport. I remember a project in an old downtown building where the service elevator was too small for a traditional transformer. We easily moved the triplex core transformer piece by piece and assembled it on-site.

2. Flexible Installation

Triplex core transformers offer more flexibility in terms of layout. You can arrange the three single-phase units in various configurations to fit the available space. This is particularly useful in buildings with irregular-shaped utility rooms.

3. Reduced Need for Large Access Points

With traditional transformers, you often need to create large access points or even remove walls to get the equipment in place. Triplex core transformers can usually be brought in through standard doorways, reducing installation costs and structural modifications.

4. Easier Future Replacements or Upgrades

If you need to replace or upgrade the transformer in the future, the modular design of triplex core transformers makes this process much simpler. You don’t need to worry about how you’ll remove a large, integrated unit.

Here’s a comparison table of installation considerations:

| Factor | Triplex Core Transformer | Traditional Transformer |

|---|---|---|

| Transportation | Easy, can be moved in parts | Challenging, requires large access |

| Layout Flexibility | High, can be arranged to fit space | Low, fixed configuration |

| Access Requirements | Standard doorways often sufficient | May require wall removal or large openings |

| Future Replacement | Simplified, can replace parts | Complex, may require complete unit removal |

In my experience, the advantages of triplex core transformers in tight spaces go beyond just the initial installation. I once worked on a project where we needed to upgrade the power capacity of an old office building. The existing utility room was cramped, with no easy way to remove the old transformer or bring in a new, larger one. By switching to a triplex core design, we were able to increase capacity without major construction work.

The ability to work within existing spatial constraints is becoming increasingly important as cities grow denser and buildings are repurposed. Triplex core transformers offer a solution that can adapt to these challenges, making them an excellent choice for urban environments and retrofit projects.

How Do You Install and Maintain a Triplex Core Transformer?

Installing and maintaining a triplex core transformer might seem daunting at first, but with the right approach, it can be more straightforward than you might think. Let me walk you through the process based on my years of experience in the field.

Installing a triplex core transformer involves transporting the disassembled units, reassembling them on-site, and connecting them to the power system. Maintenance includes regular inspections, oil testing (for oil-filled units), and occasional part replacements. The modular design allows for easier maintenance compared to traditional transformers.

Let’s break down the installation and maintenance process:

Installation Process

-

Site Preparation

- Ensure the installation area meets size and weight requirements

- Prepare a proper foundation or mounting surface

-

Transportation

- Move the disassembled units to the installation site

- This is often easier than moving a single large transformer

-

Assembly

- Carefully reassemble the three single-phase units

- Follow manufacturer guidelines for proper alignment

-

Connection

- Connect the primary and secondary windings

- Install any necessary cooling systems or monitoring equipment

-

Testing

- Conduct thorough testing before energizing the transformer

Maintenance Procedures

-

Regular Inspections

- Visual checks for any signs of damage or wear

- Listen for unusual noises during operation

-

Oil Testing (for oil-filled units)

- Regular oil sampling and analysis

- Top up or replace oil as needed

-

Thermal Imaging

- Use infrared cameras to detect hot spots

-

Part Replacement

- Replace individual components as needed, without necessarily replacing the entire transformer

Here’s a maintenance schedule table based on my experience:

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Visual Inspection | Monthly | High |

| Oil Testing | Annually | Critical |

| Thermal Imaging | Bi-annually | Medium |

| Winding Resistance Test | Every 3-5 years | High |

| Insulation Resistance Test | Annually | Critical |

I remember a case where we installed a triplex core transformer in a renovated historical building. The narrow staircases and small elevator would have made it impossible to bring in a traditional transformer. We easily transported the triplex core units separately and assembled them in the basement. The modular design not only solved our installation challenge but also made future maintenance much easier.

One key advantage I’ve found with triplex core transformers is the ability to perform maintenance on one phase without necessarily shutting down the entire system. This can be crucial in applications where continuous power supply is critical.

When it comes to maintenance, always follow these best practices:

- Adhere to manufacturer guidelines and local regulations

- Keep detailed maintenance records

- Train personnel in proper handling and safety procedures

- Plan for regular maintenance to prevent unexpected failures

Remember, while the modular design of triplex core transformers can simplify many aspects of installation and maintenance, it’s still crucial to have qualified professionals handle these tasks. Proper installation and maintenance not only ensure optimal performance but also extend the life of your transformer.

What Are the Efficiency and Cost Considerations of Triplex Core Transformers?

When it comes to choosing a transformer, efficiency and cost are always top concerns. As someone who’s worked with various transformer types, I can tell you that triplex core transformers have some unique considerations in these areas.

Triplex core transformers often have slightly lower efficiency than traditional three-phase transformers due to their modular design. However, they can be more cost-effective in certain scenarios, especially when considering installation costs in tight spaces. The total cost of ownership, including maintenance and potential replacement, can be lower for triplex core transformers.

Let’s dive deeper into the efficiency and cost aspects:

Efficiency Considerations

-

Core Losses

- Triplex core transformers may have slightly higher core losses due to the three separate cores

- Modern designs are continually improving efficiency

-

Load Losses

- Generally comparable to traditional transformers

- Can be optimized for specific load profiles

-

Overall Efficiency

- Typically 1-2% lower than equivalent traditional three-phase transformers

- This gap is narrowing with advancements in materials and design

Cost Considerations

-

Initial Purchase Cost

- Often higher than traditional transformers of the same rating

- Price difference is decreasing as triplex core transformers become more common

-

Installation Costs

- Can be significantly lower, especially in tight spaces or existing buildings

- Reduced need for large access points or structural modifications

-

Maintenance Costs

- Potentially lower due to the ability to service or replace individual phases

- Easier access can reduce labor costs for maintenance

-

Replacement Costs

- Lower in the long term, as you can replace individual units rather than the entire transformer

Here’s a comparison table of efficiency and cost factors:

| Factor | Triplex Core Transformer | Traditional Transformer |

|---|---|---|

| Core Losses | Slightly higher | Lower |

| Load Losses | Comparable | Comparable |

| Overall Efficiency | 97-98% | 98-99% |

| Initial Cost | Higher | Lower |

| Installation Cost | Lower in tight spaces | Higher in tight spaces |

| Maintenance Cost | Potentially lower | Potentially higher |

| Replacement Cost | Lower (modular) | Higher (entire unit) |

I remember a project where we were upgrading the electrical system in an old hospital. The initial cost of the triplex core transformer was about 15% higher than a traditional unit. However, when we factored in the reduced installation costs (no need to remove walls) and the potential for easier future maintenance, the total cost of ownership over 20 years was actually lower for the triplex core option.

When considering efficiency and cost, keep these points in mind:

- Look at the total cost of ownership, not just the initial purchase price

- Consider the specific installation environment and how it might affect costs

- Factor in potential savings from easier maintenance and partial replacements

- Evaluate the impact of slightly lower efficiency against other benefits

In my experience, while triplex core transformers might not always be the most efficient option on paper, their practical advantages often make them a cost-effective choice, especially in challenging installation environments. As with any major equipment decision, it’s crucial to analyze your specific needs and constraints to determine the best option for your situation.

In Which Scenarios Should You Choose a Triplex Core Transformer Over Other Types?

Choosing the right transformer for your project can be a complex decision. As someone who’s been in the field for years, I’ve seen triplex core transformers shine in certain scenarios while traditional transformers were better in others.

Triplex core transformers are ideal for installations in tight spaces, buildings with limited access, and situations where future flexibility is crucial. They’re particularly well-suited for urban environments, retrofits of older buildings, and applications where minimizing downtime during maintenance is critical.

Let’s explore the scenarios where triplex core transformers are the best choice:

1. Limited Space Installations

If you’re working with a cramped utility room or a tight basement, triplex core transformers are often the go-to solution. Their modular design allows for easier transportation and installation in confined spaces.

2. Buildings with Restricted Access

For installations in high-rise buildings, historical structures, or any location with narrow corridors or small elevators, the ability to transport the transformer in parts is a huge advantage.

3. Retrofit Projects

When upgrading electrical systems in existing buildings, triplex core transformers can often be installed without major structural modifications, saving time and money.

4. Applications Requiring High Reliability

In scenarios where minimizing downtime is crucial (like hospitals or data centers), the ability to service or replace one phase without shutting down the entire system can be invaluable.

5. Future-Proofing Installations

If you anticipate the need for future capacity upgrades or potential relocation of the transformer, the modular nature of triplex core units offers greater flexibility.

Here’s a decision matrix to help guide your choice:

| Scenario | Triplex Core Transformer | Traditional Transformer | |

|---|---|---|---|

| Tight Installation Space | Ideal | Challenging | |

| Easy Access for Installation | Suitable | Preferred | |

| Critical Uptime Requirements | Excellent | Good | |

| Initial Cost Sensitivity | Less Suitable | More Suitable | |

| Future Flexibility Needs | Excellent | Limited | I recall a project where we were upgrading the electrical system in a busy downtown hotel. The existing transformer room was in the basement, accessible only through a narrow staircase. A traditional transformer would have required extensive and disruptive construction work. We opted for a triplex core transformer, which we easily transported down the stairs in pieces and assembled on-site. This choice minimized disruption to the hotel’s operations and saved significant costs in construction. |

When deciding between a triplex core and a traditional transformer, consider these factors:

-

Installation Environment

- Assess the available space and access routes

- Consider any weight restrictions on floors or elevators

-

Long-term Maintenance Plans

- Evaluate the importance of minimizing downtime during maintenance

- Consider the availability of skilled technicians for each type

-

Future Expansion Plans

- Think about potential needs for increased capacity

- Consider the likelihood of needing to relocate the transformer

-

Budget Constraints

- Look at both initial costs and long-term total cost of ownership

- Factor in potential savings from easier installation and maintenance

-

Efficiency Requirements

- Assess the impact of slightly lower efficiency in triplex core designs

- Consider local energy costs and regulations

Here’s a quick checklist to help you decide:

- [ ] Is the installation space tight or hard to access?

- [ ] Is minimizing future maintenance downtime crucial?

- [ ] Do you anticipate needing to upgrade or move the transformer in the future?

- [ ] Can you accommodate a slightly higher initial cost for long-term benefits?

- [ ] Are the efficiency differences within acceptable limits for your application?

If you answered yes to most of these questions, a triplex core transformer might be the best choice for your project.

In my experience, triplex core transformers have been game-changers in urban environments and retrofit projects. However, they’re not always the best choice. For new constructions with ample space and straightforward access, traditional transformers often remain the more cost-effective option.

Remember, every project is unique. It’s always worth consulting with experienced professionals and possibly conducting a site survey before making your final decision. The right choice will depend on a careful balance of your specific needs, constraints, and long-term goals.

Conclusion

Triplex core transformers offer unique advantages in tight spaces and challenging installations. While they may have slightly lower efficiency and higher initial costs, their flexibility in installation, maintenance, and future upgrades often makes them the ideal choice for many modern building projects.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group