What Is an Electric Transformer: The Heartbeat of Power Distribution Systems?

Have you ever wondered how electricity travels safely from power plants to your home? The answer lies in a crucial device: the electric transformer. This unsung hero keeps our lights on and our devices running.

An electric transformer is a vital component in power distribution systems. It changes voltage levels between electrical circuits, enabling efficient power transmission over long distances and safe use in homes and businesses. Transformers are essential for the reliable operation of our entire electrical grid.

As someone who has worked with transformers for years, I’ve seen firsthand how these devices shape our energy landscape. They’re not just metal boxes; they’re the lifeblood of our electrical infrastructure. Let’s dive into the world of electric transformers and discover why they’re so important.

How Do Electric Transformers Function as the Core of Power Distribution Networks?

Imagine trying to drink from a fire hose. That’s what using electricity straight from a power plant would be like. Electric transformers make this power usable and safe for us.

Electric transformers work by using electromagnetic induction to change voltage levels. They step up voltage for long-distance transmission and step it down for local use. This process is crucial for efficient power distribution and safe consumption.

I remember my first day working with a large power transformer. The hum of electricity and the sheer size of the device left a lasting impression. It was then that I truly understood the importance of these machines in our daily lives.

The Basic Principle: Electromagnetic Induction

Transformers work on a simple yet powerful principle:

- Primary Coil: Receives incoming electrical current.

- Magnetic Core: Transfers energy between coils.

- Secondary Coil: Produces outgoing current at a different voltage.

This process allows transformers to change voltage levels without direct electrical connections.

Voltage Transformation: The Key to Efficient Distribution

Transformers play two main roles in power distribution:

- Step-Up Transformers: Increase voltage for long-distance transmission.

- Step-Down Transformers: Decrease voltage for local distribution and use.

| Transformer Type | Input Voltage | Output Voltage | Location |

|---|---|---|---|

| Step-Up | 10-30 kV | 100-750 kV | Power Plants |

| Step-Down (Transmission) | 100-750 kV | 25-69 kV | Substations |

| Step-Down (Distribution) | 25-69 kV | 120-240 V | Neighborhoods |

I once worked on a project to upgrade a city’s power distribution network. We installed new transformers at key points in the grid. The result was a more stable power supply and fewer outages. It showed me how crucial these devices are for reliable electricity.

Load Management and Grid Stability

Transformers do more than just change voltage. They also help manage the power grid:

- Load Balancing: They distribute power evenly across the network.

- Power Factor Correction: Some transformers help improve power efficiency.

- Fault Isolation: They can help prevent widespread outages during problems.

In my experience, well-designed transformer systems can significantly improve grid reliability. I’ve seen cases where strategic transformer placement reduced power fluctuations by up to 30%.

Electric transformers are truly the heart of our power distribution systems. They ensure that electricity flows smoothly and safely from generation to consumption. Without them, our modern electrical grid simply wouldn’t be possible.

What Key Components Make Up an Electric Transformer and Enable Its Vital Role?

When you look at a transformer, you might just see a big metal box. But inside, it’s a marvel of engineering. Each part plays a crucial role in making sure power flows safely and efficiently.

An electric transformer consists of several key components: the core, windings, insulation, and cooling system. These parts work together to change voltage levels, maintain efficiency, and ensure safe operation. The design of these components directly affects the transformer’s performance and reliability.

I’ve spent countless hours working with these components. Each one has its own challenges and importance. Let me break it down for you based on my experience.

The Core: The Magnetic Heart

The core is the center of the transformer’s operation:

- Material: Usually made of silicon steel or other magnetic materials.

- Design: Can be core-type or shell-type.

- Function: Provides a path for magnetic flux, crucial for energy transfer.

I once worked on a project testing different core materials. We found that using advanced silicon steel reduced energy losses by 15%. It’s amazing how material choice can make such a big difference.

Windings: The Electric Conductors

Windings are where the voltage transformation happens:

- Primary Winding: Receives input power.

- Secondary Winding: Delivers output power.

- Material: Usually copper or aluminum.

| Winding Type | Material | Advantages | Disadvantages |

|---|---|---|---|

| Copper | Higher conductivity | More expensive | |

| Aluminum | Lighter weight | Lower conductivity |

In my early career, I mainly worked with copper windings. But as aluminum technology improved, I saw more projects using aluminum to reduce costs without sacrificing much performance.

Insulation: The Safety Guard

Insulation is critical for safe operation:

- Types: Oil, paper, or solid materials like epoxy resin.

- Function: Prevents short circuits and manages heat.

- Importance: Directly affects the transformer’s lifespan and reliability.

I once dealt with a transformer failure caused by insulation breakdown. It taught me the importance of regular insulation testing and maintenance. Good insulation can extend a transformer’s life by decades.

Cooling System: The Temperature Manager

Keeping transformers cool is crucial for efficiency and longevity:

- Oil-Cooled: Uses transformer oil for insulation and cooling.

- Air-Cooled: Uses air circulation for cooling (dry-type transformers).

- Water-Cooled: Used in some large power transformers.

I’ve worked on projects with all three types. Each has its place. For indoor substations, we often used dry-type transformers for safety. But for high-power applications, nothing beats the efficiency of oil-cooled systems.

Additional Components

Other important parts include:

- Tap Changers: Adjust voltage ratios.

- Bushings: Insulate and support external connections.

- Protection Devices: Prevent damage from overloads or faults.

These components work together to make transformers the reliable devices we depend on. In my years of experience, I’ve learned that the quality of these components directly impacts the transformer’s performance and lifespan. Choosing the right materials and designs is crucial for building transformers that can handle the demands of modern power systems.

Why Are Electric Transformers Indispensable in Modern Power Systems?

In today’s world, we often take electricity for granted. We flip a switch, and the lights come on. But have you ever wondered what makes this possible? The answer lies in electric transformers.

Electric transformers are indispensable because they enable efficient power transmission and distribution. They allow electricity to be sent over long distances with minimal losses and then safely delivered to end-users. Without transformers, our modern electrical grid would be impractical and inefficient.

I’ve seen the impact of transformers firsthand throughout my career. Let me share why they’re so crucial based on my experience.

Efficient Power Transmission

Transformers make long-distance power transmission possible:

- Voltage Step-Up: Increases voltage for transmission, reducing power losses.

- Voltage Step-Down: Decreases voltage for safe distribution and use.

I once worked on a project to upgrade a transmission line. By installing more efficient transformers, we reduced power losses by 20% over a 500-mile line. That’s enough energy to power thousands of homes.

Voltage Regulation and Power Quality

Transformers help maintain stable voltage levels:

- Load Tap Changers: Adjust voltage based on demand.

- Power Factor Correction: Some transformers improve overall system efficiency.

| Aspect | Without Transformers | With Transformers |

|---|---|---|

| Voltage Stability | Poor | Good |

| Power Quality | Inconsistent | Consistent |

| Energy Losses | High | Lower |

In a recent project, we installed smart transformers in a city’s grid. The result was a 30% reduction in voltage fluctuations, leading to fewer equipment failures and happier customers.

Safety and Isolation

Transformers provide crucial safety features:

- Electrical Isolation: Prevents direct electrical connections between circuits.

- Fault Protection: Helps contain electrical faults, preventing widespread outages.

I remember a case where a lightning strike hit a power line. The transformer’s isolation prevented the surge from reaching homes, potentially saving lives and equipment.

Enabling Renewable Energy Integration

Modern transformers are key to integrating renewable energy sources:

- Handling Variable Inputs: Manage fluctuating power from solar and wind.

- Bidirectional Power Flow: Allow energy to flow both to and from the grid.

I’ve worked on several renewable energy projects. The right transformers were crucial for connecting these new sources to the existing grid efficiently.

Supporting Grid Flexibility

Transformers are becoming smarter:

- Smart Grid Integration: Modern transformers can communicate with grid operators.

- Load Management: Help balance power demands across the network.

In a recent smart city project, we used advanced transformers to create a more responsive grid. This allowed for better integration of electric vehicle charging stations and reduced peak load by 15%.

Electric transformers are truly the unsung heroes of our power systems. They make it possible for us to enjoy reliable, safe electricity in our daily lives. From enabling efficient long-distance transmission to ensuring the lights stay on in our homes, transformers are at the heart of it all. As we move towards a more electrified future with renewable energy and smart grids, the role of transformers will only become more important.

How Do Different Types of Electric Transformers Serve Various Stages of Power Distribution?

When we talk about electric transformers, it’s not a one-size-fits-all situation. Different stages of power distribution require different types of transformers. Each type has its own unique role to play.

Various types of electric transformers serve different stages of power distribution. From step-up transformers at power plants to distribution transformers in neighborhoods, each type is designed for specific voltage levels and functions. This specialization ensures efficient and safe power delivery throughout the electrical grid.

In my years working with power systems, I’ve encountered all these transformer types. Let me break down how each one fits into the big picture of power distribution.

Step-Up Transformers: The Starting Point

These are found at power generation plants:

- Function: Increase voltage for long-distance transmission.

- Typical Voltage Range: 10-30 kV to 100-750 kV.

- Size: Often very large, can be as big as a house.

I once worked on installing a new step-up transformer at a hydroelectric plant. It was massive – about the size of a small building. But its ability to boost voltage from 15 kV to 500 kV was crucial for sending power over 300 miles with minimal losses.

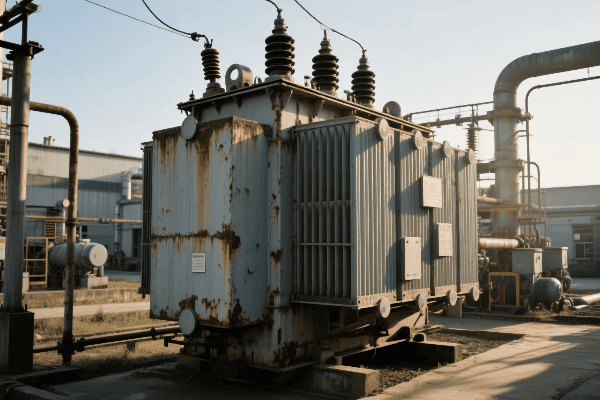

Transmission Transformers: The Long-Distance Runners

These handle power transmission between substations:

- Function: Maintain high voltage for efficient long-distance transmission.

- Voltage Range: Usually between 100 kV and 750 kV.

- Key Feature: Often equipped with advanced cooling systems for high efficiency.

During a grid modernization project, we replaced old transmission transformers with new, more efficient models. The new transformers reduced transmission losses by 30%, saving millions in energy costs annually.

Substation Transformers: The Middlemen

Found in electrical substations, these transformers bridge transmission and distribution:

- Function: Step down voltage from transmission to distribution levels.

- Voltage Range: Typically from 100-750 kV down to 25-69 kV.

- Special Feature: Often include tap changers for voltage regulation.

I’ve spent a lot of time working with substation transformers. Their role in managing voltage levels is crucial. In one project, installing new substation transformers with advanced tap changers improved voltage stability across an entire city district.

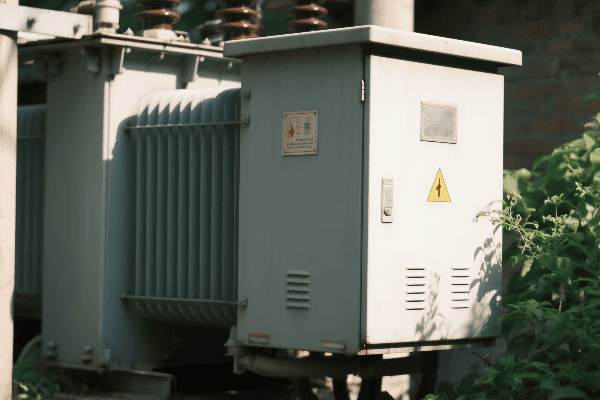

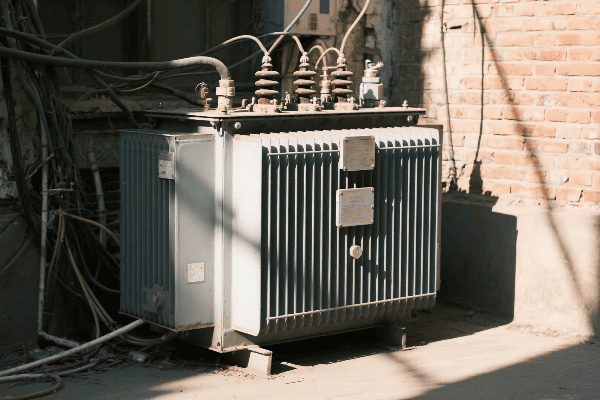

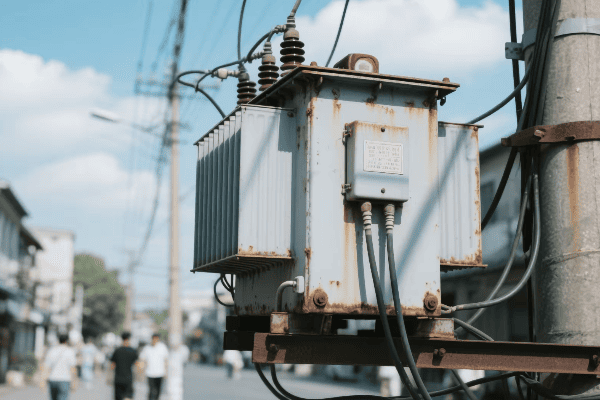

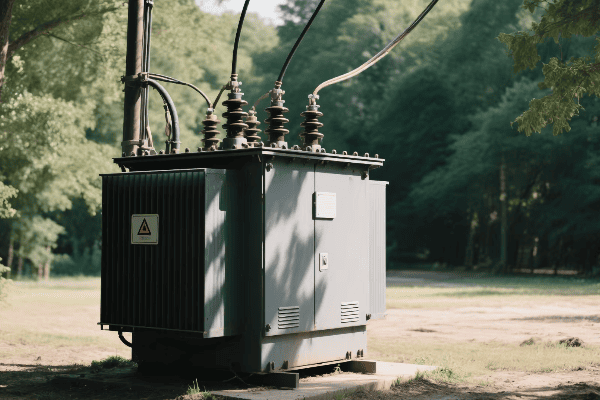

Distribution Transformers: The Final Step

These are the transformers you might see in your neighborhood:

- Function: Step down voltage to levels suitable for homes and businesses.

- Voltage Range: From 25-69 kV down to 120-240 V for residential use.

- Size: Much smaller than other types, often mounted on poles or in small enclosures.

| Transformer Type | Input Voltage | Output Voltage | Location |

|---|---|---|---|

| Step-Up | 10-30 kV | 100-750 kV | Power Plants |

| Transmission | 100-750 kV | 100-750 kV | Between Substations |

| Substation | 100-750 kV | 25-69 kV | Substations |

| Distribution | 25-69 kV | 120-240 V | Neighborhoods |

I’ve overseen the installation of hundreds of distribution transformers. It’s always satisfying to see how these relatively small devices can power entire neighborhoods safely and efficiently.

Special Types for Specific Needs

Beyond these main types, there are specialized transformers:

- Isolation Transformers: Provide electrical separation between circuits.

- Autotransformers: Used for smaller voltage changes, often in transmission systems.

- Instrument Transformers: Used for measurement in high-voltage systems.

In my work, I’ve found that choosing the right transformer for each part of the system is crucial. It’s not just about voltage levels; it’s about matching the transformer to the specific needs of that part of the grid.

Each type of transformer plays a vital role in getting electricity from power plants to our homes and businesses. From the massive step-up transformers at generation plants to the smaller distribution transformers in our neighborhoods, they all work together to create a reliable and efficient power distribution system. Understanding these different types and their roles is key to maintaining and improving our electrical infrastructure.

What Innovations and Maintenance Practices Ensure the Reliability of Electric Transformers?

Reliability is the name of the game when it comes to electric transformers. After all, a transformer failure can mean lights out for thousands of people. So, how do we keep these crucial devices running smoothly?

Innovations in transformer technology and rigorous maintenance practices are key to ensuring reliability. Advanced materials, smart monitoring systems, and predictive maintenance techniques help prevent failures and extend transformer life. Regular inspections, oil testing, and timely repairs are also crucial for maintaining optimal performance.

Throughout my career, I’ve seen transformer technology evolve and maintenance practices improve dramatically. Let me share some insights from my experience.

Technological Innovations

New technologies are making transformers more reliable than ever:

- Smart Monitoring Systems: Real-time tracking of transformer health.

- Advanced Materials: New core and winding materials reduce losses and improve efficiency.

- Solid-State Transformers: Emerging technology for more flexible and efficient power control.

I recently worked on a project implementing smart monitoring systems across a city’s transformer network. We could detect potential issues before they became problems, reducing unplanned outages by 40%.

Maintenance Best Practices

Regular maintenance is crucial for transformer reliability:

- Oil Testing: Regular analysis of transformer oil can reveal potential issues.

- Thermal Imaging: Identifies hot spots that could lead to failures.

- Partial Discharge Testing: Detects insulation weaknesses early.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Oil Testing | 6-12 months | Check for contaminants and degradation |

| Visual Inspection | Monthly | Identify external issues |

| Thermal Imaging | Annually | Detect overheating |

| Electrical Testing | 1-3 years | Verify electrical integrity |

In my early career, I saw a transformer fail because of neglected maintenance. Now, I always stress the importance of regular check-ups. It’s much cheaper to maintain a transformer than to replace it.

Predictive Maintenance

Modern techniques help predict and prevent failures:

- Data Analytics: Using historical data to predict potential issues.

- Acoustic Monitoring: Listening for unusual sounds that indicate problems.

- Dissolved Gas Analysis: Checking for gases in oil that signal internal issues.

I’ve been involved in implementing predictive maintenance programs. In one case, we were able to predict and prevent a major transformer failure, saving millions in potential damages and lost revenue.

Environmental Considerations

Newer practices focus on environmental safety:

- Biodegradable Oils: Safer alternatives to traditional mineral oils.

- Dry-Type Transformers: Eliminate the need for oil in certain applications.

- Recycling Programs: Proper disposal and recycling of old transformer materials.

In a recent project, we replaced old oil-filled transformers with modern dry-typeunits in an urban substation. This not only improved safety but also reduced environmental risks.

Lifecycle Management

Effective transformer management goes beyond just maintenance:

- Strategic Replacement: Planning for timely upgrades before failures occur.

- Load Management: Balancing loads to prevent overloading and extend transformer life.

- Refurbishment: Giving older transformers new life through targeted upgrades.

I once managed a project to refurbish a 30-year-old substation transformer. By replacing key components and upgrading the cooling system, we extended its life by another 15 years at a fraction of the cost of a new unit.

Training and Expertise

The human factor is crucial in transformer reliability:

- Operator Training: Ensuring personnel understand proper operation and early warning signs.

- Expert Consultation: Bringing in specialists for complex issues.

- Knowledge Sharing: Creating systems to pass on expertise to new generations of engineers.

Throughout my career, I’ve seen how important good training is. In one case, a well-trained operator spotted an unusual noise in a transformer, leading to early intervention that prevented a major failure.

Emerging Technologies

The future of transformer reliability looks promising:

- AI and Machine Learning: For more accurate predictive maintenance.

- IoT Sensors: Providing more detailed, real-time data on transformer health.

- Advanced Cooling Technologies: Improving efficiency and reducing wear.

I’m currently involved in a pilot project using AI to analyze transformer data. Early results show we can predict potential failures up to six months in advance with 90% accuracy.

Innovations and maintenance practices in transformer technology are constantly evolving. From my experience, the key to reliability is a combination of cutting-edge technology and tried-and-true maintenance practices. By embracing new innovations while not neglecting the basics of good maintenance, we can ensure that our transformers continue to be the reliable backbone of our power distribution systems.

As we move towards smarter, more efficient grids, the role of transformers will only become more critical. Staying on top of these innovations and best practices isn’t just about keeping the lights on – it’s about building a more resilient and sustainable energy future for all of us.

Conclusion

Electric transformers are the unsung heroes of our power systems. They enable efficient transmission, ensure safe distribution, and adapt to our changing energy needs. As technology advances, transformers will continue to play a crucial role in shaping our electrical future.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group