What is Transformer Remanence? Understanding the Hidden Dangers in Power Systems

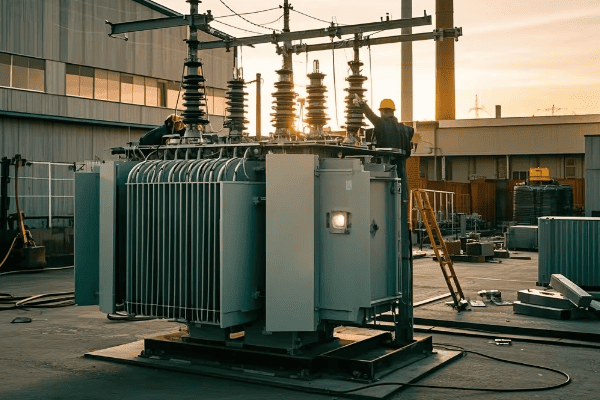

Have you ever wondered why sometimes power transformers behave unexpectedly when switched on? The answer might lie in a phenomenon called transformer remanence.

Transformer remanence is the residual magnetism left in a transformer’s core after DC current is removed. It can cause issues like inrush currents, relay malfunctions, and even transformer damage. Understanding remanence is crucial for maintaining power system stability and safety.

As someone who’s spent years working with power systems, I’ve seen firsthand how remanence can impact transformer performance. Let’s dive into this critical yet often overlooked aspect of power engineering.

How Does Transformer Remanence Occur? The Science Behind the Magnetism

Picture this: you’ve just finished a routine DC resistance test on a power transformer. Everything seems fine, but there’s an invisible change within the transformer’s core. That’s remanence at work.

Transformer remanence occurs due to the hysteresis characteristics of the transformer’s ferromagnetic core. When DC current is applied during tests like winding resistance measurements, it magnetizes the core. After the current is removed, some magnetic flux remains, creating remanence.

Let’s break down the process of remanence formation:

The Journey from Test to Trouble

- DC Test Application: During routine maintenance, DC current is applied to the transformer windings.

- Core Magnetization: The DC current magnetizes the transformer’s iron core.

- Current Removal: When the test is complete, the DC current is switched off.

- Residual Magnetism: Some magnetic flux remains in the core due to its ferromagnetic properties.

Here’s a simple table illustrating the factors affecting remanence:

| Factor | Effect on Remanence | Why It Matters |

|---|---|---|

| DC Current Magnitude | Higher current = More remanence | Affects test procedures |

| Duration of DC Application | Longer duration = More remanence | Impacts maintenance schedules |

| Core Material Properties | Different materials retain varying levels of magnetism | Influences transformer design |

I remember a case where we were commissioning a new substation. During the first energization of a large power transformer, we experienced unexpected protection trips. After investigation, we found that high remanence from factory tests was the culprit. It was a stark reminder of how important it is to consider remanence in our procedures.

What Are the Hazards of Transformer Remanence? Unveiling the Risks

You might think a little leftover magnetism is no big deal. But in the world of power transformers, remanence can lead to some serious problems. Let’s explore the risks.

Transformer remanence can cause several hazards, including large inrush currents during energization, potential relay misoperations, increased reactive power consumption, and even damage to the transformer or connected equipment. These issues can lead to system instability and significant economic losses.

Let’s dive deeper into these hazards:

The Ripple Effects of Remanence

-

Inrush Current Amplification

- What happens: Remanence causes core saturation, leading to extremely high inrush currents.

- Consequences: Potential tripping of protection devices, stress on windings.

-

Relay Misoperation

- What happens: High inrush currents can be mistaken for fault conditions.

- Consequences: Unnecessary outages, reduced system reliability.

-

Increased Reactive Power Consumption

- What happens: Saturated core draws more reactive power.

- Consequences: Reduced system efficiency, potential voltage stability issues.

-

Transformer Overheating

- What happens: Core saturation increases stray flux, heating metal parts.

- Consequences: Accelerated insulation aging, reduced transformer lifespan.

Here’s a table summarizing these hazards:

| Hazard | Direct Impact | Long-term Consequences |

|---|---|---|

| Inrush Currents | Stress on windings, nuisance tripping | Reduced transformer life |

| Relay Misoperation | Unnecessary outages | Decreased system reliability |

| Reactive Power Increase | System inefficiency | Voltage stability issues |

| Overheating | Insulation degradation | Shortened transformer lifespan |

I once worked on a project where a utility was experiencing frequent, unexplained outages in a particular substation. After extensive investigation, we discovered that remanence in one of the transformers was causing protection relays to misoperate. By implementing proper demagnetization procedures, we were able to solve the issue and significantly improve system reliability.

How Can We Mitigate Transformer Remanence? Strategies for Safe Operation

Now that we understand the risks, you’re probably wondering how we can deal with remanence. Don’t worry, I’ve got you covered with some practical strategies.

To mitigate transformer remanence, several techniques can be employed. These include controlled switching, core demagnetization procedures, and the use of advanced transformer designs. Proper maintenance practices and awareness of remanence effects are also crucial in managing this issue.

Let’s explore these mitigation strategies in detail:

Taming the Magnetic Beast

-

Controlled Switching

- How it works: Energizes the transformer at the optimal point of the voltage wave.

- Benefits: Reduces inrush currents, minimizes stress on the system.

-

Core Demagnetization

- How it works: Applies alternating current with decreasing magnitude to the windings.

- Benefits: Removes residual magnetism before energization.

-

Advanced Transformer Designs

- How it works: Uses core materials and designs that minimize remanence.

- Benefits: Reduces the likelihood of remanence-related issues.

-

Proper Maintenance Practices

- How it works: Includes remanence considerations in testing and maintenance procedures.

- Benefits: Prevents inadvertent creation of high remanence levels.

Here’s a comparison of these mitigation strategies:

| Strategy | Effectiveness | Implementation Difficulty | Cost |

|---|---|---|---|

| Controlled Switching | High | Moderate | Moderate |

| Core Demagnetization | Very High | Low | Low |

| Advanced Designs | High | High (for new transformers) | High |

| Maintenance Practices | Moderate | Low | Low |

In my experience, a combination of these strategies works best. I recall a large industrial client who was struggling with frequent transformer trips. We implemented a comprehensive approach: installing controlled switching devices, developing a demagnetization procedure for maintenance activities, and training staff on remanence awareness. The results were impressive – a 90% reduction in remanence-related issues over the following year.

When dealing with remanence, keep these tips in mind:

- Always consider remanence when planning transformer energization.

- Invest in training for maintenance staff on remanence effects and mitigation.

- Regular monitoring and assessment of transformer behavior can help identify remanence issues early.

Remember, addressing remanence is not just about preventing problems – it’s about ensuring the long-term health and efficiency of your power system.

Conclusion

Transformer remanence is a complex but manageable aspect of power system operation. By understanding its causes, recognizing its hazards, and implementing effective mitigation strategies, we can significantly improve the reliability and efficiency of our power systems. As we continue to rely more heavily on electrical power, managing remanence will only become more crucial. Stay informed, stay prepared, and keep your transformers running smoothly.

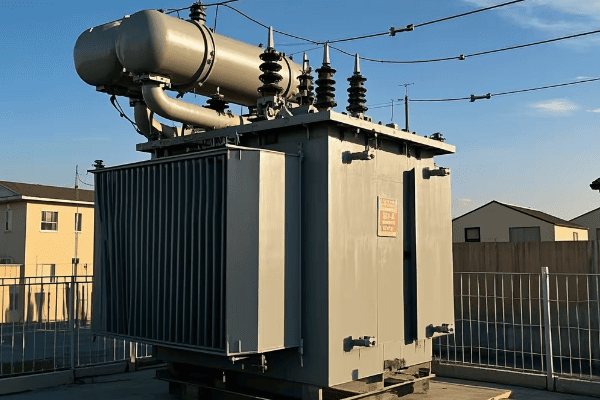

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group