Ultimate Guide to 11kV-35kV Step-Up Transformer Selection: From kVA Calculation to Customization | CHBEB

Introduction

If you don’t plan ahead, you can end up with an oversized, inefficient, and expensive step-up transformer. A lot of projects don’t do kVA calculations1 or check the materials. This tutorial talks about the requirements, cost trade-offs, and customization options for your 11kV–35kV transformer to make sure it works well for a long time.

Part 1: Defining Your Core Requirements

When essential needs aren’t obvious, projects fail. Choosing the wrong kVA or voltage can cause downtime and inefficiency. By setting load, capacity, and insulation ahead of time, you lower your risk and get ready for a seamless buying and installation procedure.

A step-by-step guide to figuring out kVA capacity

The first step in sizing is to know the load. When you undersize something, it overheats the windings; when you oversize it, it wastes money.

- List loads: motors, inverters, extras, and everything you want to add in the future.

- Find out how much demand there is: Use the power factor (PF) to change kW to kVA. To get kVA, divide kW by PF. 1,000 kW ÷ 0.85 equals 1,176 kVA, for example.

- Plan for growth by adding 15–25% extra capacity.

- Use diversity: Not all loads reach their peak at the same time; make changes that make sense.

- Check the harmonics: K-factor ratings may be needed for non-linear loads like VFDs and PV inverters.

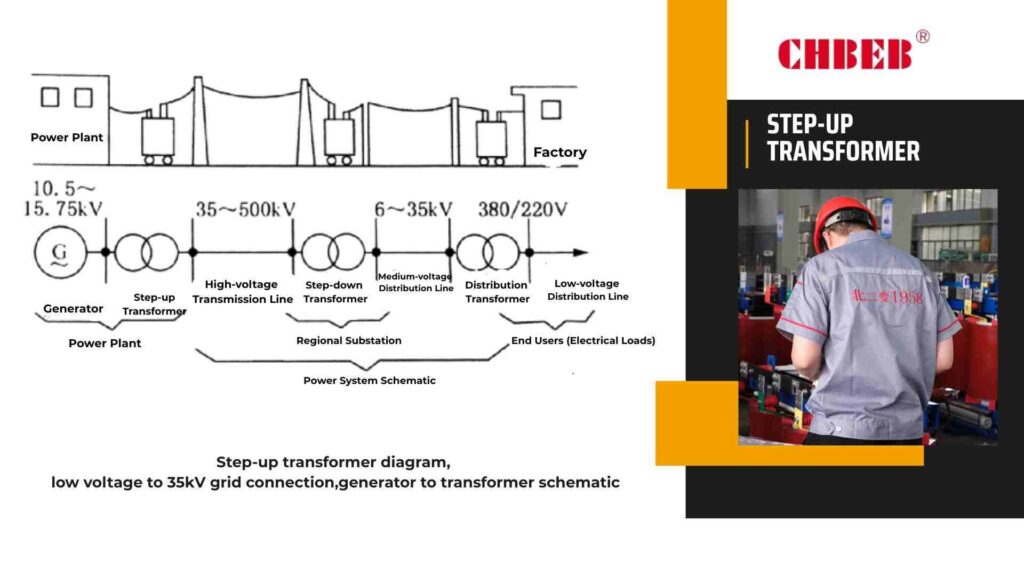

Choosing Voltage Levels & Insulation Types2

Utility rejection happens when the voltage doesn’t match. Step-up units usually raise the voltage from 400 to 1,000 V to 11, 22, or 35 kV. Think about:

- Primary voltage: The output of the generator or inverter should match.

- Secondary voltage: Set it to the same level as the grid interconnection.

- Tap range: ±5–10% (off-circuit or OLTC) for freedom.

- Insulation system: Oil-immersed for high overload capacity and small size; dry-type for fire safety indoors.

- Environment: Sealed bushings, coatings, or low-noise alternatives may be needed in coastal, desert, or metropolitan areas.

Part 2: The Critical Trade-Offs: Materials and Cost

Shortcuts that are based on cost generally don’t work. Choosing materials without looking at their lifetime leads to more losses and breakdowns. Choosing the proper winding and ownership cost ahead of time makes sure you get the best performance for the price.

Copper vs. Aluminum Windings3: Cost, Performance, and Total Cost of Ownership4

- Copper has better conductivity, less loss, is more compact, is stronger under fault stresses, usually lasts longer, and costs more to install.

- Aluminum: less expensive up front, lighter, takes up more space for the same kVA, is more sensitive to temperature cycling and oxidation, and may not last as long.

Tip for making a decision: Copper usually has a lower TCO for mission-critical grids or renewables. Aluminum may be enough for installations that are only temporary or don’t cost a lot.

The Calculation of the Total Cost of Ownership

TCO = Initial Price + (Annual Losses x Energy Cost × Service Life) + Maintenance + Downtime Cost − Residual Value

- First price: equipment, shipment, civil works, and installation.

- Losses: Monetize no-load/load losses at your tariff over 15–30 years.

- Maintenance includes testing the oil, cleaning, getting spare parts, and hiring workers.

- Downtime: the cost of stopping production or paying fines during outages.

- Residual value: what you can get for it when it’s done.

For example, paying $50,000 extra for copper that saves $10,000 a year in losses will save $200,000 or more in 20 years, which easily makes up for

Part 3: Making Your Decision: Certifications and Customization

Not following the rules or not paying attention to project details leads to rejections and redesigns. Get certificates in line early on and make changes where necessary to make sure that they are accepted and work well in the long run in all markets.

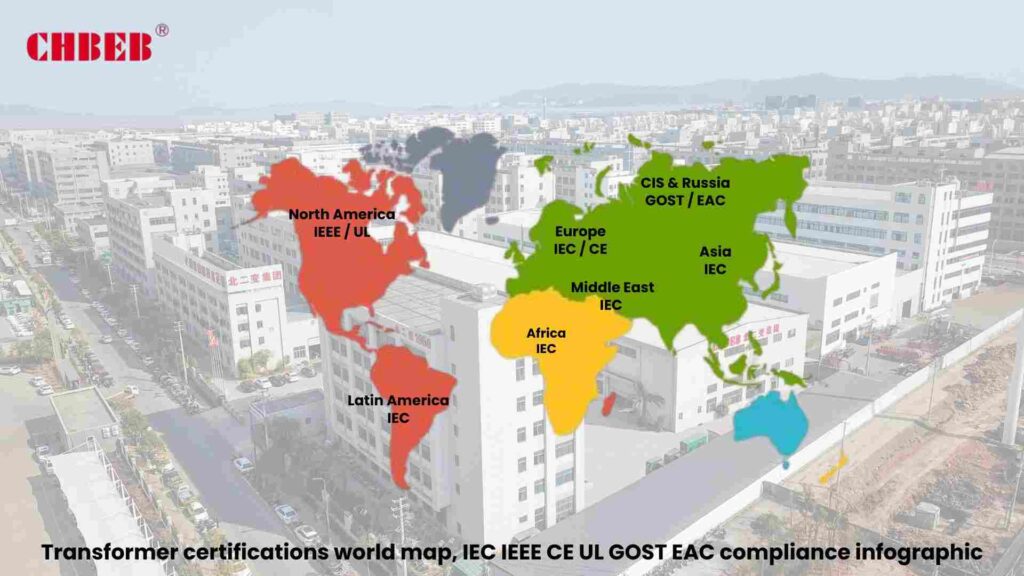

How to Understand International Certifications for Global Projects

- IEC 600765: The global standard for power transformers.

- IEEE/ANSI C57: What North America needs.

- CE marking: Required for access to the EU market.

- UL: Common for safety compliance for dry types.

- GOST/EAC: Russia and the CIS are in line with each other.

- ISO 9001/14001/45001: Management of quality, the environment, and health and safety at work.

Tip: Before buying, make sure you know the requirements for utility interconnection and witness testing.

When and why to choose a custom transformer

- Special voltages and vector groups: hybrid systems, phase shifts, and neutral needs.

- Better cooling: ONAF/ODAF during hot weather or when the load is too high for a short time.

- Compact enclosures: Pads or retrofits that take up less space.

- Noise reduction: Low-flux cores, dampening, and acoustic screens for hospitals and cities.

- Marine/C5-M protective coatings and sealed bushings for coastal and industrial areas.

- Digital monitoring: RTDs, moisture, dissolved gas, and gateways for planned maintenance.

Conclusion

When selecting an 11kV–35kV step-up transformer, price alone should never be the deciding factor. A truly reliable investment requires looking at the full picture.

Define your needs clearly: Match kVA to actual and future load, allow 15–25% growth margin, and account for harmonics or special duty cycles. This prevents both oversizing and costly failures from undersizing.

Evaluate materials wisely: Copper costs more up front but ensures lower losses, stronger fault tolerance, and longer service life. Aluminum may be suitable for budget-sensitive or temporary projects, but often results in higher lifetime costs.

Calculate the Total Cost of Ownership (TCO): Consider equipment price, civil works, energy losses over 20–30 years, maintenance, downtime risk, and residual value. Often, a slightly higher initial investment pays back many times in savings and reliability.

Check certifications and customization: Ensure compliance with IEC, IEEE/ANSI, CE, or local standards, and tailor features such as cooling, insulation, vector groups, coatings, and monitoring to your site conditions.

In short: Choosing the right step-up transformer is about more than buying hardware. It’s about securing safe interconnection, efficient performance, and the lowest lifetime cost for your project. By combining accurate sizing, material selection, TCO analysis, and compliance checks, you gain not just a transformer, but a long-term guarantee of stability and value.

- Apparent Power and Power Factor — All About Circuits ↩︎

- Transformer types — Wikipedia ↩︎

- Comparison of Copper and Aluminum in Transformers — ScienceDirect ↩︎

- Total Cost of Ownership in Electrical Distribution — Schneider Electric ↩︎

- IEC 60076 Power Transformer Standards — IEC ↩︎

Learn More

Want to explore more transformer solutions? Download our latest product catalog or browse our product categories to find the right fit for your project.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

We'd like to work with you

- +86 15558785111

- chbebgroup@chbebpower.com

- +86 15558785111

What We Do

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

Latest Product

address

BeiJing

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

JiangSu

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

WenZhou

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

contact us

- chbebgroup@chbebpower.com

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group