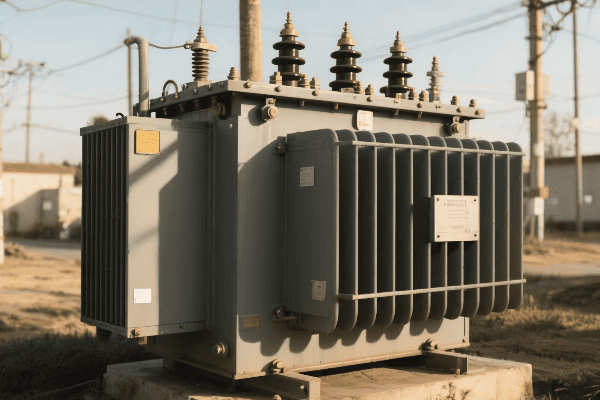

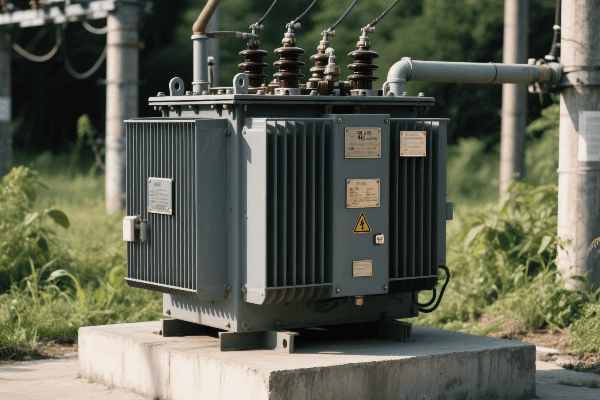

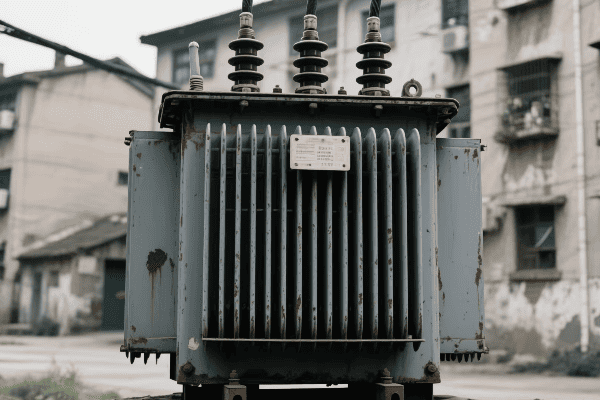

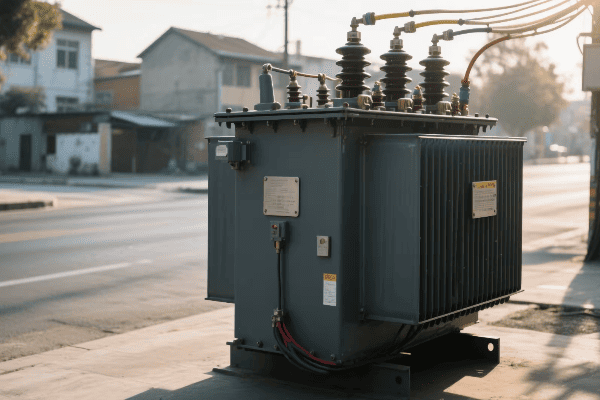

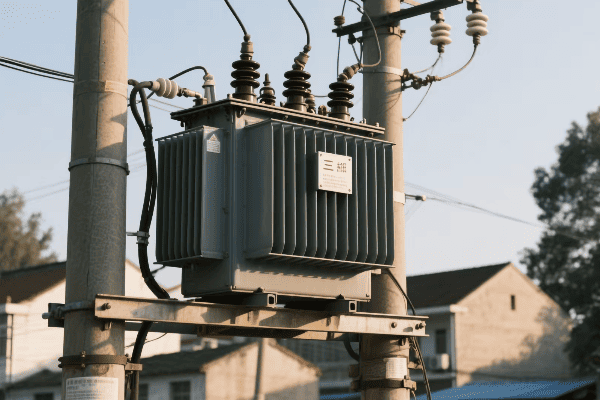

3 Phase Distribution Transformer: Maximizing Efficiency in High-Density Commercial Areas?

Commercial areas need a lot of power. But old systems waste energy. How can we keep up with growing demands while saving energy?

3 phase distribution transformers are key to maximizing efficiency in high-density commercial areas. They deliver more power, use less space, and reduce energy losses, making them ideal for busy urban business districts.

I’ve worked with power systems in many commercial areas. I’ve seen how 3 phase transformers can change the game. Let’s explore how these transformers are making a big difference in our cities.

High Capacity Solutions: Designing 3 Phase Transformers for Peak Commercial Demands?

Businesses use more power than ever. How can transformers keep up without breaking down?

3 phase transformers designed for peak commercial demands offer high capacity solutions. They use advanced cooling systems, robust materials, and smart load management to handle intense power needs reliably and efficiently.

In my years working with commercial power systems, I’ve seen demands grow rapidly. Here’s how we’re designing transformers to meet these challenges:

Advanced Cooling Technologies

Keeping transformers cool is crucial for high capacity:

- Oil Natural Air Natural (ONAN): This is the basic cooling method.

- Oil Natural Air Forced (ONAF): This uses fans to improve cooling.

- Oil Forced Air Forced (OFAF): This uses pumps and fans for even better cooling.

I once installed an OFAF system in a busy shopping mall. It could handle peak holiday shopping power demands without overheating.

Robust Core and Winding Materials

The heart of a transformer needs to be strong:

| Material | Benefit |

|---|---|

| Grain-oriented silicon steel | Reduces core losses |

| Copper windings | Handles high currents better |

| Nomex insulation | Withstands higher temperatures |

For a high-rise office building, we used a transformer with copper windings and Nomex insulation. It could handle the building’s high power needs even on the hottest summer days.

Smart Load Management

Modern transformers can adjust to changing power needs:

- On-Load Tap Changers: These adjust voltage levels without interrupting power.

- Dynamic Rating Systems: These allow transformers to safely handle higher loads when conditions allow.

- Load Balancing: This spreads the load evenly across all three phases.

In a tech hub with variable power demands, we installed a transformer with dynamic rating. It could handle sudden spikes in power use when all the companies were working on big projects.

Overload Capacity

Sometimes, transformers need to go above and beyond:

- Short-time overload: Can handle 20-30% over rated capacity for a few hours.

- Long-time overload: Can handle 10-15% over rated capacity for extended periods.

- Emergency overload: Can handle up to 50% over rated capacity for short periods in emergencies.

During a heatwave, I saw a transformer use its overload capacity to keep a hospital running at full power. It was a real lifesaver.

Compact Power: Space-Efficient 3 Phase Transformer Configurations for Urban Environments?

Space is tight in cities. But we need more power. How can transformers fit in?

Space-efficient 3 phase transformer configurations are crucial for urban environments. These compact designs deliver high power in a small footprint, using innovative layouts and materials to maximize output while minimizing space requirements.

I’ve worked on many urban power projects. Space is always a challenge. Here’s how we’re making transformers fit into tight spots:

Vertical Designs

Going up instead of out saves space:

- Stacked Core: This puts the core sections on top of each other.

- Shell Type: This wraps the windings around the core vertically.

- Toroidal Core: This doughnut shape is very compact.

I once installed a vertical shell type transformer in a narrow alley between two buildings. It powered a whole block while taking up minimal ground space.

Modular Configurations

Breaking transformers into smaller parts can help:

| Configuration | Benefit |

|---|---|

| Split-core design | Easier to transport and install |

| Scalable units | Can add or remove capacity as needed |

| Distributed layout | Spreads the load and heat |

For a growing tech company, we used a modular system. We could add more units as the company expanded, without needing a big installation space all at once.

High-Density Materials

New materials pack more power into less space:

- Amorphous metal cores: These are more efficient and can be smaller.

- High-temperature superconductors: These can carry more current in less space.

- Advanced insulation: This allows components to be closer together safely.

In a retrofit project for an old building, we used an amorphous core transformer. It fit in the same space as the old unit but delivered 30% more power.

Innovative Cooling

Better cooling means transformers can be smaller:

- Ester fluids: These biodegradable oils cool better than mineral oil.

- Phase change materials: These absorb heat very efficiently.

- Heat pipe technology: This moves heat away quickly without pumps.

For a data center in a crowded part of town, we used a transformer with ester fluid cooling. It ran cooler and safer in a smaller package than traditional designs.

Energy Optimization: Cutting-Edge 3 Phase Transformer Technologies for Commercial Efficiency?

Energy waste costs money. How can new transformer tech save energy and cash?

Cutting-edge 3 phase transformer technologies significantly enhance commercial efficiency. These innovations include advanced materials, smart monitoring systems, and energy management features that minimize losses and optimize power distribution.

I’ve seen energy bills drop dramatically with new transformer tech. Here’s what’s making the biggest difference:

Low-Loss Core Materials

The core is where most energy is lost. New materials are changing this:

- Amorphous metal: This can cut core losses by up to 70%.

- High-grade silicon steel: This is getting better all the time.

- Nanocrystalline materials: These promise even lower losses.

I replaced an old transformer with an amorphous metal core model in a large office complex. The energy savings paid for the new unit in just two years.

Advanced Winding Techniques

How we wind the coils affects efficiency:

| Technique | Benefit |

|---|---|

| Continuous disc winding | Reduces eddy current losses |

| Foil winding | Improves current distribution |

| Interleaved winding | Minimizes leakage inductance |

For a green office building project, we used transformers with foil windings. They reduced load losses by 15% compared to traditional designs.

Smart Monitoring and Control

Modern transformers can manage their own efficiency:

- Real-time loss monitoring: This tracks where energy is being lost.

- Automatic voltage regulation: This keeps voltage at the most efficient level.

- Load tap changers: These adjust the transformer’s ratio to match demand.

In a smart city project, we installed transformers with real-time monitoring. The city could see exactly where energy was being used and adjust for maximum efficiency.

Energy Storage Integration

Some new transformers work with energy storage:

- Battery integration: This can store excess energy for peak times.

- Supercapacitor systems: These handle short-term power quality issues.

- Flywheel storage: This provides very fast response to load changes.

For a commercial district with lots of solar panels, we used transformers with integrated battery storage. They could store excess solar power during the day and use it during evening peak hours.

Ensuring Reliability: Robust 3 Phase Transformer Systems for High-Density Business Districts?

Power outages can cost businesses big money. How can we make sure the lights stay on?

Robust 3 phase transformer systems ensure reliability in high-density business districts. These systems use redundant designs, advanced protection features, and predictive maintenance to minimize downtime and maintain consistent power supply.

I’ve worked in areas where even a short outage can be disastrous. Here’s how we’re making transformers more reliable:

Redundant Designs

Having backups is key to reliability:

- N+1 configuration: This adds one extra transformer beyond what’s needed.

- Ring bus systems: These allow power to flow from multiple directions.

- Parallel operation: This uses multiple smaller transformers instead of one big one.

I set up a parallel system for a financial district. When one transformer needed maintenance, the others could pick up the load without interruption.

Advanced Protection Features

Modern transformers can protect themselves:

| Feature | Function |

|---|---|

| Buchholz relay | Detects gas buildup from faults |

| Differential protection | Quickly isolates internal faults |

| Overload protection | Prevents damage from excess current |

In a tech hub with sensitive equipment, we used transformers with multiple protection layers. They could respond to issues in milliseconds, preventing damage and outages.

Predictive Maintenance

Fixing problems before they cause outages is crucial:

- Oil analysis: This can detect developing faults early.

- Thermal imaging: This finds hot spots before they cause failures.

- Acoustic monitoring: This can hear problems developing inside the transformer.

For a critical manufacturing area, we implemented a predictive maintenance program. It caught several developing issues before they could cause shutdowns.

Environmental Hardening

Transformers need to withstand tough conditions:

- Seismic reinforcement: This helps in earthquake-prone areas.

- Flood-resistant designs: These keep working even in high water.

- Extreme temperature ratings: These handle both very hot and very cold weather.

I installed environmentally hardened transformers in a coastal business district. They’ve weathered storms and floods without failing.

Adaptive Power Distribution: Flexible 3 Phase Transformer Solutions for Evolving Commercial Needs?

Business needs change fast. How can power systems keep up?

Flexible 3 phase transformer solutions provide adaptive power distribution for evolving commercial needs. These systems can adjust to changing loads, integrate with new technologies, and scale up or down to match business growth or contraction.

I’ve seen many businesses struggle with changing power needs. Here’s how new transformer systems are adapting:

Scalable Capacity

Growing or shrinking? The power system can change too:

- Modular designs: These let you add or remove capacity easily.

- Wide-range transformers: These can handle big changes in load.

- Portable substations: These can be moved to where they’re needed most.

For a rapidly growing tech park, we used a modular transformer system. We could add new modules as startups moved in and expanded.

Smart Grid Integration

Modern transformers work with smart grid technology:

| Feature | Benefit |

|---|---|

| Two-way communication | Allows real-time adjustments |

| Power quality monitoring | Ensures clean, stable power |

| Demand response capability | Helps balance grid load |

In a smart city project, our transformers could talk to the grid. They adjusted their output based on real-time demand across the whole city.

Renewable Energy Compatibility

Many businesses are adding solar or wind power. Transformers need to handle this:

- Bi-directional power flow: This manages power going both ways.

- Harmonic mitigation: This cleans up power from renewable sources.

- Energy storage integration: This smooths out variable renewable output.

For a green office complex with rooftop solar, we installed transformers that could handle power flowing both to and from the building. They kept the power stable even on cloudy days.

Adaptive Voltage Regulation

Keeping voltage steady is crucial for modern electronics:

- Dynamic tap changing: This adjusts voltage levels in real-time.

- Voltage optimization: This keeps voltage at the most efficient level.

- Power factor correction: This improves overall system efficiency.

In a district with lots of digital businesses, we used transformers with adaptive voltage regulation. They kept the power clean and stable, protecting sensitive equipment.

Conclusion

3 phase distribution transformers are crucial for efficient power delivery in high-density commercial areas. They offer high capacity, compact designs, energy optimization, reliability, and adaptability to meet the evolving needs of modern businesses.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group