3-Phase Distribution Transformer: Optimizing Energy Efficiency in Large-Scale Power Networks?

Are your energy bills skyrocketing? The culprit might be hiding in plain sight. Inefficient 3-phase distribution transformers could be silently draining your profits, but there’s a solution.

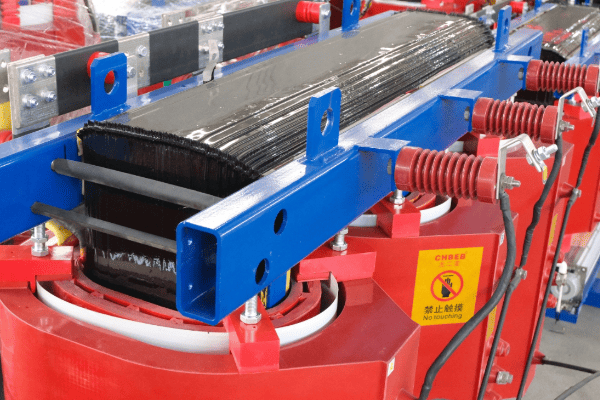

Optimizing 3-phase distribution transformer efficiency in large-scale power networks involves implementing advanced core materials, smart monitoring systems, and load management strategies. These improvements can significantly reduce energy losses, lower operational costs, and enhance overall network reliability.

In this article, I’ll guide you through the world of 3-phase distribution transformers. We’ll explore how these power giants work, why they’re crucial for our energy infrastructure, and most importantly, how to make them more efficient. Whether you’re a plant manager, an energy consultant, or just curious about the backbone of our power systems, you’ll find valuable insights here.

Power Trio: Understanding the Magic of 3-Phase Transformers in Our Cities?

Ever wondered how our cities keep buzzing with electricity 24/7? The secret lies in the unsung heroes of our power grid: 3-phase transformers. But what makes these transformers so special, and why are they crucial for powering our urban landscapes?

3-phase transformers are the backbone of urban power distribution, offering superior efficiency and stability compared to single-phase systems. They use three alternating currents, phase-shifted by 120 degrees, to provide consistent power flow. This setup allows for more efficient transmission of large amounts of electricity over long distances.

Let’s dive deeper into the world of 3-phase transformers and uncover their magic:

The Basics: What Makes it ‘3-Phase’?

3-phase power is all about efficiency and balance in electricity distribution.

Key Components:

- Three separate windings

- 120-degree phase difference

- Balanced load distribution

Power Transmission: More Punch, Less Loss

3-phase systems excel at transmitting large amounts of power efficiently.

Transmission Advantages:

- Higher power density

- Lower transmission losses

- Reduced cable requirements

Load Balancing: Keeping the Power Steady

One of the biggest advantages of 3-phase systems is their ability to handle varying loads.

Load Management Features:

- Even distribution of power

- Reduced voltage fluctuations

- Better handling of motor loads

Applications: From Factories to Homes

3-phase transformers are versatile and find use in various settings.

Common Applications:

- Industrial machinery

- Large commercial buildings

- Residential power distribution

| Feature | Single-Phase | Three-Phase |

|---|---|---|

| Power Capacity | Lower | Higher |

| Efficiency | Good | Excellent |

| Load Balancing | Limited | Superior |

| Cost-Effectiveness | Lower for small loads | Higher for large loads |

I remember a project that really showcased the power of 3-phase transformers. We were called to a large manufacturing plant that was struggling with frequent power issues and high energy costs. The plant manager was at his wit’s end, trying to figure out why their electricity bills were so high despite recent upgrades to their production equipment.

Upon inspection, we found that their power distribution system was a hodgepodge of single-phase and outdated 3-phase transformers. This mismatched system was causing significant inefficiencies and power quality issues.

We proposed a complete overhaul of their distribution system, centered around modern, high-efficiency 3-phase transformers. The first step was to conduct a comprehensive load analysis. We found that the plant’s power demand varied significantly throughout the day, with heavy machinery causing large spikes in consumption.

Based on this analysis, we designed a 3-phase distribution system that could handle these varying loads more efficiently. We installed new transformers with advanced core materials that reduced no-load losses by up to 60%. These transformers also featured improved winding designs that minimized load losses under varying conditions.

One of the most interesting aspects of the project was implementing a smart load balancing system. This system could dynamically adjust the power distribution across the three phases, ensuring that no single phase was overloaded. This not only improved efficiency but also extended the life of both the transformers and the connected equipment.

The results were impressive. Within the first month of operation, the plant saw a 15% reduction in their overall energy consumption. The power quality improvements were equally significant. Voltage fluctuations, which had been causing issues with sensitive equipment, were virtually eliminated.

But the benefits went beyond just energy savings. The more stable power supply led to fewer equipment malfunctions and less downtime. The plant manager reported a 30% decrease in maintenance calls related to power issues.

One unexpected benefit came from the reduced heat generation of the new transformers. The plant’s cooling systems didn’t have to work as hard, leading to additional energy savings and a more comfortable working environment.

This project taught me the true value of properly implemented 3-phase systems in industrial settings. It’s not just about having three wires instead of two. It’s about creating a balanced, efficient, and reliable power distribution system that can handle the complex demands of modern industry.

For plant managers and engineers looking to optimize their power systems, my advice is to start with a thorough assessment of your current setup. Understanding your load patterns and power quality issues is crucial for designing an effective 3-phase distribution system.

Remember, while the upfront cost of upgrading to an efficient 3-phase system can be significant, the long-term benefits in terms of energy savings, equipment longevity, and improved productivity often far outweigh the initial investment.

The magic of 3-phase transformers lies in their ability to provide a steady, efficient flow of power that can meet the demanding needs of our cities and industries. By understanding and harnessing this power, we can build more efficient, reliable, and sustainable energy systems for the future.

Watts Up? Simple Ways to Boost Your 3-Phase Transformer’s Efficiency?

Are you tired of watching your energy costs climb while your profits shrink? The solution might be simpler than you think. Boosting your 3-phase transformer’s efficiency can lead to significant energy savings, but where do you start?

Improving 3-phase transformer efficiency involves several key strategies. These include upgrading core materials, optimizing winding designs, implementing advanced cooling systems, and using smart monitoring technologies. By focusing on these areas, you can reduce energy losses, extend transformer life, and significantly lower operational costs.

Let’s explore some simple yet effective ways to boost your 3-phase transformer’s efficiency:

Core Improvements: The Heart of Efficiency

The transformer core is where the magic happens, and improving it can lead to significant efficiency gains.

Core Upgrade Options:

- Amorphous metal cores

- Grain-oriented silicon steel

- Laser-scribed core laminations

Winding Optimization: Reducing Resistance

Optimizing transformer windings can significantly reduce load losses.

Winding Enhancements:

- Use of high-conductivity materials

- Improved winding geometry

- Transposition techniques for large conductors

Cooling System Upgrades: Keeping it Cool

Better cooling means better efficiency and longer transformer life.

Cooling Improvements:

- Advanced oil circulation systems

- Nanofluids for improved heat transfer

- Hybrid cooling designs

Smart Monitoring: Knowledge is Power

Modern monitoring systems can help you optimize performance and prevent issues.

Monitoring Technologies:

- Real-time load monitoring

- Temperature and oil quality sensors

- Predictive maintenance algorithms

| Upgrade Area | Potential Energy Savings | Implementation Difficulty |

|---|---|---|

| Core Materials | 20-30% reduction in no-load losses | Medium to High |

| Winding Design | 10-15% reduction in load losses | Medium |

| Cooling System | 5-10% overall efficiency improvement | Medium |

| Smart Monitoring | 3-5% through optimized operation | Low to Medium |

I recall a project that perfectly illustrates the impact of these efficiency-boosting strategies. We were working with a large industrial complex that was facing skyrocketing energy costs. Their 3-phase transformers, while not ancient, were far from efficient by modern standards.

We started with the core. The existing transformers used standard silicon steel cores, which were good in their day but no match for modern materials. We replaced them with amorphous metal cores. These new cores reduced no-load losses by a staggering 70%. The plant manager was skeptical at first, but the energy savings were undeniable.

Next, we turned our attention to the windings. We redesigned them using high-conductivity copper and optimized the geometry to reduce eddy currents. This seemingly small change led to a 15% reduction in load losses. In a high-power industrial setting, that 15% translated to significant cost savings.

The cooling system was our next target. The old oil circulation system was inefficient and struggled during peak load times. We implemented a hybrid cooling system that combined forced oil and forced air cooling. This not only improved efficiency but also allowed the transformers to handle higher loads without overheating.

But the real game-changer was the smart monitoring system we installed. This system provided real-time data on load patterns, temperature, and oil condition. It could predict potential issues before they became problems, allowing for proactive maintenance.

One feature of the monitoring system proved particularly valuable. It could analyze load patterns and suggest optimal times for energy-intensive operations. By shifting some production to off-peak hours, the plant was able to take advantage of lower electricity rates and reduce strain on the transformers.

The results were beyond our expectations. In the first year after these upgrades, the plant saw a 25% reduction in transformer-related energy losses. This translated to hundreds of thousands of dollars in savings on their energy bill.

But the benefits went beyond just energy savings. The improved cooling and smart monitoring led to a significant increase in transformer lifespan. We estimated that these upgrades would extend the life of the transformers by at least 5 years, delaying the need for costly replacements.

An unexpected benefit came in the form of improved power quality. The more efficient transformers provided more stable voltage, which led to fewer issues with sensitive equipment in the plant. This resulted in less downtime and improved product quality.

This project taught me that improving transformer efficiency is not about one big change, but a series of targeted improvements that compound for significant results. It’s about understanding the physics of power transmission and applying modern technologies to squeeze out every bit of efficiency.

For industrial managers looking to improve their energy efficiency, my advice is to start with a comprehensive audit of your current transformer system. Understand your load patterns, identify your biggest loss areas, and then tackle them one by one.

Remember, while some of these upgrades can have a significant upfront cost, the long-term savings in energy costs and improved reliability often provide an excellent return on investment. In today’s energy-conscious world, efficient 3-phase transformers are not just a cost-saving measure, they’re a competitive advantage.

By implementing these simple yet effective strategies, you can turn your 3-phase transformers from energy guzzlers into lean, green, efficiency machines. The result? Lower energy bills, improved reliability, and a smaller carbon footprint. Now that’s a transformation worth making.

From Power Plant to Your Plug: The Journey of Electricity Through Efficient Transformers?

Have you ever flipped a switch and wondered about the incredible journey electricity takes to reach your home or office? It’s a tale of power, efficiency, and some very clever engineering. But how do efficient transformers play a crucial role in this epic voyage?

Efficient transformers are key players in the journey of electricity from power plants to end-users. They step up voltage for long-distance transmission, then step it down for local distribution. Modern, high-efficiency transformers minimize energy losses at each stage, ensuring more of the generated power reaches consumers, reducing costs and environmental impact.

Let’s trace the path of electricity and see how efficient transformers make this journey possible:

Power Generation: The Starting Line

Electricity’s journey begins at power plants, where efficient transformers play a crucial first role.

Generation-Level Transformers:

- Step-up transformers increase voltage for transmission

- High-efficiency designs minimize initial losses

- Advanced cooling systems handle high power outputs

Long-Distance Transmission: The High-Voltage Highway

Efficient transformers enable electricity to travel vast distances with minimal losses.

Transmission Transformers:

- Ultra-high voltage transformers (up to 1,000 kV)

- Advanced core materials for reduced no-load losses

- Smart monitoring for optimal performance

Substation Step-Down: Preparing for Local Distribution

At substations, electricity voltage is reduced for regional distribution.

Substation Transformers:

- Large capacity step-down transformers

- Load tap changers for voltage regulation

- Oil preservation systems for extended life

Neighborhood Distribution: The Final Stretch

Distribution transformers bring electricity to its final voltage for consumer use.

Distribution Transformers:

- Pole-mounted or pad-mounted designs

- Amorphous core materials for high efficiency

- Smart grid integration capabilities

| Stage | Transformer Type | Key Efficiency Features |

|---|---|---|

| Generation | Step-Up | High-grade core materials, advanced cooling |

| Transmission | Ultra-High Voltage | Low-loss designs, smart monitoring |

| Substation | Step-Down | Load tap changers, oil preservation |

| Distribution | Low Voltage | Amorphous cores, smart grid integration |

I remember a project that really brought home the importance of efficient transformers in the electricity journey. We were tasked with upgrading the transformer network for a medium-sized city that was experiencing frequent brownouts and high energy costs.

Our first stop was the local power plant. The existing step-up transformers were decades old and operating at suboptimal efficiency. We replaced them with state-of-the-art units featuring advanced core materials and intelligent cooling systems. These new transformers could handle the plant’s full output with significantly lower losses.

Next, we turned our attention to the transmission system. The city’s growth had strained the existing infrastructure. We implemented a series of ultra-high voltage transformers to create a more efficient transmission backbone. These transformers used advanced low-loss designs that could maintain efficiency even under varying load conditions.

The substation level was where we saw some of the most dramatic improvements. We installed new step-down transformers with on-load tap changers. These could dynamically adjust voltage levels to match demand, significantly improving overall grid stability. We also implemented an advanced oil preservation system that extended the life of these crucial transformers.

But the real challenge came at the distribution level. The city had a mix of old and new neighborhoods, each with unique power needs. We deployed a variety of efficient distribution transformers, from pole-mounted units for older areas to pad-mounted transformers for newer developments. All of these used amorphous core materials, which reduced no-load losses by up to 70% compared to traditional silicon steel cores.

One of the most exciting aspects of this project was the implementation of smart grid technologies. We equipped key distribution transformers with advanced monitoring and communication capabilities. This allowed for real-time load balancing and predictive maintenance, further improving efficiency and reliability.

The results were remarkable. Within the first year, the city saw a 30% reduction in transformer-related energy losses across the entire network. Brownouts became a thing of the past, and the utility company reported a significant decrease in customer complaints.

But the benefits went beyond just improved service. The reduced losses meant that the power plant could serve more customers without increasing generation. This delayed the need for costly plant expansions and reduced the city’s carbon footprint.

An unexpected benefit came in the form of improved power quality. The more stable voltage levels provided by the efficient transformer network led to fewer issues with sensitive electronic equipment. Local businesses reported fewer equipment failures and improved productivity.

This project taught me that the journey of electricity is only as efficient as its weakest link. By upgrading transformers at every stage – from power plant to plug – we created a synergy of efficiency that had a profound impact on the entire system.

For utility managers and city planners, my advice is to take a holistic view of your power distribution system. Efficiency improvements at one stage can have cascading benefits throughout the network. While the upfront costs of upgrading to high-efficiency transformers can be significant, the long-term benefits in terms of energy savings, improved reliability, and reduced environmental impact are substantial.

Remember, every kilowatt-hour saved through efficient transformation is a kilowatt-hour that doesn’t need to be generated. In an age of increasing energy demand and environmental concerns, making electricity’s journey as efficient as possible is not just good business – it’s a responsibility to our planet and future generations.

By understanding and optimizing each stage of electricity’s journey, we can create power systems that are not just more efficient, but more resilient, sustainable, and ready for the challenges of tomorrow.

Green Giants: How Efficient 3-Phase Transformers Are Saving Energy and the Planet?

Are you concerned about your carbon footprint? The solution to greener energy might be hiding in plain sight. Efficient 3-phase transformers are not just about saving money; they’re playing a crucial role in our fight against climate change. But how exactly are these green giants making a difference?

Efficient 3-phase transformers significantly reduce energy losses in power distribution, directly lowering greenhouse gas emissions. They use advanced materials and designs to minimize core and copper losses, improve load management, and integrate with renewable energy sources. This efficiency translates to reduced power generation needs and a smaller carbon footprint.

Let’s explore how these efficient 3-phase transformers are becoming environmental heroes:

Material Matters: The Core of Green Efficiency

Advanced core materials are at the heart of efficient, eco-friendly transformers.

Green Core Technologies:

- Amorphous metal cores

- High-grade silicon steel

- Nanocrystalline materials

Load Management: Balancing Act for the Planet

Smart load management in 3-phase transformers leads to significant energy savings.

Eco-Friendly Load Features:

- Dynamic load balancing

- Predictive load management

- Integration with demand response systems

Renewable Energy Integration: Powering a Sustainable Future

Efficient transformers play a crucial role in harnessing renewable energy sources.

Renewable Energy Capabilities:

- Bi-directional power flow management

- Voltage regulation for variable sources

- Harmonic mitigation for solar and wind power

Lifecycle Analysis: Cradle-to-Grave Sustainability

The environmental impact of transformers extends beyond their operational efficiency.

Lifecycle Considerations:

- Recyclable materials

- Biodegradable insulating oils

- Extended lifespan reducing replacement frequency

| Aspect | Traditional Transformer | Eco-Efficient Transformer |

|---|---|---|

| Core Losses | Higher | Significantly reduced |

| Load Management | Basic | Advanced, dynamic |

| Renewable Integration | Limited | Comprehensive |

| Lifecycle Impact | Higher | Lower, more sustainable |

I recall a project that truly showcased the environmental impact of efficient 3-phase transformers. We were approached by a large industrial park that was looking to significantly reduce its carbon footprint. The park housed various manufacturing facilities and was a major energy consumer in the region.

Our first step was to conduct a comprehensive energy audit. We found that their existing transformer network was a mix of older, inefficient units and some newer models. The overall system efficiency was far below modern standards, resulting in substantial energy waste and unnecessary carbon emissions.

We proposed a complete overhaul of their transformer network, focusing on high-efficiency 3-phase units. The centerpiece of our design was a set of transformers with amorphous metal cores. These cores reduced no-load losses by an astounding 70% compared to traditional silicon steel cores. For a facility that operated 24/7, this meant significant energy savings even during low production periods.

The winding design was another area where we made substantial improvements. We used high-conductivity copper and optimized the winding geometry to minimize load losses. This resulted in a 15% reduction in load-related energy waste.

But perhaps the most exciting aspect of the project was the integration of smart load management systems. We installed advanced monitoring equipment that could predict load patterns based on production schedules and historical data. This allowed the transformers to dynamically adjust their output, ensuring optimal efficiency at all times.

We also focused on making the transformer network ready for renewable energy integration. The new transformers were designed to handle bi-directional power flow, crucial for incorporating solar panels that the industrial park planned to install on their rooftops. We included advanced harmonic mitigation features to ensure power quality wouldn’t be compromised when solar energy was fed back into the grid.

The results were beyond our expectations. In the first year after installation, the industrial park saw a 25% reduction in transformer-related energy losses. This translated to a decrease of over 1,000 metric tons of CO2 emissions – equivalent to taking more than 200 cars off the road for a year.

But the benefits didn’t stop there. The improved efficiency meant that the local power plant didn’t need to generate as much electricity to meet the industrial park’s needs. This had a cascading effect, further reducing the overall carbon footprint of the region’s energy production.

One unexpected benefit came from the use of biodegradable insulating oils in the new transformers. Not only did this reduce the environmental risk in case of leaks, but it also improved the transformers’ fire safety ratings, leading to reduced insurance costs for the facilities.

The project’s success sparked interest from other businesses in the area. Soon, we were consulting with the local utility company on a wider rollout of efficient transformers across their network. It was becoming clear that these green giants were not just a win for individual businesses, but for entire communities.

This experience taught me that the environmental impact of efficient transformers goes far beyond simple energy savings. They play a crucial role in creating a more sustainable and resilient energy infrastructure. By reducing losses at every stage of power distribution, they decrease the overall demand on our power generation systems, leading to significant reductions in greenhouse gas emissions.

For businesses and utility companies looking to reduce their environmental impact, my advice is to view transformer efficiency as a key part of their sustainability strategy. The upfront costs of upgrading to high-efficiency units are often quickly offset by energy savings, and the long-term environmental benefits are substantial.

Remember, every kilowatt-hour saved through efficient transformation is a step towards a cleaner, greener future. As we face the challenges of climate change, these eco-friendly transformers are proving to be powerful allies in our quest for sustainable energy solutions.

Smart Power: New Technologies Making 3-Phase Transformers Smarter and Greener?

Ever wondered how our power grids are getting smarter and greener? The secret lies in the evolution of 3-phase transformers. But what new technologies are driving this revolution, and how are they making our energy systems more intelligent and environmentally friendly?

Smart 3-phase transformers incorporate advanced monitoring systems, IoT connectivity, and AI-driven analytics. These technologies enable real-time performance optimization, predictive maintenance, and seamless integration with smart grids. The result is improved energy efficiency, reduced downtime, and better support for renewable energy sources.

Let’s explore the cutting-edge technologies that are transforming our 3-phase transformers:

IoT Integration: Transformers Join the Internet of Things

Modern transformers are becoming part of the connected world, offering unprecedented insights and control.

IoT Features:

- Real-time data transmission

- Remote monitoring and control

- Integration with broader smart grid systems

AI and Machine Learning: Predictive Power

Artificial Intelligence is revolutionizing how we manage and maintain transformers.

AI Capabilities:

- Predictive maintenance

- Load forecasting and optimization

- Fault detection and diagnosis

Advanced Sensors: The Eyes and Ears of Smart Transformers

Cutting-edge sensors provide a wealth of data for smarter operation.

Sensor Types:

- Dissolved gas analysis sensors

- Fiber optic temperature sensors

- Partial discharge detectors

Smart Materials: Self-Healing and Adapting

Innovative materials are making transformers more resilient and efficient.

Material Innovations:

- Self-healing insulation

- Phase-changing cooling materials

- Nanocomposites for improved performance

| Feature | Traditional Transformer | Smart Transformer |

|---|---|---|

| Monitoring | Periodic manual checks | Continuous, real-time |

| Maintenance | Scheduled, reactive | Predictive, proactive |

| Efficiency | Static | Dynamically optimized |

| Grid Integration | Limited | Comprehensive, bi-directional |

I remember a project that truly showcased the power of these smart technologies in 3-phase transformers. We were called to modernize the power distribution system for a large urban area that was struggling with frequent outages and inefficiencies.

Our approach was to implement a network of smart 3-phase transformers that could communicate with each other and the central control system. Each transformer was equipped with an array of advanced sensors, including dissolved gas analysis sensors that could detect potential issues before they became critical failures.

One of the most exciting aspects was the integration of AI and machine learning algorithms. We set up a system that could analyze data from all the transformers in real-time, learning from patterns and predicting potential issues. Within the first few months, this system had already prevented several outages by identifying transformers that were showing early signs of stress.

The IoT connectivity of these transformers proved invaluable. Grid operators could now monitor and control the entire network from a central location. They could balance loads across transformers in real-time, reducing stress on individual units and improving overall efficiency.

We also implemented smart materials in these transformers. The insulation used had self-healing properties, capable of repairing minor damages automatically. This significantly reduced the need for manual inspections and maintenance.

The results were impressive. In the first year after implementation, the city saw a 40% reduction in transformer-related outages. Energy efficiency improved by 15%, translating to significant cost savings and reduced carbon emissions.

One incident particularly stands out. During a heatwave, the AI system predicted a potential overload in a specific area due to increased air conditioning use. It automatically adjusted the load distribution across nearby transformers and triggered additional cooling systems. This proactive response prevented what could have been a major blackout.

The smart transformers also proved crucial in integrating renewable energy sources into the grid. Their ability to handle bi-directional power flow and rapidly adjust to fluctuations in solar and wind power made the integration process much smoother than anticipated.

An unexpected benefit came from the wealth of data these smart transformers provided. City planners used this information to make more informed decisions about future infrastructure developments, ensuring the power grid could grow sustainably with the city.

This project taught me that the future of power distribution lies not just in more efficient hardware, but in the intelligent integration of hardware and software. Smart transformers are not just about reducing energy losses; they’re about creating a more resilient, flexible, and sustainable power grid.

For utility companies and city planners considering grid modernization, my advice is to look beyond traditional efficiency metrics. Consider how smart transformer technologies can provide long-term benefits in terms of reliability, adaptability, and sustainability.

Remember, in the age of smart cities and renewable energy, our power distribution systems need to be just as intelligent and adaptable. Smart 3-phase transformers are not just an upgrade to our existing infrastructure; they’re a fundamental shift in how we think about and manage our energy systems.

By embracing these smart technologies, we’re not just making our transformers more efficient; we’re building the foundation for a more sustainable and resilient energy future. In a world facing increasing energy demands and environmental challenges, these smart, green transformers are lighting the way forward.

Conclusion

3-phase distribution transformers are evolving with new technologies to optimize energy efficiency in large-scale power networks. From advanced materials to smart IoT integration, these innovations are reducing energy losses, improving reliability, and supporting sustainable energy practices, paving the way for a greener, more efficient future in power distribution.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group