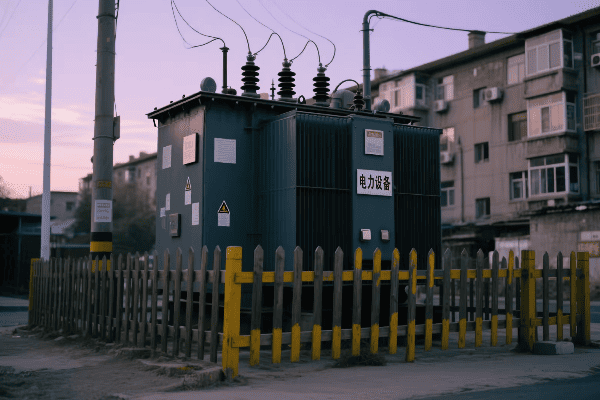

# 3 Phase Pad Mounted Transformer: Essential Components of Modern Power Distribution Systems?

Have you ever wondered how electricity reaches your home safely and efficiently? The answer lies in a crucial piece of equipment: the 3 phase pad mounted transformer.

3 phase pad mounted transformers are key components in modern power distribution systems. They convert high voltage electricity to lower, usable voltages for homes and businesses. These transformers are compact, safe, and efficient, making them ideal for urban and suburban areas.

In this article, I’ll share my insights on 3 phase pad mounted transformers. My experience in designing and working with these transformers has shown me their critical role in our power infrastructure.

What Are the Unique Features and Advantages of 3 Phase Pad Mounted Transformers in Power Distribution?

When I first encountered a 3 phase pad mounted transformer, I was struck by its compact design and versatility. These transformers have revolutionized power distribution in urban areas.

3 phase pad mounted transformers offer several unique features and advantages. They are compact, aesthetically pleasing, and provide easy access for maintenance. Their enclosed design enhances safety, while their three-phase configuration allows for efficient power distribution to both residential and commercial customers.

Let’s dive deeper into these features and advantages:

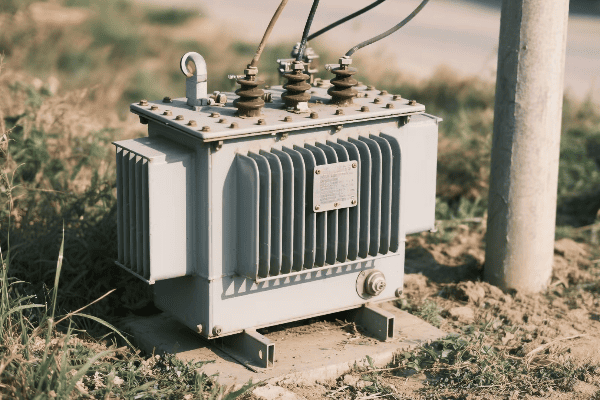

Compact and Aesthetically Pleasing Design

The design of these transformers is a game-changer:

- Space-Saving: They require less space compared to pole-mounted transformers.

- Low Profile: Their height is typically less than 6 feet, reducing visual impact.

- Customizable Appearance: They can be painted or enclosed to blend with surroundings.

I once worked on a project in a historic district where we had to design a pad mounted transformer that looked like a garden shed. It was a challenge, but the result was both functional and visually appealing.

Enhanced Safety Features

Safety is a top priority in these transformers:

| Feature | Benefit |

|---|---|

| Enclosed Design | Prevents unauthorized access and protects from weather |

| Lockable Compartments | Separates high and low voltage sections for added safety |

| Dead-Front Construction | Eliminates exposed live parts, reducing risk of accidental contact |

In my career, I’ve seen how these safety features have significantly reduced accidents and improved worker safety during maintenance.

Easy Maintenance Access

Maintenance is much simpler with these transformers:

- Front and Side Panel Access: Allows easy reach to components.

- Removable Doors: Facilitates replacement of large components.

- Ground-Level Installation: Eliminates need for bucket trucks or climbing.

I remember a project where we retrofitted an old substation with pad mounted transformers. The maintenance team was thrilled with how much easier and safer their job became.

Three-Phase Configuration

The three-phase design offers several advantages:

- Balanced Load Distribution: Ideal for both residential and commercial areas.

- Higher Efficiency: Better power factor and reduced losses.

- Versatility: Can supply both single-phase and three-phase loads.

In a recent industrial park project, the three-phase configuration allowed us to efficiently power a mix of residential, commercial, and light industrial loads from the same transformer.

Environmental Considerations

These transformers are environmentally friendly:

- Oil Containment: Built-in features to prevent oil leaks.

- Reduced Noise: Quieter operation compared to pole-mounted transformers.

- Eco-Friendly Options: Some models use biodegradable fluids.

I’ve worked on projects where using eco-friendly insulating fluids was a key requirement. It’s amazing how far transformer technology has come in terms of environmental responsibility.

How Do 3 Phase Pad Mounted Transformers Enhance Efficiency and Reliability in Modern Grid Systems?

Efficiency and reliability are crucial in power distribution. I’ve seen firsthand how 3 phase pad mounted transformers have improved these aspects in modern grid systems.

3 phase pad mounted transformers enhance efficiency through reduced line losses and improved power factor. They increase reliability by providing better protection against outages and easier integration with smart grid technologies. Their design also allows for quicker repairs and replacements, minimizing downtime.

Let’s explore how these transformers boost efficiency and reliability:

Reduced Line Losses

Line losses are a significant concern in power distribution:

- Shorter Secondary Lines: Pad mounted transformers can be placed closer to loads.

- Lower Current: Three-phase configuration allows for lower currents at the same power.

- Improved Insulation: Modern materials reduce electrical losses.

I once worked on a project where replacing old pole-mounted transformers with pad mounted units reduced line losses by almost 15%. The energy savings were substantial.

Improved Power Factor

Power factor improvement is a key advantage:

| Aspect | Benefit |

|---|---|

| Balanced Loads | Three-phase design naturally balances loads |

| Reduced Reactive Power | Less strain on the distribution system |

| Better Voltage Regulation | Stable voltage leads to more efficient power use |

In a recent commercial district upgrade, the improved power factor from pad mounted transformers allowed us to defer a costly substation upgrade.

Enhanced Protection Features

These transformers come with advanced protection:

- Integrated Fusing: Protects against overloads and short circuits.

- Surge Arresters: Built-in protection against voltage spikes.

- Thermal Monitoring: Prevents overheating and extends transformer life.

I remember a case where the integrated protection in a pad mounted transformer prevented a major outage during a severe thunderstorm. It isolated the fault quickly, minimizing the impact.

Smart Grid Integration

Pad mounted transformers are ideal for smart grid integration:

- Sensor Integration: Easy to add monitoring devices.

- Communication Capabilities: Can be equipped with data transmission features.

- Remote Operation: Some models allow for remote switching and control.

I’ve been involved in several smart grid projects where pad mounted transformers were key to implementing advanced monitoring and control systems.

Quicker Repairs and Replacements

The design of these transformers facilitates faster maintenance:

- Modular Components: Easier to replace specific parts.

- Standardized Designs: Simplifies stocking of spare parts.

- Accessible Location: No need for specialized equipment for most repairs.

In my experience, the time to repair or replace a pad mounted transformer is often less than half that of a traditional pole-mounted unit. This significantly improves grid reliability.

What Are the Key Design Elements and Safety Considerations for 3 Phase Pad Mounted Transformers?

Designing 3 phase pad mounted transformers requires careful consideration of both functionality and safety. I’ve spent years refining these designs to meet evolving industry standards and customer needs.

Key design elements of 3 phase pad mounted transformers include compartmentalized construction, robust insulation systems, and efficient cooling mechanisms. Safety considerations encompass tamper-resistant enclosures, internal arc containment, and proper grounding. These features ensure safe operation and maintenance in public areas.

Let’s delve into the crucial design elements and safety considerations:

Compartmentalized Construction

The internal layout is critical:

- High Voltage Compartment: Isolated section for incoming lines.

- Low Voltage Compartment: Separate area for outgoing distribution.

- Transformer Section: Houses the core and windings.

I once redesigned a transformer layout to improve compartmentalization. This change significantly enhanced safety for maintenance workers and reduced the risk of accidental contact with high voltage components.

Insulation Systems

Proper insulation is vital:

| Component | Insulation Type | Purpose |

|---|---|---|

| Windings | Oil or Dry-Type | Prevents short circuits |

| Bushings | Porcelain or Polymer | Safely conducts current through the enclosure |

| Core | Oil or Air | Provides cooling and insulation |

In a recent project, we experimented with biodegradable insulating fluids. The results were promising, offering both excellent insulation properties and environmental benefits.

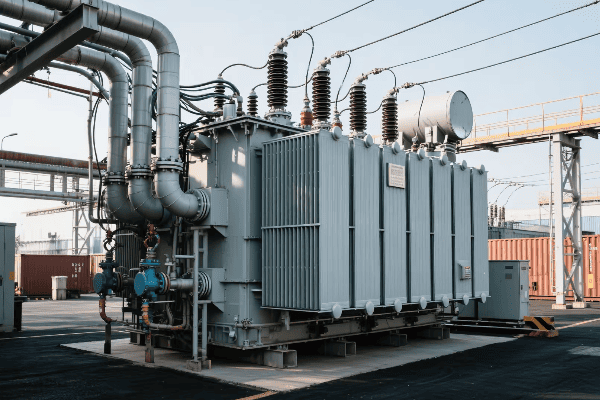

Cooling Mechanisms

Effective cooling is essential for longevity:

- Oil-Filled Designs: Use natural convection or forced oil cooling.

- Dry-Type Units: Employ air natural or forced air cooling.

- Hybrid Systems: Combine different cooling methods for optimal performance.

I’ve worked on developing cooling systems for transformers in extreme climates. In one case, we designed a custom cooling solution for a transformer in a desert environment, ensuring reliable operation in temperatures exceeding 50°C.

Tamper-Resistant Enclosures

Security is a top priority:

- Padlocked Doors: Prevent unauthorized access.

- Tamper-Proof Bolts: Secure access panels.

- Warning Labels: Clearly indicate dangers of entry.

I recall a project where we had to design extra secure enclosures for transformers in a high-crime area. The solution involved reinforced panels and advanced locking mechanisms.

Internal Arc Containment

Protecting against internal faults is crucial:

- Pressure Relief Devices: Safely vent internal pressure during faults.

- Reinforced Tank Design: Contains potential explosions.

- Arc-Resistant Doors: Prevent ejection of hot gases and oil.

I once witnessed a demonstration of arc containment features. The transformer contained a simulated internal fault without any external damage, showcasing the effectiveness of these safety measures.

Proper Grounding

Grounding is fundamental for safety:

- Equipment Grounding: Ensures all metal parts are at earth potential.

- System Grounding: Provides a return path for fault currents.

- Lightning Protection: Includes surge arresters and proper grounding.

In my experience, proper grounding is often overlooked but is critical for safety. I’ve seen cases where inadequate grounding led to dangerous touch potentials during fault conditions.

How Are 3 Phase Pad Mounted Transformers Integrated with Smart Grid Technologies?

The integration of 3 phase pad mounted transformers with smart grid technologies is revolutionizing power distribution. I’ve been at the forefront of this integration, witnessing the transformation of traditional grids into intelligent, responsive systems.

3 phase pad mounted transformers are integrated with smart grid technologies through advanced monitoring systems, communication capabilities, and automated control features. This integration enables real-time data collection, remote management, and improved grid responsiveness, enhancing overall efficiency and reliability.

Let’s explore how these transformers are becoming key components of smart grids:

Advanced Monitoring Systems

Modern transformers are equipped with sophisticated monitoring:

- Temperature Sensors: Track winding and oil temperatures.

- Load Monitoring: Real-time tracking of power flow.

- Dissolved Gas Analysis (DGA): Detect potential internal faults.

I recently worked on a project where we retrofitted existing pad mounted transformers with advanced monitoring systems. The utility gained unprecedented visibility into their distribution network’s performance.

Communication Capabilities

Communication is key in smart grids:

| Feature | Benefit |

|---|---|

| Wireless Connectivity | Allows remote data transmission |

| Ethernet Ports | Enables integration with utility networks |

| Protocols (e.g., DNP3, IEC 61850) | Standardizes communication across devices |

In one smart grid project, we implemented a mesh network of pad mounted transformers. This allowed for robust, self-healing communication even if individual links failed.

Automated Control Features

Automation enhances grid responsiveness:

- Remote Tap Changing: Adjust voltage levels without manual intervention.

- Fault Isolation: Automatically isolate faulty sections of the grid.

- Load Balancing: Dynamically adjust power flow for optimal distribution.

I’ve seen how these automated features can significantly reduce outage times. In one case, a smart transformer isolated a fault and rerouted power in less than a minute, minimizing the impact on customers.

Data Analytics Integration

Smart transformers generate valuable data:

- Predictive Maintenance: Use data trends to forecast potential issues.

- Load Forecasting: Analyze usage patterns for better resource planning.

- Power Quality Analysis: Identify and address power quality issues proactively.

I’ve been involved in developing analytics platforms that process data from hundreds of smart transformers. The insights gained have led to more efficient grid operations and reduced maintenance costs.

Renewable Energy Integration

These transformers play a crucial role in integrating renewables:

- Bi-Directional Power Flow: Handle power from distributed generation sources.

- Voltage Regulation: Maintain stable voltage with variable renewable inputs.

- Energy Storage Interface: Coordinate with battery systems for load balancing.

In a recent project, we designed a network of smart pad mounted transformers to manage a neighborhood with high solar panel penetration. The system successfully balanced the variable solar input with grid demand.

What Maintenance Practices and Monitoring Techniques Ensure Optimal Performance of 3 Phase Pad Mounted Transformers?

Maintaining 3 phase pad mounted transformers is crucial for their longevity and performance. Over the years, I’ve developed and implemented various maintenance strategies to keep these vital components running efficiently.

Optimal performance of 3 phase pad mounted transformers is ensured through regular inspections, proactive maintenance, and advanced monitoring techniques. Key practices include oil analysis, thermal imaging, partial discharge monitoring, and periodic electrical testing. These methods help detect potential issues early and prevent unexpected failures.

Let’s dive into the essential maintenance practices and monitoring techniques:

Regular Visual Inspections

Visual checks are the first line of defense:

- External Condition: Check for rust, dents, or leaks.

- Bushing Integrity: Inspect for cracks or contamination.

- Oil Levels: Verify proper oil levels in sight glasses.

I once discovered a small oil leak during a routine inspection that, if left unchecked, could have led to a major failure. Never underestimate the power of a thorough visual check.

Oil Analysis

Oil testing provides crucial insights:

| Test | Purpose | Frequency |

|---|---|---|

| Dissolved Gas Analysis (DGA) | Detect internal faults | Annually or semi-annually |

| Oil Quality Tests | Check for contamination and degradation | Annually |

| Furan Analysis | Assess paper insulation condition | Every 3-5 years |

I remember a case where routine DGA revealed an early-stage winding fault. We were able to schedule a repair before it led to a catastrophic failure.

Thermal Imaging

Infrared scanning can reveal hidden issues:

- Hot Spot Detection: Identify overheating components.

- Connection Integrity: Check for loose or corroded connections.

- Cooling Efficiency: Assess the performance of cooling systems.

During a summer heatwave, thermal imaging helped us identify several transformers operating near their thermal limits. We implemented emergency cooling measures to prevent outages.

Partial Discharge Monitoring

PD monitoring is crucial for insulation health:

- Online Monitoring: Continuous tracking of partial discharges.

- Periodic Testing: Scheduled PD measurements during maintenance.

- Trend Analysis: Track PD levels over time to predict insulation degradation.

I’ve seen how effective PD monitoring can be. In one instance, we detected increasing PD levels in a transformer, allowing us to schedule a rewind before a major failure occurred.

Electrical Testing

Periodic electrical tests ensure optimal performance:

- Turns Ratio Test: Verify the accuracy of voltage transformation.

- Winding Resistance Measurement: Check for winding damage or connection issues.

- Insulation Resistance Test: Assess the overall insulation condition.

I recall a project where regular electrical testing revealed a gradual shift in turns ratio. This early detection allowed us to adjust tap settings and maintain proper voltage output.

Smart Monitoring Systems

Advanced monitoring enhances maintenance strategies:

- Real-Time Data Collection: Continuous monitoring of key parameters.

- Predictive Analytics: Use AI to forecast potential issues.

- Remote Diagnostics: Analyze transformer health from a central location.

I’ve been involved in implementing smart monitoring systems that have revolutionized maintenance practices. These systems have helped utilities transition from time-based to condition-based maintenance, significantly reducing costs and improving reliability.

Environmental Protection Measures

Protecting the environment is an integral part of maintenance:

- Oil Containment: Regular checks of oil containment systems.

- Leak Detection: Use of sensors to quickly identify and address leaks.

- Eco-Friendly Practices: Proper disposal of old oil and components.

In a recent project, we upgraded the oil containment systems of several urban transformers. This not only protected the environment but also improved the utility’s public image.

Conclusion

3 phase pad mounted transformers are essential for modern power distribution. Their unique design, smart grid integration, and proper maintenance ensure efficient, reliable, and safe power delivery in urban and suburban areas.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group