The Ultimate 11kV to 35kV Step-Up Transformer Selection Guide: From Technical Specs to TCO | CHBEB

Introduction

When step-up transformers1 are the wrong size or kind, projects fail. The outcome is tripping, overheating, and not following the rules. A well-designed 11–35 kV step-up transformer raises voltage, isolates faults, and stabilizes power quality. This makes it safe to connect, increases availability, and lowers the lifetime cost.

Technical Core: What 11kV to 35kV Step-Up Transformers Do and What Their Key Parameters Are

Copying and pasting LV specs doesn’t take into account the realities of step-up. Some of the effects are voltage drops, heat stress, and protection miscoordination. Learn how 11–35 kV step-up transformers function and which nameplate numbers are really important for safety, compliance, and efficiency. This can help you avoid costly redesigns and downtime.

Why go up? How transformers are essential to energy projects

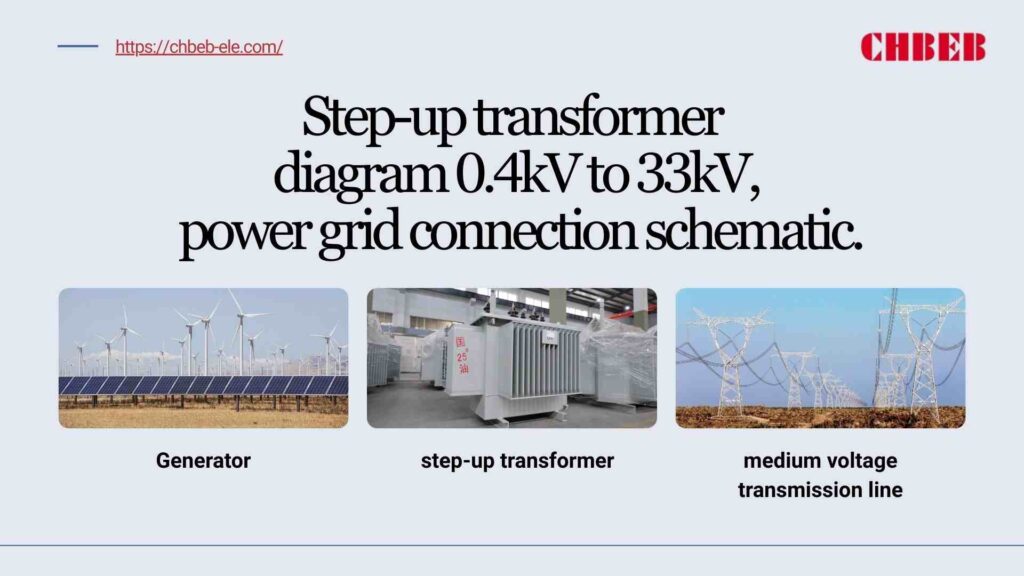

Most generators and inverters make low- or medium-voltage electricity that is not very good at traveling long distances. A step-up transformer raises the voltage (for example, from 0.4–1.0 kV to 11–35 kV), offers galvanic isolation, sets the grounding scheme, shapes fault levels, and filters triplen harmonics by choosing a vector group2. This makes connections stable, efficient, and safe.

- PV and wind: Increase the output of the inverter or generator to 22/33/35 kV collection or export feeders while keeping an eye on harmonics and DC bias concerns.

- CHP / industrial export: Make sure that process loads and grid tie-ins can be isolated, have their voltage controlled, and have a neutral connection.

- Battery storage: Allow electricity to flow in both directions and have thermal margins that are good for charge/discharge cycling.

Without the right step-up design, projects are more likely to lose money, have flickering lights, nuisance visits, and fail to meet grid code, all of which quickly eat away at ROI.

Reading the Nameplate: The Four Most Important Technical Details You Need to Know

The nameplate gives a few important values that sum up how the transformer works. Mastering these stops mistakes in specifications and speeds up approvals.

- 1) Duty and power rating (kVA/MVA): Size for continuous export with a realistic load profile. Variable renewables need thermal headroom for ramps, clipping technique, and the flexibility to handle inverter overload. If you make anything too little, it will overheat. If you make it too big, it will lose money on both the load and the no-load, as well as on capital expenditures.

- 2) Voltage ratio and vector group: Set the LV/HV ratios so they match the source and the grid. Vector groups, like Dyn11 and YNd11, decide how to handle phase shift, triplen harmonics, and the availability of neutral. Make sure your protection studies and the utility’s earthing approach are in line with each other.

- 3) Impedance (%Z) and BIL: %Z controls the current and voltage of a fault. If the yield is too low, there are a lot of faults and flickers. If it is too high, the drop under ramps is too high. Basic Insulation Level has to work with surge arresters and switching surge exposure on feeders that carry 11–35 kV.

- 4) Cooling, temperature rise, and losses: ONAN/ONAF stages, the maximum temperature rise allowed, and the promise of no-load/load losses all affect dependability and opex. If the site is hot or at a high altitude, lower the rating or add forced-air phases. Think about using natural ester fluids if you want a higher fire point and better performance in the environment.

| Parameter | What It Affects | Buyer Checklist |

|---|---|---|

| kVA/MVA rating | Thermal headroom, lifespan | Use peak export + margin; include ramps and duty cycle |

| Voltage & vector group | Grounding, harmonics, phase shift | Match utility spec; confirm neutral and earthing |

| %Z & BIL3 | Fault levels, voltage regulation, surge withstand | Coordinate with breakers, arresters, and feeder studies |

| Cooling & losses | Efficiency, hotspots, opex | Check guaranteed losses; verify ambient/altitude allowances |

A Practical Guide: Things to Think About When Choosing, Keeping, and Analyzing Total Costs

Buying based only on price might lead to hidden energy losses, service interruptions, and fines. A structured approach—using the correct type, the right environment, and the proper controls—lowers risk and operating costs. To get the best total cost of ownership and reliable output, use the checklist below to choose, install, and keep up with.

How to Choose Based on Project Needs: Types, Environment, and Customization

Start with the application and duty cycle, and then make sure that the electrical, mechanical, and environmental needs are all met. Before you order, check your assumptions with a study of protection and power quality.

- Application and duty: PV and wind need thermal headroom for ramps, and industrial drives may need to be able to handle larger short-time overloads.

- Type & dielectric: Oil-immersed (mineral or natural ester) is the most common type used outside. Esters make the fire point higher and the biodegradability better. Dry-type suits are better for interior locations where liquids can’t get in, but they cost more and cool down differently.

- Voltage and taps: Set LV to the source (for example, 0.48/0.69/0.8–1.0 kV) and HV to the grid (for example, 11/22/33/35 kV). Off-circuit taps, like ±2 × 2.5%, aid with seasonal or feeder-length changes. OLTC is rare at this rating, but it can be used on weak or lengthy lines.

- Impedance and parallel operation: Set %Z to work with upstream devices and flicker restrictions. To manage circulating current in parallel units, set the %Z and vector group to the same value.

- Vector group and grounding: Pick a delta or star orientation to block triplens and make a stable neutral when needed (solid, high-resistance, or resonant earthing).

- Environment: List the temperature class, altitude derating, corrosion category (for example, C4/C5-M), sand/salt ingress control, animal guards, and acoustic targets that are close to communities.

- Mechanical and footprint: Make sure there is enough room for terminations, fans, and tap access. Check the weight and size of the transport and the pad loading.

- Protection and monitoring: Surge arresters, PRV/RPRR, oil level/temp gauges or winding RTDs, fan control, and optional digital sensors (moisture, hotspot) make predictive maintenance possible.

- Documentation and tests: Ask for regular test reports; for important units, ask for type or custom tests. Make sure that the tolerances for loss and impedance match what you think they should be in your study.

| Scenario | Design Focus | Why It Matters |

|---|---|---|

| Utility-scale PV on long feeders | Higher %Z, wider taps, low losses | Stabilizes voltage along feeders and cuts feeder losses |

| Onshore wind farm | Thermal headroom, arresters, corrosion control | Handles gust-driven ramps and harsh coastal climates |

| Industrial cogeneration | Vector group/grounding, noise control | Protects sensitive loads and meets acoustic limits |

| Battery storage (bi-directional) | Symmetrical thermal design, monitoring | Supports charge/discharge cycling without overheating |

More than just price: figuring out long-term value by looking at the total cost of ownership (TCO)

The lowest offer might cost the most to own. To compare options fairly, turn guaranteed loss values and expected availability into cash.

TCO = Capex + Installation/Civil + Energy Losses + Maintenance + Downtime/Risk − Residual Value

- Energy losses: No-load losses happen all the time, while load losses go up with load2. To figure out how much they cost, multiply (kW) by the number of hours in a year and the tariff.

- Value of availability: A single day of curtailment might erase years of “savings” from a unit that costs less and runs hotter.

- Cooling strategy: More ONAF fans cost more upfront, but they lower the temperature of hotspots, which makes insulation last longer and lowers the danger of failure.

- Choosing a fluid: Natural esters might lower the cost of fire safety and environmental liability. Please include numbers for these offsets.

- Serviceability: Standardized bushings, front access, clear tap indication, and replacement parts all make outages shorter and labor costs lower.

- Warranty and supplier strength: Longer warranties and test data that has been confirmed to work reduce the risk of ownership. Give them dollar weight in comparisons.

Tip: When bids are close, make money off the losses and downtime that you expect. The transformer with the “lowest price” isn’t always the cheapest to own.

Installation and Maintenance Basics: How to Keep Things Running Smoothly

Even the best equipment can break down if it isn’t installed correctly or is not checked on regularly. You can’t change civil works, bonds, terminations, or monitoring.

Installation

- Civil and placement: a level, load-rated pad with drainage away from the plinth; keep ventilation and working space clear.

- Grounding and bonding: Connect all metal parts; make sure the arrester MCOV/BIL matches the feeder surge levels; keep the earthing lines short and straight.

- Terminations: Follow the bend radii; torque to spec; check the phase rotation and vector group; write down the tap position and baseline temperatures.

- Commissioning: Check the insulation (IR/tan δ if necessary), the fans, the alarm setpoints, and the protection coordination.

Maintenance

- Operational monitoring: Use IR scans to find connection hot spots early on, and keep an eye on trend load, winding hotspot, and ambient.

- For liquid-filled units, take a sample of the oil to check for moisture and condition. Also, examine the cleanliness of the PRV/RPRR, gauges, gaskets, and radiator.

- Check the enclosure filters, clean the ducts, and make sure the RTDs and fans are working.

- Spares and records: Keep a set of gaskets, fans, relays, elbows, and bushings that match; write down alarms, trips, and interventions so you can find the root cause quickly.

Conclusion

Step-up transformers in the 11–35 kV range are more than nameplate ratings—they are the gateway that lets your project export power safely, legally, and profitably. Unlike distribution transformers that step voltage down for end users, a step-up unit boosts low generator/inverter voltages to grid levels so transmission is efficient and stable.

What this means for buyers

- Losses drive real money: No-load and load losses become electricity bills over decades. Ask for guaranteed loss values and annualize them.

- Uptime protects revenue: Warranties, critical spares, and service commitment reduce unplanned downtime and curtailment risk.

- Fit to environment: Specify coatings, cooling stages, and derating for desert heat, coastal corrosion, altitude, and acoustic limits.

How to control TCO in practice

- Request data, not just price: Include guaranteed no-load/load losses, temperature rise, and ONAN/ONAF stages in bids, and convert losses (kW) × hours × tariff → yearly cost.

- Contract for reliability: Compare warranty length, response SLAs, and a spares list (fans, gaskets, bushings, relays). Treat uptime value as cash in evaluations.

- Match application: Align vector group, %Z, and tap range with grid studies (fault levels, flicker, grounding). Avoid “one-spec-fits-all.”

- Plan the site: Require pad loading/footprint confirmation, clear termination access, and documented commissioning (IR/tan δ if needed).

- Prove compliance: Ask for routine test reports to IEC/IEEE; for critical units, add type/special tests and loss tolerances.

In short: selecting the right 11–35 kV step-up transformer isn’t only about passing grid approval. It’s about turning every kilowatt-hour into long-term revenue by controlling losses, safeguarding uptime, and specifying the right design for your environment and duty—so your project delivers stable output at the lowest lifetime cost.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group